El mecanizado de ranura es un proceso de metalurgia común pero importante utilizado para crear canales o recovecos estrechos en una pieza de trabajo. Si bien puede sonar simple, Grooving es una operación precisa que juega un papel importante en cómo las partes se ajustan, función, e incluso como se ven. Desde ranuras de sellado para juntas tóricas hasta acentos decorativos en productos de metal, Grooving se utiliza en todas las industrias como Automotive, aeroespacial, aceite & gas, y fabricación.

Esta guía desglosa qué es el mecanizado de ranura, como funciona, los tipos de máquinas y herramientas utilizadas, Técnicas para el éxito, Desafíos comunes, y aplicaciones prácticas.

¿Qué es el mecanizado??

El mecanizado de ranuras es un proceso de fabricación sustractiva donde una herramienta de corte elimina el material para formar un canal, ranura, o sección empotrada en la superficie de una pieza de trabajo.

Las ranuras pueden ser externo (en el diámetro exterior), interno (dentro de un agujero o orificio), o en una superficie plana.

Los principales propósitos de ranura incluyen:

Sellando - P.EJ., Surcos de junta tórica en componentes hidráulicos.

Asamblea - Proporcionar un espacio para la retención de anillos o anillos.

Funcionalidad - Hacer vías para fluidos o cables.

Decoración - Agregar detalles estéticos a los productos.

Cómo funciona el mecanizado de ranura

Sostener la pieza de trabajo estable

Primero, la pieza de trabajo (el material que estás mecanizando) se sujeta en su lugar, generalmente en un torno, fresadora, o máquina CNC. Esto se asegura de que no se mueva mientras la herramienta está cortando.

Elegir la herramienta adecuada

La herramienta de ranura tiene una forma especialmente para que coincida con el surco que deseas. Por ejemplo, puede ser directo para un canal simple, o tener una punta redondeada para formas especiales. En muchos casos, Se utilizan herramientas con punta de carburo o recubierto para una mejor resistencia al desgaste.

Posicionar la herramienta

La herramienta está cuidadosamente alineada con el lugar donde se realizará el ritmo. En Mecanizado CNC, Este posicionamiento se realiza automáticamente con una precisión muy alta..

Haciendo el corte

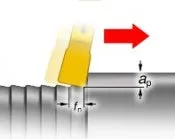

La herramienta se mueve hacia el material y corta una sección estrecha. La profundidad y el ancho del surco dependen del diseño de la pieza y la forma de la herramienta. El corte se puede hacer en un pase para ranuras poco profundas, o en múltiples pases para los más profundos para evitar el estrés de la herramienta.

Control de velocidad y alimentación

La velocidad de corte (Qué tan rápido se mueve la herramienta) y tasa de alimentación (Qué tan rápido avanza en el material) se ajustan para evitar el desgaste de la herramienta, calentamiento excesivo, o mal acabado superficial. Los materiales más duros requieren velocidades más lentas y un enfriamiento cuidadoso.

Terminando el ritmo

Después de que se corta el ritmo, La herramienta puede hacer un pase final para suavizar la superficie. A veces, se utilizan procesos adicionales como el pulido o el desgaste para eliminar los bordes afilados y garantizar que el surco cumpla con las especificaciones exactas.

Herramientas utilizadas en operaciones de ranura

Insertos de ranura

Estos son pequeños, Consejos de corte reemplazables que se ajustan a un portavasos. Vienen en muchas formas y tamaños para que coincidan con el surco que necesitas cortar. Los insertos de carburo son populares porque son duros y duran mucho, Incluso en materiales más duros.

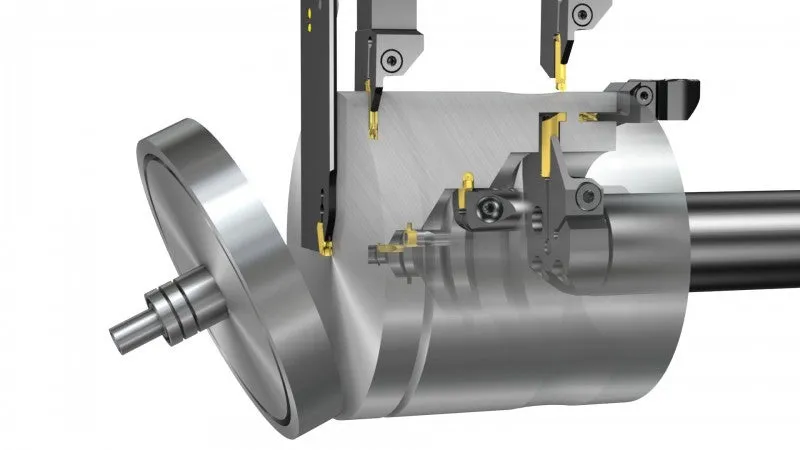

Herramientas de giro de ranura

Utilizado principalmente en tornos, Estas herramientas ayudan a cortar los surcos a lo largo de una pieza de trabajo giratorio. Vienen en diferentes diseños para ranuras rectas, ritmos de cara, o incluso ranuras de contorno especiales.

