À la base, le prototypage rapide est un change la donne dans la fabrication moderne et le développement de produits. Il permet aux créateurs de tester rapidement leurs conceptions, obtenez des commentaires concrets, et affiner les produits avant de s'engager dans une production à grande échelle. Au lieu de vous fier à la théorie ou aux dessins 2D, les entreprises peuvent produire des modèles tangibles qui ressemblent, sentir, et parfois même fonctionner comme le produit final.

Dans cet article, nous allons plonger profondément dans le processus, étapes, types, et outils de prototypage rapide, explorer comment il est né, Comment ça fonctionne, et pourquoi il est devenu un pilier essentiel d'industries allant de l'aérospatiale et de l'automobile aux soins de santé et à l'électronique grand public..

À la fin, vous comprendrez non seulement ce qu'est le prototypage rapide, mais également comment choisir la bonne approche pour votre propre projet. Alors, commençons!

Qu'est-ce que le prototypage rapide?

Qu'est-ce que le prototypage rapide

Prototypage rapide (PR) fait référence à un ensemble de techniques utilisées pour fabriquer rapidement un modèle réduit ou une pièce physique directement d'un 3D Conception assistée par ordinateur (GOUJAT) déposer. Contrairement au prototypage traditionnel, ce qui nécessite souvent des moules spécialisés ou de longs processus d'usinage, le prototypage rapide accélère le parcours en créant directement des modèles, généralement couche par couche.

L'une des méthodes les plus courantes de prototypage rapide est 3Impression D. Ici, des matériaux comme le plastique, résines, ou même des métaux sont déposés ou solidifiés couche après couche pour construire un objet physique. Mais le prototypage rapide ne se limite pas à la seule impression 3D. Il comprend également Usinage CNC, coupe à jet d'eau, moulage à vide, et procédés laser.

Pour le dire simplement:

Prototypage traditionnel = lent, cher, et souvent limité à une ou deux itérations.

Prototypage rapide = rapide, abordable, et permet plusieurs itérations jusqu'à ce que la conception soit parfaite.

Cela signifie que les entreprises peuvent tester de nouvelles idées de produits sans investir des sommes énormes dans l'outillage., et ils peuvent également répondre aux commentaires des utilisateurs presque instantanément. Considérez-le comme le « bouton d'avance rapide » du développement de produits.

Un autre aspect critique du prototypage rapide est son Polyvalence. Vous pouvez créer différents types de prototypes, dont certains ressemblent simplement au produit. (pour les présentations et le marketing), et d'autres qui fonctionnent réellement comme le produit (pour les tests de performances). Cette flexibilité en fait une solution incontournable, que vous soyez une startup testant une invention ou une entreprise mondiale peaufinant une pièce de moteur à réaction..

Histoire du prototypage rapide

Comme la plupart des technologies révolutionnaires, le prototypage rapide n’est pas apparu du jour au lendemain. Son histoire commence dans le 1980s, une décennie qui a vu des progrès remarquables dans la technologie informatique, automation, et fabrication.

Qui a inventé le prototypage rapide?

Le mérite de la toute première technique de prototypage rapide revient à Chuck Hull, un ingénieur américain. Dans 1984, La coque inventée stéréolithographie (ANS), une méthode qui utilisait un faisceau laser pour solidifier la résine liquide couche par couche. Ce fut la première imprimante 3D fonctionnelle au monde et le début d’une révolution manufacturière. Hull a ensuite cofondé 3Systèmes D, l'une des entreprises leader dans l'impression 3D aujourd'hui.

Son invention était révolutionnaire parce que, pour la première fois, les concepteurs pourraient passer d'un fichier CAO numérique à un véritable objet 3D sans moules, outils, ou mise en forme manuelle. C'était comme regarder la science-fiction devenir réalité.

Comment le prototypage rapide a-t-il évolué au fil du temps?

De la première imprimante SLA de Hull, la technologie s'est rapidement développée. Peu de temps après est arrivé Modélisation des dépôts fondus (FDM) à la fin des années 1980, une technique où le filament thermoplastique est extrudé à travers une buse chauffée. Puis suivi Frittage sélectif au laser (SLS), qui utilise des lasers pour fusionner des matériaux en poudre comme le nylon ou le métal.

Au fil des décennies, le prototypage rapide a évolué vers des dizaines de techniques, chacun répondant à des besoins spécifiques:

Prototypes très détaillés avec SLA et DLP.

Fort, parties fonctionnelles avec SLS, DMLS, et GDT.

Abordable, modèles faciles à utiliser avec les imprimantes FDM.

Prototypes à grande échelle avec usinage CNC et découpe jet d'eau.

Ce qui a commencé comme une technologie de niche est devenu courant. Aujourd'hui, le prototypage rapide n'est pas seulement utilisé dans les laboratoires de recherche mais également dans les salles de classe, hôpitaux, ateliers, et même des maisons. L’essor des imprimantes 3D de bureau abordables a mis le pouvoir du prototypage rapide entre les mains des étudiants., amateurs, et les entrepreneurs.

