Anodizado de aluminio: un proceso electroquímico para mejorar la capacidad del metal para soportar diversas condiciones.. Estas condiciones pueden incluir el uso, corrosión, y endurecimiento general de la superficie. Esta técnica es más efectiva en el sector aeroespacial., automotor, y las industrias de la construcción en las que son deseables nuevos estándares de materiales compuestos ligeros.. El anodizado funciona espesando la capa de óxido, lo que hace que el aluminio sea más útil de lo que es.. En este articulo, aprenderás qué es el aluminio anodizado, como funciona, y los detalles importantes sobre el uso de esta técnica.

¿Qué es el aluminio anodizado??

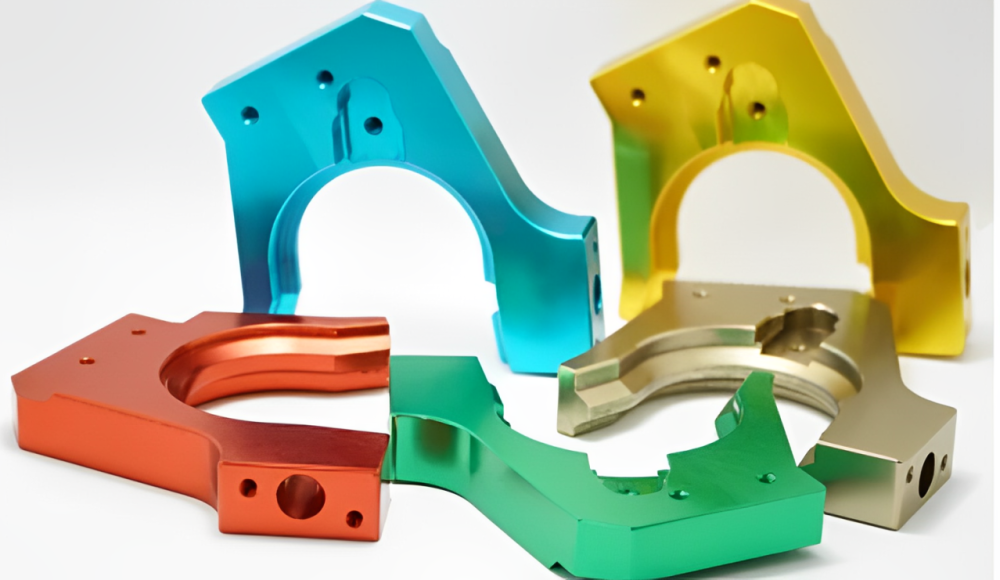

El aluminio anodizado es un proceso electroquímico que le confiere una capa de óxido natural más gruesa.. Esta fina capa de óxido actúa como barrera y mejora la protección contra la corrosión., mejor dureza superficial, y la eficacia de los coloridos acabados anodizados. El proceso de anodizado sirve para lo mismo que aluminio, es decir. inoxidable al acero. También hace que el aluminio sea más útil en aplicaciones en las que la durabilidad y la belleza son cruciales..

Un proceso completo de anodizado de aluminio

Entonces, El siguiente es un proceso paso a paso de anodizado de aluminio.:

1. Limpieza

Primero se lava el aluminio para eliminar la suciedad., es decir. polvo y otras partículas que puedan influir en el proceso de anodizado.

2. Pretratamiento

Esto implica el uso de tweels. (lijar o pulir) o un proceso químicamente reactivo (aguafuerte) listo para anodizar.

3. Anodizado

En diseño automotriz, El aluminio se sumerge en un baño de electrolito ácido., y dejamos pasar la corriente eléctrica a través de él. Con el tiempo se formará una capa de óxido natural para una protección aún mejor..

4. Colorante (Opcional)

Se pueden incorporar diferentes colores en la capa de óxido porosa para que los tintes o pigmentos produzcan el mejor color de un ser humano..

5. Sellando

La última capa de anodización está sellada para minimizar la porosidad original.. Ayuda a aumentar la resistencia a la corrosión además de cualquier retención de soluciones que mejoren el color..

Ocho cosas que necesita saber sobre el anodizado de aluminio

Estas son algunas de las cosas importantes que necesita saber sobre el anodizado de aluminio.:

1. Mayor resistencia a la corrosión

El anodizado imbuye al aluminio con una capa de óxido natural más gruesa que es una capa protectora que protege el metal de la humedad y los productos químicos.. Esto lo hace adecuado para aplicaciones donde las estructuras se enfrentan a los elementos, como aplicaciones exteriores..

2. Dureza superficial mejorada

El anodizado fortalece el aluminio y hace que las superficies de aluminio sean más resistentes a los rayones o al desgaste.. Esta característica es buena para productos predominantemente "manipulados" o "estresados mecánicamente"..

3. Variedad estética

También se puede colorear mediante anodizado, ya que se estableció que la capa de óxido porosa puede aceptar teñido.. Esto hace que el aluminio anodizado sea bueno para diseños que le den variedad en el mercado..

4. Respetuoso con el medio ambiente

El anodizado es respetuoso con el medio ambiente porque no genera productos químicos nocivos cuando lo procesamos.. No utiliza materiales tóxicos en el proceso y por lo tanto es respetuoso con el medio ambiente para las industrias que adoptarán el proceso..

