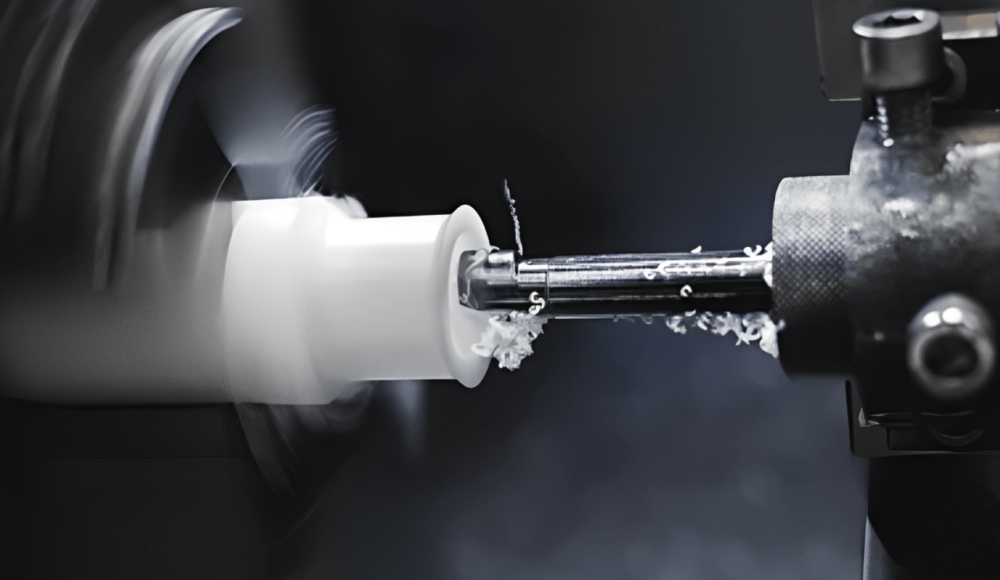

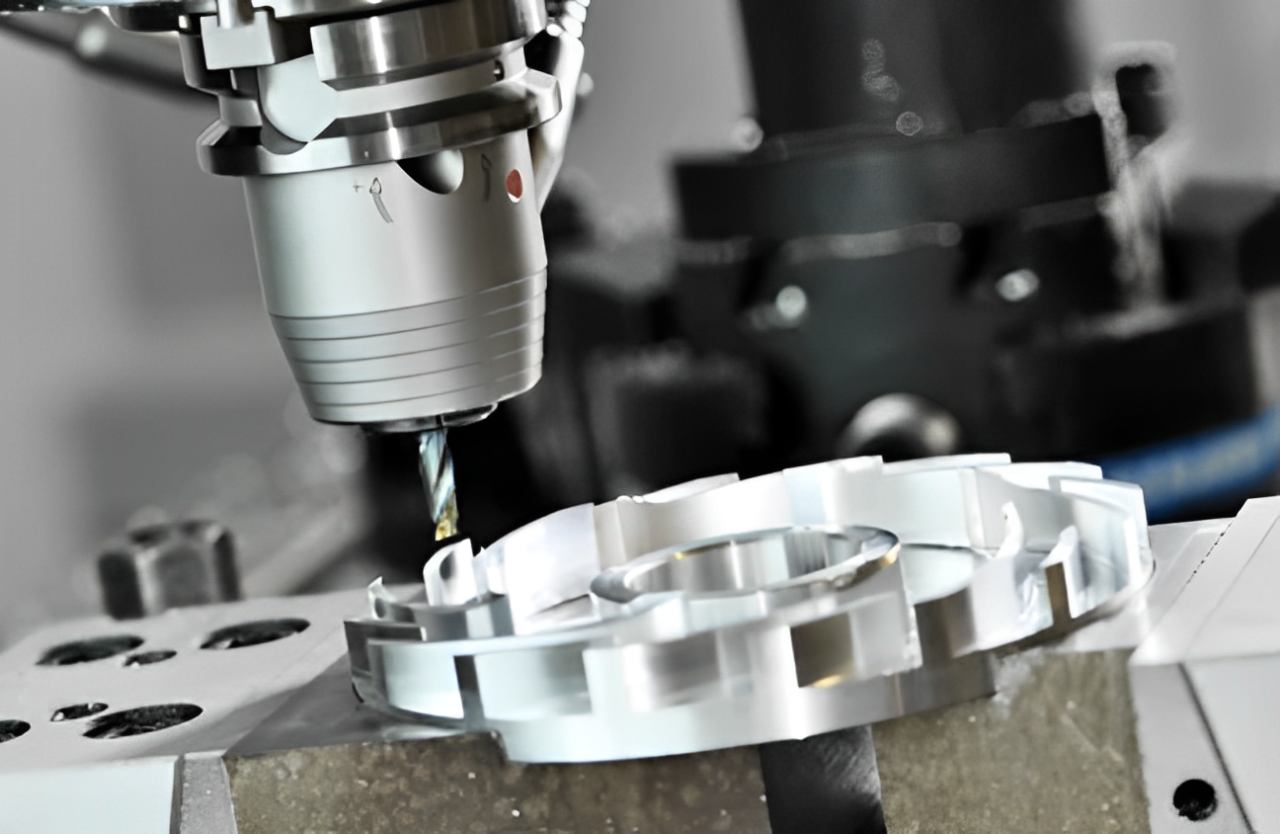

Usinage CNC est populaire pour sa fonction d'automatisation. Cela n'accélère pas seulement la vitesse. Mais favorise également une haute précision et exactitude. mis-à-part, il est utilisé dans de nombreuses applications dans de nombreux secteurs. Donc, quand nous parlons d'usinage CNC et de ses produits de sortie. Nous prenons également en compte les matériaux que nous utilisons pour le processus d'usinage CNC. Dans cet article, we will explore the different materials ideal for CNC machining, the factors to consider when selecting materials, and tips for optimizing material choices for your projects.

Different Categories of Material in CNC Machining

CNC machining is a versatile process capable of working with a wide array of materials. While metal and plastic are the most commonly used materials, CNC machining can also accommodate materials such as ceramics, bois, et matériaux composites. Each material category has distinct advantages and challenges, which make it important to choose the right one depending on the application.

Categories of Matériaux d'usinage CNC:

- Les métaux– Commonly used in industries like aerospace, automobile, and medical devices due to their durability and strength.

- Plastiques– Popular in the consumer goods and medical industries, where lightweight, corrosion-resistant parts are needed.

- Matériaux composites– Used in specialized industries such as aerospace and sports equipment manufacturing, offering high strength-to-weight ratios.

- Wood and Ceramics– Used for specialized and low-volume production, typically for artistic or unique products.

Types of Metal Materials for CNC Machining and Examples

Metals are the go-to material for most CNC machining operations due to their strength, résistance à la chaleur, and ability to endure heavy loads. Ci-dessous, we explore the most commonly used metals in CNC machining.

