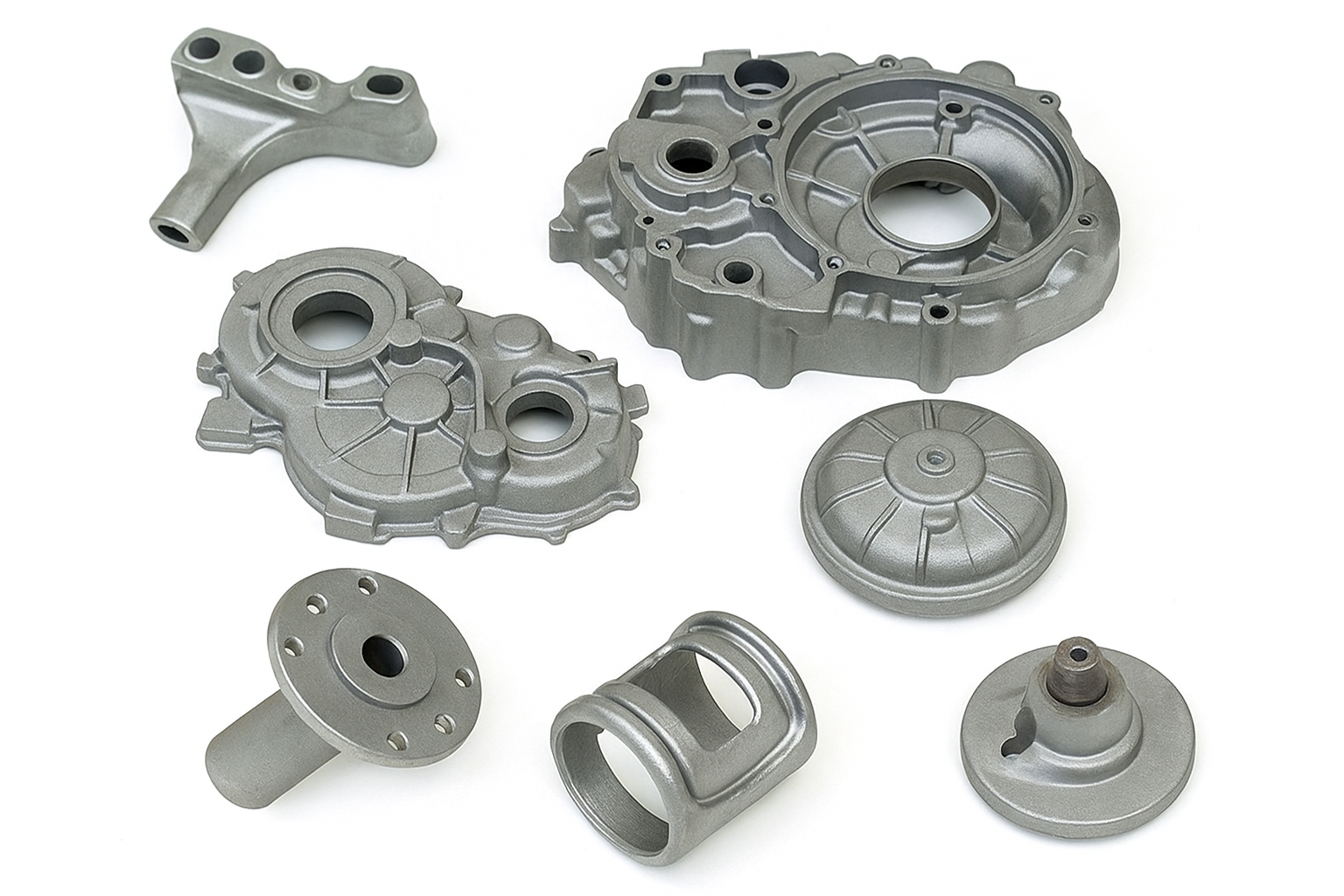

Fundición es una técnica avanzada de fabricación de metales ampliamente reconocida para producir eficientemente precisas, piezas de metal de alto volumen. Entre los factores críticos que afectan la calidad de la fundición, Seleccionar la aleación de aluminio apropiada es primordial. Este artículo explora las aleaciones de aluminio populares utilizadas en la fundición de la matriz, Examinando a fondo sus características únicas, fortalezas, limitaciones, y aplicaciones adecuadas.

