En su núcleo, La prototipos rápidos es un Cambiar el juego en la fabricación moderna y el desarrollo de productos. Empodera a los creadores para probar los diseños rápidamente, Obtenga comentarios del mundo real, y refinar productos antes de comprometerse con la producción a gran escala. En lugar de confiar en la teoría o los dibujos 2D, Las empresas pueden producir modelos tangibles que parecen, sentir, y a veces incluso funcionan como el producto final.

En este articulo, Vamos a sumergirnos en el proceso, etapas, tipos, y herramientas de prototipos rápidos, Explorando cómo llegó a la vida, como funciona, y por qué se ha convertido en un pilar esencial de industrias que van desde aeroespaciales y automotrices hasta la salud y la electrónica de consumo.

Al final, No solo comprenderá qué es la prototipos rápidos, sino también cómo elegir el enfoque adecuado para su propio proyecto. Entonces comencemos!

¿Qué es la prototipos rápidos??

¿Qué es la prototipos rápidos?

Prototipos rápidos (RP) se refiere a un Colección de técnicas utilizadas para fabricar rápidamente un modelo de escala o parte física directamente de un 3D Diseño asistido por computadora (CANALLA) archivo. A diferencia de la creación de prototipos tradicionales, que a menudo requiere moldes especializados o largos procesos de mecanizado, La prototipos rápidos acelera el viaje creando modelos directamente, Por lo general, capa por capa.

Uno de los métodos más comunes detrás de la prototipos rápidos es 3impresión D. Aquí, Materiales como los plásticos, resinas, o incluso los metales se depositan o se solidifican la capa sobre la capa para construir un objeto físico. Pero la prototipos rápidos no se limita solo a la impresión 3D. También incluye Mecanizado CNC, corte de chorro de agua, colocación de aspiradoras, y procesos basados en láser.

Para decirlo simplemente:

Prototipos tradicionales = lento, caro, y a menudo limitado a una o dos iteraciones.

Prototipos rápidos = rápido, asequible, y permite múltiples iteraciones hasta que el diseño sea perfecto.

Esto significa que las empresas pueden probar nuevas ideas de productos sin verter grandes sumas en herramientas, y también pueden responder a los comentarios de los usuarios casi al instante. Piense en ello como el "Botón rápido" del desarrollo de productos.

Otro aspecto crítico de la prototipos rápidos es su versatilidad. Puede hacer diferentes tipos de prototipos, algunos que se parecen al producto (Para presentaciones y marketing), y otros que realmente funcionan como el producto (Para pruebas de rendimiento). Esta flexibilidad lo convierte en una solución para que sea una startup que prueba una invención o una empresa global que refina una parte del motor a reacción.

Historia de la prototipos rápidos

Como la mayoría de las tecnologías innovadoras, La prototipos rápidos no apareció solo durante la noche. Su historia comienza en el 1980s, una década que vio saltos notables en tecnología informática, automatización, y fabricación.

Quien inventó prototipos rápidos?

El crédito para la primera técnica de prototipos rápidos es para Casco de chuck, un ingeniero estadounidense. En 1984, Hull Invented estereolitmicromografía (SLA), un método que usó un Viga láser para solidificar la capa de resina líquida por capa. Esta fue la primera impresora 3D que trabaja en el mundo y el comienzo de una revolución de la fabricación. Hull más tarde cofundó 3Sistemas D, Una de las compañías líderes en la impresión 3D hoy.

Su invención fue innovador porque, por primera vez, Los diseñadores podrían pasar de un archivo CAD digital a un objeto 3D real sin moldes, herramientas, o formación manual. Fue como ver a la ciencia ficción convertirse en realidad.

¿Cómo ha evolucionado la prototipos rápidos con el tiempo??

De la impresora SLA inicial de Hull, la tecnología se expandió rápidamente. Poco después llegó Modelado de deposición fusionada (MDF) A fines de la década de 1980, Una técnica donde el filamento termoplástico se extruye a través de una boquilla calentada. Luego siguió Sinterización láser selectiva (SLSS), que usa láseres para fusionar materiales en polvo como nylon o metal.

Durante las décadas, La prototipos rápidos evolucionó en docenas de técnicas, Cada atendiendo a necesidades específicas:

Prototipos de alta detonancia con SLA y DLP.

Fuerte, partes funcionales con SLS, DMLS, y SLM.

Asequible, modelos fáciles de usar con impresoras FDM.

Prototipos a gran escala con mecanizado CNC y corte de chorro de agua.

Lo que comenzó como una tecnología de nicho se ha convertido en la corriente principal. Hoy, La prototipos rápidos no solo se usa en los laboratorios de investigación sino también en las aulas, hospitales, talleres, e incluso casas. El aumento de las impresoras 3D de escritorio asequibles ha puesto el poder de la prototipos rápidos en manos de los estudiantes, aficionados, y empresarios tanto.