En bref, le prototypage rapide est passé du statut de innovations de luxe dans les années 1980 à un nécessité d'un développement de produits moderne au 21ème siècle.

Comment fonctionne le processus de prototypage rapide?

Comment fonctionne le processus de prototypage rapide?

Comprendre la puissance du prototypage rapide, décomposons le processus étape par étape. Quelle que soit la méthode : l’impression 3D, Usinage CNC, ou casting : le parcours de l'idée au prototype suit généralement ces étapes principales:

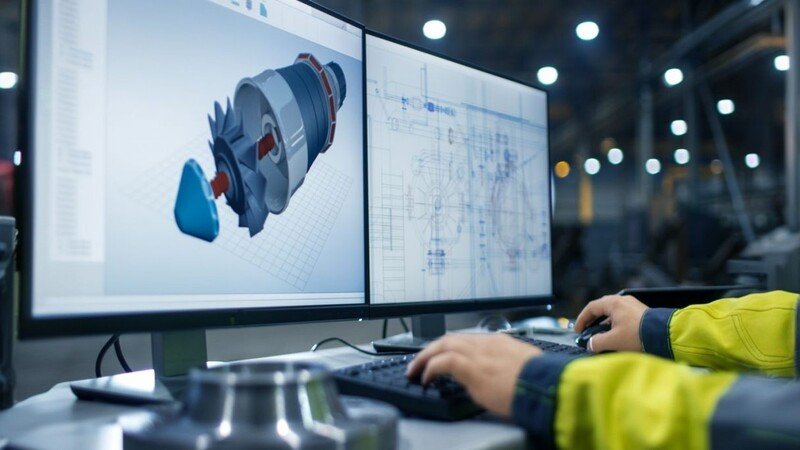

Étape 1: Création de conception

Tout commence par un 3Conception numérique D créé en utilisant Logiciel CAO comme SolidWorks, Autocad, Fusion 360, ou CATIA. Cette étape est cruciale car le fichier numérique sert de « plan » au prototype.. Les concepteurs se concentrent sur la création de modèles précis qui reflètent la taille prévue, forme, et caractéristiques du produit final.

Étape 2: Préparation des données

Une fois le modèle prêt, ça doit être converti dans un format lisible par machine, généralement un Fichier STL. Ce format décompose la conception 3D en minuscules triangles, permettant à la machine de prototypage de l'interpréter et de le recréer couche par couche. Selon la technologie choisie, un logiciel de découpage supplémentaire peut être utilisé pour définir des paramètres tels que l'épaisseur de la couche, vitesse d'impression, et le type de matériau.

Étape 3: Configuration de la machine

Vient ensuite la préparation de la machine de prototypage. Cela implique:

Calibrer la plateforme de construction.

Chargement du matériel approprié (résine, filament, poudre, ou en métal).

Définition des conditions environnementales telles que la température et l'humidité (important pour les matériaux comme le nylon ou la résine).

Étape 4: Bâtiment prototype

La magie opère ici. La machine construit l'objet couche par couche selon la conception CAO. Par exemple:

SLA utilise un laser pour durcir la résine liquide.

Extrudations FDM filament en plastique chauffé.

SLS utilise un laser pour fusionner un matériau en poudre.

Ce processus peut durer de minutes à plusieurs heures, en fonction de la taille, complexité, et méthode choisie.

Étape 5: Post-traitement

Une fois le prototype brut construit, cela nécessite souvent touches finales. Le post-traitement peut inclure:

Ponçage ou polissage pour une surface plus lisse.

Peinture ou revêtement pour des looks réalistes.

Traitement thermique pour plus de solidité.

Assemblage si plusieurs pièces ont été imprimées séparément.

Cette dernière étape transforme le prototype d'un modèle approximatif en quelque chose de prêt à être présenté., essai, voire une utilisation fonctionnelle à petite échelle.

Pourquoi le prototypage rapide est-il important dans la fabrication?

Maintenant que nous avons expliqué ce qu'est le prototypage rapide et comment il fonctionne, parlons-en pourquoi c'est si grave dans l'industrie manufacturière.

Traditionnellement, les entreprises ont dû s'appuyer sur des méthodes de prototypage lentes et coûteuses. Imaginez concevoir une pièce de voiture et attendre des semaines pour un modèle physique, seulement pour découvrir qu'il ne s'adapte pas correctement. Ce retard pourrait coûter des milliers de dollars et des mois d’efforts inutiles. Le prototypage rapide change la donne en permettant des, itérations abordables.

Voici pourquoi c’est vital:

Itérations plus rapides: Les concepteurs peuvent tester plusieurs versions d'un produit en quelques jours au lieu de quelques mois.

Développement rentable: L'identification précoce des défauts de conception réduit le besoin de retouches coûteuses ultérieurement..