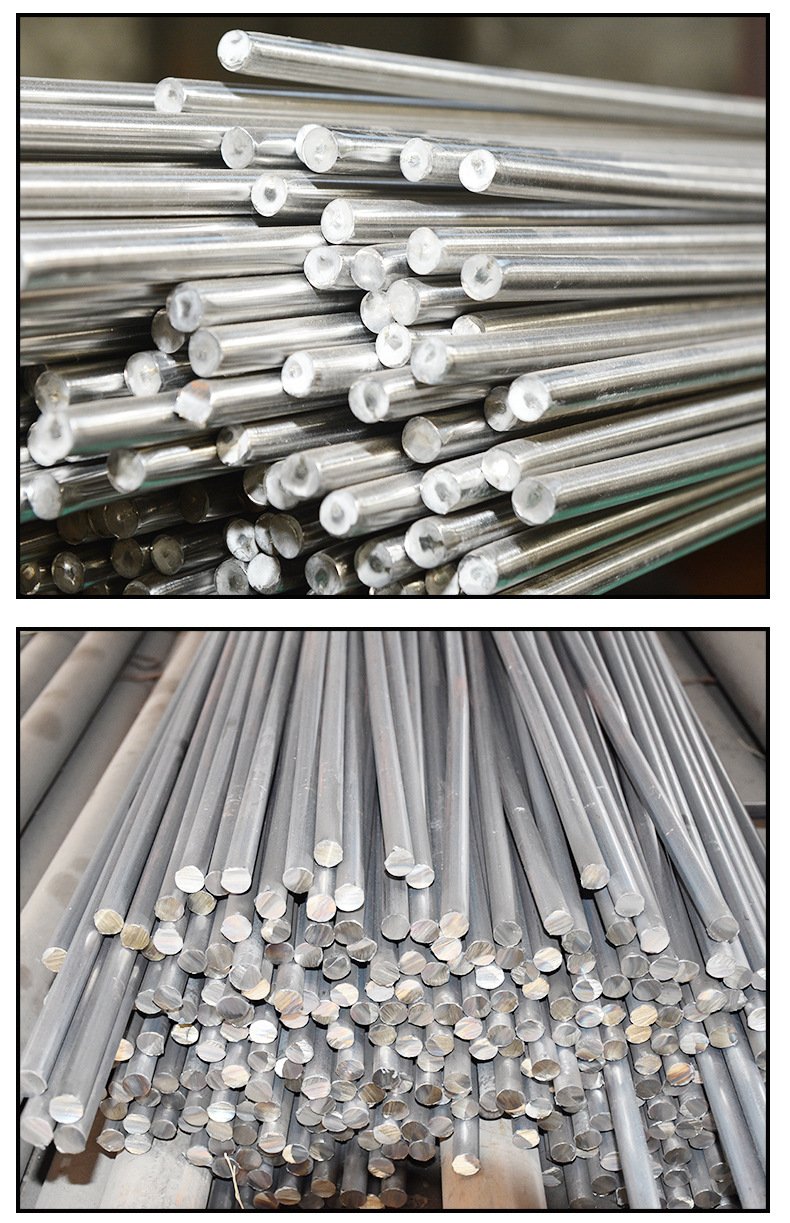

Aluminium

Aluminum is one of the most commonly used metals in CNC machining. Its advantages include a low density, rapport résistance/poids élevé, et excellente machinabilité. Alliages d'aluminium, tel que 6061 et 7075, are widely used in industries requiring lightweight but strong materials, comme l'aérospatiale, automobile, et électronique grand public. It’s corrosion-resistant and offers excellent surface finishes, making it suitable for both functional and aesthetic parts.

Acier inoxydable

Stainless steel is known for its corrosion resistance, dureté, and high strength. Il est souvent utilisé dans les dispositifs médicaux, aérospatial, and marine applications. While stainless steel has superior resistance to corrosion, its hardness can make it challenging to machine. Common grades of stainless steel used in CNC machining include 303, 304, et 316.

Carbon Steel and its Alloys

Carbon steel is widely used due to its excellent machinability, force, et l'abordabilité. It is especially favored for applications requiring robust mechanical properties like structural components, engrenages, et attaches. Cependant, carbon steel’s lack of corrosion resistance limits its applications in harsh environments unless coated.

Copper and its Alloys

Copper is chosen for its high thermal and electrical conductivity. It’s often used in electrical components like wiring and connectors, as well as in cooling systems. Laiton et bronze, alloys of cuivre, offer improved machinability and corrosion resistance, making them ideal for manufacturing precision components like gears, roulements, et connecteurs.

Titane

Titanium offers an exceptional combination of strength and lightweight properties. It’s widely used in high-performance industries, including aerospace and medical implants. Cependant, titanium is difficult to machine due to its toughness, so specialized tooling and machining processes are required.

Magnésium

Magnesium is one of the lightest metals, making it a suitable choice for applications that require reduced weight, comme l'automobile et l'aérospatiale. Magnesium’s properties also make it excellent for high-temperature applications. Cependant, its flammability during machining poses a challenge.

