Para fabricantes, ingenieros, y diseñadores, comprensión moldeo por inyección de plástico es esencial. Afecta el diseño del producto., rentabilidad, sostenibilidad, e incluso innovación futura. En este articulo, caminaremos a través Cinco aspectos clave que debes saber sobre el moldeo por inyección de plástico, cubriendo sus conceptos básicos, Consideraciones de diseño, ventajas y desafíos, impacto ambiental, y tendencias emergentes.

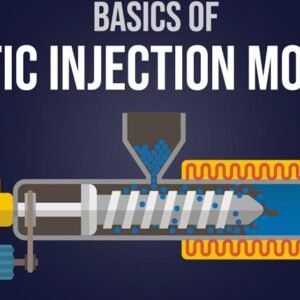

1. Los fundamentos del moldeo por inyección de plástico

Los fundamentos del moldeo por inyección de plástico

¿Qué es el moldeo por inyección??

En su núcleo, El moldeo por inyección de plástico es un proceso que transforma los gránulos de plástico en piezas terminadas.. El proceso funciona de la siguiente manera.:

Pellets de plástico Se introducen en la máquina a través de una tolva..

Los pellets son calentado y derretido en un barril mediante calentadores y un tornillo giratorio.

El plástico fundido es inyectado a alta presión en una cavidad de molde.

el plastico se enfría y solidifica, tomando la forma exacta del molde.

El molde se abre, y el la pieza terminada es expulsada, Listo para acabado secundario si es necesario..

Este proceso es rápido, repetible, y adecuado para producir millones de artículos idénticos.

Materiales comúnmente utilizados

Diferentes productos exigen diferentes propiedades plásticas, Por eso la elección del material es fundamental.:

Termoplástico (como polietileno, polipropileno, abdominales, poliestireno): Se puede recalentar y remodelar., haciéndolos versátiles y reciclables. Utilizado en embalaje, juguetes, piezas automotrices, y electrónica.

Plásticos termoendurecibles (como resinas epoxi y resinas fenólicas): Una vez configurado, no se pueden volver a fundir. Se utilizan en aplicaciones que requieren alta resistencia al calor., como aislamiento eléctrico o mangos de utensilios de cocina.

La elección del material adecuado depende de factores como la resistencia mecánica., flexibilidad, resistencia a la temperatura, durabilidad química, y costo.

Componentes clave de una máquina de moldeo por inyección

Una máquina de moldeo por inyección tiene varias partes esenciales.:

Tolva: Punto de entrada para los pellets de plástico en bruto.

Barril de calentamiento & Tornillo: Derrite los pellets e inyecta el plástico fundido en el molde..

Moho: Herramienta de acero o aluminio hecha a medida que define la forma., tamaño, y acabado superficial de la pieza.

Unidad de sujeción: Mantiene el molde cerrado con gran fuerza durante la inyección y el enfriamiento..

Sistema de eyección: Empuja el enfriado, pieza endurecida fuera del molde.

Comprender cómo funcionan juntos estos componentes ayuda a solucionar problemas y mejorar la eficiencia de la producción..

2. Consideraciones de diseño y creación de prototipos

Consideraciones de diseño y creación de prototipos

Importancia del diseño

El diseño no se trata sólo de estética: afecta directamente la facilidad con la que se puede moldear una pieza y cuánto cuesta producirla.. Buen diseño:

Previene defectos de fabricación como deformaciones., marcas de fregadero, y llenado incompleto.

Reduce el uso de material y el tiempo del ciclo..

Garantiza que el producto final sea funcional y visualmente atractivo..

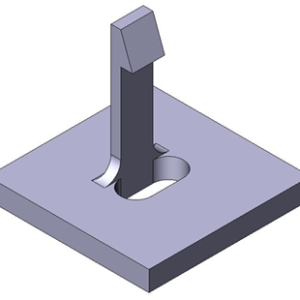

Directrices de diseño clave para el moldeo por inyección

Espesor de pared uniforme: Garantiza una refrigeración constante y evita la deformación..

ángulos de tiro: Los pequeños conos en las paredes verticales facilitan la expulsión de piezas del molde..

Costillas y refuerzos: Añade fuerza sin aumentar el espesor., pero debe diseñarse cuidadosamente para evitar la contracción..

Ubicación de la puerta: Determina cómo el plástico fundido fluye hacia el molde., afectando el acabado superficial y la integridad estructural.

Esquinas redondeadas: Reducir la concentración de tensiones y mejorar el flujo plástico..

Subsidio de contracción: Explica el hecho de que los plásticos se contraen al enfriarse..

Papel de la creación de prototipos y la impresión 3D

Antes de invertir en moldes caros, la creación de prototipos es esencial. 3La impresión D y otros métodos rápidos de creación de prototipos permiten a los diseñadores:

Probar el ajuste de los modelos funcionales, ergonomía, y fuerza.

Identificar fallas de diseño tempranamente.

Presentar muestras físicas a clientes y partes interesadas para recibir comentarios..