Meilleure prise de décision: Parties prenantes, investisseurs, et les clients peuvent physiquement tenir et évaluer un modèle plutôt que de simplement regarder un dessin.

Qualité du produit améliorée: Les prototypes fonctionnels permettent des tests en conditions réelles, s'assurer que le produit final fonctionne comme prévu.

Avantage compétitif: Les entreprises qui utilisent le prototypage rapide peuvent lancer leurs produits plus rapidement, garder une longueur d'avance sur les concurrents.

Prenez le industrie automobile, par exemple. Les constructeurs automobiles utilisent le prototypage rapide pour concevoir des tableaux de bord, pièces de moteur, et systèmes d'éclairage. Au lieu d'attendre des mois, ils peuvent créer un prototype en quelques jours, teste-le, affiner-le, et passez plus rapidement à la production. De la même manière, dans soins de santé, les chirurgiens peuvent s'entraîner sur des modèles anatomiques imprimés en 3D avant d'opérer un patient, ce qui est inimaginable avant le prototypage rapide.

En bref, le prototypage rapide n'est pas qu'un outil; c'est un avantage stratégique pour les entreprises qui souhaitent innover plus rapidement et plus intelligemment.

Avantages du prototypage rapide

Les avantages du prototypage rapide vont bien au-delà de la vitesse. C'est un outil puissant qui transforme la façon dont les produits sont développés et raffinés.. Voyons les principaux avantages:

1. Vitesse de développement

L’un des plus grands atouts du prototypage rapide est sa capacité à transformer rapidement des idées en modèles. Ce qui prenait auparavant des semaines ou des mois peut désormais être réalisé en quelques jours, voire quelques heures.. Cela permet aux entreprises de raccourcir leurs cycles de développement de produits et de réagir plus rapidement aux besoins des clients..

2. Réduction des coûts

Les erreurs de conception peuvent s’avérer coûteuses lorsqu’elles sont découvertes tard dans le processus.. Le prototypage rapide minimise ce risque en permettant des tests précoces. Corriger les défauts d'un prototype coûte bien moins cher que repenser l'intégralité d'un moule de production.. Cela rend le processus de développement global plus économique.

3. Qualité de conception améliorée

Chaque itération d'un prototype améliore la conception. Parce que le prototypage rapide permet des ajustements rapides, les designers peuvent affiner l’esthétique, ergonomie, et la fonctionnalité jusqu'à ce que le produit soit aussi parfait que possible.

4. Encourage la créativité et l’innovation

Avec des méthodes traditionnelles, les concepteurs étaient souvent limités par le coût et le temps. Mais avec un prototypage rapide, ils ont la liberté d'expérimenter. Formes complexes, détails complexes, et les idées audacieuses peuvent toutes être testées sans casser le budget.

5. Personnalisation et personnalisation

Des secteurs tels que la santé et les produits de consommation bénéficient énormément du prototypage rapide. capacité à créer des solutions personnalisées. Des prothèses personnalisées aux wearables sur mesure, les possibilités sont infinies.

6. Tests fonctionnels

De nombreuses méthodes de prototypage rapide produisent des pièces suffisamment solides pour être testées en situation réelle.. Cela signifie que les entreprises peuvent évaluer non seulement l'apparence d'un produit, mais également ses performances..

7. Réduction des déchets

Contrairement à la fabrication soustractive (où le matériau est coupé), de nombreuses méthodes de prototypage rapide sont additif, en utilisant uniquement le matériau nécessaire à la création de la pièce. Cela rend le processus plus respectueux de l’environnement et plus rentable.

8. Avantage du marché

Enfin, la rapidité et la flexibilité du prototypage rapide permettent aux entreprises de battre les concurrents sur le marché. Dans les secteurs en évolution rapide comme l’électronique, cet avantage peut faire la différence entre être leader sur le marché ou prendre du retard.

Principales techniques utilisées dans le prototypage rapide

Le prototypage rapide n’est pas un processus unique. Plutôt, il comprend un variété de techniques, chacun avec ses propres atouts, faiblesse, et applications. Le choix de la bonne technique dépend de facteurs tels que le budget, matériaux, précision souhaitée, et objectif du prototype. Explorons les méthodes les plus largement utilisées.

Stéréolithmicromographie (ANS)

SLA est le grand-père de l'impression 3D, inventé par Chuck Hull en 1984. Cela fonctionne en guérissant résine liquide avec un laser UV, couche par couche, jusqu'à ce qu'un objet solide soit formé.

Avantages: Haute précision, finition de surface lisse, idéal pour les modèles détaillés.

Limites: Les matériaux sont fragiles par rapport aux thermoplastiques, et un post-durcissement est nécessaire.

Mieux pour: Modèles dentaires, prototypes de bijoux, et prototypes visuels nécessitant des détails fins.

Modélisation des dépôts fondus (FDM)

FDM est l'une des méthodes les plus populaires en raison de son prix abordable et de sa facilité d'utilisation.. Il fonctionne en extrudant un filament thermoplastique fondu à travers une buse chauffée.

