En el mundo impulsado por la precisión de la fabricación moderna, Pocas herramientas han revolucionado el diseño y la producción como CANALLA (Diseño asistido por computadora). Desde ingeniería aeroespacial y desarrollo automotriz hasta electrónica y arquitectura, CAD se ha convertido en la columna vertebral digital de cómo se imaginan los productos físicos, desarrollado, probado, y producido.

En esta guía, nos sumergimos profundamente en lo que es CAD, como funciona, y por qué es esencial en el panorama de fabricación competitivo de hoy, especialmente cuando se combina con Mecanizado CNC.

¿Qué es exactamente CAD??

Sobre el hombro del ingeniero que trabaja con software CAD en la computadora de escritorio, La pantalla muestra borradores técnicos y dibujos. En la instalación de ingeniería de antecedentes especializadas en diseño industrial

CANALLA, o Diseño asistido por computadora, se refiere al uso de un software especializado para crear dibujos 2D detallados o modelos 3D de componentes físicos antes de fabricarlos. Reemplaza la redacción manual tradicional con precisión digital y capacidades de simulación.

Con CAD, Los diseñadores pueden:

Visualizar sus ideas en dimensiones realistas

Modificar diseños al instante

Ejecutar simulaciones para probar el rendimiento del producto

Comunicar la intención de diseño claramente a las partes interesadas y las máquinas

Si está desarrollando una carcasa de teléfonos inteligentes, Diseño de un bloque de motor de automóvil, o construir un dispositivo médico, CAD proporciona las herramientas para que suceda con la máxima eficiencia y un error mínimo.

¿Cómo funciona CAD??

En su núcleo, El software CAD opera en un sistema de coordenadas—Típicamente x, Y, y ejes z, manteniendo cada línea, punto, y forma que se colocará con precisión en el espacio virtual.

Las operaciones clave CAD incluyen:

