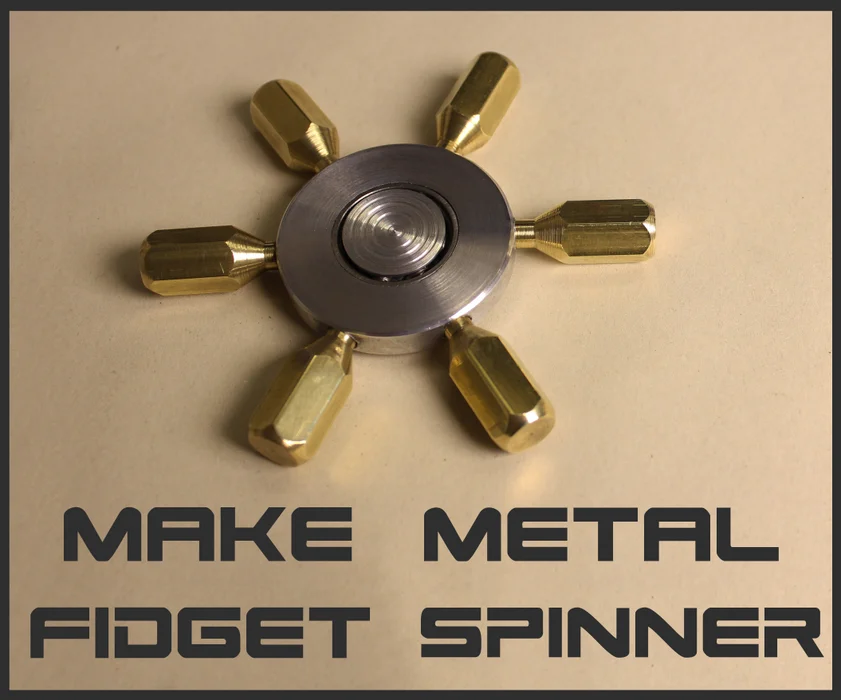

Our CNC Machined Fidget Spinners Provide Perfect Balance Every Time

Balance starts at the machine bed. To remove bulk material, we first cut raw blanks on a Haas VF-4 vertical machining center. From there, finishing takes place on our DMG Mori 5-axis machines, where toolpaths are programmed to keep material removal perfectly even across every arm.

We maintain the concentricity of the bearing seat to the outer profile within five microns, as checked on our Mitutoyo coordinate measuring machine. By running these checks at multiple stages, we eliminate drift that could throw off weight distribution.

The result is a fidget spinner that stays centred. Each rotation feels steady in your hand, without wobble, resistance, or noise, just pure, repeatable balance with every spin.