Fatigue Testing is a fundamental evaluation method in material science and mechanical engineering used to understand how materials behave under repeated or cyclic loading. Unlike static tests, which apply a load once until failure, fatigue testing simulates real-world service conditions, where components experience fluctuating stresses over long periods.

Fatigue-related failures are particularly dangerous because they often occur without visible warning and at stress levels well below a material’s ultimate tensile strength. Como resultado, fatigue testing plays a critical role in industries such as aeroespacial, automotor, energía, construcción, dispositivos médicos, y electrónica, where reliability and safety are paramount.

Fundamentals of Fatigue Behavior

Cyclic Loading and Repeated Stress

Cyclic loading refers to stresses that vary with time, such as tension–compression, doblando, or torsion. Even relatively low stress levels can cause damage if applied repeatedly.

Fatigue Life and Endurance Limit

Vida fatigada (Nf): The number of cycles a material can withstand before failure.

Endurance Limit: For some materials (notably certain steels), a stress level exists below which fatigue failure theoretically does not occur.

Crack Initiation and Propagation

Fatigue failure typically progresses through:

Crack initiation at surface defects, inclusions, or stress concentrators

Crack propagation with each load cycle

Final fracture when the remaining cross-section can no longer carry the load

Stress–Strain Behavior Under Cyclic Loads

Repeated loading causes materials to exhibit cyclic hardening or softening, visible in stress–strain hysteresis loops. These loops reveal how energy is absorbed and dissipated during each cycle.

What Does Fatigue Testing Measure?

Fatigue testing provides quantitative and qualitative data, incluido:

Endurance Limit

Cycles to Failure (Vida fatigada)

Stress–Strain Relationship under Cyclic Loads

Crack Initiation Points and Growth Rates

Material Damping and Energy Dissipation

Effects of Surface Finish, Geometría, and Environment

This information is essential for selección de material, component design, lifetime prediction, and safety assessment.

Purpose and Objectives of Fatigue Testing

Fatigue testing serves multiple engineering objectives:

Understanding material response to real service loads

Predicting failure mechanisms and service life

Improving product design and structural integrity

Ensuring compliance with international standards

Supporting quality control in manufacturing

Reducing maintenance, falta del tiempo, and warranty costs

Enhancing safety in critical systems

Enabling research and development of advanced materials

Types of Fatigue Testing

High-Cycle Fatigue (HCF)

Low stress, high cycle count (>10⁶ cycles)

Common in rotating machinery and aerospace structures

Low-Cycle Fatigue (LCF)

High stress, low cycle count (<10⁴ cycles)

Typical in pressure vessels and seismic structures

Strain-Controlled Fatigue Testing

Strain is controlled rather than stress

Useful for plastic deformation analysis

Thermal-Mechanical Fatigue (TMF)

Combined mechanical loading and temperature cycling

Critical for turbines and exhaust systems

Multiaxial Fatigue Testing

Simultaneous loading in multiple directions

Represents complex real-world stress states

Corrosion Fatigue Testing

Fatigue under corrosive environments

Essential for marine and chemical applications

Fretting Fatigue Testing

Fatigue caused by small-amplitude relative motion

Common in bolted and press-fit joints

Vibration Fatigue Testing

High-frequency oscillatory loads

Used for electronics and transportation equipment

Fatigue Testing Calculation and Analysis Methods

Loading Condition Definition

Stress range (Δσ)

Mean stress (σₘ)

Stress amplitude (σₐ)

Load ratio (R)

Number of cycles

Material Property Characterization

El S–N curve (Wöhler curve) relates stress amplitude to fatigue life and is central to fatigue design.

Fatigue Life Prediction Models

Goodman: Linear, conservative

Gerber: Parabolic, less conservative

Soderberg: Highly conservative for safety-critical designs

Statistical and Environmental Considerations

Fatigue data often shows scatter; statistical tools and confidence intervals are used to ensure reliability. Temperatura, humedad, and corrosion effects must also be considered.

Software and Experimental Validation

Finite element analysis (FEA) and fatigue simulation software are widely used but must be validated through physical testing.