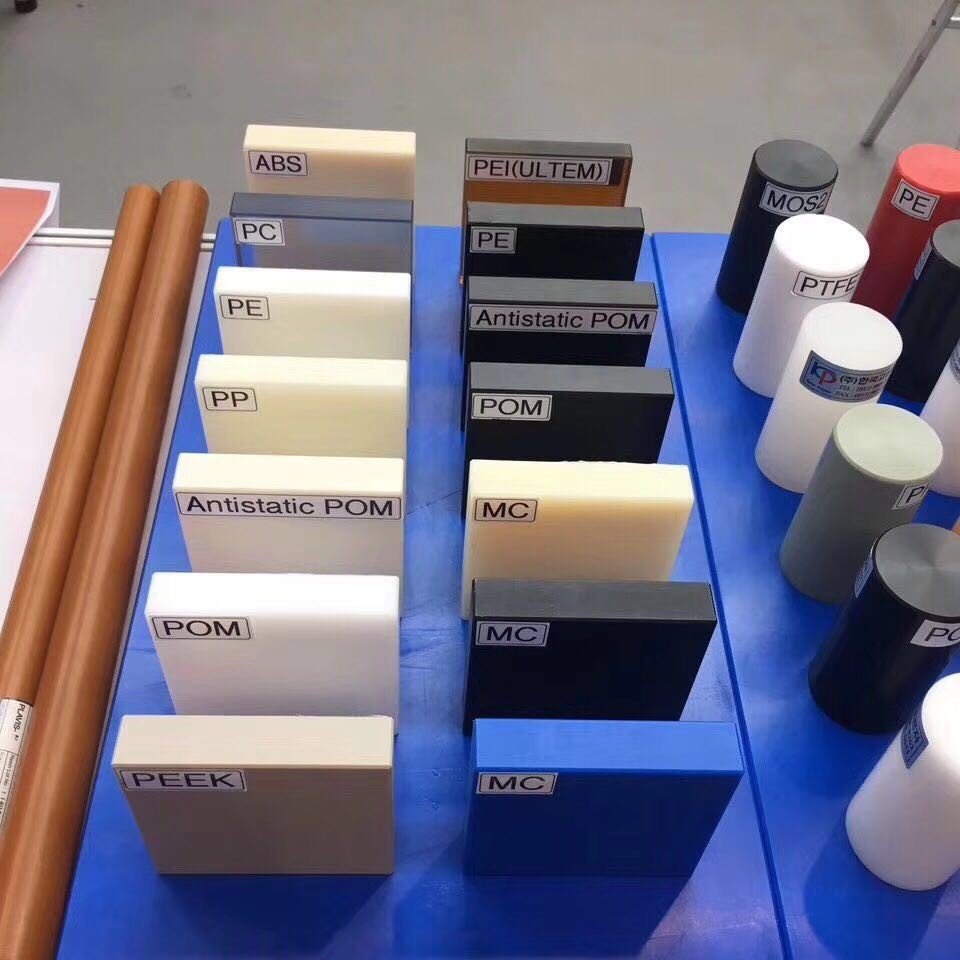

Types of Plastic Materials for CNC Machining and Examples

While metals dominate CNC machining, plastics are gaining traction, especially for applications where lightweight, durabilité, and flexibility are necessary. The following plastics are frequently used in CNC machining:

Acrylique (PMMA)

Acrylique, or PMMA, is widely used for its optical clarity and rigidity. It is often used as a substitute for glass in applications such as windows, affichages, and signage. Acrylic is versatile but prone to cracking, especially under high stress, which must be considered during machining.

Polypropylène (PP)

Polypropylene is known for its chemical resistance and fatigue strength. It’s commonly used in medical applications and consumer goods. Cependant, its tendency to soften at high temperatures makes it challenging to machine in some cases.

Acétal (POM/Delrin)

Acetal is known for its superior strength, moisture resistance, et excellente machinabilité. It’s frequently used in precision components like gears and bearings due to its ability to maintain its shape even under heavy loads.

Nylon

Nylon is a strong, durable, and impact-resistant material used in numerous applications, including bearings, engrenages, et composants électriques. It also has low friction, making it a common choice for parts exposed to wear.

abdos

ABS is an affordable plastic with good machinability, résistance à la traction, et résistance à l'impact. It’s used in producing automotive parts, enceintes de protection, and prototypes. ABS is also highly colorable, making it a good choice for aesthetic applications.

UHMW-PE

Ultra-high-molecular-weight polyethylene (UHMW-PE) is highly resistant to wear and abrasion, making it suitable for applications like bearings, engrenages, and sliding surfaces. Although it can be difficult to machine, its exceptional properties make it a valuable material for high-stress environments.

Polycarbonate (PC)

Polycarbonate is known for its excellent impact resistance and optical clarity. It is often used in high-temperature applications, as well as in the production of electronic components, Équipement médical, et pièces automobiles.

Polyéthernethketone (COUP D'OEIL)

PEEK is a high-performance plastic with outstanding chemical resistance, résistance mécanique, et stabilité dimensionnelle, making it ideal for use in extreme environments such as aerospace, transformation des aliments, et pétrole et gaz.

Chlorure de polyvinyle (PVC)

PVC is a low-cost plastic with excellent machinability. It’s used in applications requiring resistance to chemicals and high impact, such as plumbing systems, electrical fittings, et composants automobiles.

