Design & Programming

Your CAD model is translated to optimized CNC code, taking into consideration thermal sensitivity and mechanical characteristics of Ultem.

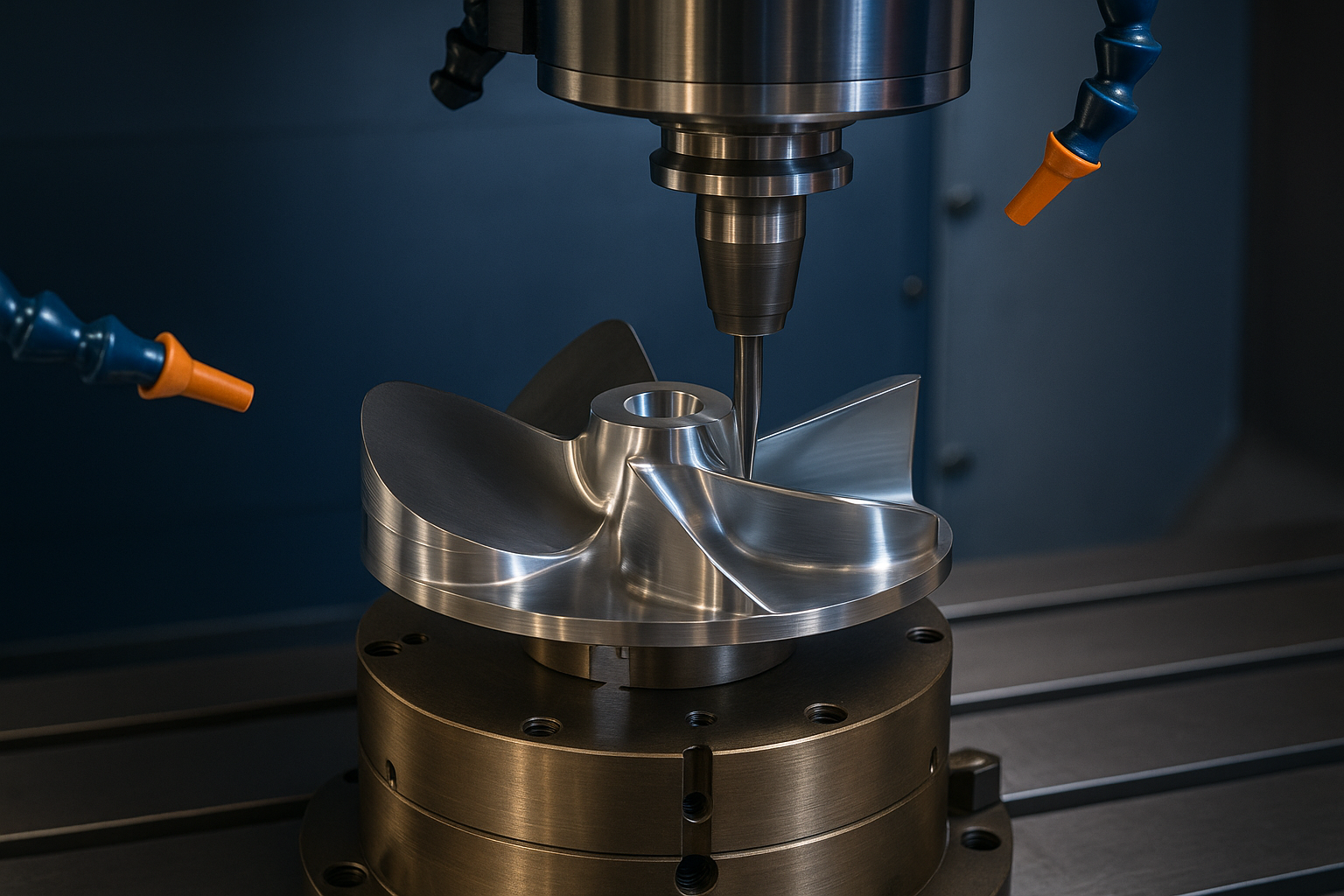

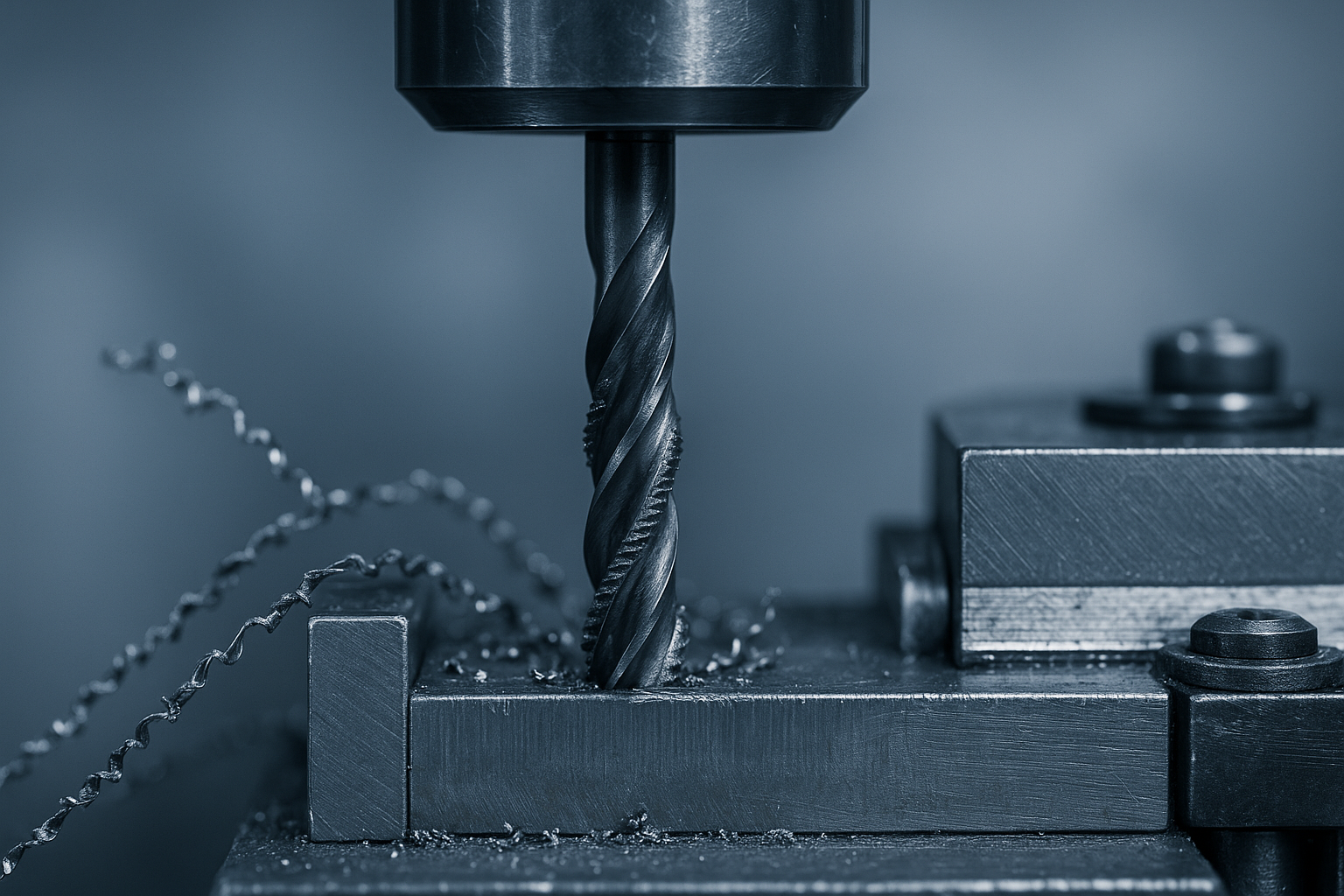

Toolpath Optimization

We customize cutting speeds, feeds, and tool movements in order to prevent heat buildup and eliminate shape deformity when machining.

Tool Selection

Tools with a sharp carbide or diamond coating are used in order to reduce the tool wear and achieve a smooth surface.

