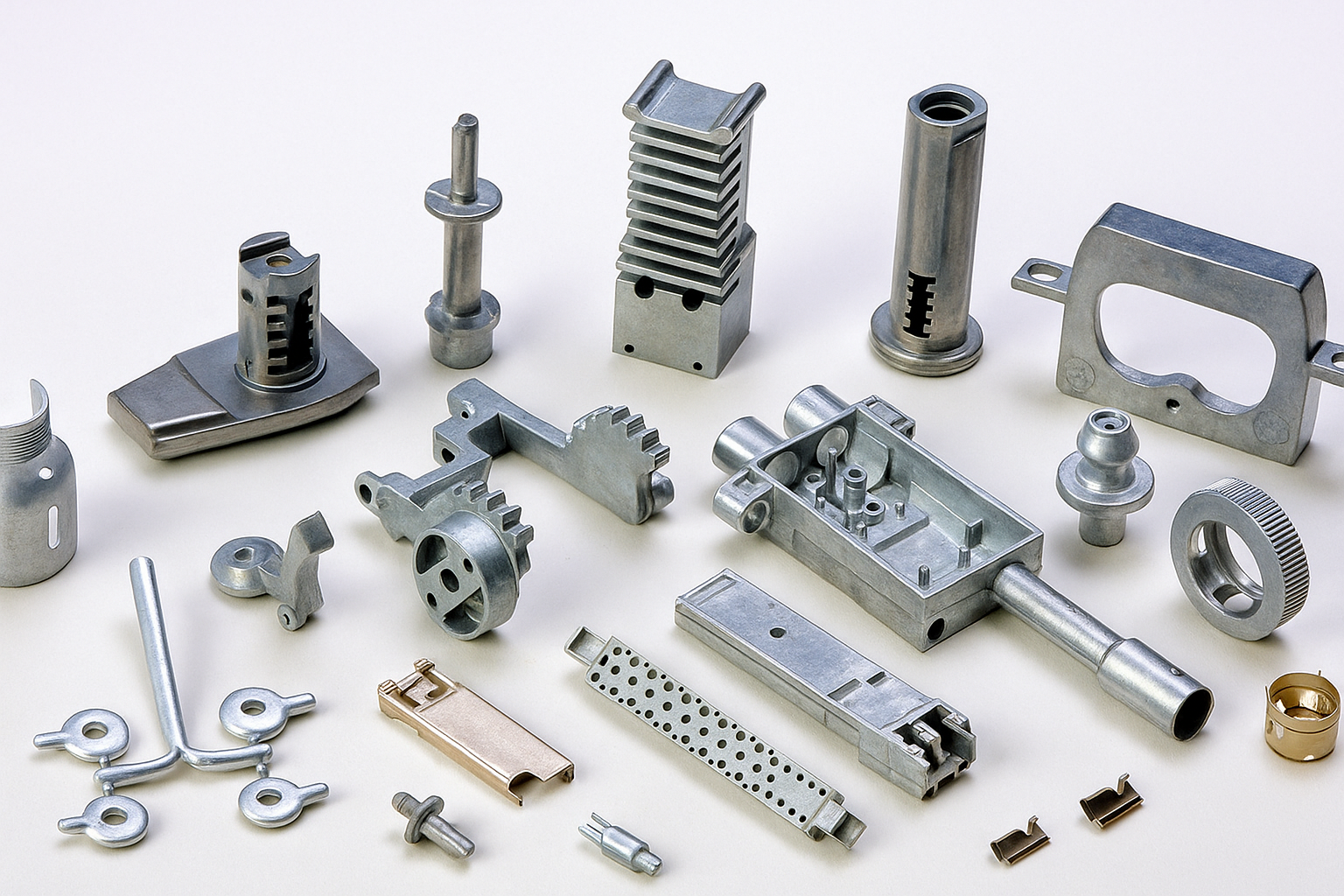

Zinc die casting is a widely used manufacturing process involving the injection of molten zinc or zinc alloys into molds under high pressure, utilizando principalmente el método de cámara caliente. Conocido por la precisión y la fuerza, El casting de zinc die tiene ventajas específicas y algunos inconvenientes notables. This article provides a comprehensive understanding of both the benefits and limitations of zinc die casting, as well as insights into its applications and how it compares with other common metals.

Ventajas del casting de zinc die

Higher Precision and Strength Compared to Aluminum

Zinc die-cast components offer significantly better dimensional accuracy and mechanical strength than aluminum parts. Zinc alloys have excellent castability, enabling manufacturers to produce intricate, detallado, and structurally robust components suitable for demanding engineering applications.

Lower Melting Point for Easy Reshaping

The relatively low melting point of zinc alloys (around 380–420°C) simplifies the process of reshaping or redesigning components when necessary. This flexibility can reduce production delays, lower rework costs, and enable quick adjustments during manufacturing.

