Le choix de la bonne fraiseuse CNC a une influence directe sur votre cadence de production ainsi que sur la qualité des pièces. Comme il existe différents types et options, il est crucial de comprendre la différence entre les équipements à 3 axes et à 12 axes.. Ainsi, les processus de fabrication modernes nécessitent des compétences très précises adaptées au type de projets. Les fraiseuses CNC sont classées selon le nombre d'axes, 3 axes, 4 axes, 5 axes, jusqu'à 12 axes. Une machine 3 axes n'assure que des fonctions de base sur trois plans différents; adapté aux opérations simples. Alors que, la machine à 12 axes offre une capacité de travail multidimensionnelle pour des pièces plus élaborées et des découpes avec moins de temps de configuration.

Cet article vous aidera à comprendre les différences entre les fraiseuses CNC 3 axes et 12 axes.. De plus, nous détaillerons leurs caractéristiques, avantages, et considérations pour choisir la bonne machine de fabrication.

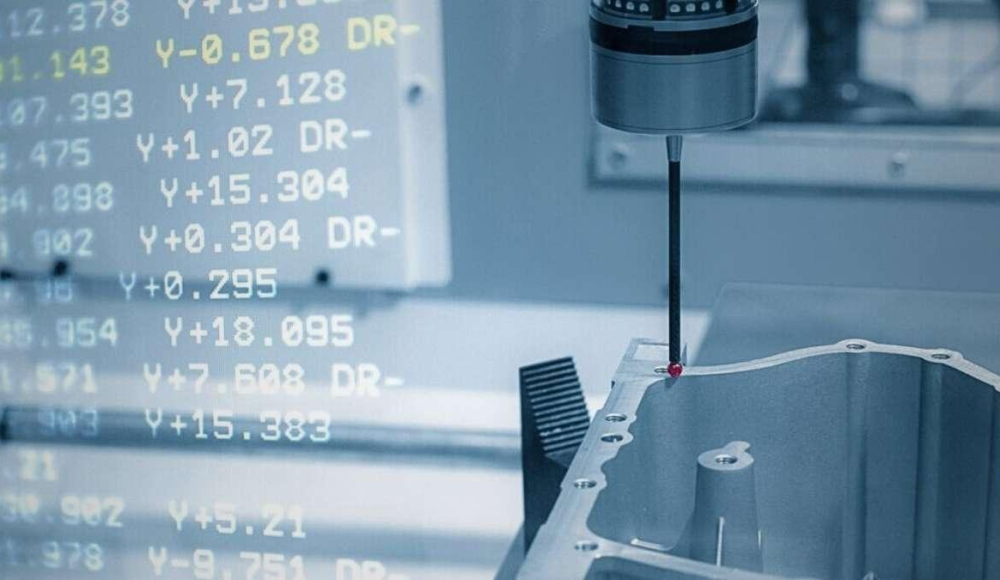

3-Usinage CNC d'axes

3-L'usinage axial fait référence à un processus de fraisage dans lequel l'outil de coupe se déplace le long de trois axes perpendiculaires.: X, Oui, et Z. Cette configuration permet d'avoir un contrôle précis dans le formage et la découpe des matériaux.

Mouvement des axes:

- Axe X: Mouvement vertical de haut en bas: Mouvement horizontal de gauche à droite.

- Axe Y: Le mouvement latéral du corps d’un côté à l’autre dans une direction antéro-postérieure.

- Axe Z: Mouvement latéral sur le côté.

Applications:

Idéal pour les surfaces planes, contours, et les formes simples sont faciles à usiner.

Apparaissant dans des applications comme l'aérospatiale, automobile, et fabrication générale de composants comme les supports, socles, et logements.

Outillage:

Comprend différents outils de coupe tels que des fraises en bout et des forets qui peuvent être remplacés sur certains systèmes CNC par un changeur d'outils.

Logiciel:

Contrôlé via un logiciel CAO/FAO qui permet la programmation et la simulation de processus.

Limites:

Ne peut créer que des formes relativement simples; besoin de changer de tête de coupe pour différentes faces; difficile d'atteindre certaines zones; il est souvent impossible d'obtenir une finition de surface élevée sur des contours fins; pas bon pour les matériaux hautement usinables.

