We facilitate passivation and electropolishing, bead blasting, anodizing, and medical-grade finishing. They are applied to improve performance, sterilization, and surface smoothness for patient care.

Quality is at the core concern. We are certified to ISO 9001, and all articles/items are checked with the most updated measuring equipment. These ensure that all our stock components are made with accuracy in specifications and regulations before their arrival.

- Home

- Services

- Industries

- Automation

- Consumer Electronics

- Medical CNC Machining

- PCB Milling

- Aerospace Machining

- Automotive CNC Machining

- CNC Machined Bicycle Parts

- CNC Bottle Opener Machining

- CNC Camshaft Machining

- CNC Screw Machining

- CNC Machining Spare Parts

- CNC Piston Machining

- CNC Machined Gifts

- CNC Machined Fly Wheel

- CNC Machined Safety Razor

- CNC Machined Fidget Spinner

- CNC Machined Dice

- CNC Machined Chess Pieces

- Gallery

- Resources

- About Us

Medical CNC Machining

We manufacture complex medical components with micron-level precision—achieving tolerances as tight as ±0.002 mm.

Every part is produced under ISO 9001 certified processes, ensuring biocompatibility, consistency, and reliability.

From surgical instruments to implantable devices, each piece is crafted with strict quality control and 100% inspection to meet the highest healthcare standards and support life-saving applications.

Send Your Inquiry Today

Our Medical Parts Machining Capabilities

Tops Precision uses superior materials, including stainless steel, titanium, aluminum, PEEK, Delrin, and medical plastics. These are selected based on the durability, corrosion resistance, and their biocompatibility to make sure that they conform to the medical device requirements.

Our services are offered in a broad spectrum of machining services, i.e., CNC machining, precision turning, micro-drilling, and EDM. With such advanced technology, we can generate complex geometries, micro-fines, and small tolerances required in surgical equipment, implants, and diagnostic equipment.

Our Superior Rapid Prototyping Services for Medical Parts

Our prototyping is done quickly and accurately on medical parts to allow you to test and improve the design before complete production. We have a team that can handle sophisticated equipment to produce complex part designs to your project specifications.

It is possible to create prototypes with compatible with medical use, like lightweight titanium, strong stainless steel, and high-grade polymers. The individual pieces are cut and machined to the specifications of the necessary size and serve a purpose.

We provide performance-enhancing and aesthetic finishes on surfaces, such as smooth finishing and protective finishing. This allows the prototypes to be tried in real conditions.

Under a scrutinized process in all its stages, we make sure your prototypes are consistent and accurate. They come ready to be tested in practical settings.

Send Your Inquiry Today

Our Medical Device Manufacturing Techniques

We make medical devices with care and precision. Every part is made to meet strict safety and quality standards.