En breve, La prototipos rápidos ha pasado de ser un innovación de lujo en la década de 1980 a un necesidad para el desarrollo moderno de productos en el siglo XXI.

¿Cómo funciona el proceso rápido del proceso de prototipos??

¿Cómo funciona el proceso rápido del proceso de prototipos??

Para comprender el poder de la prototipos rápidos, Desglosemos el proceso paso a paso. No importa el método: impresión 3D, Mecanizado CNC, o casting: el viaje de idea a prototipo generalmente sigue estas etapas centrales:

Paso 1: Creación de diseño

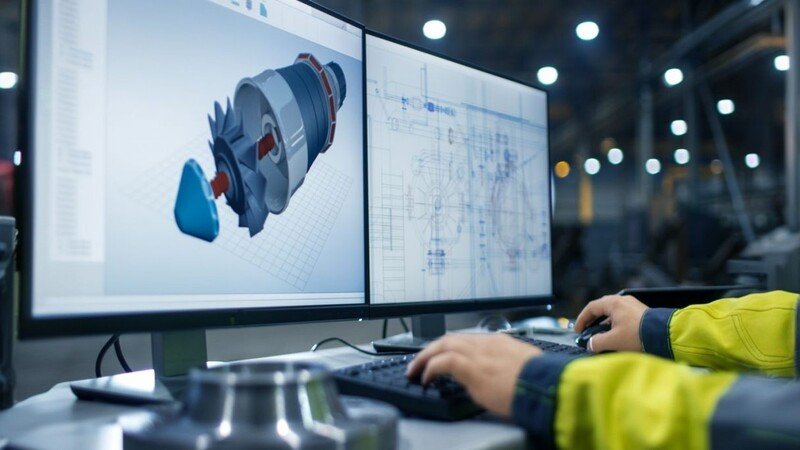

Todo comienza con un 3D Diseño digital creado usando Software CAD como SolidWorks, AutoCAD, Fusión 360, o Catia. Esta etapa es crítica porque el archivo digital sirve como el "plano" para el prototipo. Los diseñadores se centran en crear modelos precisos que reflejen el tamaño previsto, forma, y características del producto final.

Paso 2: Preparación de datos

Una vez que el modelo esté listo, Debe ser convertido en un formato legible por máquina, generalmente un Archivo stl. Este formato desglosa el diseño 3D en pequeños triángulos, Permitir que la máquina de creación de prototipos interprete y recree la capa por capa. Dependiendo de la tecnología elegida, Se puede usar un software de corte adicional para establecer parámetros como el grosor de la capa, velocidad de impresión, y tipo de material.

Paso 3: Configuración de la máquina

Luego viene la preparación de la máquina de prototipos. Esto involucra:

Calibrar la plataforma de compilación.

Cargando el material apropiado (resina, filamento, polvo, o metal).

Establecer condiciones ambientales como la temperatura y la humedad (importante para materiales como nylon o resina).

Paso 4: Edificio prototipo

La magia sucede aquí. La máquina Construye la capa de objeto por capa Según el diseño CAD. Por ejemplo:

SLA usa un láser para endurecer la resina líquida.

FDM extruye filamento de plástico con calefacción.

SLS usa un láser para fusionar material en polvo.

Este proceso puede tomar en cualquier lugar desde Minutos a varias horas, Dependiendo del tamaño, complejidad, y método elegido.

Paso 5: Postprocesamiento

Una vez que se construye el prototipo en bruto, a menudo requiere Toques finales. El procesamiento posterior puede incluir:

Lijando o pulido para una superficie más suave.

Pintura o recubrimiento para una apariencia realista.

Tratamiento térmico para mayor resistencia.

Ensamblaje si se imprimieron varias partes por separado.

Este paso final transforma el prototipo de un modelo aproximado en algo listo para la presentación., pruebas, o incluso un uso funcional a pequeña escala.

¿Por qué es importante la prototipos rápidos en la fabricación??

Ahora que hemos cubierto qué es la prototipos rápidos y cómo funciona, Hablemos de Por qué es tan importante en la industria manufacturera.

Tradicionalmente, Las empresas tuvieron que confiar en métodos de prototipos lentos y costosos. Imagine diseñar una parte de un automóvil y esperar semanas para un modelo físico, Solo para descubrir que no encaja correctamente. Ese retraso podría costar miles de dólares y meses de esfuerzo desperdiciado. La prototipos rápidos cambia el juego al permitir rápido, iteraciones asequibles.

He aquí por qué es vital:

Iteraciones más rápidas: Los diseñadores pueden probar múltiples versiones de un producto en días en lugar de meses.

Desarrollo rentable: Identificar fallas de diseño temprano reduce la necesidad de una reelaboración costosa más tarde.