4-Usinage CNC d'axes

4-L'usinage sur axes est similaire à l'usinage sur 3 axes avec la rotation supplémentaire autour du quatrième axe ou axe A.. Cela permet d'autres procédures de mouvement et d'usinage, améliorant ainsi la capacité à fabriquer des pièces avec des mesures détaillées.

Mouvement des axes:

- Axe X: Mouvement de gauche à droite de la figure(conception)

- Axe Y: Mouvement d'avant en arrière dans le plan latéral.

- Axe Z: Le type de mouvement par lequel un objet monte et descend dans une direction perpendiculaire est appelé mouvement vertical..

- Axe A: Pour obtenir un mouvement sur l'axe A, un mouvement de rotation autour de l'axe x a été incorporé pour permettre des coupes angulaires.

Applications:

- Idéal pour les opérations de tournage, des formes et des détails complexes doivent être tournés pendant l'opération de tournage.

- Largement appliqué dans les secteurs manufacturiers tels que le médical, aérospatial, automobile, et la fabrication d'appareils tels que des arbres, engrenages, et supports.

Outillage:

Utilise une large gamme d'outils de coupe comme ceux utilisés dans les machines à 3 axes mais avec l'avantage de pouvoir utiliser des outils angulaires grâce à l'axe rotatif.

Logiciel:

Permet l'utilisation d'un logiciel CAD CAM sophistiqué pour la programmation, ce qui permet à son tour de créer des parcours d'outils plus longs et plus complexes à simuler..

Limites:

Mouvements supplémentaires, ce qui signifie plus de programmation et de configuration que 3 axes, nécessitent des outils spécialisés, temps de cycle plus long, machines plus coûteuses, et machines multi-axes.

5-Usinage des axes

4-L'usinage des axes ressemble à l'usinage à 3 axes avec la rotation supplémentaire autour du quatrième axe ou axe A.. Cela permet un mouvement supplémentaire dans les procédures d'usinage, améliorant ainsi la capacité à fabriquer des composants de fonctionnalités détaillés.

Mouvement des axes:

- Axe X: Mouvement de l'outil de gauche à droite

- Axe Y: Mouvement d'avant en arrière dans le plan latéral.

- Axe Z: Le type de mouvement dans lequel un objet monte et descend dans une direction perpendiculaire est appelé mouvement vertical..

- Axe A: Pour réaliser ce mouvement, un mouvement de rotation autour de l'axe x a été incorporé pour permettre des coupes angulaires.

Applications:

Largement appliqué dans les secteurs manufacturiers tels que l'aérospatiale, automobile, et la fabrication de dispositifs médicaux pour des pièces telles que des arbres, engrenages, et supports.

Outillage:

Utilise une large gamme d'outils de coupe comme ceux utilisés dans les machines à 3 axes mais avec l'avantage de pouvoir utiliser les outils sous un angle grâce à l'axe rotatif.

Logiciel:

5-L'usinage CNC sur axes utilise un logiciel CADCAM sophistiqué à utiliser dans la programmation, ce qui permet à son tour de créer des parcours d'outils plus longs et plus complexes pouvant être simulés..

Limites:

Mouvements supplémentaires, ce qui signifie plus de programmation et de configuration que 3 axes, nécessitent des outils spécialisés, temps de cycle plus long, machines et entretien plus coûteux, et ne peut toujours pas produire certaines formes très complexes par rapport aux machines multi-axes.

7-Usinage des axes

7-L'usinage d'axes pousse le concept de fraisage CNC un peu plus loin en ajoutant un axe de rotation supplémentaire et davantage d'axes de mouvement linéaire..

Mouvement des axes:

- X, Oui, Axes Z: Mouvements latéraux et verticaux ordinaires.

- UN, B, Axes C: Autour du X, Oui, et mouvements de rotation de l'axe Z.

- Axe D: A un réglage de l'inclinaison ou de l'angle, ce qui le rend encore plus polyvalent que le modèle précédent.

Applications:

- Spécial pour les pièces complexes avec des surfaces et des formes de pointe complexes, y compris les avions et les moules.