Avantages: Rentable, large gamme de matériaux (PLA, abdos, PETG, etc.), accessible aux amateurs.

Limites: Résolution inférieure à celle du SLA, lignes de calque visibles.

Mieux pour: Modèles de concepts rapides, prototypes fonctionnels à faible coût.

Frittage sélectif au laser (SLS)

SLS utilise un laser pour fusionner un matériau en poudre-généralement des poudres de nylon ou composites-en couches solides.

Avantages: Pas besoin de structures de support (la poudre fait office de support), pièces fonctionnelles durables, géométries complexes.

Limites: Finition de surface rugueuse, machines coûteuses.

Mieux pour: Prototypes d'ingénierie, pièces fonctionnelles en petits lots.

Traitement numérique de la lumière (DLP)

DLP est similaire à SLA mais utilise un projecteur de lumière numérique au lieu d'un laser. Cela rend le processus plus rapide, car chaque couche peut être durcie en un seul flash de lumière.

Avantages: Grande vitesse, haute résolution.

Limites: Limité aux résines photopolymères, post-durcissement nécessaire.

Mieux pour: Prototypes très détaillés où la vitesse est cruciale.

Fabrication d'objets laminés (LOM)

LOM construit des prototypes en laminant des feuilles de matériau (comme du papier, plastique, ou en métal) et les découper en forme avec des lasers ou des lames.

Avantages: Faible coût, bien pour les grands modèles.

Limites: Mauvaise finition de surface, résolution de détail limitée.

Mieux pour: Modèles conceptuels à grande échelle.

Jet de liant

Dans ce processus, un liant liquide est déposé sur des couches de poudre pour les « coller » ensemble. La pièce est ensuite durcie et parfois infiltrée avec un autre matériau pour plus de résistance..

Avantages: Peut imprimer en couleur, relativement abordable.

Limites: Les pièces sont fragiles à moins d'être post-traitées.

Mieux pour: Prototypes visuels, modèles architecturaux.

Frittage laser direct des métaux (DMLS) & Fusion laser sélective (GDT)

DMLS et SLM sont utilisés pour le prototypage métallique. Ils utilisent des lasers puissants pour fusionner les poudres métalliques couche par couche..

Avantages: Extrêmement durable, adapté aux pièces métalliques d'utilisation finale.

Limites: Coût élevé, nécessite une opération experte.

Mieux pour: Aérospatial, automobile, et implants médicaux.

Fusion par faisceau d'électrons (EBM)

EBM utilise un faisceau d'électrons au lieu d'un laser faire fondre des poudres métalliques.

Avantages: Pièces métalliques solides, stress interne minimal.

Limites: Limité aux métaux conducteurs, cher.

Mieux pour: Implants aérospatiaux et orthopédiques.

Impression PolyJet

PolyJet fonctionne en pulvérisant de minuscules gouttelettes de résine liquide et en les durcissant à la lumière UV. Plusieurs matériaux et couleurs peuvent être imprimés en un seul passage.

Avantages: Multi-matériaux, détail élevé, look réaliste.

Limites: Durabilité matérielle limitée, cher.

Mieux pour: Des prototypes qui nécessitent une esthétique réaliste.

