What are the Different Titanium Alloys Available?

We machine the most in-demand titanium alloys in China.

Alloy | Description | Applications |

Ti-6Al-4V (Grade 5) | It is the most widely used alloy. Strong, heat-resistant. | Aerospace, medical |

Ti-6Al-4V ELI (Grade 23) | Higher purity. Improved ductility. | Implants, surgical tools |

Ti-3Al-2.5V (Grade 9) | High corrosion resistance, medium strength. | Marine, sports |

Commercially Pure (CP) Titanium | Grades 1-4. Malleable, corrosion-resistant. | Heat exchangers, medical |

Send Your Inquiry Today

Material Properties of Titanium

High Strength-to-Weight Ratio

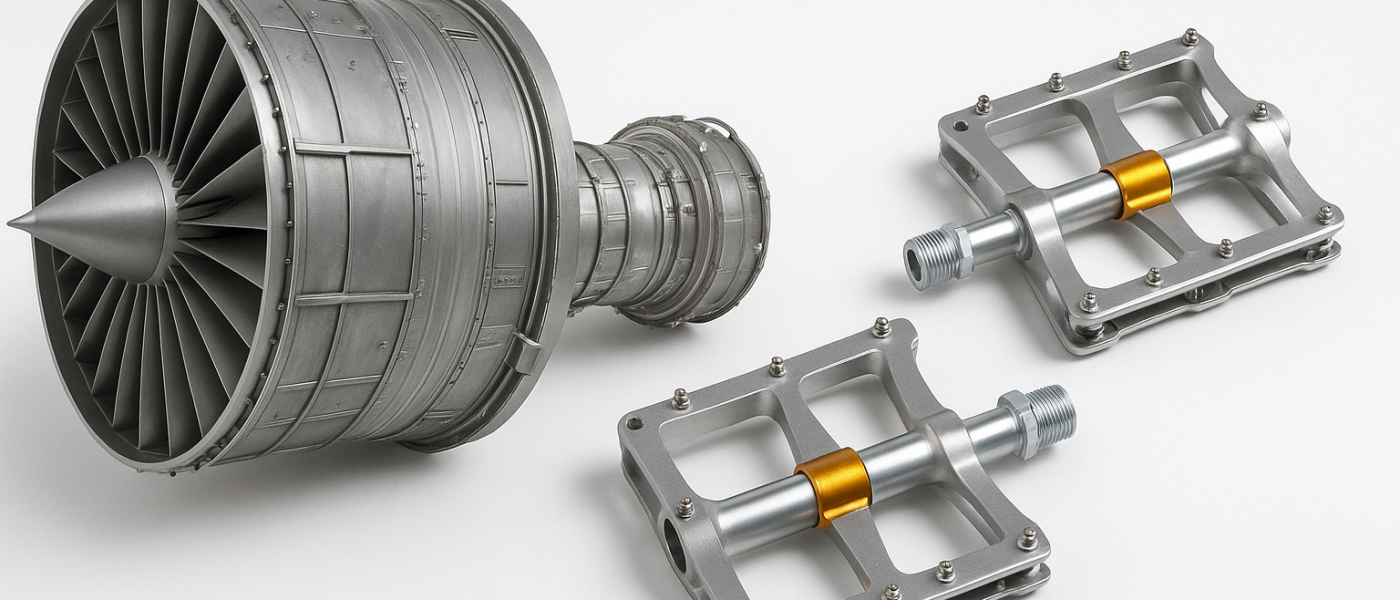

Titanium delivers the strength of steel while being nearly 45% lighter, making it ideal for aerospace, automotive, and premium applications where reducing weight is crucial.

Corrosion Resistance

Naturally resistant to corrosion, titanium performs exceptionally well in harsh environments such as saltwater and aggressive chemicals, making it a top choice for marine and chemical processing uses.

Biocompatibility

Titanium is non-toxic and highly compatible with the human body, which is why it’s frequently used in medical implants, surgical tools, and dental applications.