Mejor toma de decisiones: Partes interesadas, inversores, y los clientes pueden sostener y evaluar físicamente un modelo en lugar de solo mirar un dibujo.

Calidad mejorada del producto: Los prototipos funcionales permiten pruebas del mundo real, Asegurar que el producto final funcione como se esperaba.

Ventaja competitiva: Las empresas que usan prototipos rápidos pueden lanzar productos más rápido, mantenerse por delante de los competidores.

Tomar el industria automotriz, por ejemplo. Los fabricantes de automóviles usan prototipos rápidos para diseñar paneles, piezas del motor, y sistemas de iluminación. En lugar de esperar meses, Pueden crear un prototipo en días, probarlo, refinarlo, y pasar a la producción más rápido. Similarmente, en cuidado de la salud, Los cirujanos pueden practicar en modelos anatómicos impresos en 3D antes de operar con un paciente, algo inimaginable antes de la prototipos rápidos.

En breve, La prototipos rápidos no es solo una herramienta; Es un ventaja estratégica Para las empresas que desean innovar de manera más rápida e inteligente.

Ventajas de prototipos rápidos

Los beneficios de la prototipos rápidos se extienden mucho más allá de la velocidad. Es una herramienta poderosa que transforma la forma en que se desarrollan y refinan los productos.. Veamos las principales ventajas:

1. Velocidad de desarrollo

Una de las mayores fortalezas de prototipos rápidos es su capacidad para Transformar ideas en modelos rápidamente. Lo que solía llevar semanas o meses ahora se puede lograr en cuestión de días, o incluso horas. Esto permite a las empresas acortar sus ciclos de desarrollo de productos y reaccionar más rápido a las necesidades del cliente..

2. Reducción de costos

Los errores en el diseño pueden ser caros cuando se descubren al final del proceso.. La prototipos rápidos minimiza este riesgo al habilitar las pruebas tempranas. La fijación de fallas en un prototipo cuesta mucho menos que rediseñar un molde de producción completo. Esto hace que el proceso de desarrollo general sea más económico.

3. Calidad de diseño mejorada

Cada iteración de un prototipo mejora el diseño. Porque la prototipos rápidos permite ajustes rápidos, Los diseñadores pueden ajustar la estética, ergonomía, y funcionalidad hasta que el producto esté lo más cerca posible.

4. Fomenta la creatividad y la innovación

Con métodos tradicionales, Los diseñadores a menudo estaban limitados por el costo y el tiempo. Pero con prototipos rápidos, Tienen la libertad de experimentar. Formas complejas, detalles intrincados, y las ideas audaces se pueden probar sin romper el presupuesto.

5. Personalización y personalización

Industrias como la atención médica y los productos de consumo se benefician enormemente de la rápida prototipos Capacidad para crear soluciones personalizadas. Desde prótesis personalizadas hasta dispositivos portátiles personalizados, Las posibilidades son infinitas.

6. Prueba funcional

Muchos métodos de prototipos rápidos producen piezas lo suficientemente fuertes para las pruebas del mundo real. Esto significa que las empresas pueden evaluar no solo cómo se ve un producto, sino también cómo funciona.

7. Residuos reducidos

A diferencia de la fabricación de sustractivos (Donde se corta el material), Muchos métodos rápidos de prototipos son aditivo, Usar solo el material necesario para crear la pieza. Esto hace que el proceso sea más amigable con el medio ambiente y rentable..

8. Ventaja de mercado

Finalmente, La velocidad y la flexibilidad de la prototipos rápidos permiten que las empresas vencer a los competidores al mercado. En industrias de rápido movimiento como la electrónica, Esta ventaja puede significar la diferencia entre liderar el mercado o quedarse atrás.

Técnicas principales utilizadas en prototipos rápidos

La prototipos rápidos no es un proceso único para todos. En cambio, Incluye un variedad de técnicas, cada uno con sus propias fortalezas, debilidades, y aplicaciones. Elegir la técnica correcta depende de factores como el presupuesto, materiales, precisión deseada, y propósito prototipo. Exploremos los métodos más utilizados.

Estereolitmicromografía (SLA)

Sla es el Abuelo de la impresión 3D, inventado por Chuck Hull en 1984. Funciona curando resina líquida con un láser UV, capa por capa, Hasta que se forme un objeto sólido.

Ventajas: Alta precisión, acabado superficial liso, Ideal para modelos detallados.

Limitaciones: Los materiales son frágiles en comparación con los termoplásticos, y se requiere después del curado.

Mejor para: Modelos dentales, prototipos de joyas, y prototipos visuales que requieren detalles finos.

Modelado de deposición fusionada (MDF)

FDM es uno de los métodos más populares debido a su asequibilidad y facilidad de uso. Funciona extrudiendo el filamento termoplástico derretido a través de una boquilla calentada.

Ventajas: Rentable, amplia gama de materiales (Estampado, abdominales, PETG, etc.), accesible para aficionados.