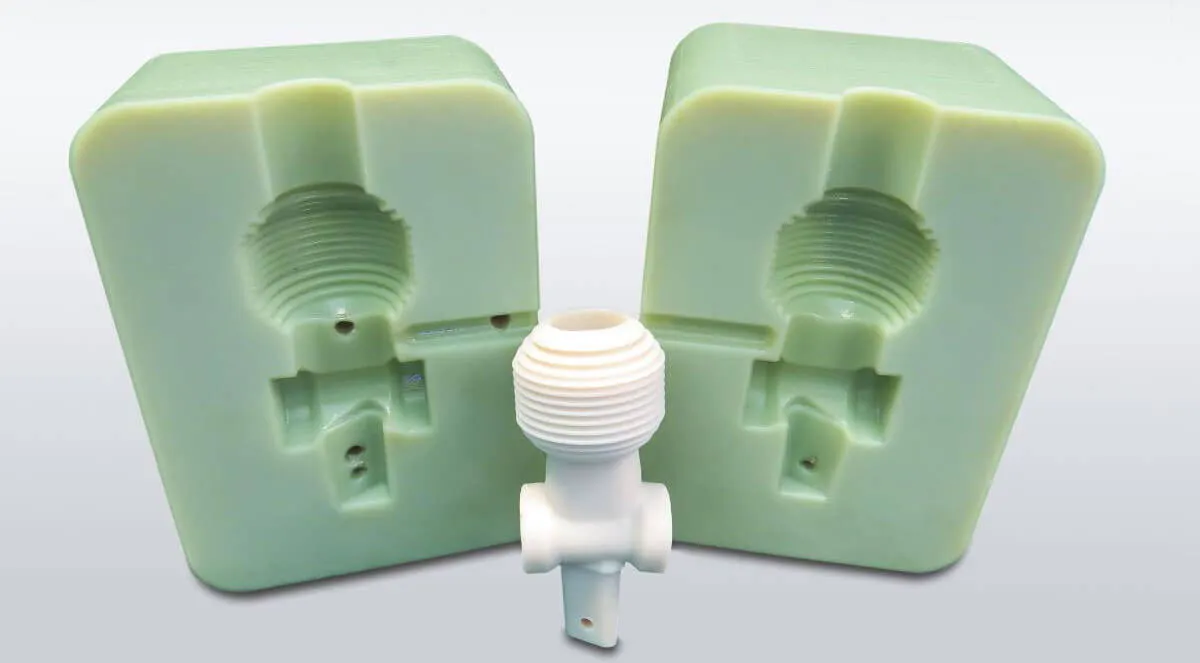

Moulage par injection avec outillage rapide

Moulage par injection avec outillage rapide

Cela implique de créer des moules rapidement (via impression 3D ou CNC) et les utiliser pour le moulage par injection en petits lots.

Avantages: Produit des pièces réelles identiques à la production finale.

Limites: L'outillage prend encore du temps et de l'argent.

Mieux pour: Production de pont entre le prototype et la fabrication de masse.

Fusion multi-jets (mjf)

MJF utilise un agent fondant déposé sur un lit de poudre, qui est ensuite fondu par la chaleur.

Avantages: Pièces fonctionnelles solides, détail fin, plus rapide que SLS.

Limites: Options matérielles limitées (principalement du nylon).

Mieux pour: Prototypes fonctionnels nécessitant solidité et détails.

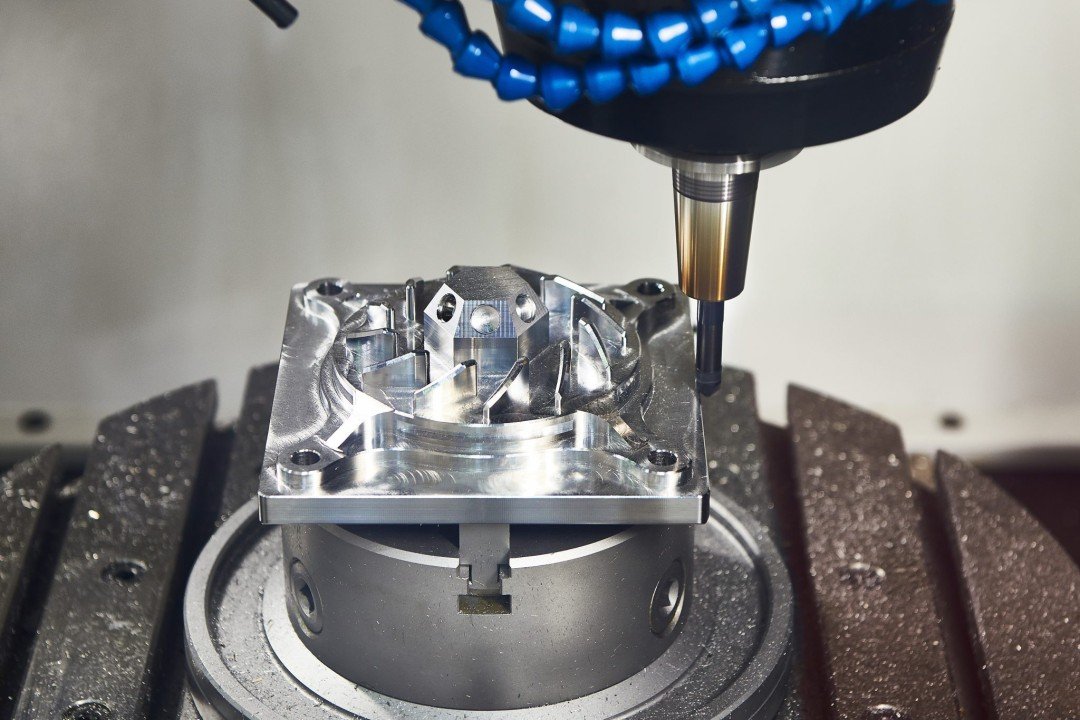

Usinage CNC

Usinage CNC

Bien que non additif, L'usinage CNC est considéré comme un prototypage rapide car il permet de produire rapidement des prototypes à partir de matériaux réels..

Avantages: Haute résistance, précision, et de larges options de matériaux (les métaux, plastiques).

Limites: Processus soustractif, gaspillage de matériel.

Mieux pour: Prototypes d'ingénierie et tests fonctionnels.

Découpe au jet d'eau

Découpe au jet d'eau

Utilise de l'eau à haute pression (parfois avec des abrasifs) couper un matériau.

Avantages: Peut couper presque tous les matériaux, y compris le métal et le verre.

Limites: Limité aux conceptions 2D ou plates.

Mieux pour: Prototypes plats rapides.