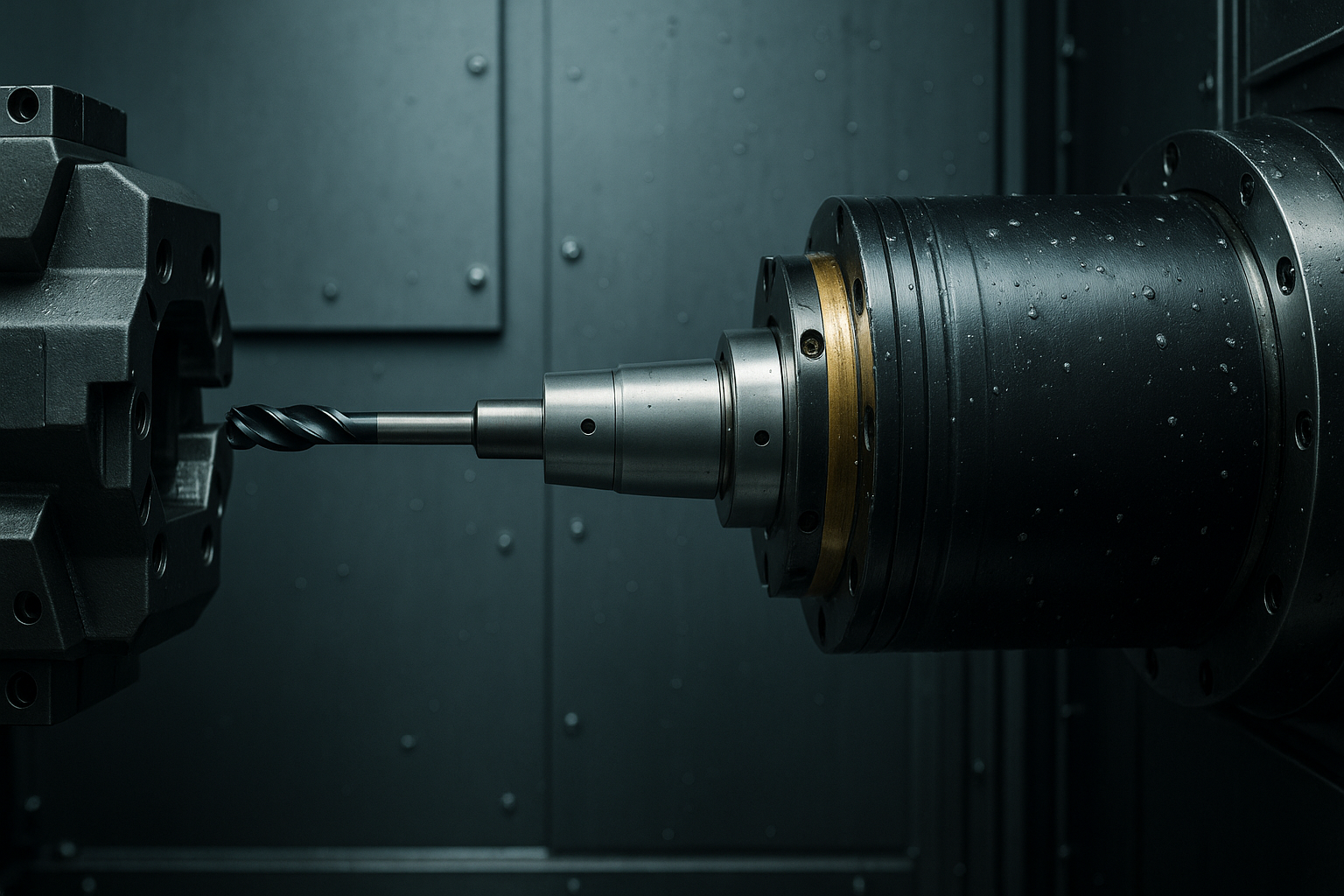

Low Thermal Conductivity

Titanium has poor heat conductivity, requiring advanced cooling strategies during machining to prevent overheating and maintain dimensional accuracy.

Non-Magnetic

Its non-magnetic nature makes titanium suitable for environments where magnetic interference could compromise performance, such as in medical devices, electronics, and aerospace systems.

Excellent Fatigue Resistance

Capable of enduring repeated stress cycles without failure, titanium offers exceptional reliability for structural components and load-bearing applications.

Send Your Inquiry Today

Applications of Titanium

Titanium’s properties make it invaluable in the industries that require strength, lightness, a nd durability.

Material Properties of Titanium

Aerospace: structural elements, fasteners, and parts of engines.

Medical: Implants, surgical apparatus, prosthetics.

Automotive: parts (performance parts, valve, exhaust systems).

Marine: Submarine parts, propeller shafts, and seawater systems.

Energy: Drilling equipment for offshore description, nuclear power systems.