Limitaciones: Resolución más baja en comparación con SLA, líneas de capa visibles.

Mejor para: Modelos conceptuales rápidos, Prototipos funcionales de bajo costo.

Sinterización láser selectiva (SLSS)

SLS usa un láser para fusionar material en polvo—Unlalmente polvos de nylon o compuestos en capas sólidas.

Ventajas: No hay necesidad de estructuras de soporte (El polvo actúa como apoyo), piezas funcionales duraderas, geometrías complejas.

Limitaciones: Acabado superficial rugoso, maquinaria costosa.

Mejor para: Prototipos de ingeniería, piezas funcionales de lotes pequeños.

Procesamiento de luz digital (DLP)

DLP es similar a SLA pero usa un proyector de luz digital en lugar de un láser. Esto hace que el proceso sea más rápido, Como cada capa se puede curar en un solo flash de luz.

Ventajas: Alta velocidad, resolución alta.

Limitaciones: Limitado a resinas de fotopolímeros, Se necesita después del curado.

Mejor para: Prototipos de alta detonancia donde la velocidad es crucial.

Fabricación de objetos laminados (Lomo)

LOM construye prototipos al laminar las hojas de material (como papel, plástico, o metal) y cortarlos en forma con láseres o cuchillas.

Ventajas: Bajo costo, Bueno para modelos grandes.

Limitaciones: Mal acabado superficial, Resolución de detalle limitada.

Mejor para: Modelos conceptuales a gran escala.

Puñetazo

En este proceso, a agente de enlace líquido se deposita en capas de polvo para "pegarlas". La parte se cura más tarde y a veces se infiltra con otro material para la resistencia..

Ventajas: Puede imprimir a todo color, relativamente asequible.

Limitaciones: Las piezas son frágiles a menos que se procesen.

Mejor para: Prototipos visuales, modelos arquitectónicos.

Sinterización de láser de metal directo (DMLS) & Derretimiento láser selectivo (SLM)

Tanto los DML como SLM se utilizan para la creación de prototipos de metales.. Emplean láseres poderosos para fusionar la capa de polvos de metal por capa.

Ventajas: Extremadamente duradero, Adecuado para piezas de metal de uso final.

Limitaciones: Alto costo, Requiere operación experta.

Mejor para: Aeroespacial, automotor, e implantes médicos.

Derretimiento del haz de electrones (MBE)

EBM usa un haz de electrones en lugar de un láser para derretir polvos de metal.

Ventajas: Piezas de metal fuertes, estrés interno mínimo.

Limitaciones: Limitado a los metales conductores, caro.

Mejor para: Implantes aeroespaciales y ortopédicos.

Impresión de Polyjet en

Polyjet funciona rociando pequeñas gotas de resina líquida y curándolas con luz UV. Se pueden imprimir múltiples materiales y colores en una sola ejecución.

Ventajas: Multimaterial, detalle, apariencia realista.

Limitaciones: Durabilidad de material limitado, caro.

Mejor para: Prototipos que requieren una estética realista.