Herramientas de separación (Herramientas de corte)

Piense en estas como herramientas de ritmo con un rol doble: son principalmente para cortar una parte terminada del material sobrante, pero también pueden cortar ranuras estrechas cuando sea necesario..

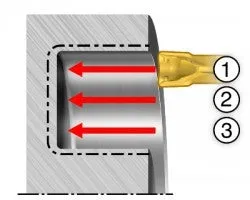

Herramientas de ranura internas

Estas herramientas entran en las partes huecas, Como tubos o tuberías, Para cortar ranuras en las superficies adentro. Son más largos y delgados para que puedan alcanzar esos puntos apretados..

Herramientas de ranura externa

Se usa para cortar ranuras en la superficie exterior de una parte, Estos vienen en una variedad de formas para adaptarse a diferentes tamaños y perfiles de ranuras..

Herramientas de ranura

Diseñado para surcos en la cara plana de una parte, Estas herramientas pueden llegar a las áreas que las herramientas regulares de ranura no pueden.

Interruptores de chips

No es exactamente una herramienta de corte, sino un complemento importante: los interruptores de chips ayudan a dividir las astillas de metal en piezas más pequeñas para que no se enreden o causen daños durante el corte.

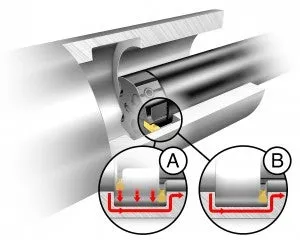

Sistemas de entrega de refrigerante

Mantener las cosas frescas durante el ritmo es crucial. Boquillas de refrigerante especializadas apunte líquido justo en la zona de corte para reducir el fuego, extender la vida útil de la herramienta, y mejorar el acabado.

Tipos de máquinas de surcos

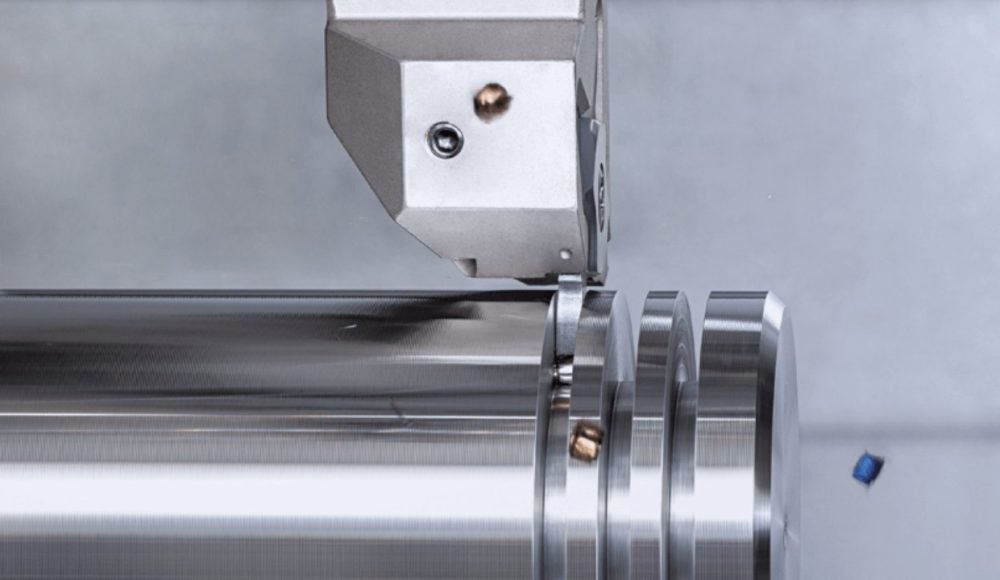

Máquinas de torno

Estos son los más comunes para ranurecer. La pieza de trabajo gira mientras la herramienta de corte escala lentamente el ritmo.

Perfecto para hacer piezas redondas como ejes, tubería, y casquillos.

Ideal tanto para pequeñas piezas personalizadas como para producción a gran escala..

