Propiedades importantes del material FR4

FR4 es un laminado reforzado con fibra de vidrio epoxi epoxi, Particularmente anotado por su fuerza, aislamiento eléctrico, y resistencia al calor. Estas especificaciones fundamentales lo clasifican como un excelente aislante eléctrico, tarjeta de circuito impreso, y soporte aeroespacial, Entre otros componentes de precisión crítica. Las siguientes son las cualidades distintivas de FR4:

1. Resistencia dieléctrica

FR4 tiene un aislamiento eléctrico muy alto, pero generalmente se prefiere en aplicaciones de alto voltaje, con los valores de resistencia dieléctrica muy altos (más que 19.7 KV/mm). Esto es esencial en las placas de circuitos impresos (PCBS), conectores, y SwitchGear, donde el aislamiento de la señal es una necesidad.

2. Resistencia térmica

FR4 se puede usar en 130-150 O C Temperaturas de servicio continuas con estabilidad mecánica y eléctrica. Esto califica para ser utilizado en obras de soldadura y lugares expuestos al calor intenso. Tiene una baja temperatura de deflexión de calor, que permite que se utilice en la fabricación de equipos industriales y electrónicos.

3. Estabilidad dimensional

FR4 tiene un coeficiente térmico bajo de expansión (~ 14 16 PPM/C), y no está sujeto a urdimbre o distorsión debido a cargas mecánicas o térmicas. Posee tolerancias estrictas, Por lo tanto, es adecuado para aplicar en geometrías complejas o el conjunto de conjuntos de apareamiento.

4. Resistencia mecánica

FR4 tiene un módulo de compresión alto con una resistencia a la flexión de más que 480 MPa, lo que lo hace muy rígido y puede soportar cargas altas. Encuentra su aplicación habitual en trabajos de soporte estructural, como los soportes aeroespaciales en el espacio y los sistemas automotrices., así como espaciadores y placas traseras.

5. Resistencia a la humedad

FR4 absorbe poca cantidad de agua (generalmente <0.1%) y es bastante estable en condiciones húmedas o húmedas. Esta resistencia al agua sirve para salvaguardar los delicados circuitos y proporciona estabilidad eléctrica a largo plazo.

6. Retraso de la llama

Como su nombre lo indica, Fría (Retardante de la llama) 4 tiene un UL94 V-0 calificación de inflamabilidad, lo que significa que puede autoextinguirse en un corto curso de tiempo sin dejar caer. Esta característica garantiza la seguridad en lugares de espacios confinados o ubicaciones térmicamente calientes, como paneles de potencia y transformadores..

7. Resistencia química

Fr4 fr4 es resistente a los ácidos, bases, y solventes, Por lo tanto, se usa en aplicaciones químicamente expuestas como laboratorios, sistemas de batería, o unidades de control industrial. No disminuye a una condición fácilmente rota en absoluto, Mientras se use.

