Dans le monde de la fabrication de précision, moulage sous pression se distingue comme l’une des méthodes les plus efficaces et reproductibles pour produire des composants métalliques complexes. Au cœur de ce processus se trouve outil de moulage sous pression—un moule usiné avec précision conçu pour résister aux injections à haute pression de métal en fusion. Bien que l'outillage représente un investissement initial important, comprendre le facteurs qui influencent le coût des outils de moulage sous pression peut vous aider à prendre de meilleures décisions, réduire les déchets, et maximisez votre retour sur investissement tout au long du cycle de vie du produit.

Pourquoi les outils de moulage sous pression sont chers

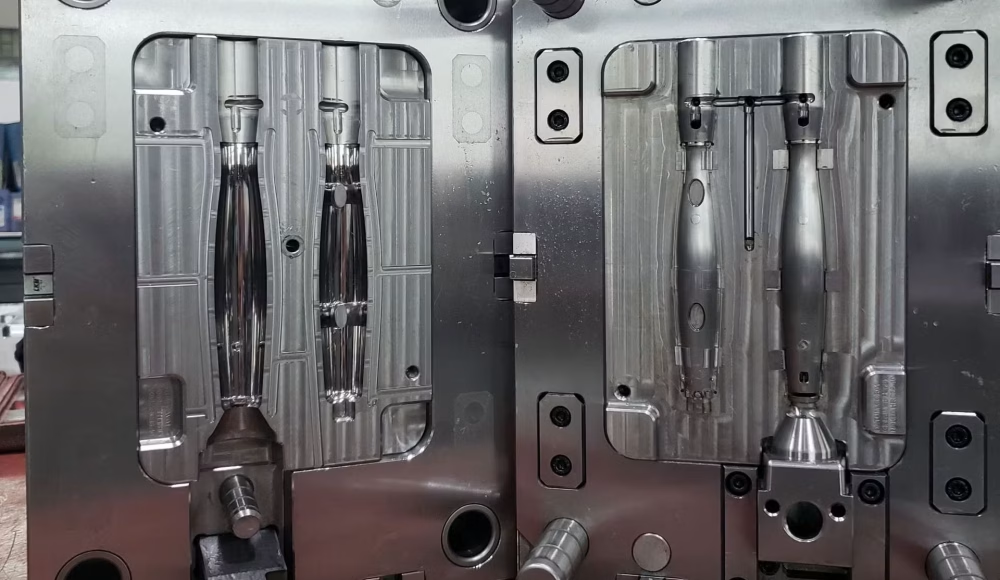

L'outillage de moulage sous pression est soumis à conditions extrêmes— températures élevées, pression intense, et une contrainte mécanique constante. Par conséquent, les outils doivent être construits à partir de aciers à outils spéciaux de haute qualité, conçu avec précision pour chaque projet. Les matrices de haute qualité peuvent coûter plus cher au départ, mais s'avèrent rentables avec le temps grâce à la réduction des temps d'arrêt., moins de défauts, Et la vie de l'outil plus longue.

Facteurs clés qui influencent le coût de l'outillage

Conception d'outils: La base du succès à long terme

La phase de conception est le facteur le plus critique pour déterminer à la fois coût et performances. Un outil de moulage sous pression bien conçu garantit une qualité de produit constante, temps de cycle optimaux, et opérations secondaires minimes. Mauvaise conception des outils, d'autre part, conduit souvent à:

Parties défectueuses

Éclair, porosité, et problèmes de rétrécissement

Des taux de rebut plus élevés

Augmentation des coûts d’usinage et de finition

Conception pour la fabrication (DFM) les principes doivent être appliqués tôt. Facteurs tels que les angles de dépouille, épaisseur de paroi, lignes de séparation, et les systèmes d'éjection doivent être optimisés à l'aide d'un logiciel de modélisation et de simulation 3D. Il est conseillé de investir dans des outils de validation et de simulation de conception avant de couper l'acier.

Systèmes de glissières et de ventilation: Contrôler le flux de métaux

Un bon système de canaux garantit que le métal en fusion est distribué uniformément et rapidement dans la cavité du moule.. Une ventilation adéquate permet aux gaz de s'échapper, empêchant l'air emprisonné et les remplissages incomplets.