Quick View: CNC Machining Material Chart

Here’s a quick overview of common CNC materials, their key properties, and some examples of where they’re used.

| type de materiau | Matériel | Propriétés clés | Applications courantes | Notes & Codes |

| Métal | Aluminium | Poids léger, résistant à la corrosion, excellente machinabilité | Aerospace frames, pièces automobiles, électronique, construction | Al 1050, Al 6061, Al 7075 |

| Acier inoxydable | Fort, résistant à la corrosion, résistant à la chaleur | Medical equipment, marin, enceintes extérieures | SS 303, SS 304, SS 316 | |

| Acier au carbone | Haute résistance, excellente machinabilité | Mechanical fasteners, composants structurels | 1018, 4130, 4140 | |

| Cuivre | Great thermal/electrical conductivity, malléable, résistant à la corrosion | Electrical wire, magnetic devices, bijoux | Cu, Cu + Zn, Cu + Be | |

| Titane | Rapport résistance/poids élevé, résistant à la corrosion | Aérospatial, militaire, biomedical parts | Ti Grade 1, Ti Grade 2 | |

| Magnésium | Lumière, excellent thermal properties | Composants du moteur, automobile, aérospatial | Mg, Alliage de magnésium | |

| Plastique | Acrylique (PMMA) | High optical clarity, rigide, durable | Signalisation, light fixtures, pièces automobiles, biens de consommation | PMMA-Acrylic, PMMA-High Temp |

| Nylon (PA6) | Fort, durable, Résistant aux impacts, good for wear-resistance | Engrenages, roulements, pièces automobiles | PA6, PA66, Nylon 6-6 | |

| Polycarbonate (PC) | Shatter-resistant, résistant à la chaleur, clarté optique | Dispositifs médicaux, pièces automobiles, electronic components | PC, PC + Glass Fill | |

| COUP D'OEIL | High chemical resistance, maintains stiffness at high temperatures | Aérospatial, Équipement médical, composants semi-conducteurs | COUP D'OEIL | |

| abdos | Bonne usinabilité, Résistant aux impacts, résistance à la traction | Enclos, prototypage rapide, pièces automobiles | abdos, ABS-High Temp | |

| Composite | Fibre de carbone | Haute résistance, léger, high stiffness | Aérospatial, automobile, équipement sportif | CFRP, CRP, CFRTP |

What Is the Most Used Machining Material?

En ce qui concerne l'usinage CNC, metal and plastic are the most commonly used materials. Cependant, if we had to pick one, aluminium takes the top spot.

Why Is Aluminum So Popular?

- Facile à usiner– It cuts smoothly without excessive wear on tools.

- Lightweight yet strong– Ideal for industries like aerospace and automotive.

- Résistant à la corrosion– Great for outdoor and high-moisture applications.

- Abordable– Compared to titanium or stainless steel, aluminum is budget-friendly.

- Recyclable– Eco-friendly and widely available.

Other Popular Materials for CNC Machining:

- Acier– Strong, durable, and used in heavy-duty applications.

- Laiton– Excellent for precision parts and electrical components.

- Plastique (abdos, POM, Nylon)- léger, abordable, and great for prototypes.

What Material Is Easiest to Machine?

If you’re looking for a material that cuts like butter, laiton is one of the easiest to machine.

Why Is Brass So Easy to Machine?

- Soft and smooth– It cuts cleanly without chipping.

- Faible frottement– Reduces heat buildup, so it doesn’t damage tools.

- Great surface finish– Needs little to no post-processing.

- Doesn’t work-harden– Unlike stainless steel, brass stays easy to machine.

Other Easy-to-Machine Materials:

- Aluminium– Almost as easy as brass but stronger.

- Plastiques (abdos, POM, Nylon)– These cut quickly and don’t dull tools.

- Acier doux– Softer than stainless steel and easier to cut.

Which Material Is Difficult to Machine?

Quelques matériaux eat up cutting tools, cause excessive heat, or require special techniques à la machine. Le most challenging materials to work with include titane, Inconel, et acier durci.

Why Are These Materials Hard to Machine?

- Titane– High strength-to-weight ratio makes it tough, but it also generates a lot of heat, causing tool wear.

- Inconel (Alliage nickel)– Used in aerospace and high-heat applications, this metal is extremely hard and resists cutting.

- Acier trempé– It’s great for durability but requires slow speeds, outillage spécial, and coolant to machine effectively.

- Fibre de carbone & Matériaux composites– These can fray, fissure, or produce harmful dust when machined.