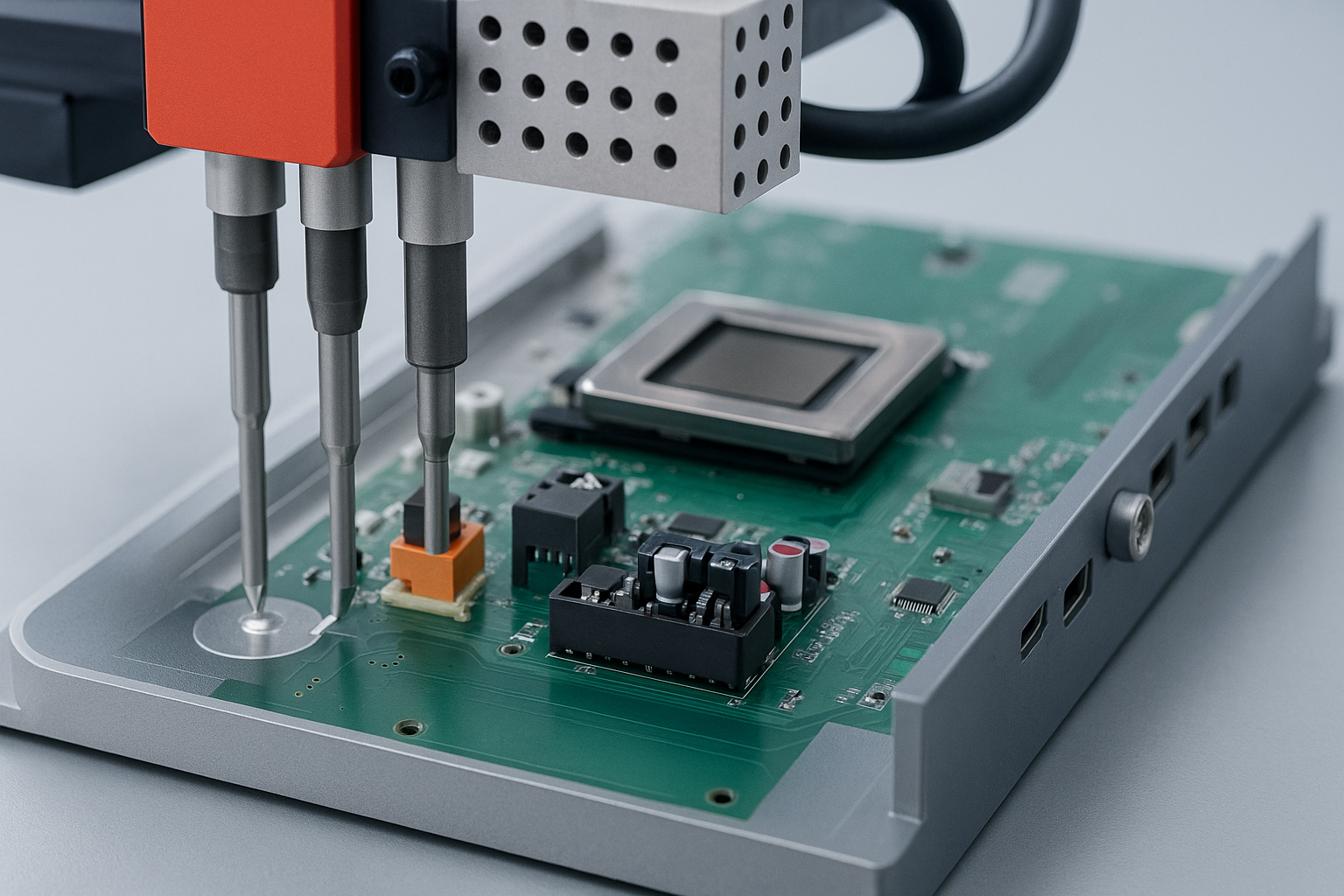

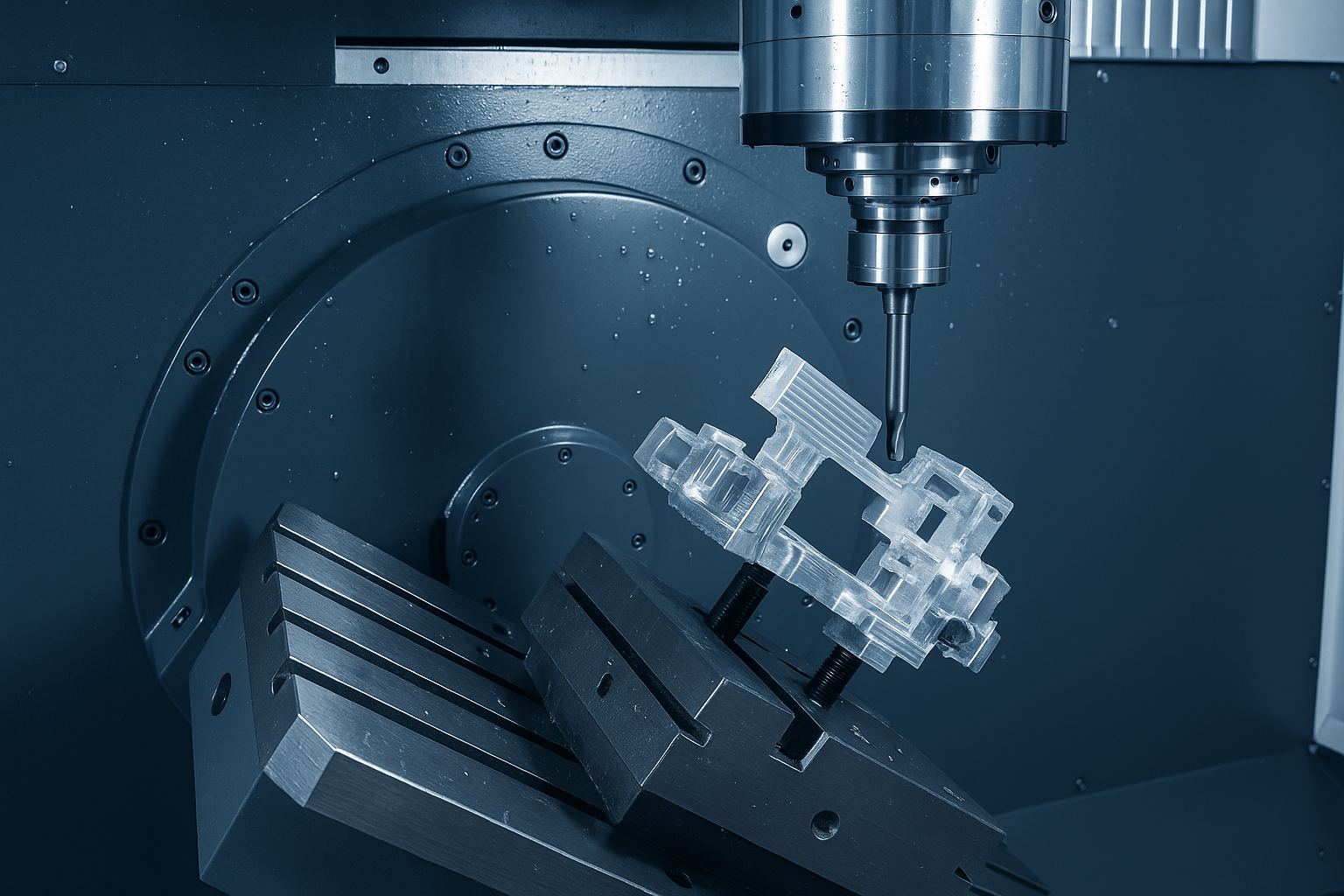

Precision Machining

Due to close attention being paid to dimensions and material behavior, the part is machined using 3- and 5-axis CNC milling or turning centers.