Les équipes de conception modernes utilisent logiciel de simulation de coulée à:

Prédire et visualiser le comportement des écoulements en fusion

Identifier les zones de porosité potentielles

Optimiser les emplacements des portes et des trop-pleins

Les améliorations de conception apportées à ce stade réduisent considérablement le risque de problèmes de production et de refonte des outils, réduire le coût global de votre projet.

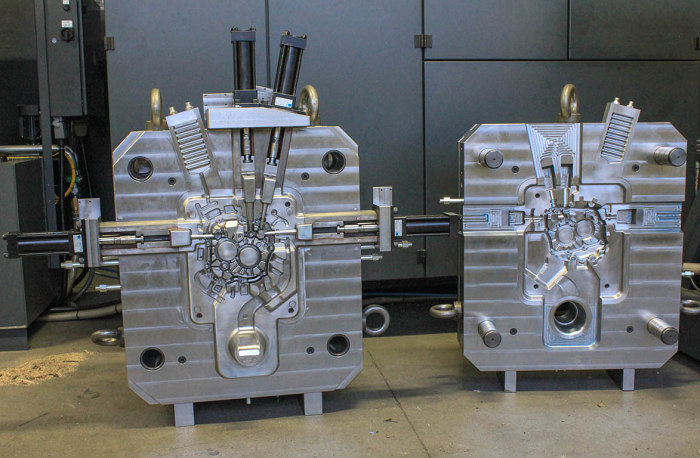

Conception du circuit de refroidissement: Gestion thermique pour la qualité et la longévité

Pendant le moulage sous pression, le métal en fusion refroidit et se solidifie dans le moule. Si le refroidissement est irrégulier ou mal contrôlé, le résultat peut être des contraintes internes, gauchissement, ou des temps de cycle plus lents.

Les circuits de refroidissement (canaux intégrés au moule pour le flux du liquide de refroidissement) aident à gérer la température.. Certains fabricants réduisent leurs coûts en plaçant des canaux de refroidissement génériques, mais analyse thermique stratégiquement conçue aboutit à:

Meilleure cohérence des pièces

Temps de refroidissement plus courts

Durée de vie prolongée de l'outil grâce à la réduction des chocs thermiques

Alors que l'analyse thermique ajoute au coût initial, il améliore considérablement la productivité et la qualité des pièces au fil du temps.

Inserts d'outillage: Conception intelligente pour la rentabilité

Les inserts d'outillage sont composants modulaires dans un moule de moulage sous pression plus grand. Au lieu de remplacer l'ensemble de l'outil en raison de l'usure ou de l'érosion, seul l'insert doit être remplacé.

Les inserts offrent de multiples avantages:

Coût de maintenance réduit à long terme

Flexibilité pour adapter ou modifier la conception des outils

Délais de réparation plus rapides

Qualité constante des pièces tout au long de la durée de vie de l'outil

Zones soumises à une forte usure, comme les portes et les coins, doit être équipé d’inserts remplaçables. Les outilleurs expérimentés peuvent prédire les zones d'usure et incorporer des plaquettes en conséquence.

Matériau de l'outil: Adaptation de la nuance d'acier à l'application

La sélection de la nuance d'acier à outils a un impact direct sur la durabilité et le coût. Les matériaux couramment utilisés comprennent:

Acier à outils H13: Offre un bon équilibre entre résistance à la chaleur et ténacité. Idéal pour l'aluminium et le magnésium.

H21 / H22: Idéal pour les opérations à haute température comme le moulage sous pression du zinc ou du laiton.

Aciers à outils en poudre (par exemple., Notes CPM): Aciers haut de gamme avec une résistance à l'usure supérieure, idéal pour les longues séries de production.

Le bon matériau dépend de:

Matériel de coulée (aluminium, zinc, magnésium)

Durée de vie prévue de l'outil (nombre de tirs)

Complexité des pièces et exigences de finition

Dépenser davantage pour un acier de meilleure qualité peut permettre d'économiser des dizaines de milliers de dollars en coûts de reconstruction d'outillage lors d'une production en grand volume..