Tips for Machining Hard Materials:

✔ Utiliser carbide or diamond-coated tools for longer tool life.

✔ Apply liquide de refroidissement to prevent overheating.

✔ Utiliser slow speeds and proper feed rates to reduce tool wear.

✔ Consider specialized CNC machines designed for hard metals.

Si votre projet nécessite ultra-durable parties, these materials are worth the challenge, mais be prepared for longer machining times and higher costs.

Key Factors for CNC Machining Materials Selection

How do you make sure you’re choosing the best material? There are several important factors to consider, and understanding these can help you make more informed decisions.

Part Applications

The first thing to think about is what your part will actually be used for. Different materials are better suited to different applications. Par exemple, if you’re creating parts for the aerospace industry, you’ll need materials that are lightweight yet strong, comme titane ou aluminium. D'autre part, if you’re making parts for a food processing system, you might need a material that’s resistant to high temperatures and harsh chemicals, tel que acier inoxydable ou COUP D'OEIL plastique.

Each material has its strengths and weaknesses, and you want to match the material’s properties to the demands of the application. Understanding the environment your part will function in—whether it will face high pressure, températures extrêmes, or constant wear and tear—can guide you to the right material choice.

Poids partiel

The weight of your part plays a significant role in material selection. For parts that need to be light and easy to handle (like components in the automobile ou aérospatial industries), you’ll need materials with a low density, tel que aluminium ou titane. These materials are not only lightweight but also durable and strong.

En revanche, if your part will need to support heavy loads, you’ll want a material that is denser and stronger, tel que acier. Understanding the weight requirements of your part helps ensure that it performs as expected without unnecessary material costs or processing time.

Part Accuracy and Tolerance

Accuracy is often one of the most critical aspects when choosing a material. Some materials are easier to machine to precise dimensions than others. Par exemple, aluminium is generally easier to machine to tight tolerances compared to tougher materials like titane ou acier au carbone. The more difficult a material is to machine, the higher the cost and time it will take to achieve the desired precision.

If your part requires high accuracy and tight tolerances, be prepared to work with materials that are harder to machine or that may require additional processes (like heat treatment or specialized tooling). Make sure to factor in the level of precision required when choosing a material, as it will directly affect your machining costs and timelines.

Part Properties

Think about the properties your part needs to have. Par exemple:

- Force: Does your part need to withstand heavy loads? Des matériaux comme acierou titane provide excellent strength.

- Résistance à la corrosion: Will your part be exposed to moisture or chemicals? Considérer acier inoxydableou aluminium.

- Stabilité thermique: Is your part going to be exposed to high temperatures? Céramiqueet titane are great for heat resistance.

Each material has specific properties that make it ideal for particular environments and uses. Lors de la sélection d'un matériau, consider how these properties will help your part function well in its intended application.

Product Aesthetics

Parfois, the way a part looks is just as important as how it performs. Par exemple, dans biens de consommation ou électronique, the appearance of the part can play a major role in consumer acceptance. Des matériaux comme plastiques (par exemple., abdos ou polycarbonate) can be easily molded and colored to meet design specifications.

D'autre part, les métaux comme acier inoxydable et aluminium can also provide a sleek, look moderne. If aesthetics are a big concern, make sure to choose materials that can either be easily finished or already have the look you’re aiming for.

Surface Finish Options

When machining a part, the surface finish is important for both its appearance and functionality. Quelques matériaux, comme aluminium ou acier inoxydable, are easier to polish and finish, tandis que d'autres, comme acier au carbone or certain plastics, may require additional finishing steps to achieve the desired look or smoothness.

Surface finishes also play a role in the performance of the part. Par exemple, parts that will be used in high-friction environments (such as gears or bearings) will need a finish that reduces wear, while parts used in medical or aerospace applications may require a smooth, polished surface for functionality and aesthetic reasons.

Usinabilité

Some materials are easier to machine than others, which can affect both the cost and the time it takes to produce the part. Softer materials like aluminium et plastiques are easier to machine and can reduce tooling wear and overall production time. D'autre part, harder materials like titane ou tungstène are more difficult to machine, nécessitant des outils spécialisés, additional time, and potentially higher costs.

If your project has strict deadlines or budget constraints, it’s important to consider the machinability of the material, as choosing a material that’s too difficult to machine can significantly increase the time and cost of production.

