- Certified aerospace material machining such as Ti-6Al-4V, 7050 and 7150 aluminium alloys, and high temperature superalloys (such as Inconel).

- High multi-axis capabilities through 5-axis and 6-axis machines to deal with complicated forms with minimum setups and high repeatability.

- Full traceability and well-developed, strong internal quality systems in AS9100-certified processes.

- In-process probing, in-line measurements, and SPC of real-time quality monitoring to provide early detection of errors.

- Home

- Services

- Industries

- Automation

- Consumer Electronics

- Medical CNC Machining

- PCB Milling

- Aerospace Machining

- Automotive CNC Machining

- CNC Machined Bicycle Parts

- CNC Bottle Opener Machining

- CNC Camshaft Machining

- CNC Screw Machining

- CNC Machining Spare Parts

- CNC Piston Machining

- CNC Machined Gifts

- CNC Machined Fly Wheel

- CNC Machined Safety Razor

- CNC Machined Fidget Spinner

- CNC Machined Dice

- CNC Machined Chess Pieces

- Gallery

- Resources

- About Us

Aerospace Machining

We deliver aerospace components with tolerances as tight as ±0.002 mm and surface finishes up to Ra 0.2 μm, ensuring flawless performance in critical systems.

Our machining processes comply with ISO 9001 standards, backed by 100% dimensional inspection and CMM verification.

From turbine components to structural parts, every piece is manufactured with absolute accuracy, consistency, and reliability for mission-critical aerospace applications.

Send Your Inquiry Today

Aerospace CNC Machining Capabilities at Tops Precision

- We offer CNC machining for aerospace parts with precision built into every step. From raw material to final inspection, each component meets strict quality and performance standards.

- Tolerances down to ±0.0001 inchesfor critical engine parts like turbine blades, and ±0.002 to 0.005 inches for structural sections such as fuselages and control surfaces

- Rotating parts require surface finishes as fine as 0.25µin Ra, and our general aerospace machining typically achieves 8 µin Ra.

Advantages of Aerospace CNC Machining

At Tops Precision, we understand what aerospace components demand. Accuracy, reliability, and consistency come first. That’s why we use CNC machining to deliver exact results on every part.

Our process holds tight tolerances across full-scale runs. You always receive parts that meet critical specifications without variation. From engine mounts to structural brackets, each component is built to perform.

We work with advanced materials used across aerospace platforms. This includes titanium alloys, aluminium grades, and high-strength superalloys. Our machining protects material integrity and supports complex designs with ease.

Repeatability is another key advantage. Once a part is programmed, each unit follows the same precise path. That means no deviation in shape, size, or finish. So, you can count on us for medium to high-volume output.

Our CNC machining allows faster production without cutting corners. With fewer setups and real-time checks, we avoid delays and keep your project on track.

Every stage of the process is designed to meet strict aerospace standards. From early prototypes to final builds, Tops Precision ensures consistent quality with every part.

Send Your Inquiry Today

Aerospace CNC Machining Materials

At Tops Precision, we machine a wide range of aerospace-approved materials. Each is selected based on performance, weight, and thermal properties. Here is a quick overview of the materials we work with and how they’re used in real aerospace components.

| Material | Common Aerospace Applications | Machining Notes |

| Ti‑6Al‑4V Titanium | Turbine housings, engine brackets, landing gear parts | High strength and heat resistance, slower cutting speeds |

| 7075 / 7050 Aluminium | Fuselage frames, bulkheads, wing ribs | Lightweight, strong, easily machined |

| Inconel 718 / 625 | Exhaust parts, nozzles, combustion components | Excellent at high temps, requires rigid tooling |

| Stainless Steel (17-4, 15-5) | Structural mounts, clamps, and connector housings | Strong and corrosion-resistant, moderate machinability |

| Magnesium Alloys | Interior brackets, housings, enclosures | Extremely lightweight, needs controlled machining |

| Aerospace Plastics (PEEK, Ultem) | Insulation covers, cable guides, interior panels | Easy to machine, excellent thermal stability |

Send Your Inquiry Today

Aerospace CNC Machining Processes

At Tops Precision, we offer advanced CNC machining methods to meet your aerospace needs. We initially evaluate your diagram, choose the part’s shape, material, and how it will be used. Our goal is to provide precise, reliable parts every time.

