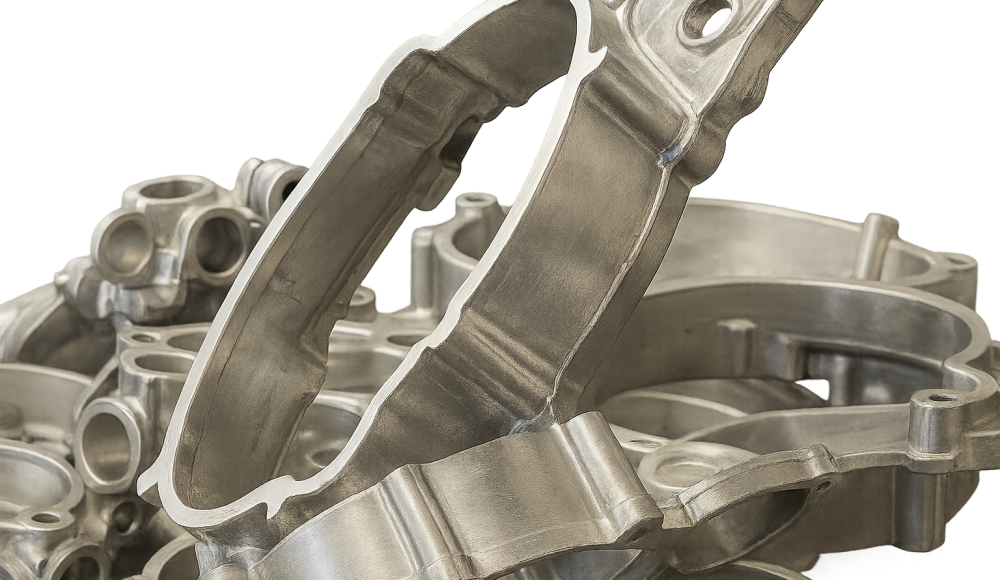

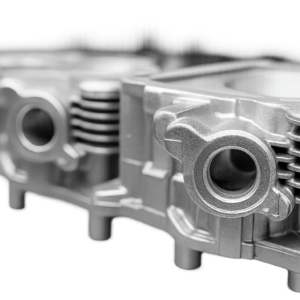

Moulage is a highly efficient and precise manufacturing process where molten metal is injected into a steel mold under high pressure. It’s widely used for creating complex metal components that are difficult or expensive to machine by conventional methods. Cependant, the success of any die casting project depends heavily on the quality of the design. A well-thought-out design ensures structural integrity, minimizes defects, reduces cost, and enhances manufacturability.

This article provides a comprehensive guide to die casting design tips, highlighting critical variables that every engineer and designer should consider when developing parts for this process.

Major Considerations for Die Casting Design

Designing an effective die cast part requires balancing multiple factors. Here are the most important considerations:

Sélection des matériaux

Die casting can be performed with various alloys, tel que:

Aluminium (léger, résistant à la corrosion)

Zinc (high fluidity, adapté aux pièces complexes)

Magnésium (lightest structural metal)

Each alloy has different properties like shrinkage, conductivité thermique, and fluidity, all of which affect design decisions such as wall thickness, fillet radii, and cooling requirements.

Conception des matrices

The die must be strong enough to withstand high pressure and temperature without warping. Accurate machining of the die ensures dimensional consistency in every cycle.

Ejection and Cores

Parts should be designed for easy ejection to avoid damage and reduce cycle time. Core designs must also allow easy removal without sticking or distorting the part.

Fonctionnalité

Die cast parts used in high-load or critical applications (par exemple., automobile, aérospatial) require specific reinforcements and tolerances compared to cosmetic or lightweight applications.

Top Design Tips for Die Casting – Key Variables

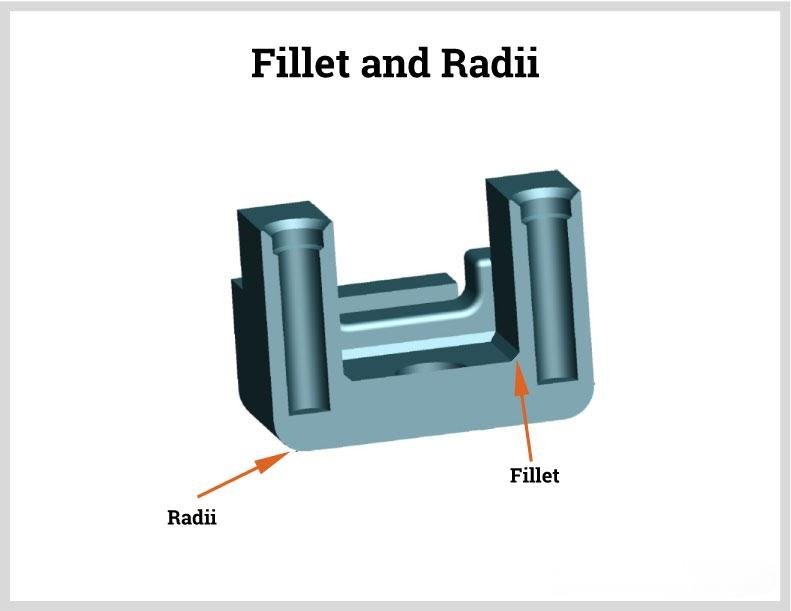

Fillets and Radii

Fillets and radii are crucial to eliminate sharp corners, reduce stress concentrations, and improve metal flow.

