Dans la fabrication de précision et le prototypage, choosing the right machining method can make the difference between a functional part and a costly redesign. While conventional Fraisage CNC et tournant excel in speed and versatility for many applications, Usinage par décharge électrique (GED) offers unique capabilities that are impossible—or prohibitively expensive—to achieve otherwise. This article explores seven specific scenarios in which EDM outperforms traditional machining, providing engineers and designers with clear criteria for selecting the optimal process for their next project.

What Is EDM?

Basic Principle

GED removes material through a series of controlled electric discharges (des étincelles) rather than physical cutting. A conductive electrode (either a shaped tool or a fine wire) is positioned just above the workpiece, both submerged in a dielectric fluid. When a voltage is applied, the dielectric breaks down at the microscopic gap, generating a spark that melts and vaporizes a tiny amount of the workpiece. The dielectric fluid then flushes away the eroded particles.

Two Main EDM Types

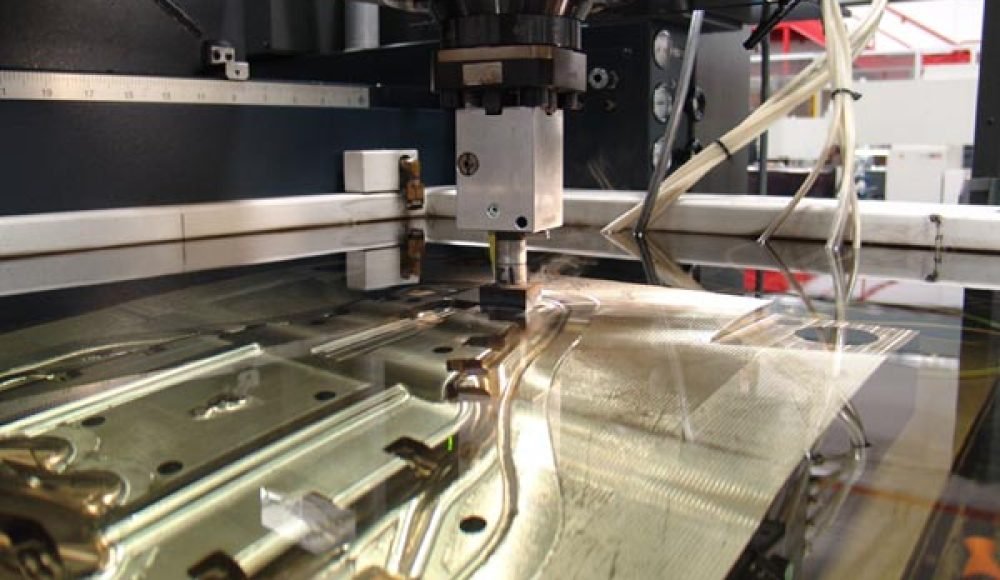

Sinker (Die-sinking) GED

Uses a pre-shaped electrode (often copper or graphite) to “stamp” complex 3D cavities into hardened metals.

Ideal for injection-molding and die-casting tooling where intricate mold features are required.

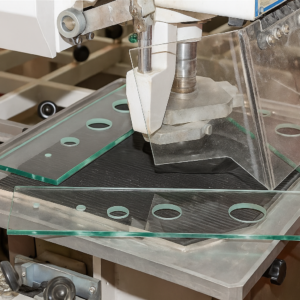

Électroérosion à fil

Employs a continuously fed, tensioned brass or coated wire (as thin as 0.1 mm) to cut through thick plates.

Enables precise 2D profiles and piercing holes in materials up to several hundred millimeters thick.

Key Characteristics of EDM

Non-contact process: Aucune force de coupe mécanique, virtually eliminating tool deflection and part deformation.

Hard-material compatibility: Equally effective on hardened steels, carbures, Superalliages, et plus.

Geometry freedom: Can produce steep walls, coins internes pointus, and undercuts that are impossible with rotary cutters.

Seven Situations Where EDM Performs Betther Than Usinage conventionnel

When Sharp Internal Corners Are Required

CNC limitation: Même un 1 mm end mill leaves a 0.5 mm radius at internal corners.

Wire-EDM advantage: With wire diameters as small as 0.1 mm, corner radii can shrink to 0.005″ (0.127 mm).

Application example: Precision mold inserts for microfluidic channels or semiconductor packaging.

When Very Deep Cavities or Holes Are Needed

CNC challenge: High length-to-diameter ratio tools (>10:1) induce chatter, Mauvaise finition de surface, and potential tool breakage.