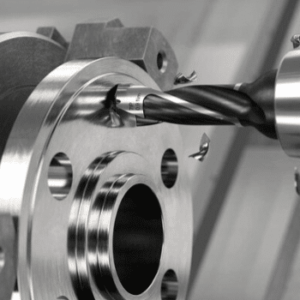

Fresadoras

En lugar de girar la pieza de trabajo, El cortador de fresador gira y se mueve a través del material para cortar ranuras.

Excelente para superficies planas, tragamonedas, y formas más complejas.

Funciona bien cuando necesita alta precisión y detalles nítidos.

CNC Grooving Máquinas

Totalmente controlado por computadora para la máxima precisión.

Puede producir surcos consistentes rápidamente y con un error humano mínimo.

Ideal para la producción de alto volumen y patrones de surco complejos.

Máquinas de surcos especializadas

Construido para tareas específicas, como cortar ranuras en discos de freno, aspectos, o tubo.

A menudo utilizado en industrias como Automotive, aeroespacial, y aceite & gas.

Proporcionar un corte más rápido y eficiente para las necesidades especializadas.

Técnicas de mecanizado de ranura

Ranura externa

Cortar un surco en la superficie exterior de una parte.

Piense en ello como tallar un anillo alrededor del borde exterior de un cilindro o tubería.

Común para hacer asientos de junta tórica, ranuras de anillo, o patrones decorativos.

Ranura interna

Cortando surcos dentro de un agujero o orificio.

Útil para agregar ranuras de sellado dentro de los cilindros o crear recovecos para componentes.

Requiere herramientas especiales para llegar al interior sin dañar la pieza.

Cara de la cara

Hacer surcos en la cara plana de una parte, No es el lado.

Imagine dibujar un círculo sobre una superficie plana y luego cortarlo en el material.

A menudo se usa para sellar superficies en bridas o asientos de válvula.

Combinación de separación y ranura

Algunas herramientas pueden cortar un ritmo y luego profundizar para separar completamente la pieza.

Ahorra tiempo y reduce los cambios de herramientas en la producción.

Corte de múltiples grados

Cortar varias ranuras en un solo pase utilizando herramientas especiales.

Ideal para piezas que necesitan patrones repetidos o ranuras paralelas múltiples.

Opciones de material para el mecanizado de ranuras

Aluminio - El metal tranquilo

El aluminio es suave y liviano, lo que lo hace súper amigable para grooving. Puedes ejecutar las máquinas más rápido, y las herramientas no se desgasta tan rápido. Pero ten cuidado con esas chips pegajosas que pueden enredarse y lanzar cosas. El uso de herramientas afiladas y mantener las papas fritas en movimiento con buen refrigerante ayuda a mantener las cosas suaves.

Acero inoxidable - El tipo duro

El acero inoxidable es fuerte y un poco terco. Es más difícil en tus herramientas y crea más calor, lo que significa que tienes que frenar un poco las cosas. También, El acero inoxidable puede endurecerse mientras lo corta (llamado endurecimiento del trabajo), Entonces, mantener sus velocidades y alimentos a la perfección es clave. No olvides mucho refrigerante para mantener las cosas frescas y tus herramientas felices.

Latón - El operador suave

Latón es como el medio feliz. Es lo suficientemente suave como para cortar rápidamente pero lo suficientemente resistente como para mantener una buena forma. Se hace pequeño, Chips manejables que no obstruyen su máquina, que es una gran ventaja. Más, Es gentil con tus herramientas, Pero un poco de lubricante contribuye en gran medida a mantener todo funcionando sin problemas.

Hierro fundido - El áspero y listo

El hierro fundido es duro y frágil. No es el material más fácil de surgir porque puede hacer que sus herramientas se desgasten rápido o incluso se rompan si no tiene cuidado. Pero si usa las herramientas correctas y las velocidades más lentas, Puedes obtener buenas ranuras sin demasiados problemas. Los refrigerantes y el control de chips son importantes aquí.

Plástica - El amigo flexible

Ranguinar plásticos suele ser más fácil porque son más suaves, pero pueden derretir o deformarse si te equivocas las velocidades. Mantenga su velocidad de corte moderada y use herramientas afiladas para evitar derretirse o agrietarse.