Superior Fluidity for Thin-Walled Components

One of zinc’s standout features is its exceptional fluidity. This characteristic enables the production of components with thinner walls and intricate shapes that might be impossible or impractical to cast accurately using other metals.

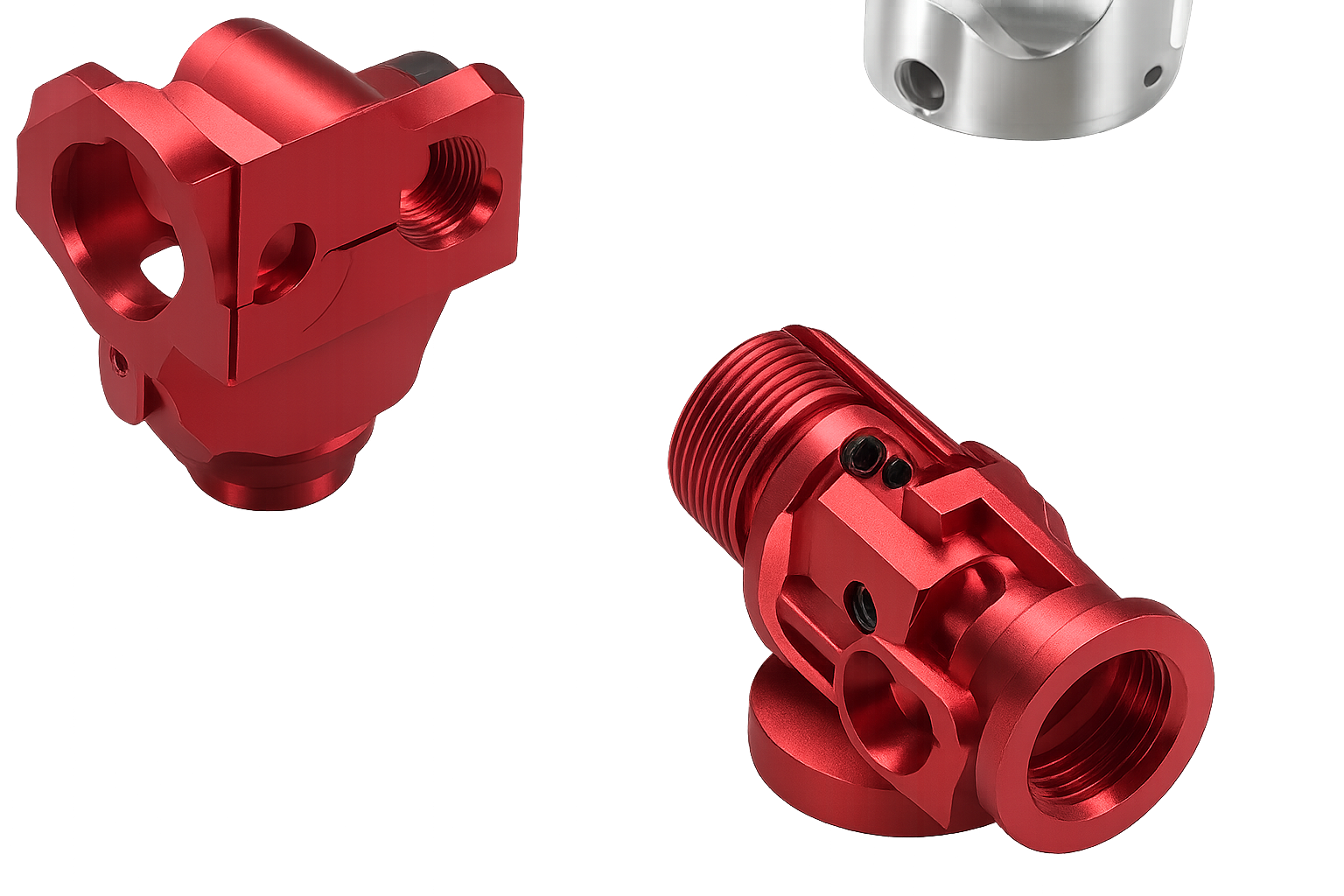

Capability to Form Complex Designs

Zinc alloys possess excellent flow characteristics that allow manufacturers to achieve complex geometric shapes with high precision and consistently smooth surfaces. This property is invaluable in applications that require aesthetic appeal or exacting standards for tight tolerances.

Easy and Versatile Surface Treatment Options

Zinc die-cast parts support a wide array of surface treatments. Processes such as grinding, cuadro, galvanoplastia, anodizado, recubrimiento en polvo, and chromate treatments are easily applicable, enhancing corrosion resistance, estética, and overall part functionality.