- Adapté aux structures multicomposants qui nécessitent une haute précision et des caractéristiques de renforcement.

Outillage:

La capacité d'utiliser une variété d'outils de coupe spécialisés pour les opérations, notamment en augmentant les possibilités d'usinage.

Logiciel:

Utiliser des systèmes complets de conception/fabrication assistée par ordinateur développés pour les applications multi-axes afin de garantir un routage correct des outils..

Limites: Coût élevé des machines; compétences élevées en programmation nécessaires; plus de temps pour la configuration; maintenance plus élevée en raison de la complexité.

9-Usinage des axes

9-L'usinage des axes est une avancée par rapport à 5 et usinage 6 axes, car il ajoute encore plus de capacités de mouvement au mélange, et lui permet d'effectuer des opérations d'usinage très complexes qui ne peuvent être réalisées avec moins d'axes.

Mouvement des axes:

- X, Oui, Axes Z: Mouvements linéaires standards.

- UN, B, Axes C: Mouvements vibratoires le long de chacun des trois axes linéaires de translation.

- Axes D et E: Autres axes de mouvement rotatif et axes d'inclinaison permettant un réglage angulaire plus élevé.

- Axe F: Cela peut inclure des mouvements spécifiques supplémentaires basés sur la construction de la machine qui permettent des opérations d'usinage spécifiques..

Applications:

Idéalement utilisé pour l'aérospatiale, moules d'implants médicaux, et autres pièces nécessitant une grande précision et des formes à tolérances serrées.

Outillage:

Capable d'utiliser plusieurs instruments complexes, tels que des instruments polyvalents qui peuvent changer de fonction sans avoir besoin de réglage.

Logiciel:

Une programmation sophistiquée est requise ainsi qu'un système CAO/FAO spécifique pour un contrôle de mouvement 9 axes de haute précision..

Limites:

Coûts globalement plus élevés et plus compliqué; les opérateurs doivent être bien formés; ont un temps de production plus lent; et peut être limité en termes de taux d'enlèvement de matière en raison d'une conception complexe.

12-Usinage des axes

12-L'usinage des axes est le plus haut niveau d'innovation CNC. En général, il est utilisé lorsqu'un degré élevé de flexibilité dans la production de pièces est requis. Cette configuration est surtout préférée dans les applications sensibles aux exigences élevées, surtout en termes de géométrie.

Mouvement des axes:

- X, Oui, Axes Z: Mouvements linéaires standards.

- UN, B, Axes C: Mouvements oscillatoires qui se produisent autour de chacun des trois axes spatiaux.

- D, E, F, Axes G: Autres possibilités de mouvements de rotation ou de glissement, permettant une manipulation étendue des pièces dans diverses directions.

Applications:

Largement utilisé dans l'aérospatiale, automobile, et industries médicales pour la fabrication de petites et grandes pièces avec une haute précision, par exemple, pales de turbines et outils chirurgicaux compliqués.

Outillage:

Equipé de systèmes d'outillage complexes pour effectuer des opérations multifonctionnelles en un seul cycle, augmentant ainsi le taux de production.

Logiciel:

Equipé du dernier logiciel CAO/FAO pour relever les défis de programmation des applications 12 axes afin de fournir un travail de précision.

Limites:

Coût initial élevé; besoin de personnel spécialisé/compétent; codage et contrôle complexes; plus de temps nécessaire pour l'installation et le réglage; chances d'entretien fréquent en raison de l'équipement avancé.

Usinage CNC de précision avec Tops Precision

À Précision au sommet, nous intégrons une technologie de pointe dans la fabrication, y compris l'usinage 5 axes, pour répondre aux configurations de conception simples et complexes. Nous sommes spécialisés dans les services CNC adaptés à la production en courte série de prototypes fonctionnels et d'autres pièces..

Pour obtenir une offre de prix individuelle pour votre projet CNC, vous pouvez télécharger vos fichiers CAO en utilisant le formulaire de contact.. Notre équipe d’ingénieurs vous proposera rapidement un devis détaillé, cela prendra 1 à 2 jours.

2 réflexions sur "3-Axe à 12 axes: Comparaison des capacités des fraiseuses CNC”