Moulage à vide

Moulage à vide

Cette technique crée des moules en silicone à partir d'un maître modèle, qui sont ensuite utilisés pour produire des prototypes en plastique.

Avantages: Rentable pour la production à faible volume, reproduit la qualité du moulage par injection.

Limites: Pas idéal pour les volumes élevés.

Mieux pour: Exécutions de pré-production et tests fonctionnels.

Types de prototypage rapide

Différents projets nécessitent différents types de prototypes. Voici les principaux types:

Prototypes de validation de principe

Ce sont des modèles simples utilisés pour démontrer la faisabilité. Ils ne ressemblent peut-être pas au produit final, mais servent à valider si l'idée fonctionne..

Prototypes basse fidélité

Modèles de base créés rapidement, souvent pour des discussions internes. Ils privilégient la rapidité et le coût plutôt que l'apparence.

Prototypes haute fidélité

Détaillé, des modèles réalistes qui ressemblent beaucoup au produit final en termes d'apparence et de sensation. Utilisé pour les présentations et les pitchs d'investisseurs.

Prototypes ressemblant

Concentrez-vous sur l’esthétique – la forme, couleur, la texture plutôt que la fonction. Idéal pour le marketing ou les commentaires des clients.

Prototypes fonctionnels

Contrairement aux prototypes qui ressemblent à des prototypes, l'accent est mis sur la fonctionnalité plutôt que sur l'apparence..

Prototypes d'ingénierie

Utilisé pour tester les propriétés mécaniques, performance, et durabilité dans des conditions réelles.

Validation & Fabrication de prototypes

Il s'agit de versions quasi finales utilisées pour tester la fabricabilité, assemblée, et le respect des normes.

Rôle du logiciel dans le prototypage rapide

Le matériel peut construire les pièces, mais le logiciel pilote le processus. Sans outils avancés de conception et de simulation, un prototypage rapide ne serait pas possible.

Logiciel de CAO

Des outils comme Autocad, Solide, Catia, et Fusion 360 sont la base du prototypage. Ils permettent aux concepteurs de créer des modèles 3D détaillés.

Simulation & Logiciel d'analyse

Des programmes comme ANSYS et CFD Autodesk simuler les contraintes du monde réel, débit de fluide, ou transfert de chaleur sur les conceptions avant qu'elles ne soient testées physiquement.

Logiciel Slicer pour l'impression 3D

Des applications comme Traitement, Simplifier3D, et Slic3r préparer des fichiers CAO pour l'impression 3D en les découpant en couches.

Logiciel de FAO pour CNC

Des logiciels tels que Mastercam et GibbsCAM convertit les conceptions CAO en instructions machine pour l'usinage CNC.

Outils de prototypage spécialisés

PréForme (pour les imprimantes SLA).

Matérialiser la magie (pour l'édition STL).

Aperçu (pour machines FDM industrielles).

En bref, le bon logiciel garantit que les prototypes sont précis, efficace, et fiable.

Matériaux utilisés dans le prototypage rapide

Matériaux utilisés dans le prototypage rapide

Le matériau que vous choisissez peut faire ou défaire votre prototype. Différentes technologies permettent différents matériaux:

Plastiques

abdos, PLA, PETG, Nylon, Polycarbonate.

Largement utilisé en raison de son prix abordable, Polyvalence, et facilité d'impression.

Les métaux

Aluminium, Titane, Acier inoxydable, Inconel.

Idéal pour les forts, prototypes fonctionnels dans l'aéronautique et l'automobile.

Résines

Photopolymères utilisé en SLA et DLP pour les pièces très détaillées.

Les options incluent la flexibilité, difficile, transparent, ou résines coulables.

Matériaux composites

Fibre de carbone, fibre de verre, Plastiques renforcés de Kevlar.

Des matériaux légers mais solides pour des pièces hautes performances.

Céramique et Cire

Utilisé pour des applications spécialisées comme les couronnes dentaires ou le moulage de précision.

Applications du prototypage rapide dans tous les secteurs

Le prototypage rapide s'est répandu dans presque tous les secteurs. Voici où ça brille le plus:

Automobile

Composants du moteur, tableaux de bord, et prototypes d'éclairage.

Réduit les délais de commercialisation des nouveaux modèles de voitures.

Aérospatial

Pièces légères aux géométries complexes.

Essentiel pour réduire la consommation de carburant et améliorer l’efficacité.

Soins de santé

Prothèses sur mesure, implants, et guides chirurgicaux.

3Modèles anatomiques imprimés en D pour la pratique avant la chirurgie.

Electronique grand public

Coques de téléphone, appareils portables, et prototypes d'appareils.

Aide les marques à affiner l'ergonomie et le design avant le lancement.

Architecture

Maquettes de bâtiments pour présentations clients.

Mode & Vêtements

Chaussure, bijoux, et accessoires personnalisés.

Éducation & Recherche

Outils pédagogiques, expériences en laboratoire, et projets étudiants.