Por qué es importante la selección de aleación

Un aleación is a homogeneous combination of two or more metals or elements designed to enhance mechanical, térmico, y propiedades físicas. En fundición a presión de aluminio, Aluminio de aleación con materiales como cobre, silicio, zinc, y el magnesio influye significativamente en el rendimiento de la pieza.

La elección de aleación correcta afecta directamente:

Fuerza y durabilidad: Determina la capacidad de la pieza para soportar cargas mecánicas sin falla.

Resistencia a la corrosión: Define cuán efectivamente se desempeña la aleación en condiciones ambientales duras.

Resistencia al calor: Indica idoneidad para aplicaciones de alta temperatura.

Propiedades de fundición: Influye en qué tan bien la aleación llena los moldes y replica geometrías detalladas.

Seleccionar una aleación inadecuada puede conducir a fallas en parte, ropa prematura, excessive costs, o funcionalidad inadecuada. Por eso, Comprender las características de las aleaciones de aluminio es esencial para un casting exitoso.

Aleaciones de aluminio populares para el casting de matriz

2.1 Aleación de aluminio A380

La aleación A380 es la aleación de aluminio de fundición más común debido a su equilibrio favorable de costo y rendimiento.

Ventajas:

Excelente aleación de uso general

Menor costo en comparación con aleaciones especializadas

Ligero con buena relación de fuerza / peso

Conductividad eléctrica superior

Buena capacidad para diseños detallados e intrincados

Limitaciones:

Resistencia moderada a la corrosión; puede requerir tratamientos superficiales adicionales

No recomendado para entornos altamente corrosivos o de alto estrés

Aplicaciones Típicas:

Componentes electricos

Soportes

Cajas de cambios

Productos de consumo

2.2 Aleación de aluminio A383

La aleación de aluminio A383 comparte muchas propiedades con A380, pero sobresale en la capacidad de fundición.

Ventajas:

Capacidad excepcional de llenado de moho, especialmente para las intrincadas geometrías

Resistencia térmica mejorada, Reducir el riesgo de agrietamiento térmico

Buena estabilidad dimensional a temperaturas elevadas

Limitaciones:

Costo ligeramente más alto en comparación con A380

Durabilidad mecánica reducida en aplicaciones altamente estresadas

Aplicaciones Típicas:

Componentes de carcasa complejos

Thin-wall structures

Accesorios eléctricos que requieren detalles finos

2.3 Aleación de aluminio A360

Para proyectos que exigen un mayor rendimiento mecánico, A360 se destaca.

Ventajas:

Excelente fuerza y ductilidad, especialmente a altas temperaturas

Resistencia de corrosión superior adecuada para entornos agresivos

Excelente estabilidad dimensional

Limitaciones:

Difícil de lanzar geometrías complejas debido a capacidades limitadas de llenado de moho

Mayor costo de producción por parte

Aplicaciones Típicas:

Componentes automotrices

Equipo industrial de alto rendimiento

Piezas marinas expuestas a condiciones duras

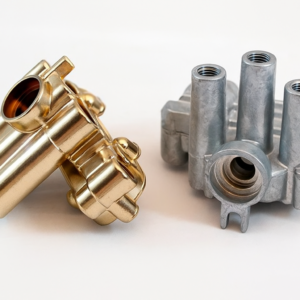

2.4 Aleación de aluminio za-8 (Aleación de zinc-aluminio)

ZA-8 es una aleación de zinc-aluminio, con un contenido de aluminio más bajo, dando como resultado una mayor densidad y un punto de fusión más bajo.

Ventajas:

Alta resistencia, dureza, y durabilidad

Procesos de fundición de died de cámara de cámara caliente utilizable, Acelerar las tasas de producción

Excelente calidad de acabado de superficie y estabilidad dimensional

Limitaciones:

Mayor peso debido a un mayor contenido de zinc

No es ideal para aplicaciones sensibles a peso

Aplicaciones Típicas:

Componentes industriales

Carcasa mecánica

Hardware decorativo que requiere alta resistencia y precisión

2.5 Aleación de aluminio ZA-12 (Aleación de zinc-aluminio)

Con aumento del contenido de aluminio, ZA-12 ofrece una mezcla bien equilibrada de propiedades mecánicas.