Coût

Cost is always a factor in material selection. While it’s tempting to go for the highest-performance material, it may not always be the most cost-effective choice. Des matériaux comme aluminium are generally more affordable and offer a good balance between machinability, force, et durabilité, making them a popular choice. Cependant, high-performance materials like titane ou COUP D'OEIL can be much more expensive, both in terms of material costs and machining time.

Before deciding on a material, make sure you balance performance with cost. Parfois, a less expensive material will perform just as well for your application, allowing you to save on both material costs and machining expenses.

Tips When Using CNC Processes to Machine Different Materials

Choose the Right Tools for the Job

Not all cutting tools are created equal. Different materials require different types of tools to achieve the best results. Par exemple, harder metals like titane et acier inoxydable will need carbide or ceramic tools because they can withstand the heat and stress of cutting harder materials. For softer materials like aluminium ou plastiques, you can often get away with using high-speed steel tools.

- Conseil: Always match your tool material to the material you’re machining. This helps in reducing tool wear and ensures smoother cuts.

Control Cutting Speed and Feed Rate

Cutting speed and feed rate are crucial to achieving the desired results. If the cutting speed is too fast for a certain material, it can cause the tool to wear out faster, overheat, or even break. D'autre part, if the feed rate is too slow, it can lead to inefficient machining and increased production time.

- Conseil: For softer materials like aluminium, use faster cutting speeds and higher feed rates. For harder materials like titane ou acier, reduce the cutting speed and feed rate to avoid excessive heat buildup and tool wear.

Utilisez le bon liquide de refroidissement

Using coolant during CNC machining is essential to reduce heat buildup and prevent damage to both the tool and the workpiece. Different materials generate different levels of heat, so the type of coolant and the amount used can vary.

- Conseil: Utiliser water-based coolants for softer materials like aluminium et plastiques, as they can help prevent thermal damage. For harder materials like acier inoxydable et titane, you might want to use oil-based coolants for better cooling and lubrication.

Pay Attention to Material Thickness

The thickness of the material you’re machining affects how quickly and efficiently your CNC machine can cut through it. Thicker materials, especially metals like acier au carbone et acier inoxydable, will require more powerful machines and stronger tools to get through them. D'autre part, thinner materials like plastiques ou aluminum sheets will require less power and can be machined more quickly.

- Conseil: Always adjust your cutting depth and tool paths depending on the material thickness. For thicker materials, reduce the depth of each cut to avoid straining the machine and tooling.

Consider Material Properties Before Choosing a Machining Strategy

Each material has its own set of characteristics—some are more brittle, others are more flexible, and some can expand or contract when exposed to heat. Understanding these properties will help you determine the best machining strategy for the material.

- Conseil: For materials prone to warping, tel que plastiques comme PVC ou acétal, use lower cutting speeds and avoid deep cuts to minimize the material’s movement. For materials like titane, which expand due to heat, use a slower feed rate and ensure your machine is well-calibrated to avoid any distortions.

Assurer une bonne collaboration

Holding your material securely in place is critical, especially when machining complex shapes. If the workpiece is not properly held, it can move during machining, leading to poor tolerances, surface imperfections, or even damaged parts. Some materials are more prone to deformation or shifting, so they need extra care.

- Conseil: Use strong and reliable workholding fixtures, tel que pinces ou vacuum chuck systems, to hold your parts in place securely. For softer materials like plastiques, use softer workholding methods to avoid damaging the part.

Choose the Right CNC Machine

Not every CNC machine is suitable for every material. Des matériaux plus doux, comme aluminium, can be easily machined with standard 3-axis CNC machines. Cependant, matériaux plus durs, tel que titane ou acier, may require 5-Machines Axe CNC for more flexibility and better precision.

- Conseil: For intricate or highly detailed cuts in tough materials, consider using 5-axis CNC machining. This type of machine will allow for more angles of attack and better control of the cutting process.

Surface Finish Matters

The finish on the surface of your machined part can make a huge difference, both in terms of aesthetics and functionality. Quelques matériaux, comme aluminium et acier inoxydable, will have a naturally smooth surface finish after machining, tandis que d'autres, comme plastiques ou titane, may require additional post-machining processes like polissage ou anodisation to achieve the desired finish.

- Conseil: Always keep the desired surface finish in mind when selecting a material. If a shiny or smooth finish is needed, ensure that the material you choose is conducive to that kind of finish. Quelques matériaux, comme laiton ou acier inoxydable, can be polished easily, tandis que d'autres, comme bronze, might require extra steps.

