Nuestros servicios de giro de Precision de latón

Tops Precision se especializa en la producción de componentes de latón mecanizados de alta precisión que ofrecen un rendimiento excepcional en varias industrias. Utilizando avanzado torneado CNC tecnología, Elaboramos piezas de latón para cumplir con especificaciones ajustadas y ofrecemos excelentes acabados de superficie, cumpliendo con el automóvil, aeroespacial, médico, y los sectores de la electrónica. Nuestro equipo asegura componentes de latón precisos con tiempos de respuesta rápidos, Si necesita prototipos o carreras de producción a gran escala.

Envíe su consulta hoy

Lo que hace que nuestros servicios de giro de precisión de latón se destaquen?

Tops Precision se dedica a proporcionar servicios de giro de precisión de primer nivel utilizando materiales de latón de alto grado adaptados para aplicaciones específicas. Libre Brass C36000 ofrece una maquinabilidad excepcional, Haciéndolo ideal para la producción en masa de sujetadores y conectores eléctricos. El latón del cartucho C26000 se valora por su resistencia y resistencia a la corrosión, convirtiéndolo en una opción preferida para accesorios de plomería y componentes eléctricos. Mientras tanto, C28000 Muntz Metal sobresale en ambientes marinos debido a su resistencia superior a la corrosión de agua salada, haciéndolo una opción confiable para el hardware marino.

Nuestra instalación opera centros avanzados de Turning CNC capaces de lograr tolerancias tan apretadas como ± 0.005 mm. Este nivel de precisión garantiza que nuestras piezas de latón se integren perfectamente en los ensambles finales, Reducir las tasas de error y mejorar la consistencia del producto. Si fabricar piezas simples o componentes complejos, Nuestro sistema garantiza resultados precisos y repetibles cada vez.

Tops Precision se compromete a cumplir con la fecha límite de cada cliente sin compromiso. Cumplimos los pedidos de componentes de latón rápidamente a través de horarios de producción simplificados, completar trabajos dentro de solo 3 días hábiles. Nuestro equipo experimentado y un flujo de trabajo eficiente nos permiten manejar pedidos de volumen pequeño y grande con facilidad, Asegurando confiable, entrega a tiempo.

Nos enorgullecemos de la calidad de cada producto que producimos. Nuestros procesos de control de calidad certificados por ISO aseguran que cada componente de latón cumpla con los más altos estándares de confiabilidad y rendimiento. Al monitorear de cerca cada etapa de producción, Garantizamos duradero, Resultados de alta calidad que exceden las expectativas del cliente.

Envíe su consulta hoy

Grados de material que usamos y sus aplicaciones

Seleccionamos las mejores aleaciones de latón en función de los requisitos específicos de su proyecto. Estos son algunos de los grados más utilizados:

Grado material | Propiedades | Usos comunes | Partes hechas |

C36000 (Latón de corte libre) | Excelente maquinabilidad, resistencia a la corrosión, y alta fuerza | Conectores electricos, sujetadores, y componentes automotrices | |

C26000 (Cartucho de latón) | Buena resistencia a la corrosión, Excelentes propiedades de trabajo en frío | Accesorios de fontanería, componentes electricos, instrumentos de precisión | |

C28000 (Metal Muntz) | Mayor resistencia, resistente a la corrosión, Ideal para uso marino | Hardware marino, conectores electricos, y maquinaria industrial | |

C31000 (Níquel de latón) | Alta resistencia a la corrosión, soldadura, y fuerza | Aplicaciones marinas, piezas decorativas, y electrónica |  |

