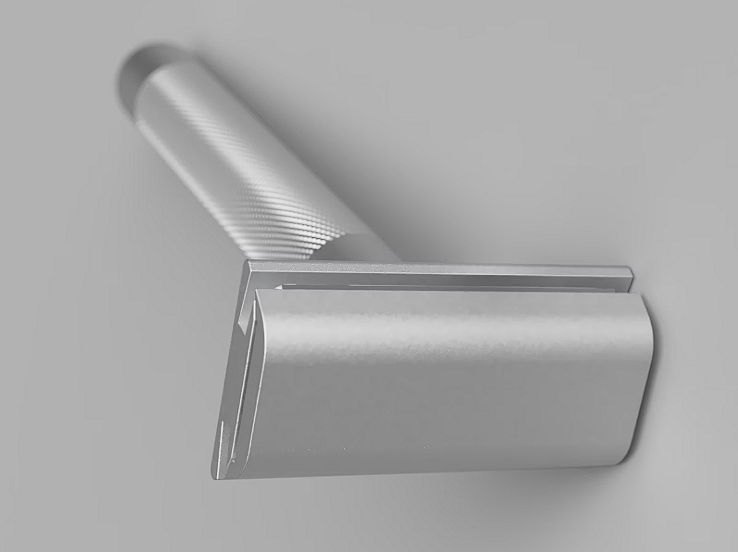

Our CNC Lathes Shape Razor Handles for Grip and Comfort

We make razor handles out of stainless steel, brass, and aluminium, and if customers want to use engineered plastics, we also have a range of options. Our machining experts ensure that diameters do not vary between batches with even a slight tolerance of +/-0.02mm. This maintains harmony and management.

We employ diamond tooling to cut knurling on the precision lathes. The depth and pitch are selected to increase grip in wet conditions. Cuts remain sharp without cutting and eroding the metal.

Single-point cuts are used, and tapped threads are avoided. This causes handles to screw into heads without any looseness. All the threads are tried until final finishing.

Tops Precision Solves Blade Alignment Challenges with Careful Fixturing

Blade alignment is dependent on optimal clamping during machining. We make special fixtures with parts lying flat and in place. This eliminates micro-movement, which may skew blade slots.

Slot depth and spacing during milling are verified by live probes. In case of offsets, they are corrected in-machine. This maintains the seating of blades even through the entire production run.

We test each razor with real blades before release. Such a practical intervention allows us to keep a balance, symmetry, and safety of shaving in practice.