5. La conductividad se reduce

Anodizado Minimiza la conductancia eléctrica del aluminio.. puede, ser un atributo desventajoso en ciertas aplicaciones. Este cambio en la conductividad puede reducir su aplicación electrónica..

6. Control de espesor

El espesor de la capa de óxido se regula fácilmente durante el anodizado, de modo que se pueden proporcionar diferentes niveles de protección y resistencia según la función para la que se utiliza..

7. Acabado no poroso

El procedimiento de anodizado produce una superficie no porosa que es más fácil de limpiar que las superficies metálicas que no están anodizadas.. El aluminio anodizado es ideal para alimentos y aparatos médicos donde es inevitable una limpieza profunda..

8. Ligero pero fuerte

El aluminio anodizado no cambia sus características de ligereza., pero adquiere un extra de durabilidad y protección contra la oxidación.. Esto lo hace muy versátil para su uso en sectores como el aeroespacial y el del automóvil..

Aplicaciones del aluminio anodizado

- Industria aeroespacial: Aplicado en piezas de aviones ya que tiene baja densidad y el NmAe es resistente a la corrosión..

- Estructuras arquitectónicas: El aluminio anodizado se utiliza ampliamente en el diseño de cortinas y fachadas., marcos de ventanas, y sistemas de techado.

- Industria automotriz: Se utiliza en piezas de automóviles donde se necesita cierto grado de dureza y belleza..

- Electrónica de consumo: El aluminio anodizado le da a un teléfono inteligente o computadora portátil un acabado elegante, y tiene aplicaciones en la industria electrónica.

- Artículos del hogar: El aluminio anodizado se utiliza en todas partes, desde utensilios de cocina hasta accesorios de iluminación, debido a la confiabilidad del material y su variedad de apariencias..

Pros y contras del aluminio anodizado

Ventajas:

- Alta resistencia a la corrosión.

- Estamos mejorando las tendencias de los parámetros anteriores en cuanto a durabilidad y dureza..

- Revestimientos de superficie atractivos y duraderos.

- Un proceso de fabricación respetuoso con el medio ambiente.

- Ligamento pero material fuerte utilizado para fabricar los teléfonos..

Limitaciones:

- Disminución de la capacidad de conducción eléctrica.,

- Restringido únicamente al aluminio y sus aleaciones..

- Existe la posibilidad de tener diferentes colores entre los archivos reales y digitales..

- Es posible que sea necesario limpiarlo con frecuencia cuando se utiliza en espacios al aire libre..

- Es relativamente costoso en comparación con el aluminio., que no ha recibido ningún tratamiento.

Los desafíos ocurren durante el anodizado de aluminio

Aquí hay algunos desafíos que puede enfrentar durante el proceso de anodizado de aluminio.:

- Variaciones de color: También es difícil conseguir el mismo tono de color en grandes cantidades., lo cual puede ser un problema con los tintes.

- Defectos superficiales: Hay que tener mucho cuidado al utilizar la técnica de anodizado porque cualquier mancha o raya que se observe en el metal base se volverá muy notoria una vez que se haya completado el proceso de anodizado..

- Calidad del sello: El problema de sellado puede provocar un nivel de protección contra la corrosión más bajo y puede cambiar de color..

- Uniformidad del espesor: A veces resulta complicado mantener constantes determinados espesores de capa de óxido en estructuras con geometrías complicadas..

Conclusión

En conclusión, El anodizado de aluminio es uno de los métodos más diversos y eficientes.. Entonces, es aprovechar las propiedades del material base, añadiendo resistencia y protección contra la corrosión. Es importante en muchos sectores y se utiliza con fines estéticos.. Sin embargo, Conozca los inconvenientes y la rigidez inherentes al anodizado., especialmente para una alta precisión y un espesor de capa de óxido idéntico. Cuando se utiliza con un control adecuado sobre el proceso., El aluminio anodizado puede servir para fines funcionales y estéticos., por eso es tan popular en muchos usos.

Preguntas frecuentes

Q1. ¿Con qué finalidad se aplica el anodizado al aluminio??

El anodizado mejora la protección contra la corrosión., recoge dureza, y crea una imagen en color en las industrias, es decir. aeroespacial, automotor, y construcción.

Q2. que es anodizado?

El anodizado somete el aluminio a un baño de ácido y luego lo recubre con una corriente eléctrica para crear una capa de óxido más gruesa y mejor protegida en su superficie..

Q3. ¿El anodizado es perjudicial para el aluminio??

En lo que respecta a las propiedades mecánicas del aluminio, el anodizado no cambia las propiedades esenciales del metal.. Mejora la dureza superficial y la resistencia superficial al desgaste..

Q4. ¿Cuánto dura el anodizado??

El aluminio anodizado tiende a tener un ciclo de vida muy largo y, por lo tanto, puede adaptarse mejor a proyectos a largo plazo cuando se mantiene bien..

Q5. ¿Cuál es la diferencia entre aluminio anodizado y normal??

El aluminio anodizado tiene una capa natural de óxido que este último no tiene.. Entonces, El aluminio anodizado es incluso más resistente a la corrosión y a los daños superficiales que el aluminio normal..

1 pensamiento en “8 Cosas que necesita saber sobre el anodizado de aluminio”