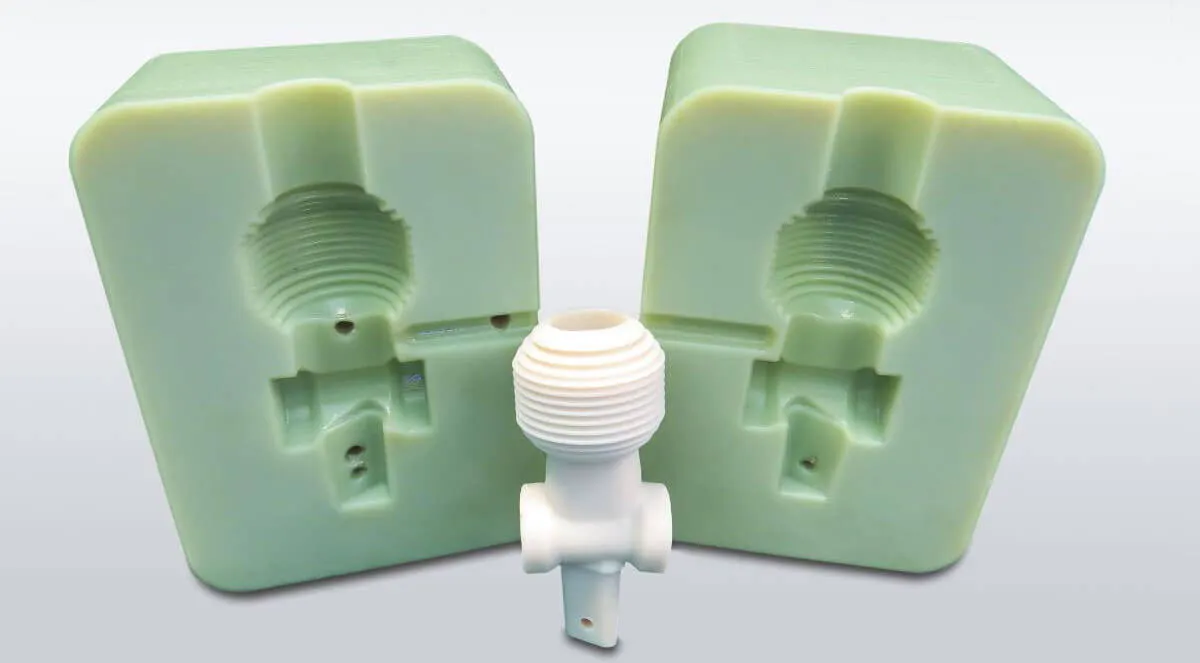

Moldado de inyección con herramientas rápidas

Moldado de inyección con herramientas rápidas

Esto implica crear moldes rápidamente (a través de la impresión 3D o CNC) y usarlos para moldeo por inyección de lotes pequeños.

Ventajas: Produce partes reales idénticas a la producción final.

Limitaciones: Las herramientas todavía llevan tiempo y costo.

Mejor para: Producción de puentes entre prototipo y fabricación de masas.

Fusión de chorro múltiple (MJF)

MJF utiliza un agente de fusión depositado en una cama de polvo, que luego se fusiona por el calor.

Ventajas: Partes funcionales fuertes, Detalle bueno, más rápido que SLS.

Limitaciones: Opciones de material limitadas (principalmente nylon).

Mejor para: Prototipos funcionales que requieren fuerza y detalle.

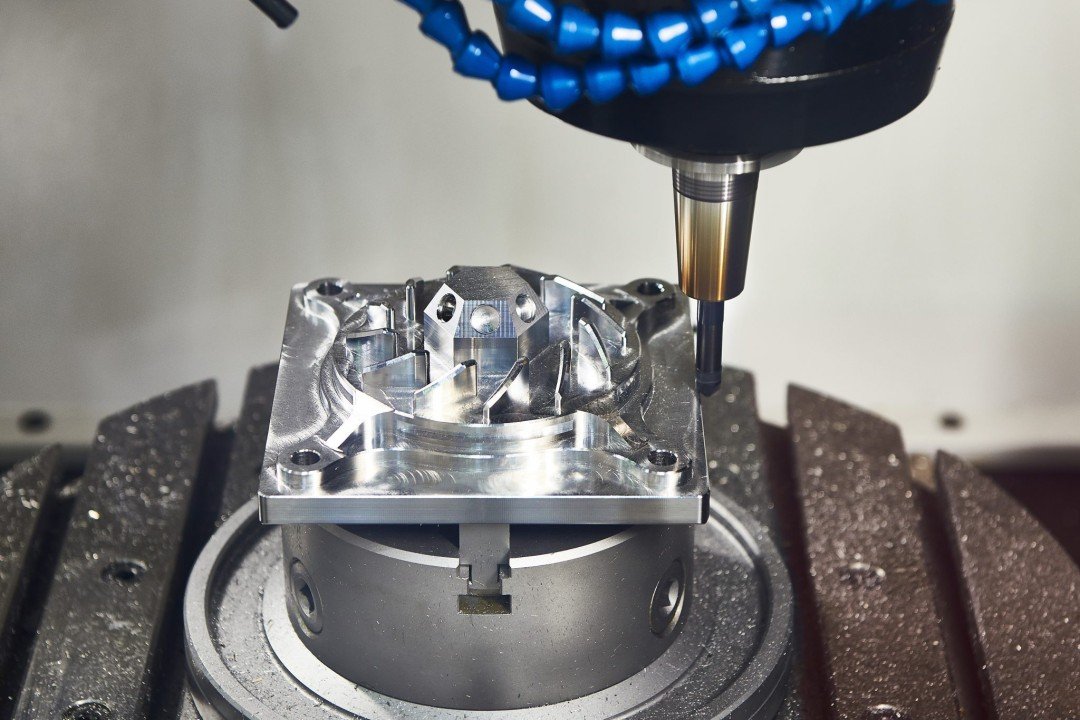

Mecanizado CNC

Mecanizado CNC

Aunque no es aditivo, El mecanizado CNC se considera prototipos rápidos porque puede producir rápidamente prototipos de materiales reales.

Ventajas: Alta resistencia, precisión, y amplias opciones de material (rieles, plástica).

Limitaciones: Proceso sustractivo, desperdicio de material.

Mejor para: Prototipos de ingeniería y pruebas funcionales.

Corte por chorro de agua

Corte por chorro de agua

Utiliza agua de alta presión (A veces con abrasivos) para cortar el material.

Ventajas: Puede cortar casi cualquier material, incluyendo metal y vidrio.

Limitaciones: Limitado a diseños 2D o planos.