Entretien et longévité: Protéger votre investissement en outils

Quelle que soit la qualité de conception de votre outillage, il s'usera inévitablement en raison des cycles haute pression et thermiques. Un entretien régulier est essentiel pour prolonger la durée de vie de l'outil et garantir une qualité constante des pièces..

Meilleures pratiques pour la maintenance des outils de matrice:

Nettoyer soigneusement les outils après les cycles de production.

Inspecter l'usure, craquage, ou fatigue thermique.

Appliquer des revêtements protecteurs (par exemple., nitruration, PVD).

Utiliser des procédures de stockage appropriées pour éviter la corrosion et les dommages.

L'entretien courant est beaucoup plus rentable que les réparations d'urgence ou le remplacement complet des outils.

Prolonger la durée de vie des outils: Question de conception et de partenariat

La longévité d’un outil n’est pas seulement une question de matériau, mais aussi de qualité de l’outil. conçu, construit, et géré tout au long de sa durée de vie.

Un partenariat avec un fournisseur de moulage sous pression expérimenté peut aboutir à:

Évaluations prédictives de la durée de vie des outils

Fonctions de compensation d'usure intégrées

Placements d'inserts optimisés

Décisions basées sur les données concernant les rénovations ou les remplacements

Si vous effectuez une production en grand volume (par exemple., >100,000 coups/an), ces économies s'accumulent rapidement.

Conclusion: Investissez judicieusement, Récoltez les récompenses

Même si les coûts d’outillage de moulage sous pression peuvent sembler élevés au départ, un outillage de qualité est un investissement, pas une dépense. La bonne approche de la conception d’outils, matériaux, inserts, et l'entretien peut entraîner:

Coût de production par pièce réduit

Moins de défauts et d’étapes de post-traitement

Rendement accru avec une qualité constante

Durée de vie des outils plus longue et fréquence de remplacement réduite

À Précision HAUTS, nous travaillons en étroite collaboration avec nos clients pour équilibrer la qualité et le coût. Notre équipe d’ingénieurs expérimentés exploite la simulation 3D, aciers à hautes performances, et une conception d'outils intelligente pour fournir des, solutions de production à grand volume.

📞 Contactez-nous aujourd'hui pour en savoir plus sur les options d'outillage de moulage sous pression, ou pour obtenir un devis adapté à vos besoins de conception et de production de pièces.

FAQ

1. Pourquoi les outils de moulage sous pression sont-ils si chers?

Les outils de moulage sous pression doivent résister à des températures extrêmes et à des pressions élevées, ce qui nécessite une conception de précision et l'utilisation d'aciers à outils coûteux. Le coût initial élevé est compensé par des coûts à long terme inférieurs grâce à une production constante et à la longévité des outils..

2. Combien de temps dure un outil de moulage sous pression?

La durée de vie de l'outil varie en fonction du matériau et de la conception, mais peut aller de 50,000 à plus 1,000,000 coups de feu. Conception appropriée, entretien, et l’utilisation d’inserts peut prolonger considérablement la durée de vie d’un outil.

3. L'outillage peut-il être réutilisé pour différentes pièces?

En général, Non. Les outils moulés sous pression sont fabriqués sur mesure pour des géométries de pièces spécifiques. Cependant, un outillage modulaire et des inserts interchangeables peuvent être utilisés pour créer des variantes de pièces similaires.

4. Comment puis-je réduire les coûts des outils de moulage sous pression sans compromettre la qualité?

Se concentrer sur Conception pour la fabrication (DFM), utiliser un logiciel de simulation dès le début, choisissez des matériaux durables, et mettre en œuvre des inserts amovibles. Un partenariat avec un fondeur sous pression expérimenté peut également conduire à des solutions d'outillage rentables et optimisées..

5. Quels matériaux sont les plus couramment utilisés pour les outils de moulage sous pression?

Acier à outils H13 est le plus courant en raison de sa grande ténacité, résistance à la fatigue thermique, et l'abordabilité. Les aciers haut de gamme comme H21 ou CPM les nuances peuvent être utilisées pour des applications plus exigeantes ou des séries plus longues.

En savoir plus:

Services de moulage sous pression

Optimisation du moule de moulage de la matrice

Conseils de conception pour le moulage

Atteindre un angle de dépouille nul