Divertissement & Film

Accessoires, costumes, et effets spéciaux.

Équipement sportif

Casque, raquettes, et des équipements améliorant les performances.

Robotique & Automatisation

Composants mécaniques fonctionnels pour tester les robots et les systèmes d'automatisation.

Limites du prototypage rapide

Si le prototypage rapide est un procédé révolutionnaire, ce n'est pas sans son défis et inconvénients. Comprendre ces limites aide les entreprises à définir des attentes réalistes et à choisir la méthode adaptée à leurs besoins..

1. Limitations de matériaux

Tous les matériaux utilisés dans le prototypage ne conviennent pas à la production finale. Par exemple, les résines photopolymères utilisées dans le SLA sont fragiles par rapport aux plastiques industriels, et de nombreux métaux imprimés en 3D peuvent nécessiter un post-traitement pour plus de résistance..

2. Contraintes de taille

La plupart des machines de prototypage rapide ont des volumes de construction limités. Les grandes pièces doivent être imprimées en sections puis assemblées, ce qui peut affecter la résistance et l'esthétique.

3. Problèmes de finition de surface

Quelques méthodes, comme FDM, laisser des lignes de couche visibles qui nécessitent un ponçage ou un polissage. Bien que cela puisse être amélioré avec le post-traitement, cela ajoute du temps et des coûts.

4. Résistance et durabilité

Tous les prototypes ne peuvent pas résister aux contraintes du monde réel. Par exemple, Les pièces SLA peuvent paraître époustouflantes mais manquent souvent de durabilité pour les tests fonctionnels.

5. Coût de la production à grande échelle

Même si le prototypage rapide est rentable pour les modèles uniques ou les petits lots, ce n'est pas toujours adapté à la fabrication en grand volume. Pour des courses plus grandes, les méthodes traditionnelles comme le moulage par injection restent plus économiques.

6. Problèmes de précision et de tolérance

Même si la technologie s'améliore, certaines méthodes de prototypage peinent encore à respecter des tolérances très strictes. Cela peut poser un problème pour des secteurs comme l'aérospatiale ou les dispositifs médicaux, où la précision est essentielle..

En bref, tandis que le prototypage rapide est incroyablement puissant, il est préférable de le considérer comme un compléter – et non remplacer – la fabrication de masse.

Coûts associés au prototypage rapide

Le coût du prototypage rapide dépend de plusieurs facteurs, et les comprendre est crucial pour la budgétisation.

Facteurs qui influencent le coût

type de materiau – Les plastiques sont moins chers que les métaux, tandis que les résines spéciales ou les composites coûtent plus cher.

Complexité de la conception – Les conceptions complexes nécessitent plus de temps machine et de matériel.

Taille du prototype – Les modèles plus grands consomment plus de ressources.

Besoins de post-traitement – Polissage, peinture, ou le traitement thermique augmente les coûts.

Technologie utilisée – SLA et FDM sont moins chers; les techniques à base de métal comme le DMLS sont beaucoup plus coûteuses.

Fourchettes de coûts estimés

Prototypes FDM: $10–200$ (en fonction de la taille et du matériau).

Modèles SLA: $50–500$.

Pièces fonctionnelles SLS: $200–2 000$.

Prototypes métalliques (DMLS/SLM): $500–10 000$+.

Pièces usinées CNC: $100–5 000$ selon la complexité.

Comparaison des coûts avec le prototypage traditionnel

Les méthodes traditionnelles comme le moulage par injection nécessitent un outillage coûteux, souvent de plusieurs dizaines de milliers de dollars.. En revanche, prototypage rapide élimine les coûts d’outillage, ce qui le rend beaucoup plus économique pour la conception précoce et les petites séries de production.

Bien que ce ne soit pas toujours le moins cher pour une production de masse, le prototypage rapide fournit économies massives pendant le développement et les tests, là où la flexibilité compte le plus.

Erreurs courantes à éviter dans le prototypage rapide

Même si le prototypage rapide est conçu pour simplifier le développement, les erreurs peuvent encore faire dérailler les projets. Voici quelques pièges courants:

1. Négliger la conception pour la fabricabilité (DfM)

Un prototype peut avoir fière allure, mais peut ne pas être réalisable pour une production à grande échelle. Concevez toujours en gardant à l’esprit la fabricabilité éventuelle.

2. Choisir le mauvais matériau

L’utilisation d’un mauvais matériau peut produire des résultats de test trompeurs. Par exemple, tester la résistance mécanique avec de la résine fragile au lieu du plastique industriel peut donner de fausses données de performances.

3. Ignorer les tolérances

Toutes les méthodes n'offrent pas une haute précision. Si vous avez besoin de tolérances strictes, les technologies comme CNC ou SLM pourraient être meilleures que FDM ou SLA.

4. Ignorer des tests approfondis

Un prototype n'est pas seulement destiné à l'apparence, c'est aussi à tester. Sauter les tests de résistance, essais thermiques, ou les commentaires des utilisateurs peuvent conduire à des erreurs coûteuses plus tard.