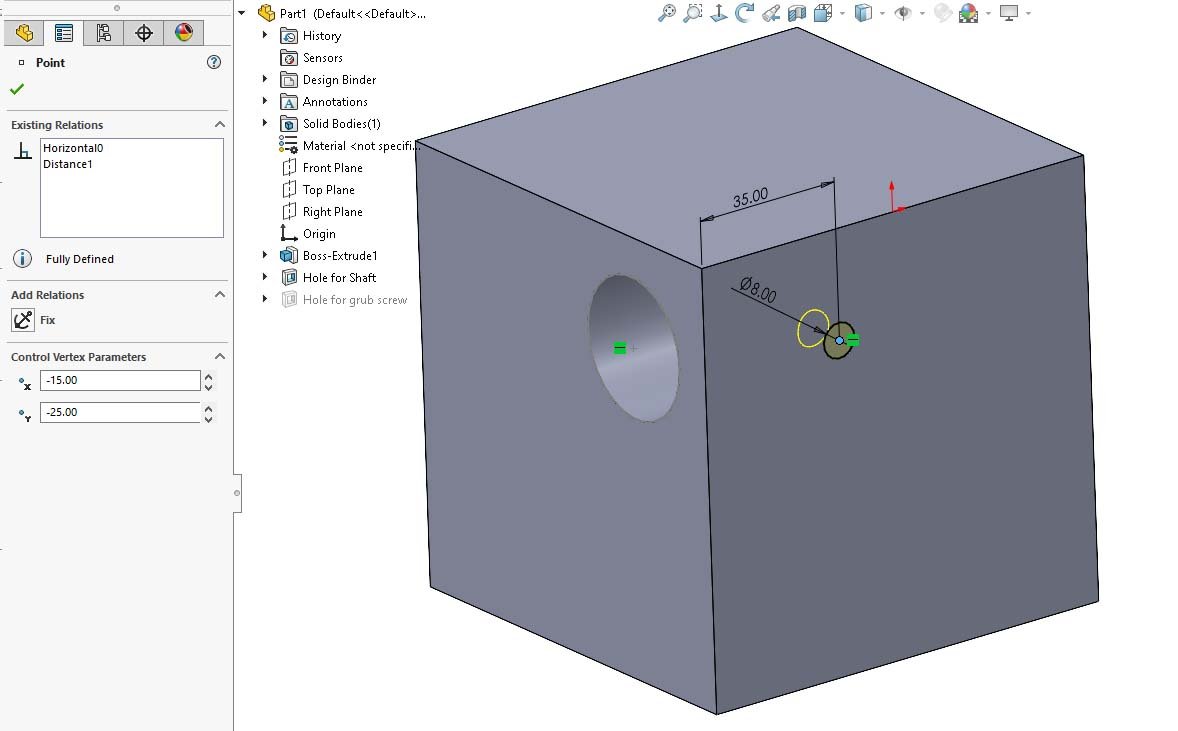

Boceto: Dibujar formas 2D usando puntos, líneas, arcos, y splines.

Modelado: Convertir bocetos 2D en objetos 3D usando extrusión, lofting, o revolución.

Asamblea: Combinando múltiples partes en un sistema para verificar el ajuste y el movimiento.

Simulación: Prueba de resistencia mecánica, resistencia al calor, y puntos de estrés en entornos virtuales.

Anotación y documentación: Agregar detalles técnicos como tolerancias, dimensiones, y materiales.

CAD no solo crea dibujos estáticos, sino que construye modelos inteligentes que interactúan con los procesos de fabricación aguas abajo., como CNC.

¿Por qué la CAD es importante en el mundo del mecanizado CNC??

🧠 CAD es el cerebro, CNC es las manos

Pensar en CANALLA (Diseño asistido por computadora) como el tablero de dibujo digital. Es donde los ingenieros y los diseñadores crean el plan completo para una parte, su tamaño, forma, curvas, agujeros, y todo lo que hay en el medio.

Ahora piensa en maquinas cnc como el manos. Leen el archivo CAD y lo siguen paso a paso, Tallando la parte del metal, plástico, u otro material.

Sin cad? No hay plan.

Sin CNC? Sin ejecución.

Funcionan mejor cuando trabajan juntos.

🎯 ¿Qué hace realmente CAD por CNC??

Esto es lo que hace que CAD sea imprescindible para el mecanizado CNC moderno:

✅ Crea un plan digital

En lugar de usar bocetos dibujados a mano, CAD le da a la máquina CNC una preciso, mapa detallado para seguir.

✅ Reduce los errores

Todo se mide hasta el fracción de un milímetro. Eso significa menos errores, Material menos desperdiciado, y piezas mejor ajustadas.

✅ acelera el proceso

Una vez que el modelo CAD esté listo, Se puede enviar directamente a la máquina CNC. No hay conjeturas, Sin redibujos, y casi no hay demora.

✅ Maneja formas complejas

Participar con las curvas, agujeros, o intrincada geometría? CAD puede manejar eso, y la máquina CNC puede seguirla exactamente.

🔄 De la idea a la realidad:

En tiendas como Hardware digno, Usamos CAD todos los días para convertir las ideas de los clientes en real, productos físicos. Si se trata de un solo prototipo o una producción completa, CAD nos da el control y la precisión, necesitamos hacerlo bien la primera vez.

En breve:

👉 CAD le dice a la máquina qué hacer.

👉 CNC lo hace posible, rápido y sin problemas.

Una breve historia de CAD

Las raíces de CAD se remontan a principios de la década de 1960 cuando El "Part de bocetos" de Ivan Sutherland introdujo la idea de dibujar en una pantalla con una pluma ligera. Para los años setenta y setenta, El software CAD estaba siendo adoptado por las principales industrias como Aeroespace y Automotive.

Hitos clave:

1962: Sketchpad demostró gráficos de computadora interactivos.

1982: AutoCAD lanzado, democratizando CAD para ingenieros y arquitectos.

2000s - presente: Herramientas basadas en la nube (como fusión 360) y surgieron plataformas CAD/CAM integradas.

Hoy, CAD es esencial para cualquier persona involucrada en el diseño de productos, creación de prototipos, o fabricación de precisión.

La relación simbiótica entre CAD y CNC Meckining

La relación entre CAD y CNC es muy similar entre un arquitecto y un equipo de construcción:

CANALLA: El arquitecto digital

Crea preciso, escalable, y planos editables

Define características como agujeros, filetes, hilos, y tolerancias

Asegura la capacidad de fabricación a través de reglas de simulación y diseño.

