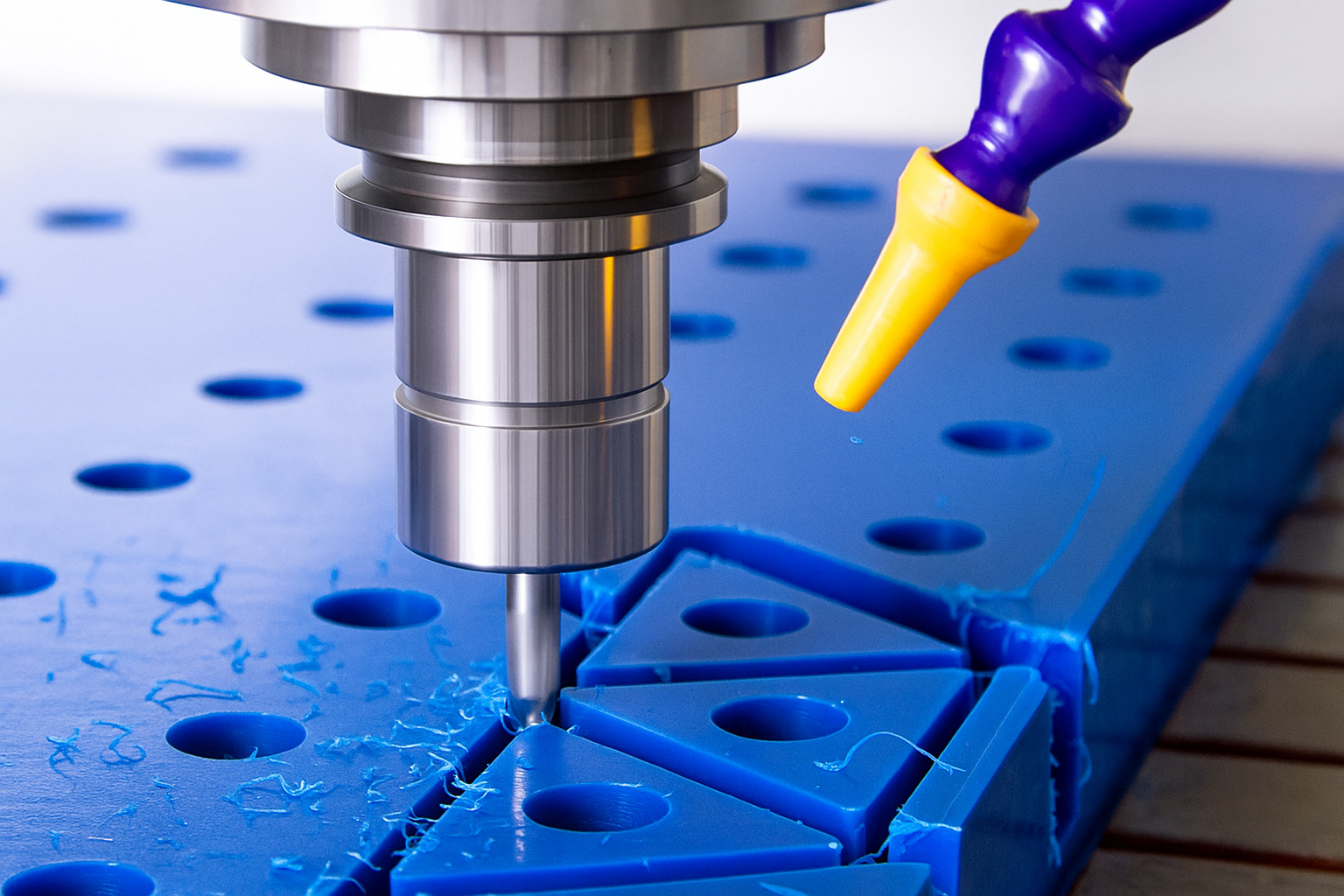

What is UHMW Machining?