Fatigue Testing of Different Material Types

Metallic Materials

Acero

Fatigue strength: ~250–500 MPa

Exhibits endurance limit

Used in aircraft, puentes, componentes automotrices

Aleaciones de aluminio

Fatigue strength: ~50–150 MPa

No clear endurance limit

Widely used for lightweight structures

Polymer Materials

Polietileno (EDUCACIÓN FÍSICA)

Fatigue strength: ~5–20 MPa

Flexible but sensitive to temperature

policarbonato (ordenador personal)

Fatigue strength: ~20–40 MPa

Buena resistencia al impacto, no endurance limit

Ceramic Materials

Alúmina (Al₂O₃)

Fatigue strength: ~300–400 MPa

Brittle behavior

circonita (Zro₂)

Fatigue strength: ~800–1200 MPa

Transformation toughening improves fatigue resistance

Materiales compuestos

CFRP

Fatigue strength: ~150–200 MPa

Highly dependent on fiber orientation

PRFV

Fatigue strength: ~70–100 MPa

Used in wind turbine blades and marine structures

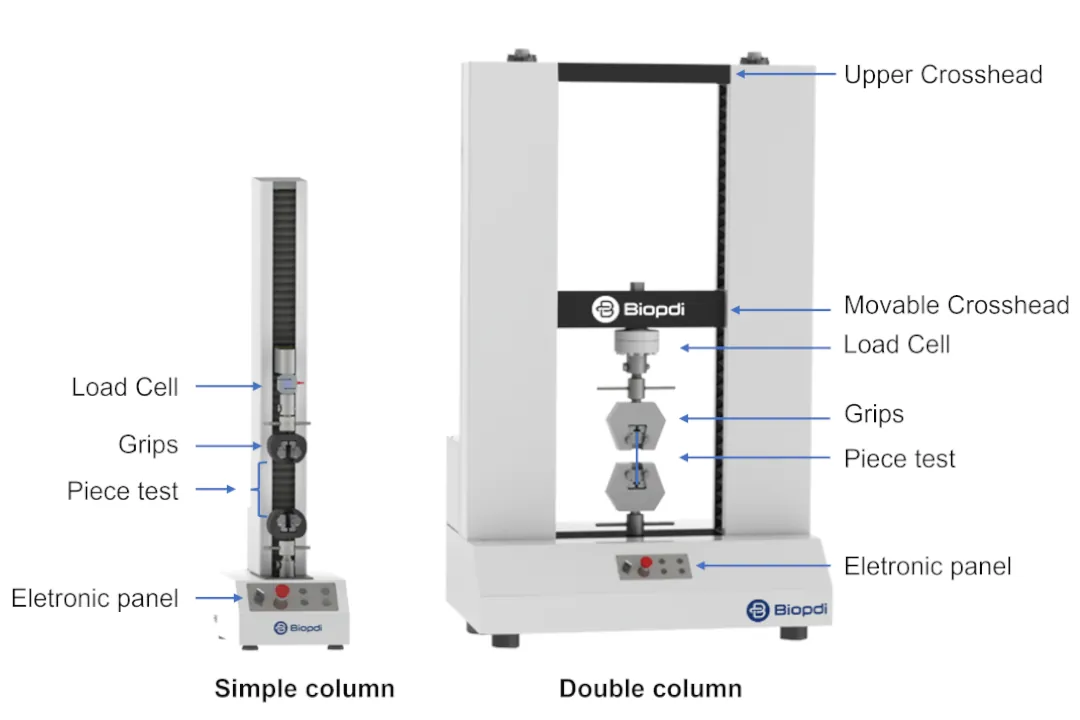

Fatigue Testing Machines and Equipment

Componentes principales

Actuator (hydraulic or electromagnetic)

Load cell

Crosshead and frame

Environmental and Control Systems

Environmental chambers

Temperature and humidity controllers

Digital control consoles and software

Data Acquisition and Safety

Medidores de deformación, extensómetros, displacement sensors

High-speed data acquisition systems

Protective shielding and emergency stops

Data Obtained from Fatigue Testing

Stress and strain histories

Hysteresis loops

Cycle counts and frequencies

Fatigue life and endurance limits

Failure modes and locations

Specimen geometry and material details

Microscopic crack observations

This data supports design validation, predictive maintenance, and failure prevention.

Fatigue Failure Analysis

Stages of Fatigue Failure

Crack initiation

Crack propagation

Sudden final fracture

Fracture Characteristics

Beach marks

Striations

Smooth crack initiation zones

Common Causes

Stress concentrations

Surface defects

Poor material selection

Adverse environments

International Standards for Fatigue Testing

Normas ISO

YO ASI 1099

YO ASI 12107

YO ASI 12110-1

YO ASI 11405

YO ASI 13003

ASTM Standards

ASTM E466

ASTM E647

ASTM E1820

ASTM D7791

ASTM D3479

These standards ensure repetibilidad, exactitud, and global acceptance of fatigue test results.