CNC: El maestro constructor

Lee trazas de herramientas generadas por CAD a través del software CAM

Ejecuta el corte de alta velocidad, molienda, perforación, o torneado

Ofrece piezas a especificaciones, a menudo con precisión del sub-milímetro

Juntos, CAD y CNC acortan los ciclos de desarrollo, Reducir los costos, y mejorar la consistencia del producto.

Tipos de sistemas CAD

🧾 1. 2D CAD - La herramienta de redacción clásica

Esta es la versión de la vieja escuela de CAD y todavía se usa ampliamente hoy.. En lugar de trabajar con formas 3D, Estás trabajando con dibujos planos, como planos.

Líneas de pensamiento, círculos, y formas dibujadas sobre una superficie plana.

Utilizado para planos de planta, diagramas eléctricos, y Diseños simples.

Es ideal para cuando no necesitas mostrar profundidad o volumen.

🛠 Mejor para: Arquitectos, ingenieros eléctricos, y bocetos de diseño rápido.

🎯 2. 3D CAD: la herramienta de modelado realista

Este es el tipo de CAD en el que la mayoría de la gente piensa hoy.. Le permite crear partes u objetos que se parecen a la cosa real, con longitud, ancho, y profundidad.

Hay algunos subtipos de CAD 3D, cada uno te da más control o realismo:

💡 A. Modelos de estructura alámbrica

Imagine un objeto 3D hecho de líneas, como un esqueleto.

Fácil de dibujar pero difícil de entender visualmente.

🧱 B. Modelos de superficie

Agrega "piel" sobre la estructura alámbrica.

Se ve mejor pero no muestra lo que hay dentro del objeto.

🧊 C. Modelos sólidos

El tipo más completo, adentro y fuera.

Muestra masa, peso, y detalles internos.

Perfecto para Mecanizado CNC y fabricación porque es muy preciso.

🛠 Mejor para: Partes mecánicas, 3Prototipos impresos en D, y cualquier cosa que necesite precisión.

🔧 3. Modelado paramétrico: diseño que sigue reglas

Este tipo de CAD le permite construir diseños utilizando dimensiones y reglas. Por ejemplo, Si le dice al software que un agujero siempre debe permanecer 10 mm desde el borde, se ajustará automáticamente si cambia la forma.

Excelente para Piezas que necesitan mantenerse consistentes con ciertas medidas.

Facilita la actualización de los diseños: cambiar un número y el resto se ajusta por sí mismo.

🛠 Mejor para: Ingenieros que construyen cosas con dimensiones exactas o piezas vinculadas.

🪛 4. Modelado directo: diseño de estilo libre

El modelado directo le brinda más libertad. Puede empujar, jalar, estirar, o remodelar objetos sin preocuparse por las reglas o restricciones.

Es rápido e intuitivo.

Excelente para el trabajo conceptual temprano o la lluvia de ideas.

🛠 Mejor para: Diseñadores de productos o cualquier persona que experimente con ideas.

Cómo CAD garantiza la calidad y la precisión

CAD permite a los fabricantes Ingeniero Calidad en el producto desde el principio.

Beneficios clave:

Visualización completa: Girar, zoom, y analizar diseños desde todos los ángulos

Simulación digital: Prueba térmica, mecánico, y tensiones fluidas sin construir un prototipo

Control de la versión & Documentación: Estandarizar dibujos con BOMS, notas, y tolerancias

Iteración de diseño: Hacer y probar 100 versiones sin desperdiciar material físico

Colaboración: Múltiples usuarios pueden desarrollar conjuntamente y aprobar modelos en tiempo real

Software y herramientas CAD populares

Dependiendo de su aplicación, Las diferentes herramientas CAD pueden ser más adecuadas:

| Software | Fortalezas | Mejor para |

| AutoCAD | 2D Redacción y diseño de uso general | Arquitectura, diseño de diseño |

| Solidworks | Modelado y ensamblajes paramétricos 3D | Ingeniería Mecánica, CNC |

| Catia | Modelado avanzado de superficie y aeroespacial | Aeroespacial, automotor |

| Fusión 360 | CAD/CAM/CAE basado en la nube en una plataforma | Desarrollo de productos, startups |

| Tinkercad | De nivel de entrada, educativo, Fácil de aprender | Para principiantes, impresión 3D básica |