Este paso reduce las costosas revisiones posteriores en la producción y acorta el tiempo de comercialización..

3. Beneficios y limitaciones

Beneficios del moldeo por inyección

Alta eficiencia y velocidad: Después de hacer el molde, Las tiradas de producción pueden ser extremadamente rápidas., produciendo miles de piezas por día.

Consistencia y precisión: Produce piezas idénticas con tolerancias estrictas..

Flexibilidad de materiales: Puede utilizar una amplia variedad de plásticos., rellenos, y aditivos para mayor resistencia, Resistencia a los rayos UV, retardante de llama, o color.

Posibles formas complejas: Se pueden moldear geometrías intrincadas y detalles finos que serían difíciles o imposibles con otros procesos..

Escalabilidad: Ideal para producción en masa donde las economías de escala reducen significativamente los costos por pieza..

Limitaciones y desafíos

Altos costos iniciales: Diseñar y mecanizar un molde requiere una gran inversión inicial.

Restricciones de diseño: Algunas características pueden ser difíciles de moldear, que requieren diseños de moldes complejos que aumentan el costo.

Restricciones materiales: Cada tipo de plástico tiene limitaciones., como resistencia al calor o fragilidad.

Requisito de volumen de producción: Sólo rentable cuando se produce en grandes cantidades, ya que el coste del molde debe repartirse entre muchas piezas.

4. Impacto Ambiental y Sostenibilidad

El desafío de los residuos plásticos

Una de las mayores críticas al moldeo por inyección de plástico es su huella medioambiental.:

Residuos plasticos procedente de piezas defectuosas y artículos de un solo uso contribuye a la contaminación de los vertederos y de los océanos..

Producción con uso intensivo de energía, especialmente calentamiento y sujeción, aumenta las emisiones de gases de efecto invernadero.

Dependencia de los combustibles fósiles, Dado que la mayoría de los plásticos se derivan del petróleo..

Esfuerzos hacia la sostenibilidad

La industria busca activamente prácticas más ecológicas.:

Reciclaje y Rectificado: Los restos de plástico se pueden volver a triturar y reutilizar, reduciendo el desperdicio.

Plásticos biodegradables y de origen biológico: Los materiales derivados de plantas o diseñados para descomponerse naturalmente están ganando popularidad.

Máquinas energéticamente eficientes: Las máquinas de moldeo por inyección eléctricas modernas consumen menos energía que los sistemas hidráulicos más antiguos..

Fabricación de circuito cerrado: Sistemas de monitoreo que minimizan los desechos y optimizan el uso de materiales..

La sostenibilidad ya no es opcional: se está convirtiendo en una necesidad para alinearse con regulaciones más estrictas y expectativas de los consumidores..

5. Innovaciones y tendencias futuras

Innovaciones y tendencias futuras

Avances tecnológicos actuales

Automatización y Robótica: Los robots ahora se encargan de retirar piezas, asamblea, y controles de calidad, Reducir los costos laborales y el error humano..

Moldes inteligentes: Los sensores integrados rastrean la presión, temperatura, y velocidades de enfriamiento en tiempo real, mejorando la consistencia.

3D Impresión para moldes: La fabricación aditiva permite una rápida, Creación de moldes rentable con geometrías complejas..

Industria 4.0 Integración: IoT y AI están haciendo que las máquinas de moldeo por inyección sean más inteligentes, permitiendo el mantenimiento predictivo y la optimización de procesos.

Direcciones futuras

Mayor enfoque en la sostenibilidad: Espere un uso más amplio de plásticos reciclados y biodegradables.

Desarrollo de nuevos materiales: Polímeros avanzados con propiedades mecánicas y ambientales mejoradas.

Producción Localizada: Más descentralizado, fábricas automatizadas que reducen la dependencia de la cadena de suministro.

Fabricación basada en datos: Análisis predictivo impulsado por IA para la reducción de defectos, tiempos de ciclo más cortos, y control adaptativo de procesos.

Conclusión

El moldeo por inyección de plástico sigue siendo uno de los procesos de fabricación más importantes de nuestro tiempo.. Proporciona una eficiencia inigualable, escalabilidad, y versatilidad, convirtiéndolo en la columna vertebral de industrias que van desde bienes de consumo hasta aeroespacial.

Sin embargo, No está exento de desafíos, especialmente cuando se trata de preocupaciones ambientales y altos costos iniciales de herramientas.. Agradecidamente, innovaciones en materiales, automatización, y las prácticas de sostenibilidad están abordando estos problemas.

Para ingenieros, diseñadores, y fabricantes, Dominar los fundamentos del moldeo por inyección de plástico: su proceso., reglas de diseño, beneficios, limitaciones, y direcciones futuras, es esencial para el éxito en el desarrollo de productos y la fabricación moderna..

Leer más:

CNC Machinine VS. Moldeo por inyección

Diseño de moldes de fundición a presión

Creación rápida de prototipos en la fabricación