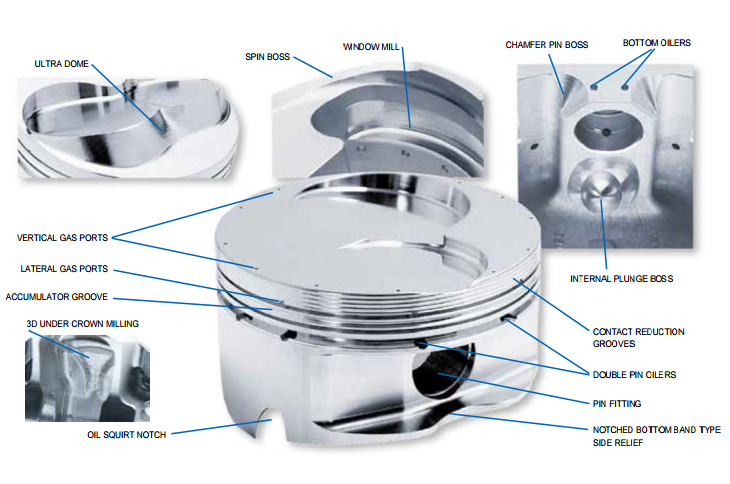

El mecanizado CNC nos brinda control total sobre la geometría del pistón. podemos crear portaaviones, servido, y coronas abovedadas basado en las necesidades de compresión. Las superficies de los anillos se cortan a anchos y profundidades específicos para un sellado adecuado.. Los orificios del pasador se perforan y escarian para que coincidan con el diámetro del pasador de muñeca..

Este método funciona para pistones personalizados únicos y lotes de producción pequeños.. Al asociarse con nosotros, Puede evitar costosos moldes de fundición y largos plazos de entrega.. Los cambios en el diseño son simples ya que solo actualizamos el programa y ejecutamos piezas nuevas..

Mecanizamos aluminio, acero forjado, y hierro fundido, dependiendo de su aplicación. Cada material corta de forma diferente, Por eso ajustamos las velocidades y la presión de la herramienta para evitar la distorsión.. El enfriamiento se controla para mantener la estabilidad del tamaño a medida que el metal se calienta durante el corte.