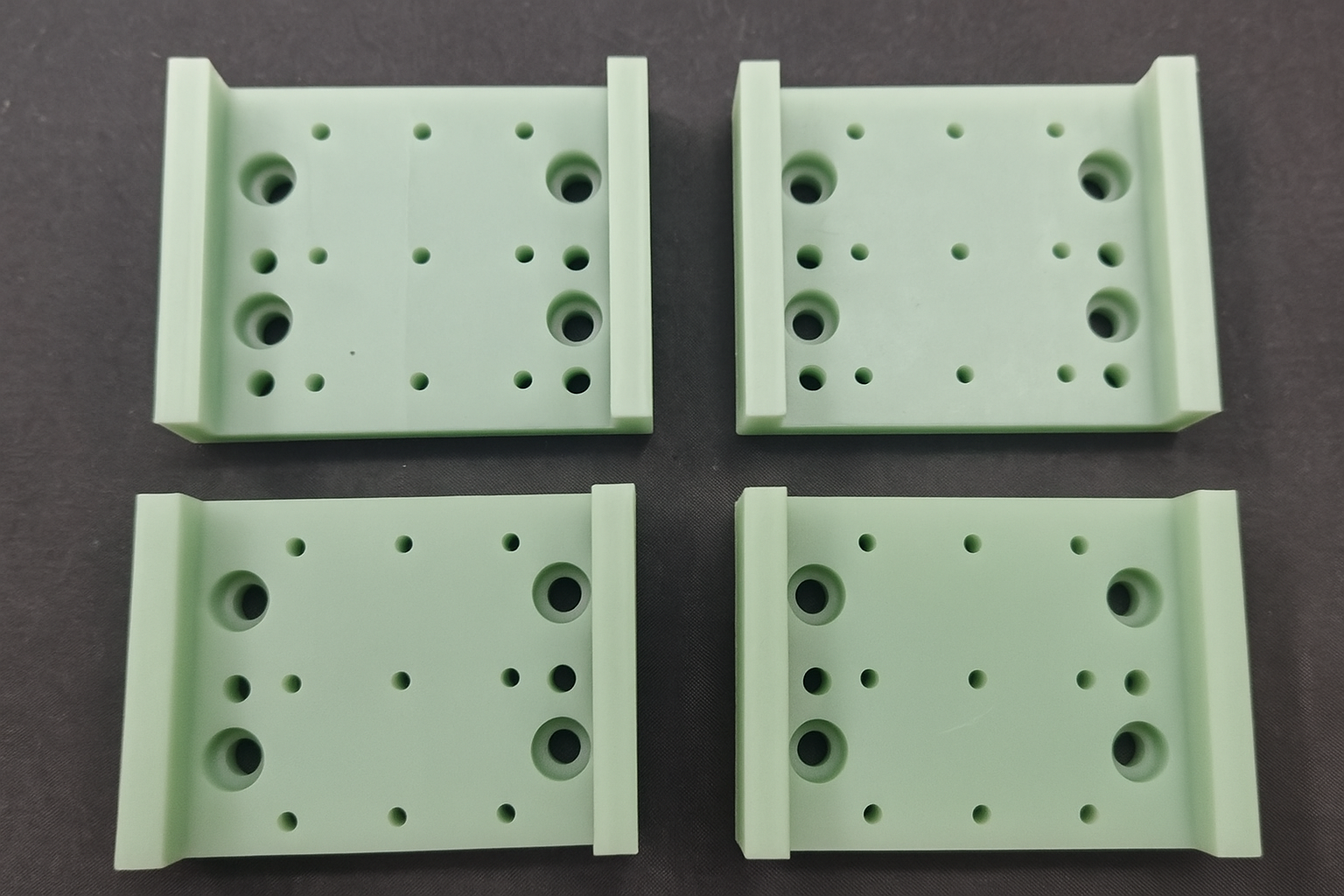

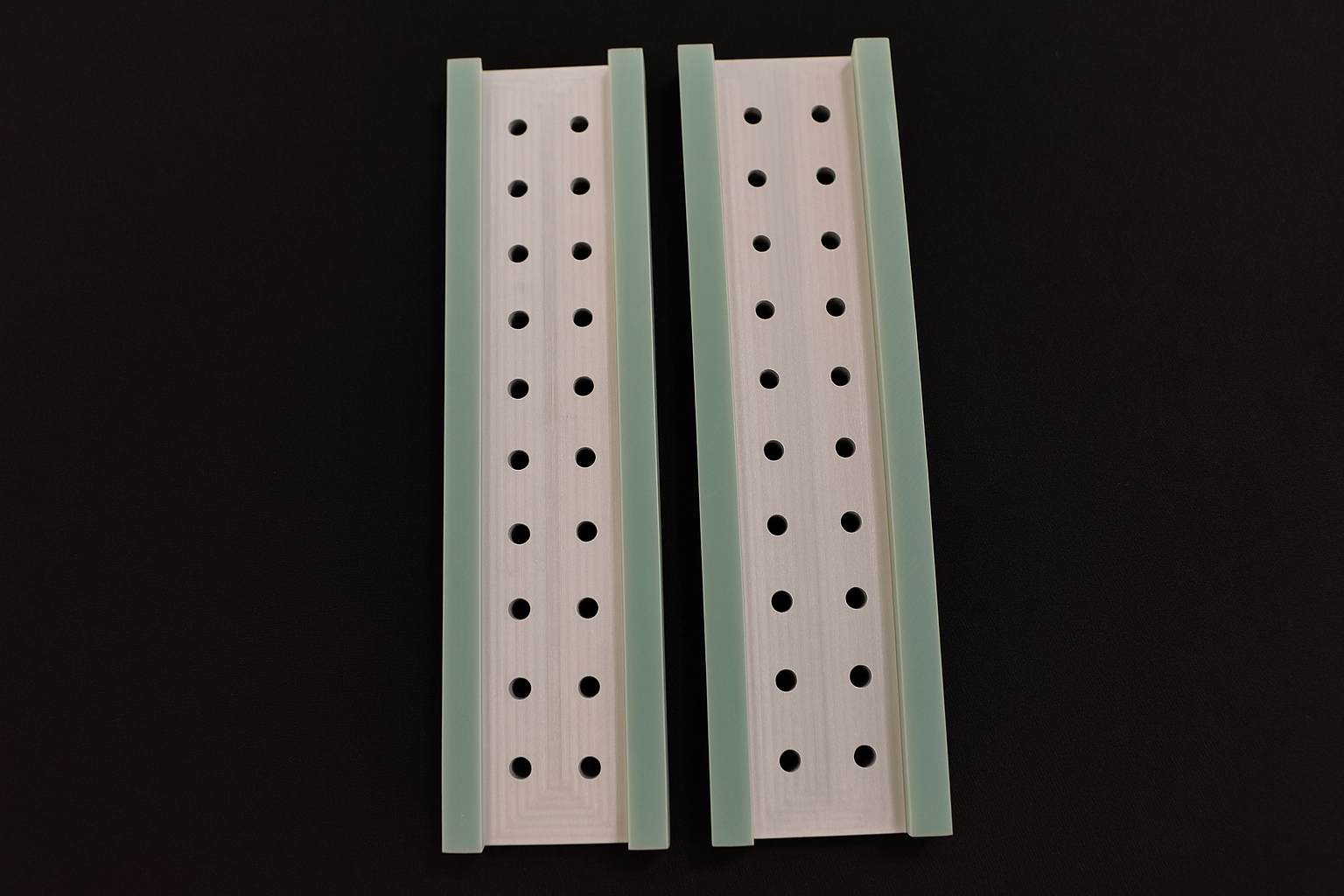

8. maquinabilidad

Máquinas FR4 bien con herramientas adecuadas, Aunque es abrasivo debido a las fibras de vidrio. Sirve una amplia gama de acabados posteriores al procesamiento, tolerancias apretadas, y formas complejas, lo que lo hace útil para fabricar piezas personalizadas en varias industrias.

Podemos resumir estas propiedades en la siguiente tabla:

Propiedad | Valor típico / Descripción | Beneficio |

Resistencia dieléctrica | > 19.7 KV/mm | Ideal para aislamiento de alto voltaje |

Resistencia térmica | Hasta 130–150 ° C continuo | Estable en entornos de alta temperatura |

Estabilidad dimensional | CTE ≈ 14–16 ppm/° C | Mantiene la precisión bajo estrés térmico/mecánico |

Resistencia a la flexión | > 480 MPA | Proporciona una excelente rigidez e integridad estructural |

Absorción de agua | < 0.1% | Funciona bien en ambientes húmedos o húmedos |

Retraso de la llama | UL94 V-0 calificado | Seguro para sistemas eléctricos y encerrados |

Resistencia química | Resiste ácidos, bases, y solventes | Adecuado para entornos químicamente duros |

maquinabilidad | Abrasivo pero compatible con CNC | Permite una fabricación precisa de piezas complejas |