Longer Die Life Due to Lower Melting Temperature

The lower casting temperatures associated with zinc alloys reduce thermal fatigue and stress on the dies. Como consecuencia, tooling used for zinc die casting typically enjoys significantly longer service life, minimizing tooling costs and maintenance.

Better Mechanical Properties

Zinc alloys like Zamak 2 y zamak 3 exhibit superior hardness, fortaleza, and toughness compared to many other non-ferrous alloys, making zinc an excellent choice for structural components requiring enhanced durability and reliability.

Disadvantages of Zinc Die Casting

Higher Density and Heavier Parts

A pesar de sus ventajas, zinc’s relatively high density (aproximadamente 6.6 g/cm³ compared to aluminum’s 2.7 gramos/cm³) results in heavier components. This property makes zinc alloys less suitable for lightweight and weight-sensitive applications, particularly in industries like aerospace or where fuel efficiency is critical.

Reduced Corrosion Resistance when Alloyed with Tin or Lead

When zinc is alloyed with metals like tin or lead to alter its properties, corrosion resistance diminishes. These alloys also tend to become less ductile and more brittle, limiting their application in environments exposed to harsh conditions or heavy impacts.

Sensitivity to High Temperatures

Exposing zinc alloys to excessively high temperatures can lead to a significant reduction in tensile strength. Components subjected to elevated temperatures become brittle and more susceptible to fractures, restricting their use in high-temperature applications.

Poor Impact Resistance at Low Temperatures

At significantly low temperatures, zinc die-cast components lose their impact resistance dramatically, becoming vulnerable to cracking or catastrophic failures under sudden impacts or shock loading.

TOPS Precisión: Leading Zinc Die Casting Manufacturer

Tops Precision has extensive experience specializing in zinc die casting, focusing on high-quality standards and precise components. With a strong emphasis on delivering consistently superior products, Tops Precision has established itself as a trusted supplier globally.

Tapas de precisión Servicios

Comprehensive Die Casting Solutions

Sunrise Metal provides complete die casting solutions, incluido:

Prototipos rápidos to validate designs quickly.

Die casting tooling with precision-engineered dies.

Zinc die casting production at volume and scale.

Mecanizado CNC for precise dimensional control.

Advanced Casting Equipment

Utilizing state-of-the-art hot chamber die casting machines with clamping forces up to 250 montones, Tops Precision l handles complex, large-scale projects effectively.

Exceptional Quality Control

Tops Precision emphasizes meticulous quality control procedures, employing advanced measuring instruments and testing methods to meet stringent dimensional and mechanical standards.

Extensive Alloy Selection

They offer a broad spectrum of zinc alloys, including standard Zamak alloys (las cargas 2, 3, 5, 7), ZA8, ZA27, and custom alloy formulations to meet specific project requirements.

Aplicaciones de la fundición de died de zinc

Zinc alloys are preferred for various applications across different industries due to their specific properties:

Industria automotriz

Automotive components frequently made from zinc alloys include:

Engine and transmission parts

Aspectos

Brake systems components

Steering system components

The strength, durabilidad, and dimensional precision of Zamak 2 specifically make it ideal for these high-stress applications.

Industria Electrónica

Zinc die-cast components serve essential roles in electronic assemblies:

Energy regulators

Switch housings

Connectors and terminals

Paneles de control

Ceramic resistor casings

las cargas 3 alloy is particularly suited for electronic applications requiring consistent dimensional stability over long periods.

Appliance Industry

Zinc casting is common for household and consumer products:

Razors and grooming accessories

Buckles, keychains, y artículos decorativos

Door locks and handles

Furniture fittings and hardware components

These products benefit from zinc’s combination of strength, asequibilidad, and ease of finishing.

Choosing Zinc Die Casting vs. Otros metales

Zinc vs. Aluminio

Zinc is superior for precision parts with intricate details, paredes delgadas, y excelente maquinabilidad.

Aluminum is lighter and more suitable for applications where weight is a critical factor.

Zinc vs. Magnesio

Zinc offers greater strength, better elongation, and superior castability at a lower cost compared to magnesium alloys.

Magnesium alloys are lighter but often more expensive and less mechanically robust.

High-Strength Applications Similar to Steel

Zinc alloys can offer comparable strength and performance to steel in certain scenarios, providing an efficient alternative when steel’s weight, complejidad, or machining costs are prohibitive.

Conclusión

Zinc die casting presents significant advantages for manufacturing complex, preciso, and strong components. Although limitations such as higher density and temperature sensitivity must be considered, zinc alloys remain indispensable in various applications. By carefully evaluating the specific requirements for each project, manufacturers can confidently select zinc alloys to achieve optimal balance between performance, calidad, y rentabilidad.