Applications of Fatigue Testing

Aeroespacial y Aviación

Aircraft parts are exposed to constant loading and unloading. Every takeoff, flight, and landing adds another load cycle.

Fatigue testing is used for:

Aircraft wings and fuselage structures

Engine parts such as turbine blades

sujetadores, articulaciones, y paréntesis

Because fatigue failure in aviation can be catastrophic, testing focuses on long life, crack growth, y damage tolerance. Many aircraft components are designed to stay safe even after small cracks appear.

Industria automotriz

Cars and trucks experience millions of load cycles during daily use. Road bumps, frenado, and vibration all contribute to fatigue damage.

Fatigue testing helps evaluate:

Suspension systems

Chassis and frame components

Engine and drivetrain parts

Welded and bolted joints

Automotive fatigue testing is especially important for diseños livianos, where thinner materials must still survive years of use.

Civil and Structural Engineering

Puentes, edificios, and rail systems carry loads for decades. Even small repeated loads can cause damage over time.

Fatigue testing is applied to:

Bridge cables and steel beams

Railway tracks and fasteners

Wind-exposed structures

Seismic-resistant designs

These tests help engineers prevent long-term failures and reduce costly repairs or unexpected shutdowns.

Medical and Biomedical Devices

Medical implants are exposed to constant motion inside the human body. A failed implant can seriously harm a patient.

Fatigue testing is used for:

Hip and knee implants

Dental implants

Stents and surgical tools

Testing ensures implants can survive millions of cycles under body loads while remaining safe and reliable for many years.

Energía y Generación de Energía

Power systems operate continuously, often under changing loads and temperatures.

Fatigue testing supports:

Wind turbine blades

Steam and gas turbine components

Nuclear and thermal power equipment

Pressure vessels and pipelines

In energy applications, fatigue testing helps prevent unexpected shutdowns and improves long-term reliability.

Marine and Offshore Equipment

Marine structures face waves, currents, corrosión, y vibración all at the same time.

Fatigue testing is critical for:

Offshore platforms

Ship hulls

Mooring systems

Subsea pipelines

Aquí, fatigue testing is often combined with corrosion testing to reflect harsh sea environments.

Electronics and Industrial Equipment

Smaller parts also suffer from fatigue, especially when vibration is involved.

Fatigue testing is used for:

Electronic connectors and cables

placas de circuito

Maquinaria industrial

Transportation equipment

These tests help avoid failures caused by vibración, thermal cycling, and repeated movement.

Consumer Products and Sports Equipment

Everyday products are also tested for fatigue to improve durability and user safety.

Los ejemplos incluyen:

Bicycles and sports gear

Herramientas eléctricas

Furniture and mechanical assemblies

Fatigue testing helps manufacturers design products that last longer and feel more reliable.

Advantages of Fatigue Testing

1. Shows How Parts Fail in Real Life

Most parts do not break from one big load. They fail because of many small loads over time. Fatigue testing copies this real working condition, making it much more useful than simple static tests.

2. Helps Predict Service Life

Fatigue testing tells engineers how long a part can last before it fails. This helps with:

Lifetime prediction

Maintenance planning

Replacement schedules

This is especially important for parts that must work safely for many years.

3. Improves Safety

In safety-critical products like aircraft, carros, puentes, or medical implants, fatigue testing helps prevent sudden and dangerous failures. Engineers can find weak points early and fix them before products go into service.

4. Supports Better Design Decisions

With fatigue test data, engineers can:

Choose better materials

Improve shapes and geometry

Reduce stress concentrations

Optimize weight without losing strength

Esto lleva a más fuerte, encendedor, and more reliable designs.

5. Helps Meet Industry Standards

Many industries require fatigue testing to meet YO ASI, ASTM, or customer standards. Testing helps prove that a product meets these rules and can be safely sold and used.

6. Reduces Long-Term Costs

Although fatigue testing can be expensive at first, it often saves money in the long run por:

Avoiding product recalls

Reducing warranty claims

Preventing early failures

Fixing problems in testing is much cheaper than fixing them in the field.

Limitations of Fatigue Testing

1. Takes a Long Time

High-cycle fatigue tests may require millions of cycles, which can take days or even weeks to complete. This can slow down product development.

2. Can Be Expensive

Fatigue testing machines, operadores calificados, and long test times all add cost. Advanced tests like corrosion fatigue or thermal fatigue are even more expensive.