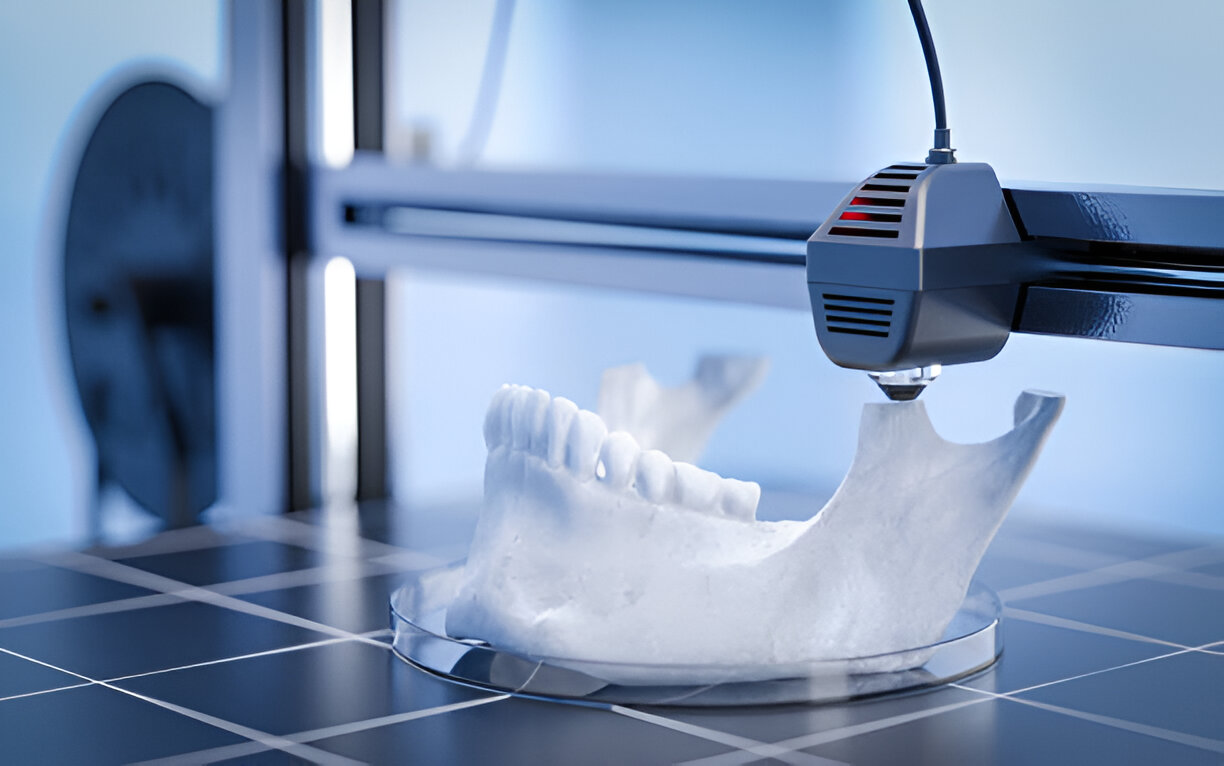

3D Printing

We start by converting your CAD designs into precise 3D models. Using medical-grade polymers or metal powders, we build components layer by layer with high resolution.

After printing, each part undergoes cleaning, support removal, surface smoothing, and dimensional verification to ensure it meets design specifications. This process is ideal for rapid prototyping, functional testing, and complex geometries. As these details and features are difficult to machine.