Conseils:

Avoid sharp internal corners

Use a radius of at least 1 mm (larger in high-stress zones)

Apply consistent radii throughout the design

Incorporate draft angles (typically 1–3°) to aid in part removal

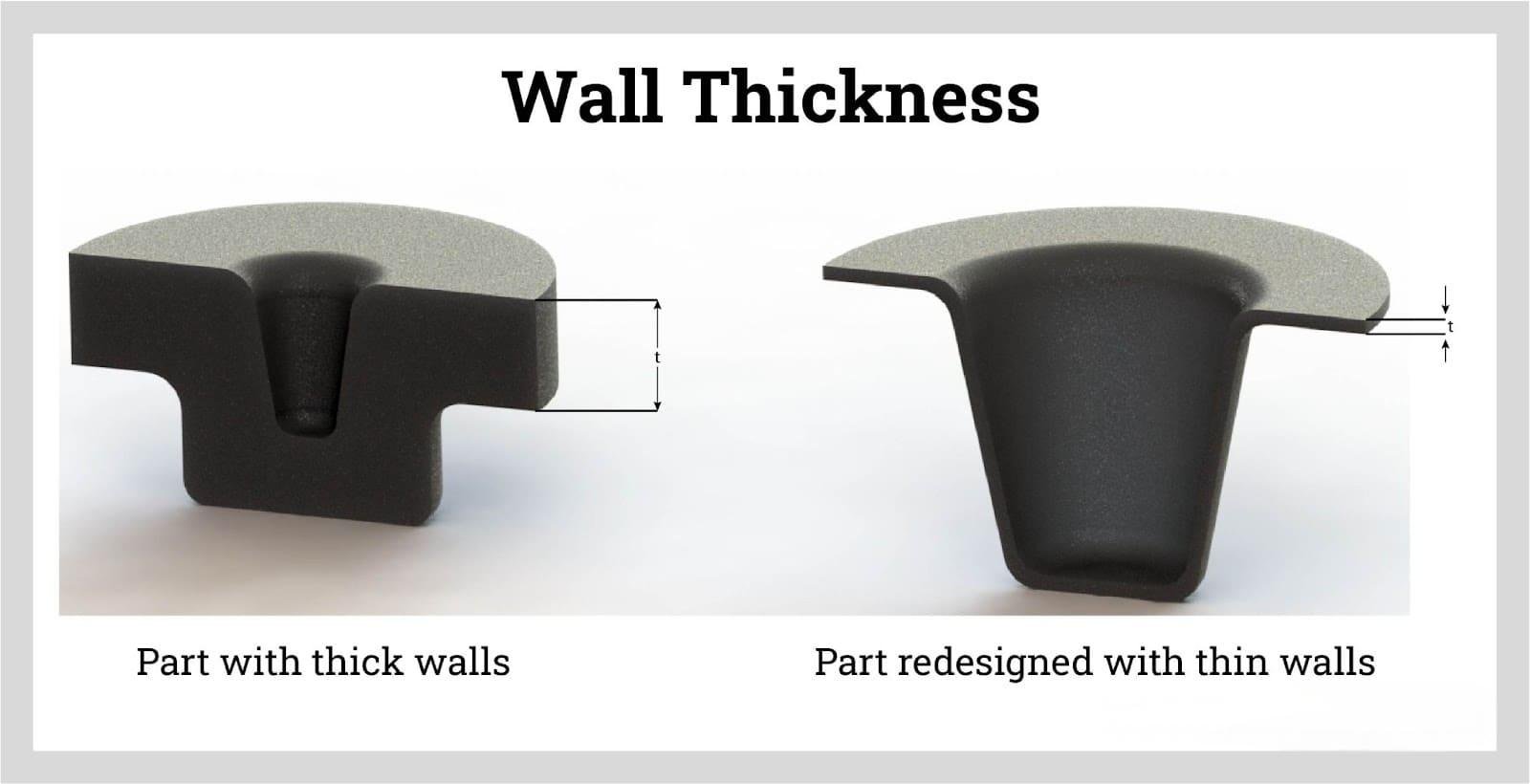

Épaisseur de paroi

Wall thickness affects cooling time, casting pressure, and overall part weight. Maintaining uniform wall thickness prevents issues such as porosity and warping.

Recommended Minimum Wall Thickness:

| Matériel | Small Parts (mm) | Large Parts (mm) |

| Aluminium | 1.016 | 2.032 |

| Zinc | 0.381 | 0.889 |

| Magnésium | 1.016 | 2.540 |

Avoid abrupt changes in wall thickness to prevent hotspots and shrinkage cavities.

Ribs and External Corners

Ribs are added to strengthen thin walls without significantly increasing weight. External corners need careful attention to avoid stress buildup.