3-Axis CNC Milling

The cutting tool is moved in 3 directions by 3-axis milling to create shapes on parts. It is effective with flat surfaces and single simple shapes, such as mounting plates and covers. Many simple aerospace parts can be produced with a high degree of precision in a short period.

We are oriented to maintaining close tolerances and finishes, particularly when using a material such as aluminium or titanium. That makes your components fit in the right places, right as intended.

4-Axis CNC Milling

With an additional fourth axis, this allows us to achieve intricate patterns. This implies that we are able to create the angled characteristics and rounded lines without having to remove the part. It is time-saving and precise.

This is perfect in cases of parts such as brackets or clamps that require precise machining on both sides. It also eliminates mistakes and accelerates the production process.

CNC Milling 5-Axis

We have 5-axis milling machines. These can move the tool in five directions simultaneously. This allows us to work with very complicated components with severe curvature or complicated shapes. This is applied in turbine blades, airfoils, and other extremely important components.

We save on accuracy through machining the parts all at once, eliminating errors that occur when several setups are used.

CNC Turning

It is ideal to use turning on circular parts such as shafts and bushings. We produce these parts on CNC turnings with close size control and smooth finishing. This is important for parts that revolve or come together.

We change the speed of cutting according to the material to prevent damage and maintain the parts' strength. Our turning machines are able to work both small- and large-scale production runs.

