Latón es una aleación de metal versátil compuesta principalmente de cobre y zinc. Los ajustes en estos elementos centrales producen variantes como latón rojo y latón amarillo, cada uno con propiedades distintas, usos, y ventajas. Esta guía ofrece una comparación en profundidad entre el latón rojo y el latón amarillo para ayudarlo a elegir la mejor aleación de metal para sus aplicaciones específicas..

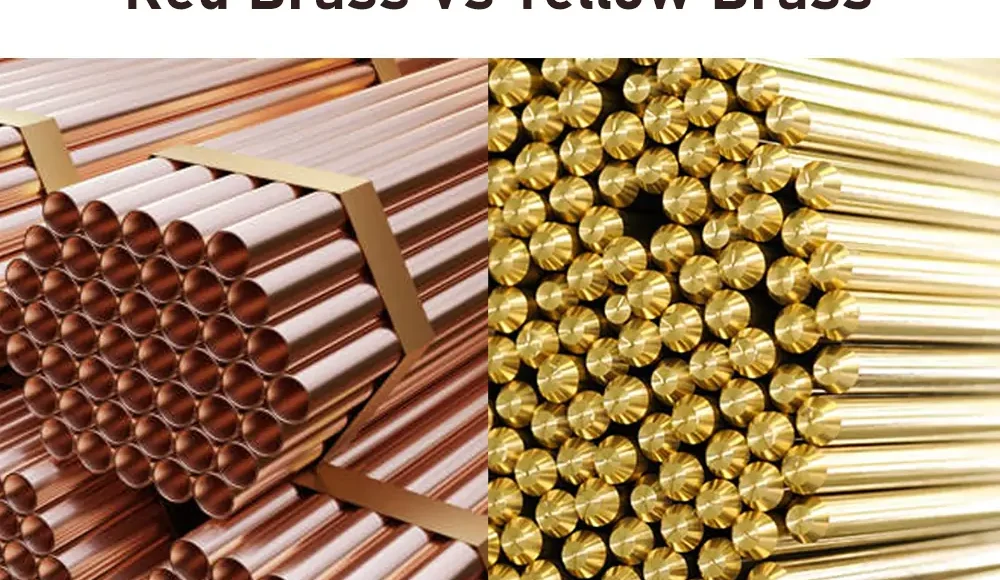

¿Qué es el latón rojo vs?. Latón amarillo?

Aunque el latón rojo y el latón amarillo se derivan de los mismos elementos base:cobre y zinc: la relación de estos elementos afecta significativamente sus propiedades, Hacerlos adecuados para diversas aplicaciones.

Comprender el latón rojo

Latón rojo, comúnmente conocido como Gunmetal, se distingue por su mayor contenido de cobre (85-90%), complementado por zinc, estaño, y trazas de plomo, hierro, manganeso, y arsénico. Esta rica concentración de cobre le da al latón rojo su color rojizo característico y una resistencia superior.

Sin embargo, Debido a la reacción de Zinc con el agua de mar, es menos adecuado para entornos marinos.

Comprender el latón amarillo

Latón amarillo contiene menos cobre (60-80%) y más zinc (30-40%), dándole un brillante, apariencia dorada. Su mayor contenido de zinc proporciona una ductilidad mejorada, maleabilidad, y maquinabilidad, Hacer latón amarillo ideal para diseños intrincados y mecanizado CNC.

Composición química: Latón rojo vs. Latón amarillo

| Elemento | Latón rojo (%) | Latón amarillo (%) |

| Cobre | 85–90 | 60–80 |

| Zinc | 5–10 | 30–40 |

| Estaño | 2 mín. | 1 máximo |

| Dirigir | 1 máximo | 1 máximo |

| Hierro | 0.1 | 0.1 |

| Manganeso | 0.5 | 0.5 |

| Arsénico | 0.01 máximo | 0.01 máximo |

Comparación de fuerza: Latón rojo vs. Latón amarillo

Un mayor contenido de cobre proporciona latón rojo con mayor resistencia (580 MPA TENSIÓN DE TENSA) En comparación con el latón amarillo (315 MPa). Esto hace que el latón rojo sea más adecuado para aplicaciones estructurales y de alta presión.

Comparación de propiedades físicas y mecánicas

Propiedades físicas

| Propiedad | Latón rojo | Latón amarillo |

| Color | Rojizo | Amarillo brillante |

| Densidad | 8.5–8.7 g/cm³ | 8.3–8.5 g/cm³ |

| Punto de fusion | 900–940 ° C (1652–1724 ° F) | 880–920 ° C (1622–1690 ° F) |

| Conductividad eléctrica | 21–24 ms/m | 25–28 ms/m |

| Conductividad térmica | 118–122 w/m · k | 109–113 w/m · k |

Propiedades mecánicas

| Propiedad | Latón rojo | Latón amarillo |

| Resistencia a la tracción | 580 MPa | 315 MPa |

| Fuerza de producción | 400 MPa | 200 MPa |

| Alargamiento | 30% | 40% |

| Dureza (media pensión) | 80–90 | 70–80 |

| maquinabilidad | Excelente | Excelente |

Comparación de costos: Latón rojo vs. Latón amarillo

El latón rojo tiende a ser más caro debido al alto contenido de cobre, especialmente dados los picos recientes en los precios del cobre. El latón amarillo es más económico y ampliamente disponible, haciéndolo preferible para proyectos sensibles a los costos.