EDM capability: Consistent depth-to-diameter ratios of 20:1 are routine; ratios up to 100:1 are achievable with specialized setups.

Use case: Deep electrode pockets in stamping dies or thin, high-aspect-ratio holes in fuel injector nozzles.

When Machining Extremely Hard Materials

Matériaux: AFFAIRS OUTILS DURANCÉS (CRH 60+), carbure de tungstène, Inconel alloys, titane, and Hastelloy.

EDM strength: Material hardness has minimal impact on spark erosion rate, allowing tight tolerances even in 65 Rc steel.

Industry example: Aerospace turbine blade root slots in Inconel 718 or medical-grade carbide burrs.

When a Mirror-Like Surface Finish Is Desired

Conventional finish: Milling leaves a directional “lay” of tool marks; grinding can still require manual polishing.

EDM finish tuning:

Low-energy, slow-pass strategy: Reduces crater size to produce Ra ≈ 0.1 µm (≈ 4 min) without post-machining.

Abrasive-assisted EDM: Adding fine aluminum oxide or silicon carbide powder to the dielectric fluid produces in-process micro-polishing.

Exemple: Die surfaces for optical tooling or reflector molds in lighting systems.

For Lights-Out, Unattended Production

Process stability: EDM runs with constant gap control and minimal mechanical wear, reducing intervention.

Automation potential: Robotic loaders can change electrodes or workpieces, permettre 24/7 “lights-out” operation.

Avantage: Maximizes equipment utilization for high-volume tooling orders during off-peak hours.

When Manufacturing Molds and Tooling

Hybrid workflows:

CNC roughing: Remove bulk material rapidly.

Die sinker EDM: Machine complex 3D cavities and parting lines.

Électroérosion à fil: Cut out finished cores and cavities from hardened blocks.

Outcome: Superior accuracy in mold inserts and reduced lead times compared to full CNC machining.

When Ultra-Tight Tolerances Are Needed

Tolerance capability: With multiple refinement passes, EDM routinely achieves ±0.0002″ (±5 µm).

No mechanical stress: Absence of cutting forces eliminates spring-back or distortion in thin walls.

Critical parts: Precision gauges, metrology fixtures, and high-accuracy dies where every micron counts.

EDM vs. Usinage conventionnel: Key Trade-Offs

| Aspect | Conventional CNC | GED |

| Material removal rate | Haut | Moderate to low |

| Tolérance | ±0.001″–±0.005″ | ±0.0002″ |

| Finition de surface | Ra 0.8–3.2 µm typical | Ra 0.1–1.0 µm achievable |

| Géométrie | Limited by cutter shape | Virtually any shape possible |

| Equipment cost | Lower per machine | Plus haut, plus electrode cost |

| Taille de lot | Flexible, small to large | Best for prototyping, low to medium volume |

Guidelines for Choosing EDM

Assess Part Geometry

Sharp internal corners, Cavités profondes, or fine features → lean toward EDM.

Evaluate Material Hardness

Hardened steels (> 60 Rc), carbures, and superalloys are prime EDM candidates.

Determine Tolerance Requirements

< ±0.001″ tolerance and no mechanical stress allowed → EDM excels.

Balance Cycle Time vs. Coût

For high-volume simple prismatic parts, CNC milling remains faster and more cost-effective.

For complex, à faible volume, or critical-tolerance parts, EDM’s precision justifies its slower rate.

Optimize EDM Parameters

Electrode selection: Copper for speed, graphite for fine detail, coated wires for surface quality.

Discharge settings: Use roughing parameters for bulk removal, then switch to finishing settings for mirror surfaces.

Dielectric management: Maintain fluid purity and temperature to ensure consistent spark behavior.

Conclusion & Next Steps

Electrical Discharge Machining bridges the gap between cutting-tool limitations and design ambitions. By harnessing spark erosion, EDM enables:

Pointu, square internal corners with sub-0.005″ radii

Deep, high-aspect-ratio cavities free from chatter

Precision machining of the hardest engineering alloys

Mirror-quality surfaces without manual polishing

Unmanned, continuous production for improved throughput

Ultra-tight tolerances down to ±5 µm

When your design demands geometry, dureté, or precision beyond CNC milling’s reach, integrate EDM into your workflow. During the design phase, flag features such as acute corners, deep slots, or critical dimensions and consult with an EDM specialist. For a detailed feasibility study and a free precision-machining quote, contact the experts at Tops Precision or your trusted EDM provider today.

En savoir plus

Conseils de conception pour le moulage sous pression

Precision CNC Machining Services