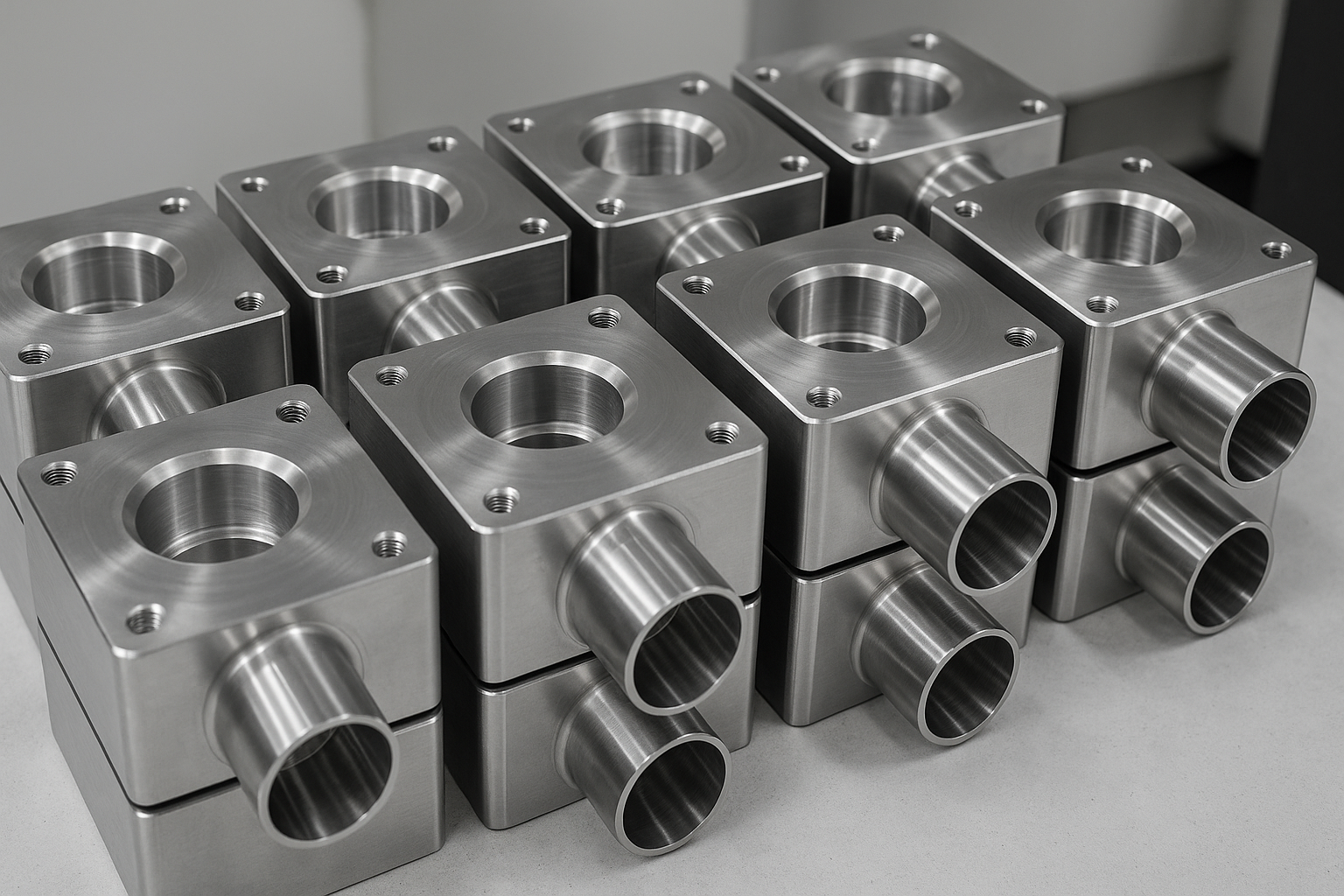

Industrial: Heat exchangers, pressure vessels, tooling.

Send Your Inquiry Today

Titanium Grades We Machine

So, here are a few titanium grades we machine

Material Properties of Titanium

| Grade | Key Features | Applications |

| Grade 1 | Soft, highly corrosion-resistant | Marine, chemical equipment |

| Grade 2 | Strong, formable, widely used | Medical, automotive, industrial |

| Grade 5 | High strength, heat-resistant | Aerospace, performance parts |

| Grade 9 | Medium strength, weldable | Tubing, implants |

| Grade 23 | Extra-pure, highly biocompatible | Surgical, aerospace components |

Send Your Inquiry Today

Advantages of Machining Titanium Parts

Strength without weight:Stronger than steel and 45% lighter.

Corrosion-Proof: Does not rust when exposed to seawater, acid, and harsh conditions.

Long Service Life: Suitable for high-stress, long-use environments.

High Temperature Resistance: Works well under high heat.

Biocompatibility: Non-toxic and nonreactive with the human body.

Send Your Inquiry Today