- Accuracy up to ±0.01 mm for detailed parts

- Cost-saving prototyping

- Fast production in just a few days

- Can make complex shapes easily

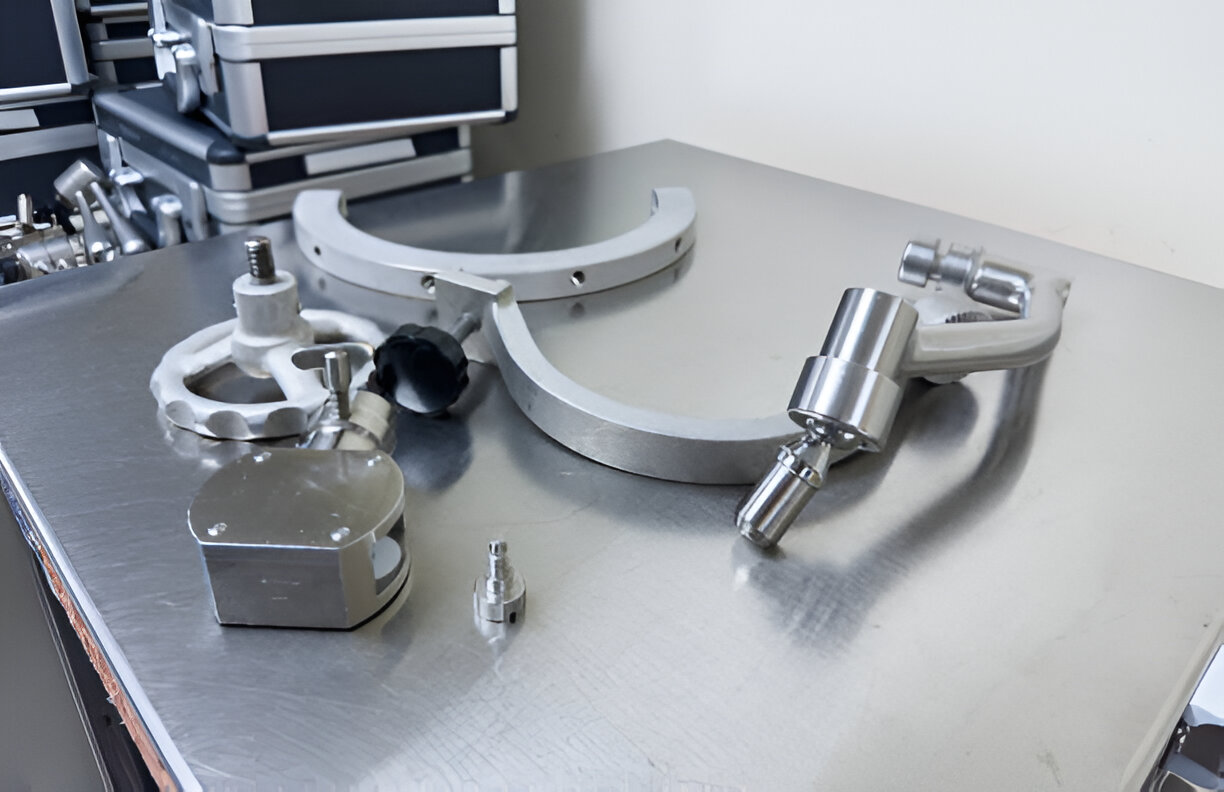

CNC Machining

We utilize CNC milling, turning, and micro-drilling on parts that demand the tightest of tolerances. The procedure starts with the right material choice, which may include titanium, stainless steel, and medical-grade plastics. Each part is machined to extreme precision, with attention to feed rates and cutting parameters to avoid work hardening or surface blemishes. Finish inspection monitors dimension, surface roughness, and mechanical integrity.

We offer

- Tolerances as tight as ±0.005 mm

- Efficient and affordable machining

- Quick turnaround for urgent parts

- Can handle complex designs

Sheet Metal Fabrication

Laser cutting, stamping, and precision press brakes cut, bend, and form sheet metal components. Depending on your application, we make use of medical-grade stainless steel or aluminium sheets. Once formed, the edges are deburred, surfaces polished, and assembled (where applicable). Construction and structural strength are confirmed, and each does fit all. We provide.

- Precise cutting, bending, and forming

- Low material waste for better cost control

- Fast production times

- Smooth and clean surfaces

Injection Molding

For high-volume plastic components, we create precision molds based on your design. Medical-grade polymers are injected under controlled temperature and pressure to allow 1000s of consistent parts to be made. Once cooled, parts are trimmed, polished, and checked for defects, warping, and dimensional deviations. Finished components can also undergo sterilization and surface finishing as per medical requirements.

- Consistent parts for high-volume production

- Low production costs

- Quick cycle times for fast delivery

- Smooth surfaces ready for sterilization

Send Your Inquiry Today

Why Choose Us for Medical Parts Manufacturing

Here are the facts, how we set ourselves apart from other competitors:

Cost-Effective Solutions

Our cost-effective production goes hand in hand with quality production of medical components. Through the organisation of every action, minimizing material waste, and efficient processes, we produce parts that are not only cost less but also precise and safe.

Completely Customised Components

Each project carries with it unique needs. We produce parts to your exact designs, either in a one-off prototype or series production. We collaborate with you very closely so that the parts are of exact dimensions, functional parameters, and material specifications.

Fast and Reliable Production

We know about the relevance of deadlines in the medical field. We have a lean operation, efficient machinery, and skilled personnel. This enables us to provide parts quickly without iterations later. Even our new generation equipment supports more complicated designs being done on time without compromising quality.

Strict Quality Control

Each component undergoes several verification processes to verify that it conforms to the requirements of ISO 13485 and ISO 9001. Surface finish, dimensions, and the integrity of the material are verified. So, all the components are safe, durable, and reliable to be used in important medical purposes.

Highly Precise and Accurate

Our tolerances and smooth finishes are kept very tight. This guarantees fit and part functions as required. Such high accuracy is key in surgical tools, implants, and diagnostic apparatus.

Regulatory Compliance

Our processes are synchronized with the rules and medical industry regulations. We have stringent protocols in place to make sure parts are safe, reliable, and fit to be used in the medical field, right down to our material selection to the final inspection.

High Technology and Innovation

All our manufacturing techniques are advanced, like 3D printing, CNC machining, sheet metal work, and injection molding. This allows us to manage complex geometries, functional test prototypes, and mass-scale production.

Cooperative and Client-friendly

Our manufacturing processes are changed to suit the particular needs of a project. It may be rapid prototyping, a low-volume specialty production run, mass manufacturing, or any combination in between. We make sure that your pieces get to you precisely as you need them.

Send Your Inquiry Today

Types of Medical Parts Machined for Medical Applications

We machine a wide variety of medical parts for different healthcare applications. Every component is designed for accuracy, durability, and safety.

Surgical Instruments

We manufacture scalpels, forceps, clamps, and other hand instruments used in surgeries. These components are fabricated using high-quality stainless steel, titanium to remain durable and able to withstand corrosion. All the instruments are smooth, accurate, and sterilized.