3. Results Can Vary

Fatigue test results often show scatter, even for similar samples. Small differences in surface finish, material quality, or test setup can affect results.

Debido a esto, fatigue data must be treated carefully and often analyzed statistically.

4. Hard to Copy Real Service Conditions Exactly

Real-world loading is often complex and unpredictable. Laboratory tests usually use simplified loading patterns, which may not fully match actual service conditions.

5. Limited Sample Size

Only a limited number of samples can usually be tested due to cost and time. This makes it harder to fully capture all possible variations in materials and manufacturing.

6. Not Always Enough by Itself

Fatigue testing alone may not tell the full story. Engineers often need to combine it with:

Computer simulations (FEA)

Field data

Pruebas no destructivas (NDT)

Juntos, these tools give a more complete picture.

Conclusión

Fatigue testing is an indispensable tool in modern engineering, offering deep insight into how materials behave under real-world loading conditions. By understanding fatigue mechanisms, selecting appropriate test methods, and adhering to international standards, engineers can design safer, más confiable, and longer-lasting products.

As materials and manufacturing technologies continue to evolve, fatigue testing—supported by advanced simulation tools and experimental validation—will remain central to innovación, seguridad, and performance optimization en todas las industrias.

Below is a set of advanced engineering-level FAQs designed to complement the article. These go beyond basic definitions, focusing on design decisions, testing strategy, data interpretation, and real-world engineering trade-offs. They are suitable for professional engineers, QA teams, and R&D specialists.

Preguntas frecuentes

1. How does mean stress affect fatigue life, and how should it be corrected in design?

Mean stress significantly influences fatigue life. Tensile mean stress accelerates crack growth, while compressive mean stress improves fatigue resistance. Engineers typically apply correction models such as Goodman, Gerber, o Soderberg to adjust S–N data and account for mean stress effects in design calculations.

2. When should strain-controlled fatigue testing be used instead of stress-controlled testing?

Strain-controlled fatigue testing is preferred when:

Plastic deformation occurs during service

Low-cycle fatigue conditions dominate

Thermal expansion and constraint effects are significant

It is especially relevant for recipientes a presión, componentes de la turbina, and seismic structures, where strain, not stress, governs failure.

3. Why do fatigue test results show large data scatter, even for identical specimens?

Fatigue behavior is highly sensitive to:

Surface roughness and residual stresses

Microstructural variations

Inclusions and defects

Minor environmental changes

Because fatigue failure initiates at microscopic flaws, statistical scatter is inherent. Engineers account for this using probabilistic fatigue analysis and confidence intervals.

4. How does surface finish influence fatigue performance?

Surface finish plays a critical role in fatigue life:

Rough surfaces increase stress concentrations

Polished or shot-peened surfaces delay crack initiation

Compressive residual stresses improve fatigue resistance

Surface treatments are often more effective than material changes in improving fatigue life.

5. What is the difference between fatigue crack initiation life and crack propagation life?

Initiation life refers to cycles required to form a detectable crack

Propagation life is the time required for the crack to grow to critical size

High-cycle fatigue is often initiation-dominated, while damage-tolerant designs focus on crack growth monitoring and control.

6. How is fatigue testing integrated with finite element analysis (FEA)?

FEA is used to:

Identify high-stress regions

Calculate local stress or strain amplitudes

Apply fatigue damage models

Test data validates simulation results, ensuring that numerical predictions accurately represent real-world behavior.

7. Why do some materials not exhibit a true endurance limit?

Materials such as aleaciones de aluminio, polímeros, y compuestos lack a clear endurance limit because:

Microcracks continue to grow even at low stress levels

Damage accumulation does not stabilize

For these materials, fatigue life is defined at a specified cycle count, rather than infinite life.

8. How does frequency affect fatigue test results?

Higher frequencies reduce test time but may:

Introduce self-heating in polymers and composites

Alter crack growth behavior

Mask environmental effects

Standards often limit frequency ranges to ensure results remain representative of service conditions.

9. What challenges exist in multiaxial fatigue testing?

Multiaxial fatigue introduces:

Complex stress states

Non-proportional loading paths

Difficulty in defining equivalent stress parameters

Advanced models and specialized equipment are required to replicate realistic loading conditions accurately.

10. How is corrosion fatigue different from standard fatigue testing?

Corrosion fatigue involves simultaneous exposure to cyclic loading and a corrosive environment. Él:

Accelerates crack initiation

Eliminates endurance limits

Requires environmental chambers and controlled media

Designs must consider combined mechanical and chemical degradation.