¿Cuál es la diferencia entre las técnicas de grooving y otras de mecanizado??

| Técnica de mecanizado | Que hace | Cómo funciona | Uso típico | Cómo difiere de la ranura |

| Ranurado | Corta ranuras o canales estrechos | La herramienta de corte crea preciso, cortes estrechos en una pieza de trabajo giratoria (generalmente en un torno) | Hacer surcos para focas, juntas tóricas, anillos de retención | Centrado en pequeño, surcos precisos en lugar de dar forma a piezas enteras |

| Torneado | Formas redondas o de partes cilíndricas | La pieza de trabajo gira, y la herramienta elimina el material para crear formas externas o internas | Hacer ejes, conos, cilindros | Grooving es una forma especializada de giro centrada en ranuras en lugar de formas completas |

| Molienda | Elimina material para crear superficies planas, bolsillos, o formas complejas | La herramienta de corte giratoria se mueve sobre una pieza de trabajo estacionaria | Creando caras planas, tragamonedas, o características 3D complejas | Molienda corta piezas estacionarias, Piezas giratorias de los cortes de ranura; Formas de fresado Características grandes |

| Molienda | Suaves y acabados superficies | La rueda abrasiva elimina pequeñas cantidades de material para pulir o piezas de tamaño | Refinamiento, Lograr tolerancias estrechas | Molilla de acabados superficies; Grooving corta material para formar ranuras |

| Ranurado | Crea mucho, cortes estrechos (tragamonedas) | La herramienta corta las ranuras lineales en la pieza de trabajo, a menudo más ancho y profundo que las ranuras | Cajas lacas, espacios de sujetador | Las ranuras suelen ser más grandes y sirven diferentes funciones que las ranuras |

Desafíos comunes en el mecanizado de ranuras

Rotura de herramientas

Las herramientas de ranura a menudo son estrechas y frágiles en comparación con las herramientas de giro estándar.

Si la velocidad de alimentación es demasiado agresiva o el material es demasiado difícil, La punta puede romperse.

Consejo: Use el tamaño correcto de la herramienta, y no lo empujes más fuerte de lo recomendado.

Mal control de chips

Cuando las papas fritas no se rompen correctamente, Pueden quedarse atascados en el ritmo, no profundizar, o envolver la herramienta.

Consejo: Elija Insertar geometrías y parámetros de corte diseñados para una mejor ruptura de chips.

Vibración y charla

Las herramientas largas o delgadas pueden vibrar, dejando ondas en la superficie del ritmo.

Consejo: Mantenga el voladizo de la herramienta, Reducir la velocidad de corte, y asegúrese de que la configuración sea rígida.

Calentamiento excesivo

El ritmo genera mucho calor en un área pequeña. Sin suficiente enfriamiento, La herramienta puede desgastarse rápidamente, Y la superficie de la parte puede arder.

Consejo: Use el flujo de refrigerante adecuado o, Para algunos materiales, refrigerante de alta presión a las chips y la temperatura de control.

Problemas de acabado superficial

Si el ritmo se ve duro o desigual, puede deberse a herramientas aburridas, vibración, o tasas de alimentación inadecuadas.

Consejo: Mantenga la herramienta afilada y ajuste las condiciones de corte para acabados más suaves.

Mantener tolerancias estrechas

En aplicaciones de sellado o ajuste, Incluso pequeños errores en el ancho o profundidad del surco pueden causar fugas o falla de la pieza.

Consejo: Medir cuidadosamente durante y después del mecanizado, y use herramientas con alta precisión dimensional.

Aplicaciones de mecanizado de ranuras

Piezas de automóviles - Desde anillos de pistón hasta ejes de conducción, Grooving ayuda a crear los espacios necesarios para los sellos, anillos, o canales de lubricación. Sin esos ritmos, Los motores y las transmisiones no funcionarían tan bien (o durar tanto).

Componentes aeroespaciales - Los aviones y la nave espacial usan piezas ranuradas para funciones críticas, como mantener los anillos de retención en su lugar o administrar el flujo de fluido en sistemas hidráulicos. La precisión es clave aquí: los errores de la tina pueden causar grandes problemas.

Hidráulica y neumática -Las ranuras ayudan a mantener juntas tóricas o elementos de sellado que evitan las fugas en sistemas de alta presión. Sin ellos, Los cilindros hidráulicos o los actuadores neumáticos no se mantendrían sellados bajo cargas pesadas.

Electrónica y conectores - Muchos conectores eléctricos y piezas mecánicas pequeñas usan surcos finos para mecanismos de bloqueo o conjuntos guía juntos.

Maquinaria industrial - De bombas a sistemas transportadores, Las ranuras se cortan en ejes, rodillos, y carcasas para la alineación, cierre, o propósitos de lubricación.

Dispositivos médicos - Herramientas quirúrgicas, implantes, y los equipos de diagnóstico a menudo tienen micro-ranuras para canales de fluidos, puntos de fijación, o diseños anti-slip.