Por qué CAD ayuda a evitar retrasos y acelerar la producción

El tiempo es dinero en la fabricación. CAD acelera cada paso:

Prototipos más rápido: Envíe el modelo a una impresora 3D o máquina CNC el mismo día

Revisiones rápidas: Arregle un defecto en minutos, no días

Menos errores de producción: No lee mal dibujos en papel o problemas de traducción

Integración CNC sin costura: Transferencia directa de CAD a CAM a Machine

Colaboración en tiempo real: Clientela, ingenieros, y todos los operadores permanecen actualizados

Ventajas y desventajas de CAD

✅ Las ventajas de CAD (Por qué es tan útil)

🎯 1. Diseños súper precisos

Con CAD, Puede crear diseños precisos hasta fracciones de un milímetro. Ese tipo de precisión es imprescindible cuando estás haciendo piezas para cosas como aviones, herramientas médicas, o máquinas de alto rendimiento.

🔄 2. Fácil de editar y actualizar

Cometió un error? Necesito cambiar una dimensión? Ningún problema. CAD le permite hacer cambios rápidamente sin comenzar de nuevo. Incluso puede ajustar una parte de un diseño y tener la actualización del resto automáticamente.

📦 3. Reutiliza tu trabajo

Una vez que hayas construido un gran diseño, puede guardarlo, copiarlo, o úsalo de nuevo para proyectos similares. Este es un gran ahorro de tiempo para la fabricación por lotes o las líneas de productos.

🧪 4. Prueba antes de construir

Muchos programas CAD te permiten simular condiciones del mundo real— -Como calor, presión, o movimiento, así que puedes ver cómo funcionará una parte antes de hacerlo. Esto ayuda a atrapar problemas temprano.

Olvídese de los grandes planos de papel. Los archivos CAD son digitales, lo que significa que puede almacenar cientos de diseños en su computadora o en la nube y enviarlos a clientes o compañeros de equipo en segundos.

❌ Las desventajas de CAD (Qué tener en cuenta)

🧠 1. Curva de aprendizaje empinada

El software CAD puede ser difícil de aprender al principio. Hay muchas herramientas, botones, y configuración, lo que significa Los nuevos usuarios necesitan tiempo y capacitación Para sentirse cómodo.

💸 2. El software puede ser costoso

Los programas CAD de primer nivel como SolidWorks o Catia no son baratos. Las licencias y suscripciones pueden ser un gran costo, especialmente para pequeñas empresas o startups.

💻 3. Necesita computadoras potentes

Porque CAD implica gráficos 3D y cálculos complejos, Necesitarás un computadora de alto rendimiento. Los sistemas más antiguos pueden retrasar o bloquear.

📐 4. Puede limitar el pensamiento creativo

A veces, Centrarse demasiado en la precisión puede hacer que los diseñadores confíen más en el software que en sus propias ideas. Para trabajo muy artístico o conceptual, Esto puede ser un inconveniente.

🔄 5. Problemas de compatibilidad

Diferentes equipos a menudo usan diferentes programas CAD. Si su software no "habla" con el suyo, Puede ser una molestia compartir archivos. Los formatos de conversión no siempre funcionan perfectamente.

Conclusión

CAD ya no es un lujo en la fabricación moderna, es un necesidad. De la ideación a la producción, CAD permite a los diseñadores e ingenieros convertir los conceptos en realidad con una precisión inigualable.

En Hardware digno, CAD no es solo una herramienta de diseño, está en el corazón de todo lo que hacemos. Si estamos produciendo complejo Piezas mecanizadas por CNC o prototipos rápidamente de un nuevo producto, CAD nos permite permanecer rápido, flexible, y láser preciso.

Si está buscando asociarse con un fabricante que combina la artesanía con tecnología de vanguardia, CAD es una de las razones por las que nuestros clientes, desde nuevas empresas hasta OEM globales, nos confían en brindar excelencia cada vez.

3 pensamientos sobre "Que es CAD (Diseño asistido por computadora)? Una guía completa para ingenieros y fabricantes”