Mejor para: Prototipos planos rápidos.

Colocación de aspiradoras

Colocación de aspiradoras

Esta técnica crea moldes de silicona de un modelo maestro, que luego se utilizan para producir prototipos de plástico.

Ventajas: Rentable para producción de bajo volumen, replica la calidad de moldeo por inyección.

Limitaciones: No es ideal para altos volúmenes.

Mejor para: Ejecuciones de preproducción y pruebas funcionales.

Tipos de prototipos rápidos

Diferentes proyectos requieren diferentes tipos de prototipos.. Aquí están los tipos principales:

Prototipos de prueba de concepto

Estos son modelos simples utilizados para demostrar viabilidad. Es posible que no se parezcan al producto final, pero sirven para validar si la idea funciona.

Prototipos de baja fidelidad

Modelos básicos creados rápidamente, a menudo para discusiones internas. Priorizan la velocidad y el costo sobre la apariencia.

Prototipos de alta fidelidad

Detallado, modelos realistas que se parecen mucho al producto final en la apariencia. Utilizado para presentaciones y lanzamientos de inversores.

Prototipos parecidos

Centrarse en la estética:, color, textura, en lugar de la función. Ideal para marketing o comentarios de los clientes.

Prototipos similares a las obras

Opuesto a los prototipos similares a la apariencia: el enfoque está en la funcionalidad en lugar de la apariencia.

Prototipos de ingeniería

Utilizado para probar propiedades mecánicas, actuación, y durabilidad en condiciones del mundo real.

Validación & Prototipos de fabricación

Estas son versiones cercanas a las final utilizadas para probar la fabricación., asamblea, y cumplimiento de los estándares.

Papel del software en la prototipos rápidos

El hardware puede construir las piezas, pero El software impulsa el proceso. Sin herramientas avanzadas de diseño y simulación, La prototipos rápidos no sería posible.

Software CAD

Herramientas como AutoCAD, Solidworks, Catia, y fusión 360 son la base de la creación de prototipos. Permiten a los diseñadores crear modelos 3D detallados.

Simulación & Software de análisis

Programas como Ansys y Autodesk CFD simular tensiones del mundo real, flujo fluido, o transferencia de calor en diseños antes de que se prueben físicamente.

Software de corta para impresión 3D

Aplicaciones como Tratamiento, Simplify3D, y slic3r Prepare archivos CAD para la impresión 3D cortándolos en capas.

Software CAM para CNC

Software como Mastercam y Gibbscam Convierte los diseños CAD en instrucciones de la máquina para el mecanizado CNC.

Herramientas especializadas de prototipos

Preformar (para las impresoras de SLA).

Materializar la magia (Para la edición STL).

Conocimiento (para máquinas FDM industriales).

En breve, El software correcto asegura que los prototipos sean preciso, eficiente, y confiable.

Materiales utilizados en prototipos rápidos

Materiales utilizados en prototipos rápidos

El material que elija puede hacer o romper su prototipo. Diferentes tecnologías permiten diferentes materiales:

Plástica

abdominales, Estampado, PETG, Nylon, policarbonato.

Ampliamente utilizado debido a la asequibilidad, versatilidad, y facilidad de impresión.

Rieles

Aluminio, Titanio, Acero inoxidable, Inconel.

Ideal para fuerte, Prototipos funcionales en aeroespacial y automotriz.

Resinas

Fotopolímeros utilizado en SLA y DLP para piezas de alta detonancia.

Las opciones incluyen flexible, difícil, transparente, o resinas fundibles.

Composicion

Fibra de carbono, fibra de vidrio, Plásticos reforzados con Kevlar.

Materiales livianos pero fuertes para piezas de alto rendimiento.

Cerámica y cera

Utilizado para aplicaciones especializadas como coronas dentales o casting de inversión.

Aplicaciones de prototipos rápidos en todas las industrias

La prototipos rápidos se ha extendido en casi todas las industrias. Aquí es donde más brilla:

Automotor

Componentes del motor, paneles, y prototipos de iluminación.

Reduce el tiempo de comercialización para modelos de autos nuevos.

Aeroespacial

Piezas livianas con geometrías complejas.

Crítico para reducir el consumo de combustible y mejorar la eficiencia.

Cuidado de la salud

Prótesis personalizadas, implantes, y guías quirúrgicas.

3Modelos anatómicos impresos en D para práctica antes de la cirugía.

Electrónica de consumo

Trampas para el teléfono, wearables, y prototipos de dispositivos.

Ayuda a las marcas a refinar la ergonomía y el diseño antes del lanzamiento.

Arquitectura

Modelos de escala de edificios para presentaciones de clientes.

Moda & Vestir

Calzado, joyas, y accesorios personalizados.

Educación & Investigación

Herramientas de enseñanza, Experimentos de laboratorio, y proyectos de estudiantes.