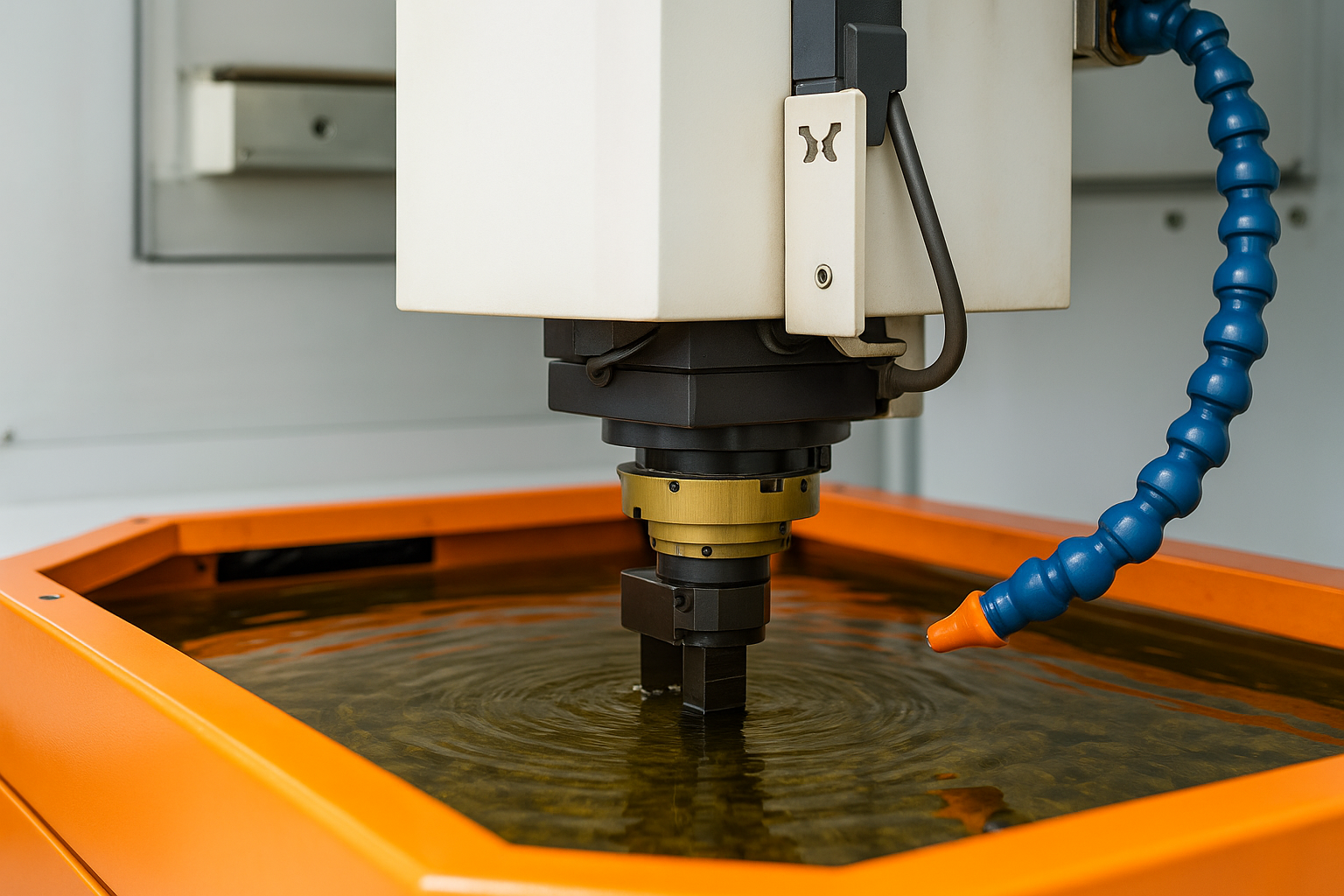

Cooling & Chip Control

Coolants and methods of the chip-breaker are used to control Ultem’s tendency to string and to reduce thermal stress.

Post-Processing

Parts get finished by polishing, deburring, and surface treatment (optional) as per final application needs.

Quality Inspection

Every part goes through the CMM inspection or dimensional verification to guarantee that all tolerances and specifications are met.

Material Properties of Ultem

Ultem is outstanding for its peculiar balance of properties.

- High Thermal Stability – for Continuous Use, to Temperatures up to 170°C (338°F)

- Flame Retardant – Conforms by itself to the UL94 V-0 standards

- Chemical Resistance – Tolerates acids, alcohols, and hydrocarbons.

- Dimensional Stability – Shrink little and little creep

- Electrical Insulation – Suitable for high-voltage components.

- Biocompatibility – (Medical and food grade uses)

Send Your Inquiry Today

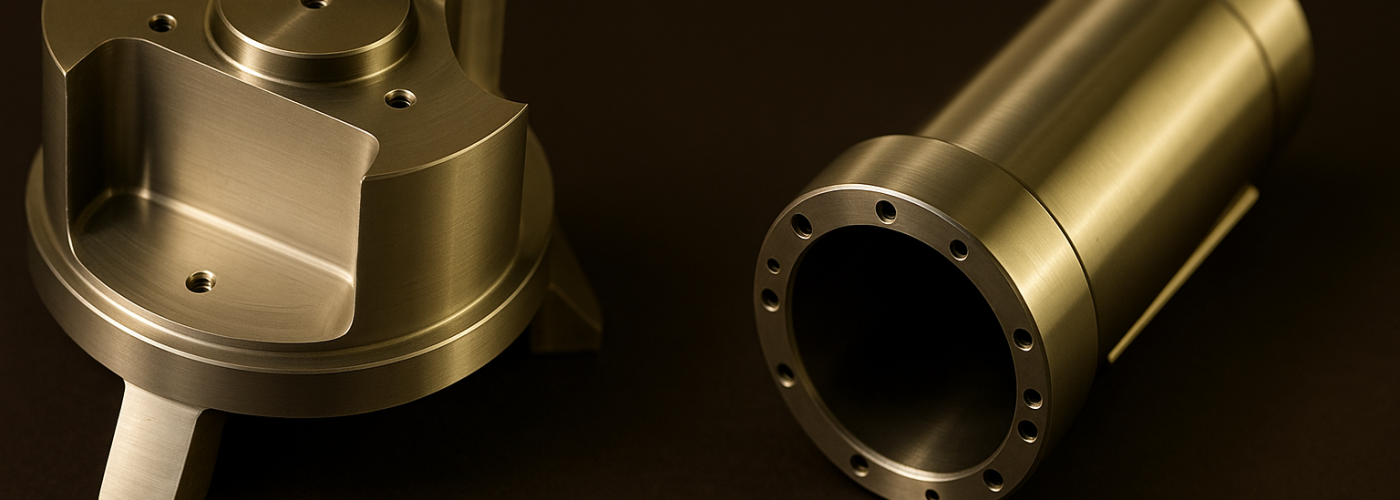

TOPS Ultem Machining Capabilities

Tops Precision is here to serve with all these processes for Ultem machining.