Ventajas:

Más fuerte y más ligero que la aleación de za-8

Buen rendimiento de fundición en procesos de cámara fría

Excelente resistencia a la tracción y el impacto

Buenas cualidades de rodamiento y resistencia al desgaste

Limitaciones:

Requiere fundición de cámara fría, Limitar la velocidad de producción

Mayores costos de procesamiento en comparación con la aleación de ZA-8

Aplicaciones Típicas:

Piezas automotrices que requieren fuerza mejorada

Componentes mecánicos de alto estrés

Elementos y engranajes de la máquina resistentes al desgaste

2.6 Aleación de aluminio za-27 (Aleación de zinc-aluminio)

La aleación ZA-27 posee el mayor contenido de aluminio en la serie ZA, ofreciendo resistencia mecánica inigualable.

Ventajas:

Fuerza excepcional y durabilidad con baja densidad en comparación con otras aleaciones de ZA

Resistencia de desgaste superior y estabilidad térmica

El más alto punto de fusión en aleaciones de ZA, Adecuado para condiciones exigentes

Limitaciones:

La aleación de ZA más desafiante para lanzar debido a la capacidad limitada de llenado de moho

Requiere un control de temperatura preciso y operadores calificados

Típicamente costos más altos y disponibilidad de instalaciones de fundición limitadas

Aplicaciones Típicas:

Componentes de servicio pesado

Accesorios industriales de alto rendimiento

Structural connectors and gears exposed to rigorous usage

Elegir la aleación adecuada para su proyecto

Seleccionar la aleación correcta requiere una cuidadosa consideración de factores específicos:

Entorno de aplicación: Evaluar la resistencia a la corrosión de la aleación, estabilidad térmica, y condiciones ambientales.

Complejidad de la pieza: Las geometrías complejas pueden requerir aleaciones con una mejor capacidad de castigo, como A383.

Necesidades de fuerza y durabilidad: Si la fuerza es crítica, Considere aleaciones de mayor resistencia como A360 o ZA-27.

Volumen de producción & Rentabilidad: Equilibrar el rendimiento del material y las limitaciones presupuestarias influyen en la selección de aleación.

Comprender estas consideraciones permite opciones de aleación precisas, Asegurar piezas confiables que cumplan con sus requisitos y restricciones específicas.

Trabajar con un experto en casting de matriz

La consultoría con expertos de la industria como TOPS Precision beneficia significativamente a la selección de aleaciones y el éxito del proyecto. Los profesionales de casting experimentados ofrecen información valiosa sobre:

Rendimiento de aleación para aplicaciones específicas

Recomendaciones de diseño para mejorar la capacidad de fabricación

Estrategias de lanzamiento rentables y metodologías de producción

La colaboración con proveedores de casting de troqueles expertos garantiza resultados optimizados, costos reducidos, y resultados exitosos del proyecto.

Conclusión

Las aleaciones de aluminio juegan un papel crucial en los proyectos exitosos de casting de dias. Elegir la aleación correcta impacta directamente la fuerza del componente, durabilidad, resistencia a la corrosión, y costos generales de producción. Si su prioridad es de bajo costo y utilidad general (A380), Castabilidad intrincada (A383), enhanced strength (A360), o aleaciones especializadas de aluminio (Serie de zagoras), Comprender claramente las características de cada aleación es esencial.

Comprometerse con los proveedores profesionales de casting de dias maximiza aún más estos beneficios, Optimización de la selección de aleaciones y la eficiencia de fabricación para Superior, partes confiables.

Preguntas frecuentes

Q: ¿Cuál es la aleación de aluminio más rentable para el casting general??

A: La aleación de aluminio A380 es la aleación de uso general más rentable, equilibrar el precio y el rendimiento de manera efectiva.

Q: ¿Qué aleación de aluminio es la mejor para geometrías complejas de piezas??

A: La aleación A383 proporciona excelentes capacidades de llenado de moho y reduce el agrietamiento térmico, ideal para diseños complejos.

Q: Qué aleación ofrece la mejor fuerza para aplicaciones industriales exigentes?

A: ZA-27 ofrece resistencia mecánica inigualable y durabilidad entre las aleaciones a base de aluminio, Ideal para componentes de servicio pesado.

Q: ¿Se pueden usar las aleaciones de ZA en la fundición de troqueles de cámara caliente??

A: Solo ZA-8 es adecuado para la fundición de died de cámara caliente debido a su punto de fusión más bajo. ZA-12 y ZA-27 requieren procesos de cámara fría.