Entretenimiento & Película

Accesorios, disfraces, y efectos especiales.

Equipo deportivo

Cascos, trefetas, y equipo para mejorar el rendimiento.

Robótica & Automatización

Componentes mecánicos funcionales para probar robots y sistemas de automatización.

Limitaciones de la prototipos rápidos

Mientras que la prototipos rápidos es un proceso revolucionario, no está sin su Desafíos y inconvenientes. Comprender estas limitaciones ayuda a las empresas a establecer expectativas realistas y elegir el método adecuado para sus necesidades.

1. Limitaciones de materiales

No todos los materiales utilizados en la creación de prototipos son adecuados para la producción final.. Por ejemplo, Las resinas fotopolímeras utilizadas en SLA son frágiles en comparación con los plásticos industriales, y muchos metales impresos en 3D pueden requerir postprocesamiento para la fuerza.

2. Restricciones de tamaño

La mayoría de las máquinas de prototipos rápidos tienen volúmenes de construcción limitados. Se deben imprimir grandes partes en secciones y luego ensamblarse, que puede afectar la fuerza y la estética.

3. Problemas de acabado superficial

Algunos métodos, como FDM, Deje líneas de capa visibles que requieren lijado o pulido. Si bien esto se puede mejorar con el procesamiento posterior, Agrega tiempo y costo.

4. Resistencia y durabilidad

No todos los prototipos pueden resistir las tensiones del mundo real. Por ejemplo, Las piezas de SLA pueden parecer impresionantes, pero a menudo carecen de durabilidad para las pruebas funcionales.

5. Costo de producción a gran escala

Mientras que la prototipos rápidos es rentable para modelos individuales o lotes pequeños, No siempre es adecuado para la fabricación de alto volumen. Para carreras más grandes, Los métodos tradicionales como el moldeo por inyección siguen siendo más económicos.

6. Preocupaciones de precisión y tolerancia

Aunque la tecnología está mejorando, Ciertos métodos de creación de prototipos aún luchan con tolerancias muy ajustadas. Esto puede ser un problema para industrias como los dispositivos aeroespaciales o médicos donde la precisión es crítica.

En breve, Si bien la prototipos rápidos es increíblemente poderoso, Se ve mejor como un complementar, no un reemplazo para la fabricación de masas.

Costos asociados con la prototipos rápidos

El costo de la prototipos rápidos depende de varios factores, y comprenderlos es crucial para presupuestar.

Factores que influyen en el costo

tipo de material - Los plásticos son más baratos que los metales, mientras que las resinas o compuestos especiales cuestan más.

Complejidad del diseño - Los diseños intrincados requieren más tiempo y material de la máquina.

Tamaño del prototipo - Los modelos más grandes consumen más recursos.

Necesidades de postprocesamiento - pulido, cuadro, o el tratamiento térmico se suma a los costos.

Tecnología utilizada - SLA y FDM son más baratos; Las técnicas a base de metales como DML son mucho más caras.

Rangos de costos estimados

Prototipos de FDM: $10- $ 200 (dependiendo del tamaño y el material).

Modelos SLA: $50- $ 500.

SLS Piezas funcionales: $200- $ 2,000.

Prototipos de metal (Dmls/slm): $500- $ 10,000+.

Piezas mecanizadas de CNC: $100- $ 5,000 dependiendo de la complejidad.

Comparación de costos con la creación de prototipos tradicionales

Los métodos tradicionales como el moldeo por inyección requieren herramientas costosas, a menudo en decenas de miles de dólares. A diferencia de, creación rápida de prototipos Elimina los costos de herramientas, haciéndolo mucho más económico para el diseño de la etapa temprana y las pequeñas carreras de producción.

Si bien no siempre es el más barato para la producción en masa, La prototipos rápidos proporciona ahorros masivos durante el desarrollo y las pruebas, Donde la flexibilidad es más importante.

Errores comunes para evitar la prototipos rápidos

Aunque la prototipos rápidos está diseñado para simplificar el desarrollo, Los errores aún pueden descarrilar proyectos. Aquí hay algunas trampas comunes:

1. Con vistas al diseño para la fabricación (DFM)

Un prototipo puede verse genial, pero puede que no sea factible para la producción a gran escala. Siempre diseñe con eventual fabricación en mente.

2. Elegir el material incorrecto

El uso del material incorrecto puede producir resultados de prueba engañosos. Por ejemplo, Prueba de resistencia mecánica con resina quebradiza en lugar de plástico industrial puede dar datos de rendimiento falsos.

3. Ignorando las tolerancias

No todos los métodos proporcionan alta precisión. Si necesitas tolerancias estrechas, Las tecnologías como CNC o SLM pueden ser mejores que FDM o SLA.

4. Omitiendo pruebas exhaustivas

Un prototipo no es solo para looks, también es para probar. Saltar pruebas de estrés, pruebas térmicas, o los comentarios de los usuarios pueden conducir a errores costosos más tarde.