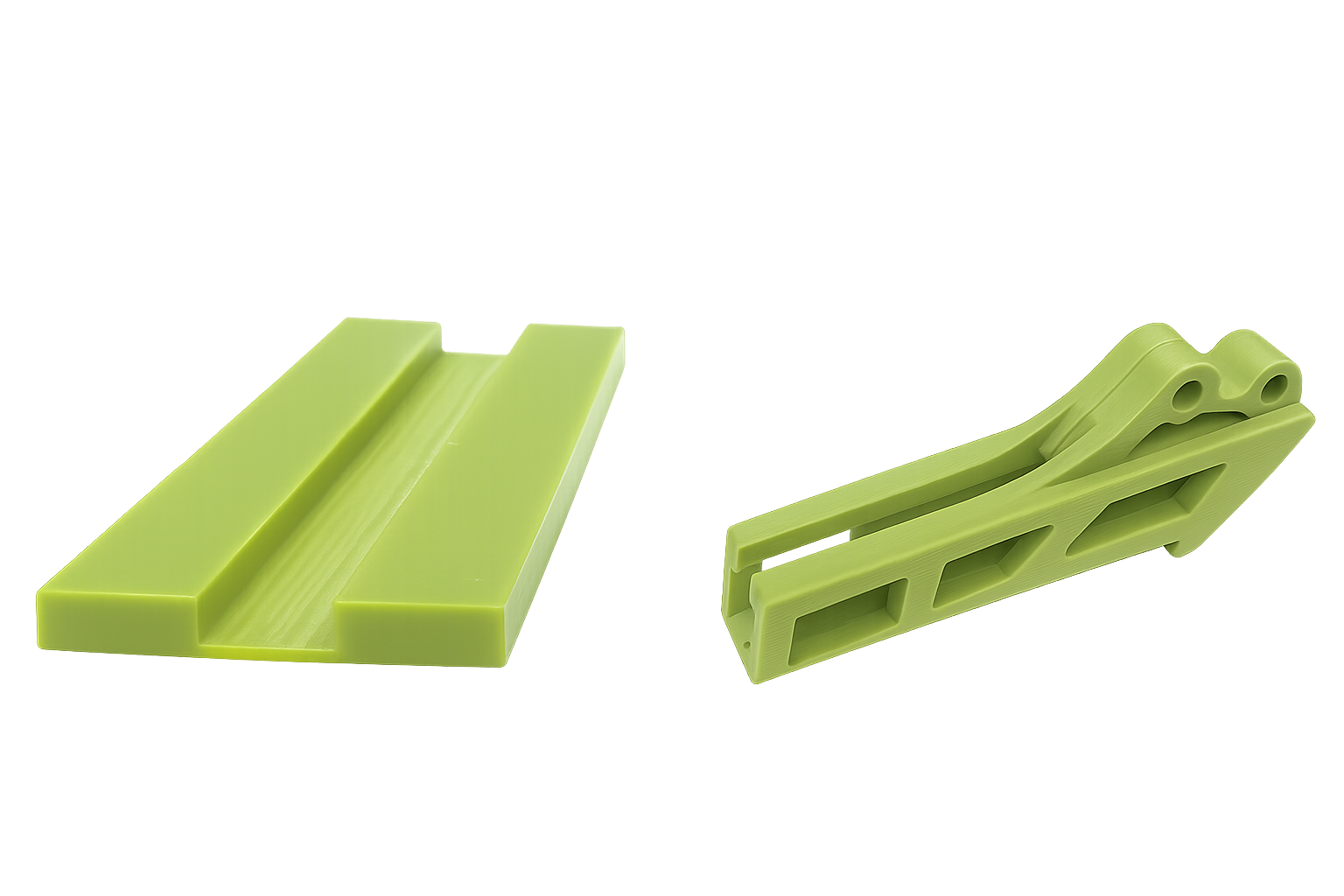

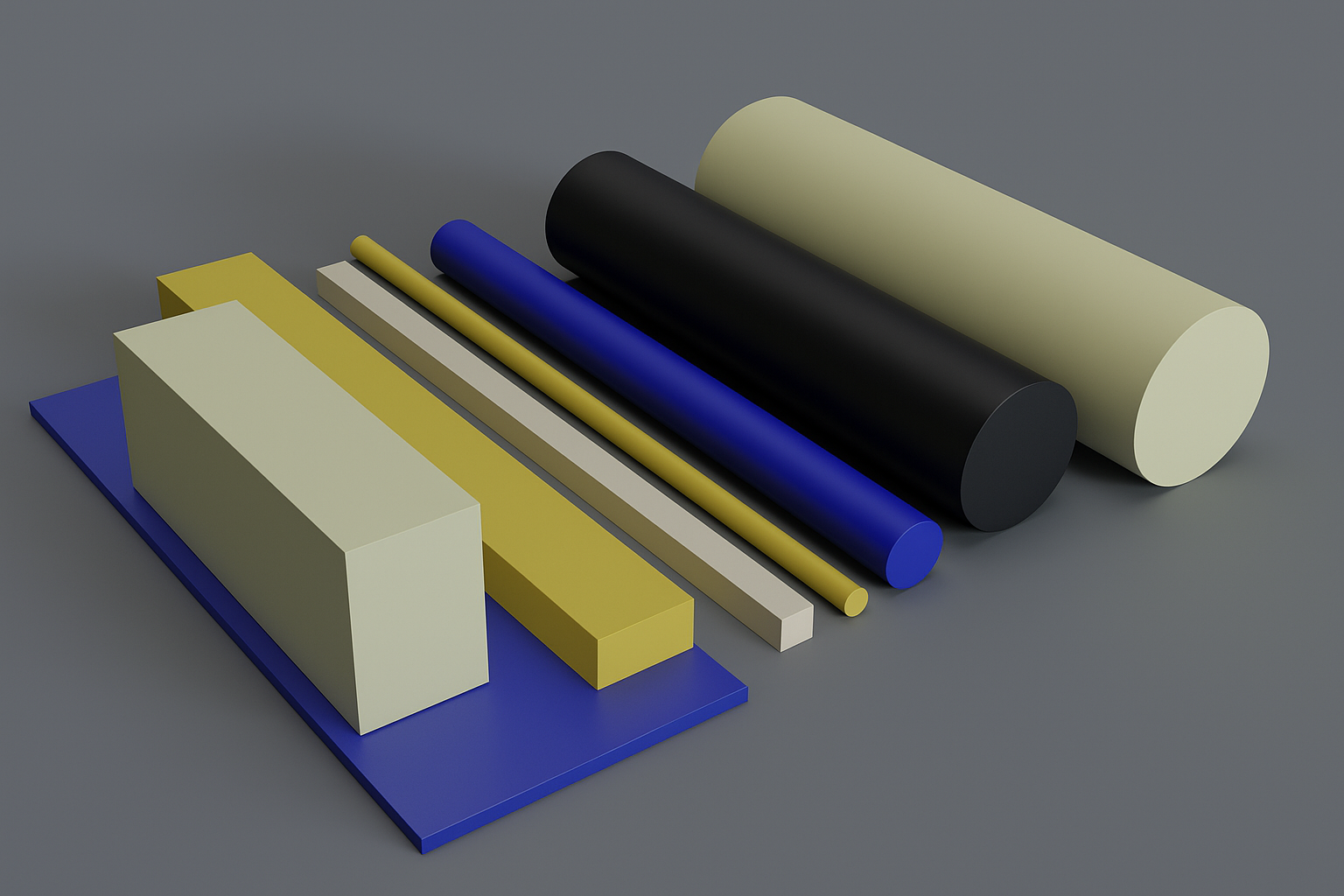

It means the process of producing custom components from Ultra-High Molecular Weight Polyethylene (UHMW-PE) with CNC machinery. UHMW-PE has polymer chains that are much longer than other types of polyethylene. Besides this, it possesses high strength after being impacted, it lasts much longer when rubbed, and it is especially smooth.

You cannot use most metals or other plastic-specific tools to machine UHMW because it is unique and has both soft attributes and a unique structure. Proper management of it allows it to become complex, high-performance parts for smooth and busy operations.