Envíe su consulta hoy

Estudio de caso: Componentes de precisión de latón para la industria automotriz

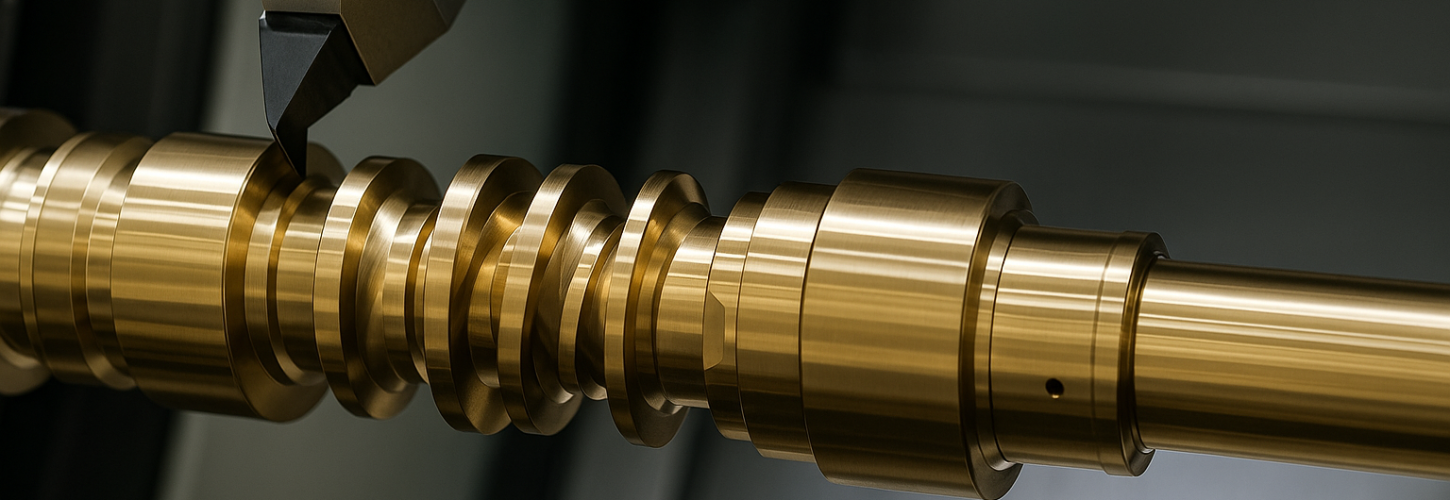

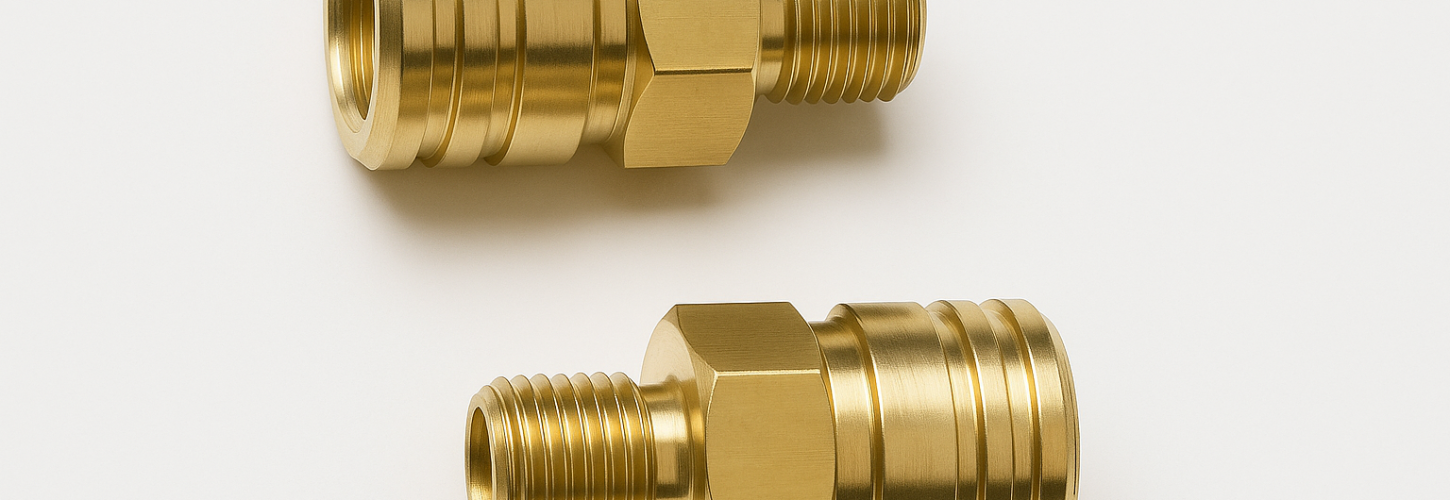

Recientemente produjimos sujetadores de latón de alta precisión para un cliente automotriz que requiere rosca exacta y tolerancias estrechas para garantizar una integración perfecta en el ensamblaje de su motor. Para satisfacer estas demandas, Elegimos Brass C36000 de corte libre, conocido por su excelente maquinabilidad y fuertes propiedades mecánicas, habilitando la producción rápida y confiable de componentes duraderos.

Los sujetadores se fabricaron utilizando máquinas avanzadas de giro CNC, Lograr tolerancias tan apretadas como ± 0.005 mm. Completamos el pedido dentro de los cinco días hábiles, Ayudar al cliente a mantenerse en el camino con su horario de producción sin comprometer la calidad. Nuestro equipo entregó componentes que cumplieron con los estrictos estándares funcionales y estéticos, Mostrar nuestra capacidad en el mecanizado de latón de precisión.

Envíe su consulta hoy

Nuestras capacidades de giro de precisión de latón

Empleamos mecanizado CNC avanzado para fabricar piezas, si es un prototipo, o parte para el uso de servicio pesado.

Torneado CNC

Tops Precision proporciona servicios de giro CNC capaces de producir piezas altamente precisas con geometrías complejas y demandas de tolerancia estrictas, Asegurar resultados confiables para nuestros clientes. Nuestro equipo de vanguardia nos permite cumplir incluso con las especificaciones de diseño más exigentes con precisión. Si fabricando piezas intrincadas a gran escala o bien, componentes delicados, Nuestras soluciones de giro de CNC ofrecen una calidad de producción excepcional.