Account for Material Cost and Availability

Material cost is always a key consideration. Titane et acier inoxydable, while excellent for certain applications, can be much more expensive than materials like aluminium ou laiton. En plus, some materials are more readily available than others, which could affect lead times.

- Conseil: Choose materials that fit within your project budget. Si acier inoxydable is over your budget, considérer aluminium ou acier au carbone as alternatives for less critical parts.

Understand the Environmental Impact

Some materials have a significant environmental impact, either through mining, traitement, or disposal. Des matériaux comme plastiques, if not recycled properly, can contribute to waste. Cependant, metals like aluminium et acier inoxydable are often highly recyclable.

- Conseil: Chaque fois que possible, choose materials that are recyclable or have a minimal environmental impact. Aluminium, par exemple, is widely recycled and has a lower environmental footprint compared to materials like plastique.

Get the Right CNC Machining Material for Your Projects

Choosing the right material is crucial for your CNC machining project. If you are unsure which material is best suited for your needs, consider seeking professional advice from CNC machining service providers who offer extensive material options and expertise.

What Are the Cost Implications of Different Machining Materials?

Choosing the right material for CNC machining isn’t just about strength and performance—it also affects your budget. Some materials are cheap and easy to machine, while others are expensive and require special tools or extra processing time.

What Drives the Cost of Machining Materials?

- Raw Material Price– Certains matériaux, comme l'aluminium, are widely available and affordable, tandis que d'autres, comme le titane, are much more expensive.

- Usinabilité– Softer materials (like brass and aluminum) machine faster, reducing labor and tool wear. Matériaux durs (like stainless steel or Inconel) require slower machining and special tools, increasing costs.

- Usure des outils– Some materials dull cutting tools quickly, leading to higher tooling costs.

- Scrap and Waste– Harder materials may result in more waste due to tool breakage or machining errors.

- Finishing Requirements– Some metals, like brass, naturally look great, tandis que d'autres, like carbon steel, require coatings or polishing, adding extra cost.

Cost Comparison of Common Machining Materials

| Matériel | Raw Material Cost | Coût d'usinage | Total Cost Impact | Meilleurs cas d'utilisation |

| Aluminium | Faible | Faible | $$ | Aérospatial, automobile, électronique |

| Laiton | Moyen | Very Low | $$ | Pièces de précision, plomberie, électrique |

| Acier inoxydable | Moyen | Haut | $$$ | Médical, transformation des aliments, parties résistantes à la corrosion |

| Titane | Très élevé | Très élevé | $$$$$ | Aérospatial, implants médicaux |

| Acier au carbone | Faible | Moyen | $$ | Pièces structurelles, outils |

| Plastiques (abdos, POM, Nylon) | Faible | Very Low | $ | Prototypes, composants légers |

| Inconel (Alliage nickel) | Extremely High | Extremely High | $$$$$$ | Moteurs à réaction, extreme heat applications |

How to Balance Cost and Performance

✅ Go for aluminum or brass si tu veux abordable, easy-to-machine materials.

✅ Use plastics for low-cost prototypes that don’t need high strength.

✅ Consider stainless steel when corrosion resistance is crucial, but be prepared for higher machining costs.

✅ Titanium and Inconel sont premium materials—use them only when absolutely necessary due to their high price and machining difficulty.

💡 Conseil de pro: If your part doesn’t need extreme strength or heat resistance, stick with aluminum or mild steel to save on both material and machining costs.

Conclusion

CNC machining is an incredibly versatile manufacturing process that accommodates a wide range of materials. Whether you’re working with metals, plastiques, ou composites, the key to success is selecting the right material based on the part’s application, propriétés, and machining requirements. By understanding the material properties and machining challenges, you can optimize the material selection process, réduire les coûts, and achieve high-quality parts.

FAQ

- What are the factors to be considered when selecting a CNC material?

Consider part application, poids, précision, propriétés, et le coût.

- Which aluminum alloy is best for CNC machining?

Aluminum 6061-T6 is commonly used for CNC machining due to its excellent machinability and strength.

- Which plastics are most machinable?

Acétal, COUP D'OEIL, and PVC offer great machinability and dimensional stability.

- What is the hardest metal to mill?

Titanium is one of the hardest metals to mill, often requiring specialized tooling and techniques.

1 réfléchi à "Matériaux d'usinage CNC, Tout ce que tu as besoin de savoir”