Conseils:

Prioritize rib placement on the thinnest sections

Maintain uniform rib spacing

Avoid sharp external corners; use generous radii instead

Rib thickness should be about 50–60% of wall thickness

Windows and Holes

Fenêtres (cutouts) and holes are often required for assembly, flux d'air, or material savings, but they can weaken a part if not designed properly.

Conseils:

Round all edges of holes and cutouts

Keep features away from corners and load-bearing areas

Apply generous draft angles on side-wall holes

Avoid unnecessary post-machining when possible

Post-Machined Features

Some geometries like threads, sous-dépouille, or tight-tolerance bores may need post-machining, which adds time and cost.

Directives de conception:

Keep post-machining to a minimum

Design features for easy tool access

Use cores to avoid secondary machining where possible

Set realistic tolerances to avoid unnecessary scrap

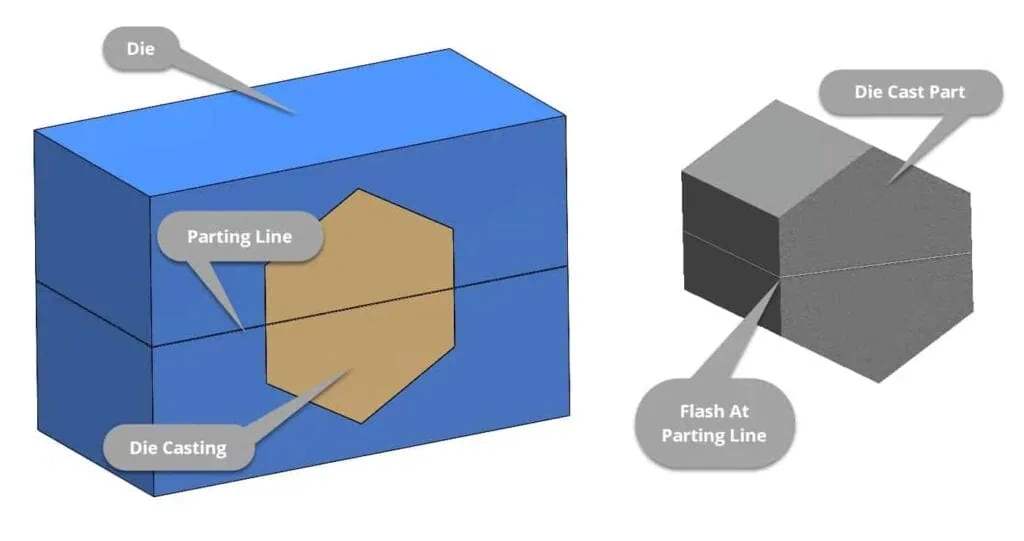

Lignes de séparation

Parting lines are the visible seams where two die halves meet. Their location impacts both function and appearance.

Conseils:

Place parting lines in less visible areas

Avoid placing them on functional surfaces

Expect some flash that must be removed in post-processing

Balance aesthetic requirements with manufacturability

Surface Finishing Grades

Die cast parts have different finishing levels based on their end use. Each grade balances cost, apparence, and functional requirements.

| Grade | Nom | Typical Use Case | Qualité de finition |

| 1 | Utility Grade | Internal or protected components | ⭐ |

| 2 | Functional Grade | Spot-polished, painted parts | ⭐⭐ |

| 3 | Note commerciale | Structural and semi-cosmetic use | ⭐⭐⭐ |

| 4 | Consumer Grade | Visible surfaces, good appearance | ⭐⭐⭐⭐ |

| 5 | Superior Grade | High-end aesthetic or sealing use | ⭐⭐⭐⭐⭐ |

Choose the lowest necessary grade to minimize cost while meeting functional needs.

Die Casting Services by HAUTS

Chez TOPS Précision, we offer high-precision die casting services for aluminum, magnésium, and zinc alloys. Our team supports you from design to production, offering expert advice on material selection, cost reduction strategies, and optimal manufacturing methods.

How to Get Started:

Send your CAD file to us by email

Receive an instant quote with material and quantity options

Adjust your design online to evaluate cost-saving opportunities

Si vous avez besoin prototypes ou production-scale parts, TOPS helps you achieve high-quality results with efficient lead times and cost control.

Conclusion

Designing for die casting is both a technical and creative process. By considering the proper wall thickness, filets, côtes, angles de dépouille, and finishing options, you can drastically improve your part’s performance and reduce manufacturing costs. Souviens-toi, the success of a die casting project lies in the details—so use these tips to make your next design smarter and more efficient.

For reliable die casting services, material expertise, and design feedback, TOPS is your trusted partner.

En savoir plus:

Moulage sous pression en aluminium

Options de finition de surface

Méta-titre:

Conseils de conception pour le moulage: Meilleures pratiques pour fonctionne & Parties rentables

Méta-description:

Explore expert die casting design tips including fillets, épaisseur de paroi, côtes, post-machining, et finition de surface. Learn how to optimize your parts with TOPS Precision.

Suggested Keywords:

die casting design tips

moulage sous pression en aluminium

die casting wall thickness

post-machined features

rib design in die casting

draft angles in casting

2 réflexions sur "Conseils de conception pour le moulage: Un guide complet pour les pièces optimisées”