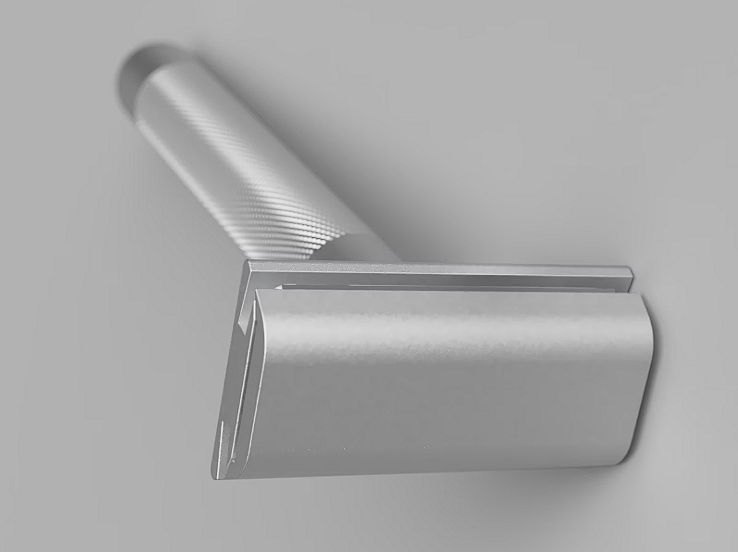

Nuestros tornos CNC dan forma a mangos de afeitar para mayor agarre y comodidad

Fabricamos mangos de afeitar de acero inoxidable., latón, y aluminio, y si los clientes quieren utilizar plásticos de ingeniería, También tenemos una gama de opciones.. Nuestros expertos en mecanizado garantizan que los diámetros no varíen entre lotes, incluso con una ligera tolerancia de +/-0.02milímetros. Esto mantiene la armonía y la gestión..

Empleamos herramientas de diamante para cortar moleteados en tornos de precisión.. La profundidad y el paso se seleccionan para aumentar el agarre en condiciones húmedas.. Los cortes permanecen afilados sin cortar ni erosionar el metal..

Se utilizan cortes de un solo punto., y se evitan roscas roscadas. Esto hace que los mangos se atornillen en las cabezas sin aflojarse.. Se prueban todos los hilos hasta el acabado final..

Tops Precision resuelve los desafíos de alineación de las hojas con una fijación cuidadosa

La alineación de la hoja depende de la óptima sujeción durante el mecanizado. Hacemos accesorios especiales con piezas planas y en su lugar.. Esto elimina los micromovimientos., que puede torcer las ranuras de las cuchillas.

La profundidad y el espaciado de las ranuras durante el fresado se verifican mediante sondas vivas. En caso de compensaciones, se corrigen en maquina. Esto mantiene el asiento de las palas incluso durante toda la producción..

Probamos cada afeitadora con hojas reales antes de su lanzamiento.. Una intervención tan práctica nos permite mantener una balance, simetría, y seguridad del afeitado en la práctica.