5. Descuidar el postprocesamiento

Muchos prototipos requieren lijado, cuadro, o tratamiento térmico. No tener en cuenta esto puede dar lugar a modelos inacabados o poco realistas.

6. Sobre enfoque en la estética

Mientras que un modelo atractivo es importante, la función nunca debe ser sacrificada. Un equilibrio entre la estética y el rendimiento asegura un producto final realista.

Evitar estos errores asegura que obtenga el resultados más precisos y útiles De sus esfuerzos de prototipos.

Cómo elegir el método correcto de prototipos rápidos

Con tantas técnicas disponibles, Seleccionar el correcto puede ser abrumador. Aquí hay una guía práctica:

1. Considere los requisitos del proyecto

¿Necesitas un modelo para presentación visual? → SLA, DLP, o polijet en.

Necesitas prueba funcional? → SLS, MDF, CNC, o MJF.

Necesitas un prototipo de metal? → DMLS, SLM, o EBM.

2. Evaluar las necesidades materiales

Para plásticos fuertes → nylon (SLSS, MJF).

Para flexibilidad → TPU o resina flexible.

Para metales → aluminio, Titanio, o acero inoxidable.

3. Evaluar la precisión y la complejidad

Si su prototipo implica detalles intrincados, Elija SLA, DLP, o polijet en. Para grande, partes robustas, CNC o FDM puede ser mejor.

4. Costo de equilibrio y presupuesto

Si estás trabajando con fondos limitados, FDM es el más asequible. Para presupuestos más altos donde importan los detalles y la fuerza, Invierte en SLA, SLSS, o impresión de metal.

5. Factor en el tiempo de comercialización

Si la velocidad es crítica, DLP y PolyJet ofrecen el cambio más rápido.

6. Alinearse con los requisitos finales del producto

Su prototipo debe imitar el producto final lo más cerca posible, ya sea que eso significa fuerza, flexibilidad, o estética.

7. Sostenibilidad e impacto ambiental

Algunas industrias priorizan materiales ecológicos. Considere plásticos biodegradables o materiales reciclables cuando sea posible.

Sopesando estos factores, Puede tomar una decisión informada que Maximiza la eficiencia, calidad, y rentabilidad.

Conclusión

La prototipos rápidos es más que una herramienta: es un cambio de paradigma en el desarrollo de productos. Desde sus humildes comienzos en la década de 1980 con la estereolitografía de Chuck Hull hasta la amplia gama de técnicas de hoy, ha transformado cómo las ideas se hacen realidad.

Ofrece velocidad, flexibilidad, y ahorros de costos que los métodos tradicionales de creación de prototipos nunca podrían coincidir. Si está creando una prueba de concepto rápida, Prueba de un diseño funcional, o prepararse para la producción en masa, La prototipos rápidos permite iteraciones más rápidas, riesgo reducido, e innovación mejorada.

Por supuesto, Tiene sus limitaciones, como restricciones materiales y desafíos de costos para la producción a gran escala, pero cuando se usa estratégicamente, Es una de las herramientas más poderosas para la fabricación moderna..

A medida que las industrias continúan evolucionando, La prototipos rápidos solo crecerá en importancia, habilitando empresas, empresarios, e incluso aficionados a dar vida a las ideas más rápido que nunca.

Preguntas frecuentes

1. ¿Cuáles son las técnicas de prototipos rápidos más comunes??

Algunas de las técnicas más utilizadas incluyen SLA, MDF, SLSS, DLP, Mecanizado CNC, y DML para metales. Cada uno tiene fortalezas únicas dependiendo de las necesidades del proyecto.

2. ¿Qué industrias se benefician más de la prototipos rápidos??

Industrias como Automotive, aeroespacial, cuidado de la salud, electrónica de consumo, y la educación son los principales adoptantes. Lo usan para todo, desde implantes médicos hasta componentes del automóvil.

3. Es la prototipos rápidos adecuados para la producción en masa?

No directamente. Mientras que la prototipos rápidos es ideal para el diseño, pruebas, y producción en pequeños lotes, La producción en masa aún es mejor atendida por métodos tradicionales como moldeo por inyección.

4. ¿Cómo difiere la prototipos rápidos de la impresión 3D??

3D La impresión es un subconjunto de prototipos rápidos. Mientras que la impresión 3D es la fabricación aditiva, La prototipos rápidos también incluye métodos como el mecanizado CNC, colocación de aspiradoras, y corte de chorro de agua.

5. ¿Cuál es el futuro de la prototipos rápidos??

El futuro se encuentra en máquinas más rápidas, Materiales más duraderos, e integración con diseño impulsado por IA. Probablemente veremos que la prototipos rápidos se convierte aún más en las aplicaciones de fabricación y de consumo.