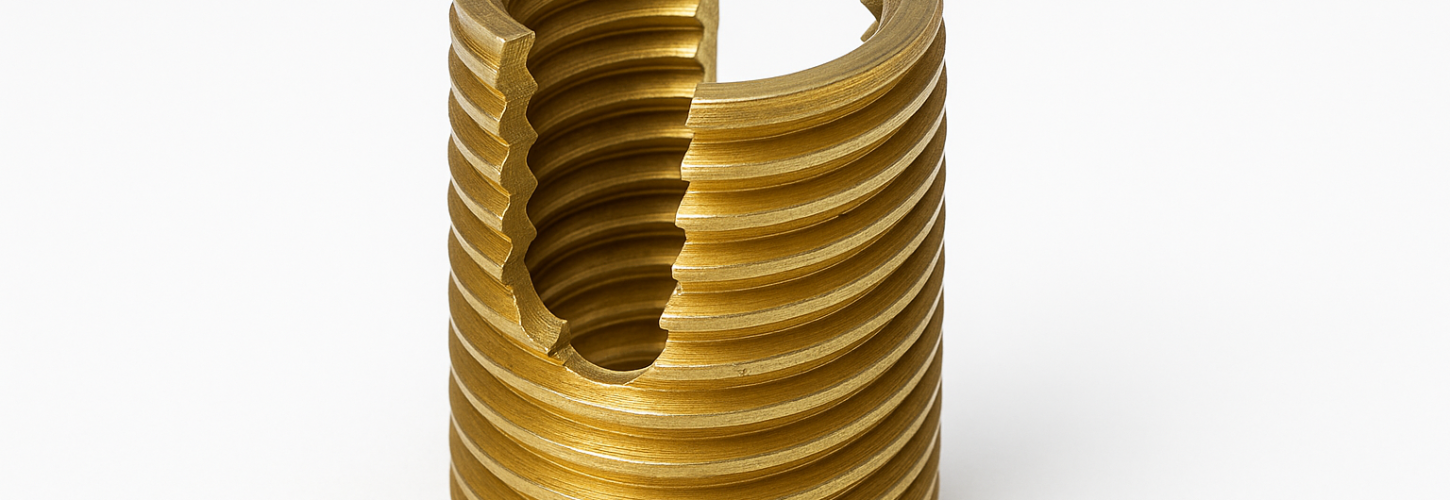

Enhebrado & tocando

Las operaciones de roscado y tapping de nuestra instalación aseguran perfiles de hilo precisos para sujetadores, pernos, y conectores, Permitir una alineación de ensamblaje perfecta. Uso de equipos avanzados de giro CNC, Creamos hilos que cumplan con los estándares de la industria, ya sea para aplicaciones a pequeña escala o producción de gran volumen. Los componentes roscados producidos por Tops Precision son confiables, piezas de alta calidad listas para uso inmediato al parecer.

Acabado superficial

Nuestros servicios ofrecen una variedad de opciones de acabado de superficie como pulido, revestimiento, y enchapado Para mejorar tanto el atractivo visual como la durabilidad de sus componentes. Estos tratamientos de acabado le permiten seleccionar entre estilos de superficie brillantes o texturizados que mejor complementan sus piezas. Cada componente entregado por Tops Precision está diseñado para cumplir con sus expectativas estéticas al tiempo que cumple con los requisitos de rendimiento funcional.

Giro de CNC personalizado

Los servicios de giro CNC CNC de Tops Precision ofrecen soluciones de fabricación a medida para todo, desde el desarrollo de prototipos individuales hasta la producción de alto volumen, Todo alineado con sus necesidades específicas. Nuestro equipo trabaja en estrecha colaboración con usted durante todo el proceso para garantizar que cada parte cumpla con las especificaciones de fabricación exactas.. En la máxima precisión, Entregamos una producción rápida y precisa de componentes personalizados únicos y grandes lotes de piezas consistentemente precisas.

Envíe su consulta hoy

Industrias que dependen de nuestros componentes de precisión de latón

Nuestros servicios de Turning Brass Precision admiten varios sectores:

Automotor: sujetadores, conectores, y componentes del motor.

Médico: Piezas de precisión para equipos de diagnóstico e instrumentos quirúrgicos.

Aeroespacial: Ligero, Partes resistentes a la corrosión para sistemas de alto rendimiento.

Electrónica: Conectores, carcasas, y otros componentes eléctricos.

Marina: Alta resistencia, Partes resistentes a la corrosión para entornos marinos.

Envíe su consulta hoy

Por qué elegir Tops Precision Para giro de precisión de latón?

- Lograr tolerancias exactas con ± 0.005 mm exactitud.

- Ofrecemos una amplia elección de aleaciones de latón que incluye C36000, C26000, y C28000 para adaptarse a las especificaciones de su proyecto.

- El proceso de producción incluye una entrega rápida porque las piezas llegan a los clientes dentro de un 3 a 5 día hábil período.

- La fabricación tiene lugar debajo ISO certificado estándares para proporcionar componentes confiables para cada producto.

- La compañía ofrece apoyo profesional de un equipo técnico que ayuda a los clientes a elegir materiales mientras diseñan productos y ejecutan producción..

Envíe su consulta hoy

Solicite una cotización para los componentes de la precisión de latón

Necesito de alta calidad, Componentes de latón personalizados para su proyecto? En Tapas de precisión, Combinamos tecnología avanzada con experiencia en la industria para ofrecer piezas mecanizadas con precisión que cumplan con sus especificaciones exactas. Contáctenos hoy para una cotización gratuita o para discutir su proyecto con uno de nuestros especialistas.!