5. Négliger le post-traitement

De nombreux prototypes nécessitent un ponçage, peinture, ou traitement thermique. Ne pas en tenir compte peut conduire à des modèles inachevés ou irréalistes..

6. Trop se concentrer sur l’esthétique

Même si un beau modèle est important, la fonction ne doit jamais être sacrifiée. Un équilibre entre esthétique et performance garantit un produit final réaliste.

Éviter ces erreurs garantit que vous obtenez le résultats les plus précis et les plus utiles de vos efforts de prototypage.

Comment choisir la bonne méthode de prototypage rapide

Avec autant de techniques disponibles, choisir le bon peut être écrasant. Voici un guide pratique:

1. Tenir compte des exigences du projet

Avez-vous besoin d'un modèle pour présentation visuelle? → SLA, DLP, ou PolyJet.

Avez-vous besoin tests fonctionnels? → SLS, FDM, CNC, ou MJF.

Avez-vous besoin d'un prototype en métal? → DMLS, GDT, ou EBM.

2. Évaluer les besoins matériels

Pour plastiques résistants → Nylon (SLS, mjf).

Pour la flexibilité → TPU ou résine flexible.

Pour métaux → Aluminium, Titane, ou en acier inoxydable.

3. Évaluer la précision et la complexité

Si votre prototype implique des détails complexes, choisissez le SLA, DLP, ou PolyJet. Pour les grands, pièces robustes, CNC ou FDM peuvent être meilleurs.

4. Équilibrer le coût et le budget

Si vous travaillez avec des fonds limités, FDM est le plus abordable. Pour les budgets plus élevés où les détails et la solidité comptent, investir dans le SLA, SLS, ou impression sur métal.

5. Tenir compte du délai de mise sur le marché

Si la vitesse est critique, DLP et PolyJet offrent le délai d'exécution le plus rapide.

6. S'aligner sur les exigences du produit final

Votre prototype doit imiter le produit final aussi fidèlement que possible, que ce soit en termes de résistance., flexibilité, ou l'esthétique.

7. Durabilité et impact environnemental

Certaines industries privilégient les matériaux écologiques. Envisagez des plastiques biodégradables ou des matériaux recyclables lorsque cela est possible.

En pesant ces facteurs, vous pouvez prendre une décision éclairée qui maximise l'efficacité, qualité, et rentable.

Conclusion

Le prototypage rapide est plus qu'un simple outil : c'est un changement de paradigme dans le développement de produits. Depuis ses modestes débuts dans les années 1980 avec la stéréolithographie de Chuck Hull jusqu’à la vaste gamme de techniques actuelles, cela a transformé la façon dont les idées deviennent réalité.

Il offre de la vitesse, flexibilité, et des économies de coûts que les méthodes de prototypage traditionnelles ne pourraient jamais égaler. Que vous créiez une preuve de concept rapide, tester une conception fonctionnelle, ou se préparer à une production de masse, le prototypage rapide permet des itérations plus rapides, risque réduit, et une innovation améliorée.

Bien sûr, il a ses limites, telles que les restrictions matérielles et les problèmes de coûts pour une production à grande échelle, mais lorsqu'il est utilisé de manière stratégique, c'est l'un des outils les plus puissants pour la fabrication moderne.

Alors que les industries continuent d'évoluer, le prototypage rapide ne fera que gagner en importance, permettre aux entreprises, entrepreneurs, et même des amateurs pour donner vie à leurs idées plus rapidement que jamais.

FAQ

1. Quelles sont les techniques de prototypage rapide les plus courantes?

Certaines des techniques les plus largement utilisées incluent le SLA, FDM, SLS, DLP, Usinage CNC, et DMLS pour les métaux. Chacun a des atouts uniques en fonction des besoins du projet.

2. Quelles industries bénéficient le plus du prototypage rapide?

Des secteurs comme l'automobile, aérospatial, soins de santé, électronique grand public, et l'éducation sont les principaux adeptes. Ils l'utilisent pour tout, des implants médicaux aux composants automobiles.

3. Le prototypage rapide est-il adapté à la production de masse?

Pas directement. Même si le prototypage rapide est idéal pour la conception, essai, et production en petites séries, la production de masse est encore mieux servie par les méthodes traditionnelles comme le moulage par injection.

4. En quoi le prototypage rapide diffère-t-il de l'impression 3D?

3L'impression D est un sous-ensemble du prototypage rapide. Alors que l’impression 3D est une fabrication additive, le prototypage rapide inclut également des méthodes telles que l'usinage CNC, moulage à vide, et découpe au jet d'eau.

5. Quel est l’avenir du prototypage rapide?

L'avenir réside dans des machines plus rapides, matériaux plus durables, et intégration avec une conception basée sur l'IA. Nous verrons probablement le prototypage rapide devenir encore plus courant dans les applications de fabrication et grand public..