Conclusión

El mecanizado de ranuras es un proceso versátil que puede ser tan simple como cortar una ranura estrecha o tan precisa como la creación de ranuras de sellado a nivel de micras en las partes aeroespaciales. La clave del éxito es usar las herramientas adecuadas., maquinas, y técnicas mientras comprenden las propiedades del material y la función del surco.

Con avances en tecnología CNC, Grooving se ha vuelto más rápido, más preciso, y más repetible, haciéndolo una habilidad esencial para cualquier maquinista moderno.

Preguntas frecuentes

1. ¿Cuál es la diferencia entre una ranura externa y una ranura frontal??

The difference is the orientación en la pieza de trabajo:

-

External Groove: A channel cut around the diámetro externo (DE) of a cylindrical part (p.ej., cortando un anillo en un eje). Esto generalmente se realiza en un torno..

-

Face Groove: A channel cut on the cara plana of a part, perpendicular al eje de rotación. Esto se usa a menudo para sellar bridas o asientos de válvulas especializados y también requiere herramientas especializadas en un torno o, a veces, en un molino..

2. ¿Por qué el “control de viruta” suele ser el mayor desafío en el ranurado en comparación con el torneado estándar??

El control de viruta es difícil porque la herramienta de ranurado es estrecha y solo ataca el material en tres lados. (front and both sides). Este confinamiento tan estrecho dificulta que las virutas se enrollen y se rompan limpiamente.. Si las fichas no se rompen, they form long, espirales fibrosas que pueden re-cut, rayar la superficie terminada, wrap around the tool, or block the coolant, todo lo cual conduce al sobrecalentamiento y falla de la herramienta.

3. Cuál es el P/M/K designación que se encuentra a menudo en insertos ranuradores?

El P/M/K La designación se refiere a los tres principales. ISO material groups para lo cual se optimizan la geometría y el recubrimiento de la plaquita:

-

PAG (Azul): Acero (p.ej., Carbon and Alloy Steels).

-

METRO (Amarillo): Acero inoxidable.

- k (Rojo): Hierro fundido. Elegir una plaquita diseñada para el grupo de materiales correcto es crucial para lograr una rotura de viruta y una vida útil óptimas..

4. ¿Cómo funciona el tipo de ranura? (O-ring vs. Snap Ring) afectan los requisitos de mecanizado?

El tipo de ranura dicta la necesidad precisión y perfil de herramienta:

-

Ranura de la junta tórica (Sellando): Requiere acabados superficiales extremadamente suaves y control dimensional preciso (depth and width) to ensure a perfect, leak-proof seal. El fondo de la ranura suele ser ligeramente redondeado..

-

Snap Ring / Retaining Ring Groove (Asamblea): El requisito clave es preciso ancho y ubicación de la ranura para anclar correctamente el anillo. Las paredes laterales deben ser verticales y las esquinas afiladas..

5. ¿Cuál es la principal causa de vibraciones y traqueteos en las operaciones de ranurado??

The primary cause is Overhang de herramientas (la longitud que la herramienta se extiende desde el soporte). Porque las herramientas de ranurado son estrechas y relativamente largas., Carecen de la rigidez de herramientas más anchas.. Si el voladizo es demasiado largo, la herramienta actúa como un diapasón, causa charla lo que resulta en un acabado superficial deficiente, ruido, and premature tool wear. Mantener el saliente de la herramienta lo más corto posible es la solución principal..

6. ¿Por qué el acero inoxidable y el aluminio blando plantean diferentes desafíos al ranurar??

Plantean desafíos debido a diferentes propiedades físicas.:

-

Acero inoxidable: The primary issue is work hardening (El material se vuelve más duro a medida que lo cortas.) y generación de calor. Esto requiere herramientas robustas, velocidades más lentas, y avances agresivos para cortar debajo de la capa superficial endurecida.

-

Soft Aluminum: The primary issue is manchas y virutas pegadas. El material es pegajoso y tiende a adherirse al filo., formación built-up edge (ARCO), lo que arruina el acabado de la superficie. Esto requiere herramientas extremadamente afiladas., higher rake angles, y excelente evacuación de virutas.

7. ¿Cuándo se utiliza una fresadora para ranurar en lugar del torno estándar??

Se utiliza una fresadora cuando es necesario crear la ranura en una non-cylindrical surface o cuando es necesario interrumpir el ritmo (not a full circle). Los ejemplos incluyen:

-

Corte chaveteros en el extremo plano de un eje.

-

Crear un patrón de ritmo en un flat plate or housing.

-

Corte muy profundo o ancho rectangular slots (que se encuentran entre el fresado y el ranurado).