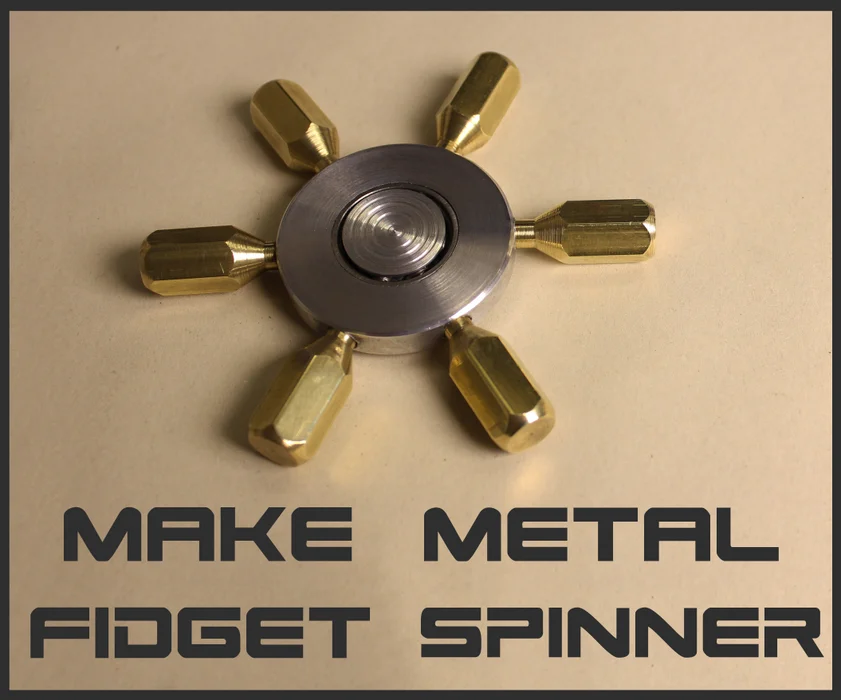

Nuestros Fidget Spinners mecanizados por CNC brindan un equilibrio perfecto en todo momento

El equilibrio comienza en la bancada de la máquina. Para eliminar material a granel, Primero cortamos piezas brutas en un centro de mecanizado vertical Haas VF-4.. De eso, El acabado se realiza en nuestras máquinas DMG Mori de 5 ejes., donde las trayectorias de herramientas se programan para mantener la eliminación de material perfectamente uniforme en cada brazo.

Mantenemos la concentricidad del asiento del rodamiento con respecto al perfil exterior dentro de cinco micras., según lo comprobado en nuestra máquina de medición de coordenadas Mitutoyo. Al ejecutar estas comprobaciones en múltiples etapas, Eliminamos la deriva que podría alterar la distribución del peso..

El resultado es un fidget spinner que permanece centrado. Cada rotación se siente estable en tu mano., sin tambaleo, resistencia, o ruido, simplemente puro, equilibrio repetible con cada giro.