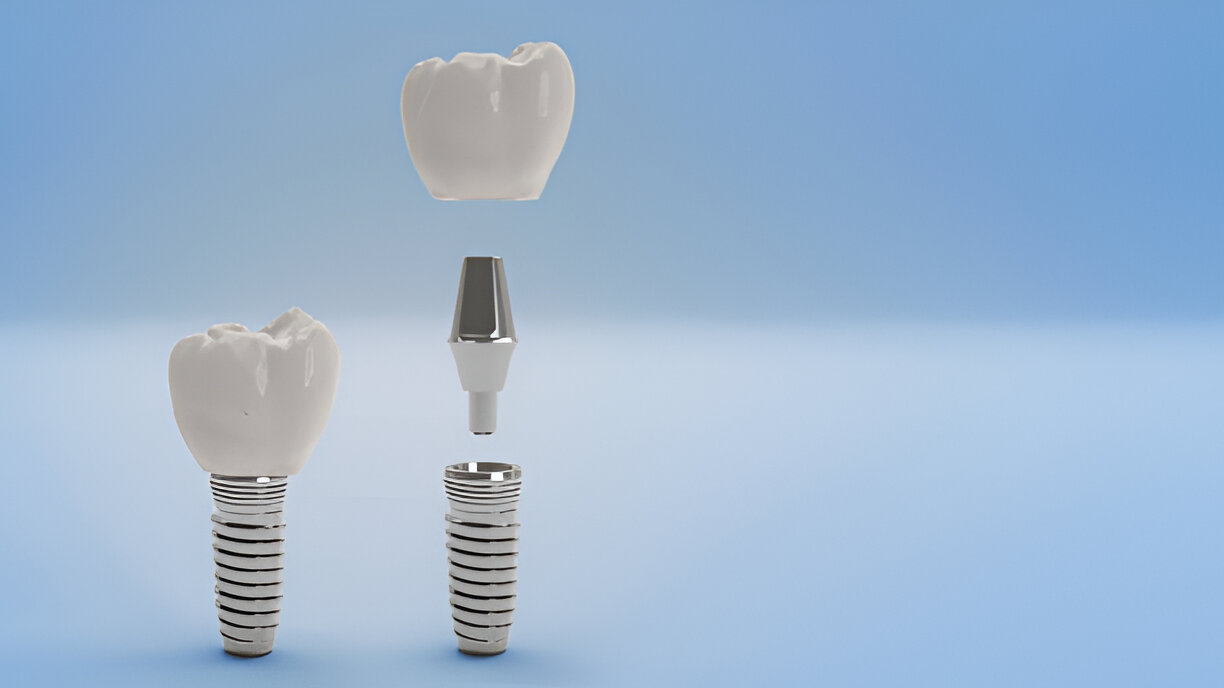

Prosthetics and Implants

We machine joint replacements, bone plates, screws, and dental implants. Biocompatibility is made with materials such as titanium and medical-grade polymers. Individual components are molded to fit and have durable performance.

Diagnostic and Imaging Components

We make components used in X-rays, MRI, and ultrasound. These include housings, brackets, and precision mounts. All the pieces are manufactured to close tolerances to ensure that they work reliably in sensitive equipment.

Medical Device Housings and Enclosures

We fabricate shielding protection cases and covers such as pacemakers, insulin pumps, and monitors. Such housings are safe, durable, and lead to a good fit between internal parts.

Laboratory Equipment Parts

Our products are machined parts of laboratory equipment such as centrifuges, pipettes, and test machines. Composites are marked to work accurately, repeatably, and be chemically resistant in laboratories.

Post-Processing for Medical Prototypes & Products

After making medical parts, we add finishing to make them strong, safe, and easy to clean. The type of finish depends on the material and use.

Finish Type | Description | Benefit |

Polishing | Smooths the surface | Easy to clean and sterilize |

Passivation | Treats stainless steel | Protects from rust |

Anodizing | Treats aluminum | Makes it stronger and durable |

Bead Blasting | Adds texture | Removes rough spots |

Medical Coatings | Protective layer | Safe for chemicals and sterilization |

These finishes make sure your parts last longer and are ready for medical use.

Send Your Inquiry Today

Frequently Asked Questions

We work with stainless steel, titanium, aluminum, PEEK, and other medical-grade plastics. These materials are chosen for strength, biocompatibility, and corrosion resistance.

Yes, we create parts according to your exact design and measurements. This includes prototypes, small batches, and full-scale production.

We use CNC machining, 3D printing, sheet metal fabrication, and plastic injection molding. Each method is chosen based on the part of your design complexity, material, and volume demands.

All parts are inspected at multiple stages. Our services are in line with ISO 13485 and ISO 9001 standards. We check dimensions, surface finish, and material integrity to ensure every component is safe and reliable.

Yes, our meticulous workflows and advanced equipment allow us to deliver prototypes and production parts quickly. So, you get parts made right without compromising accuracy and quality.