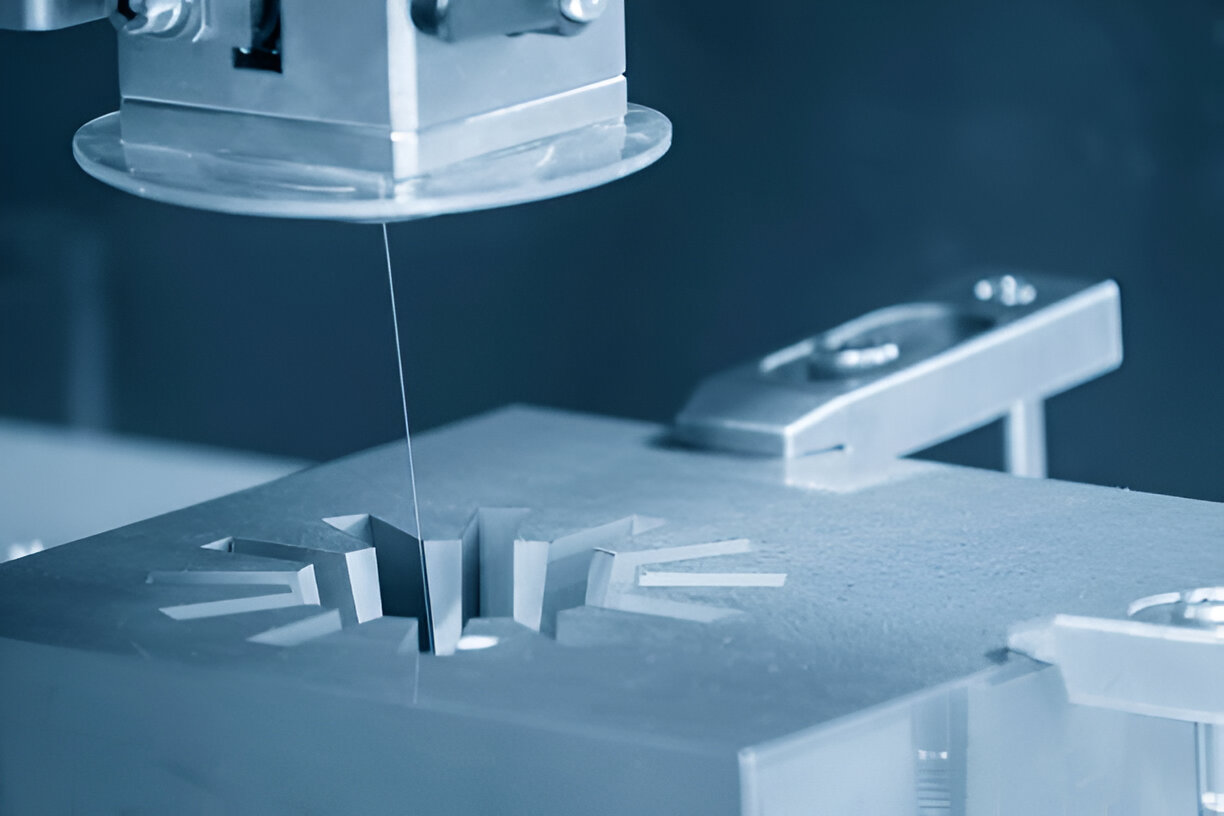

Wire EDM Machining

Wire EDM uses fine wire integrated with electric sparks to cut extremely precise shapes in hard materials. This is an economical process when it comes to working with parts having Sharp internal corners, tight-tolerance slots, intricate 2D profiles that cannot fit other machines. Inconel and hardened steel are tough materials we resort to Wire EDM. It does not heat or stress the metal at all and consequently produces clean edges.

Send Your Inquiry Today

High Precision Components and Tight Tolerances

At Tops Precision, we focus on producing aerospace parts with exacting precision. We regularly produce precision aerospace parts with close tolerances of +/-0.001 to 0.005 inches, with close attention to the requirements of the project.

To make everything in the right position, we also use GD&T callouts. We normally start at 0.020 inches, depending on the shape and material, with our smallest feature size.

In addition, we provide standard and customised threading services as well as tapped holes. Our machines can handle large-sized pieces that are 80 by 48 by 24 inches, and turned pieces are 62 inches long and 32 inches in diameter. So, we are in a position to accept very diverse aerospace parts, whether minor precision or major structure.

Aerospace Manufacturing Certifications

- AS9100

- ISO 9001

- NADCAP

- FAA Part 21

- ITAR Compliance

- MIL-STD-810

- RoHS Compliance

Send Your Inquiry Today

Why Choose Tops Precision for Aerospace CNC Machining

Choosing the right machining partner for aerospace parts is critical. At Tops Precision, we focus on precision, reliability, and deep industry knowledge to ensure your components perform exactly as needed.

Extensive Aerospace Experience

We have practical experience dealing with high standards of aerospace manufacturing. We are familiar with the requirements and standards that the parts should meet. This assists us in producing parts that are just right and can work safely in the harshest environments.

High Tech CNC Machinery

The workshop we have is fully equipped with modern CNC machines such as 5-axis milling centres and a precision lathe. We can machine complex shapes and fine details accurately using those tools. We take good care of our machines, and they are calibrated, which means you receive the same quality time after time.

Expertise with Aerospace Materials

Using titanium, Inconel, and high-quality aluminium alloys requires workmanship and attention. We modify our machining processes to guard against destruction or deformation of these materials. This will assure you that your parts will not lose their strength or perform below par.

Solid Quality Controls

All parts are inspected during manufacturing. We have in-line measurements and real-time observation in our process to detect any problems at their early stage. We also follow each stage of the process, from rough to finished component, so you know the history and quality of your components.

Send Your Inquiry Today

Frequently Asked Questions

We machine a variety of aerospace materials, including titanium alloys, aluminium, Inconel, and stainless steel. These materials are chosen for their strength, durability, and performance in demanding environments.

We can hold tolerances between plus or minus 0.001 inches and 0.005 inches. This level of precision is essential for parts that must fit and function perfectly in aerospace applications.

We provide 3-, 4-, and 5-axis CNC milling, CNC turning, and wire EDM. This range allows us to handle everything from simple shapes to very complex components with high accuracy.

Yes, every part goes through thorough inspections, including Coordinate Measuring Machine (CMM) reports, ultrasonic testing, and surface inspections. We ensure your parts meet all quality standards before delivery.

Absolutely. Our machines can work on milled parts up to 80 inches long and turned parts up to 62 inches long with large diameters. We can handle small precision parts and larger structural components alike.