Comparación de precios de desecho

Chatarra de latón rojo tiene un mayor valor de mercado ($2.10- $ 2.40 por libra) En comparación con el latón amarillo ($1.50- $ 1.80 por libra), Reflejando el valor intrínseco de las aleaciones ricas en cobre.

Comparación de peso: Latón rojo vs. Latón amarillo

Con densidad ligeramente mayor, latón rojo (8.5–8.7 g/cm³) es más pesado que el latón amarillo (8.3–8.5 g/cm³), que puede influir en su idoneidad para aplicaciones específicas que requieren materiales más resistentes.

Resistencia a la corrosión

Latón rojo, con más cobre, Demuestra resistencia a la corrosión superior. Esta propiedad hace que el latón rojo sea preferible para entornos expuestos a condiciones duras, Aunque el latón amarillo también proporciona resistencia a la corrosión razonable en escenarios menos exigentes.

Comparación de durabilidad

El latón rojo es notablemente más duradero, capaz de mantener su integridad bajo estrés, presión, y exposición ambiental prolongada. Latón amarillo, Aunque menos robusto, todavía se mantiene bien en aplicaciones de servicio más ligero.

Similitudes entre latón rojo y latón amarillo

A pesar de sus diferencias, Ambas aleaciones comparten propiedades valiosas:

Excelente maquinabilidad

Alta conductividad eléctrica y térmica

Resistencia a la empañe

Aplicaciones comunes en instrumentos musicales, objetos decorativos, y componentes eléctricos

Evaluación de fuerza: Que es más fuerte?

En general, el latón rojo es más fuerte, Adecuado para aplicaciones de alto estrés, Mientras que el latón amarillo proporciona flexibilidad y una maquinabilidad más fácil, Adecuado para trabajos detallados y componentes decorativos.

Latón rojo vs. Latón amarillo: Tabla de comparación

| Propiedad | Latón rojo | Latón amarillo |

| Apariencia | Dorado rojizo | Amarillo brillante |

| Contenido de cobre (%) | 85–90% | 60–80% |

| Contenido de zinc (%) | 5–10% | 30–40% |

| Resistencia a la tracción | Más alto (580 MPa) | Moderado (315 MPa) |

| Fuerza de producción | Más alto (400 MPa) | Moderado (200 MPa) |

| Dureza | Más alto (80–90 HB) | Moderado (70–80 HB) |

| maquinabilidad | Bien | Excelente |

| Densidad | Ligeramente más alto (8.5–8.7 g/cm³) | Ligeramente más bajo (8.3–8.5 g/cm³) |

| Punto de fusion | Más alto (900–940 ° C) | Más bajo (880–920 ° C) |

| Resistencia a la corrosión | Excelente | Bien |

| Durabilidad | Alto | Moderado |

| Costo | Más caro (Mayor contenido de cobre) | Más asequible (Contenido de cobre más bajo) |

| Aplicaciones Típicas | Piezas de servicio pesado, componentes electricos, joyas, Instrumentos musicales que requieren tonos más ricos | Objetos decorativos, plomería, componentes automotrices livianos, Instrumentos musicales que necesitan tonos estables |

Latón rojo vs. Latón amarillo: Que es mejor en general?

Ventajas de latón rojo:

Mayor resistencia y durabilidad

Resistencia a la corrosión superior

Mejor conductividad eléctrica

Ventajas de latón amarillo:

Rentable

Machinabilidad más fácil

Ampliamente disponible

Elegir la mejor opción depende de sus requisitos de aplicación específicos, presupuesto, y condiciones ambientales.

Comparaciones específicas de la aplicación

Joyas: El latón rojo es duradero y tiene un atractivo rojizo distintivo, ideal para piezas de alta calidad; El latón amarillo es rentable, más fácil de dar forma.

Instrumentos musicales:

Saxófono: Red Brass ofrece más profundo, tonos más ricos; El latón amarillo proporciona una calidad de sonido estable.

Trombón y trompeta: Brass Red Brass más oscuro, sonidos más ricos; el latón amarillo produce establo, tonos más brillantes.

Componentes de la aeronave: El latón rojo proporciona mayor resistencia y durabilidad, Mientras que la maquinabilidad de latón amarillo se adapta intrincados, componentes livianos.

Componentes marinos: Generalmente inadecuado debido al contenido de zinc; Materiales alternativos recomendados.

Componentes eléctricos: Se prefiere el latón rojo para una mejor conductividad; El latón amarillo sigue siendo práctico y asequible.

Piezas de automóviles: La resistencia de Red Brass se adapta a las piezas estructurales; El latón amarillo es rentable para componentes decorativos o no críticos.

Elegir el fabricante correcto

Seleccionar un fabricante experimentado y confiable garantiza la más alta calidad de las piezas de latón. Fabricación de KDM es un proveedor líder de componentes de latón de alta precisión, Asegurar productos adaptados con precisión a sus necesidades industriales.

Conclusión

Tanto el latón rojo como el latón amarillo tienen ventajas distintas adecuadas para necesidades específicas. Brass rojo sobresale en fuerza, resistencia a la corrosión, y durabilidad, mientras que el latón amarillo se prefiere para la asequibilidad, disponibilidad, y maquinabilidad. Evaluar cuidadosamente los requisitos de su proyecto es clave para elegir la aleación de latón correcta.

Recursos adicionales

- Comprender las aleaciones de latón

- Punto de fusión del latón

- Técnicas de mecanizado de latón

- ¿Es el latón magnético??

- Anodización de latón