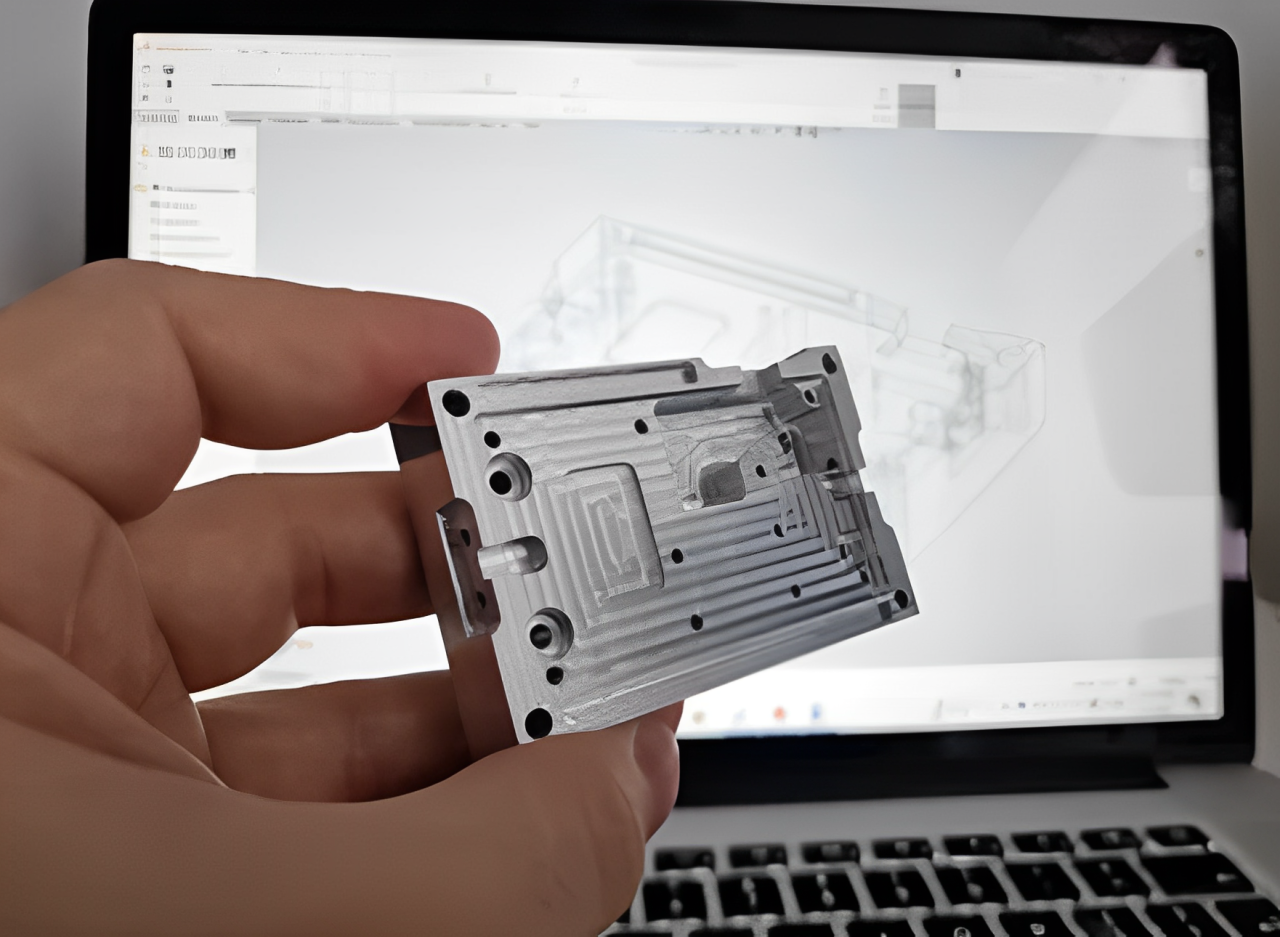

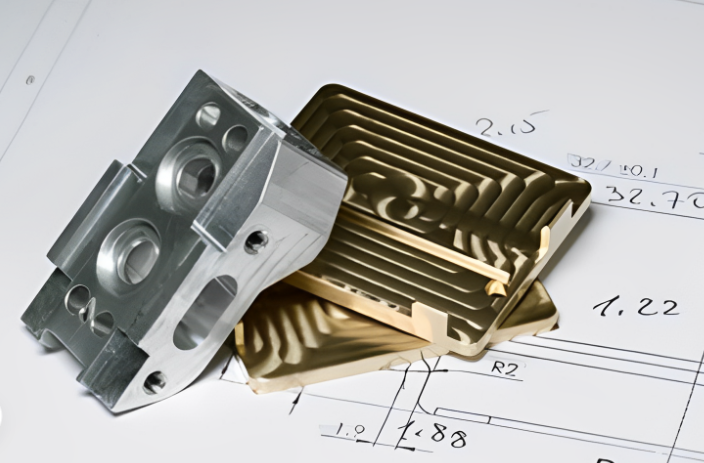

Why TOPS for Mold Making?

Having been in operation for several years in the areas of the part machining and manufacturing products TOPS is now staffed and equipped with technology which enables the firm to offer innovative ideas and excellent workmanship in the mold-making sector. Our professionals guarantee quality fits, and longevity of the molds to our clients.