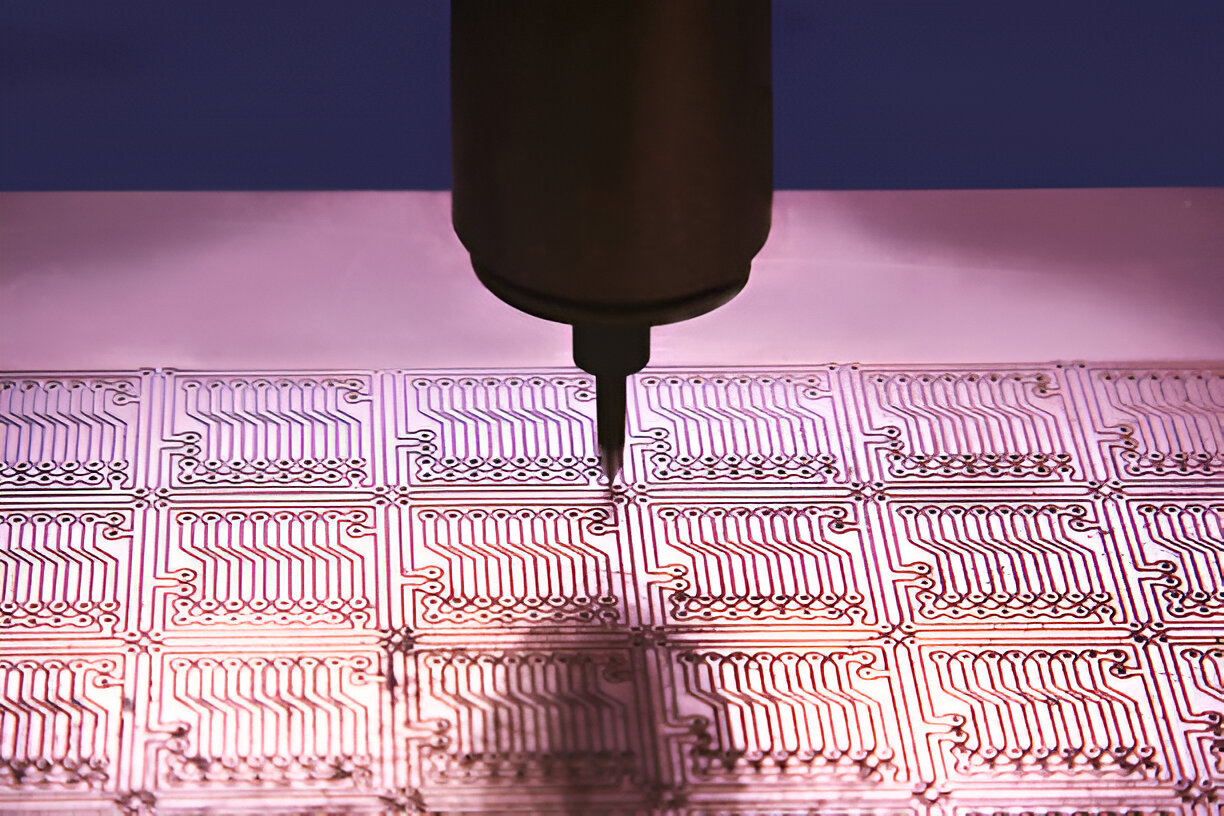

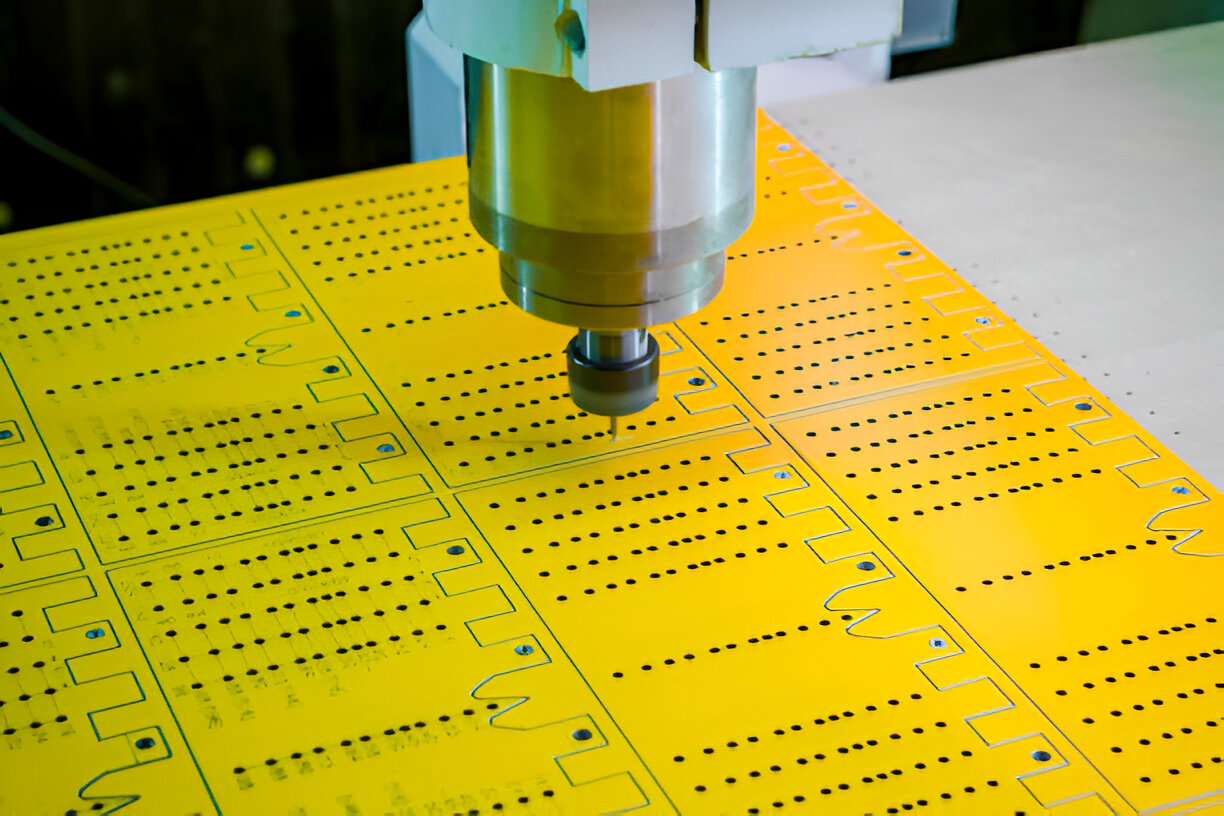

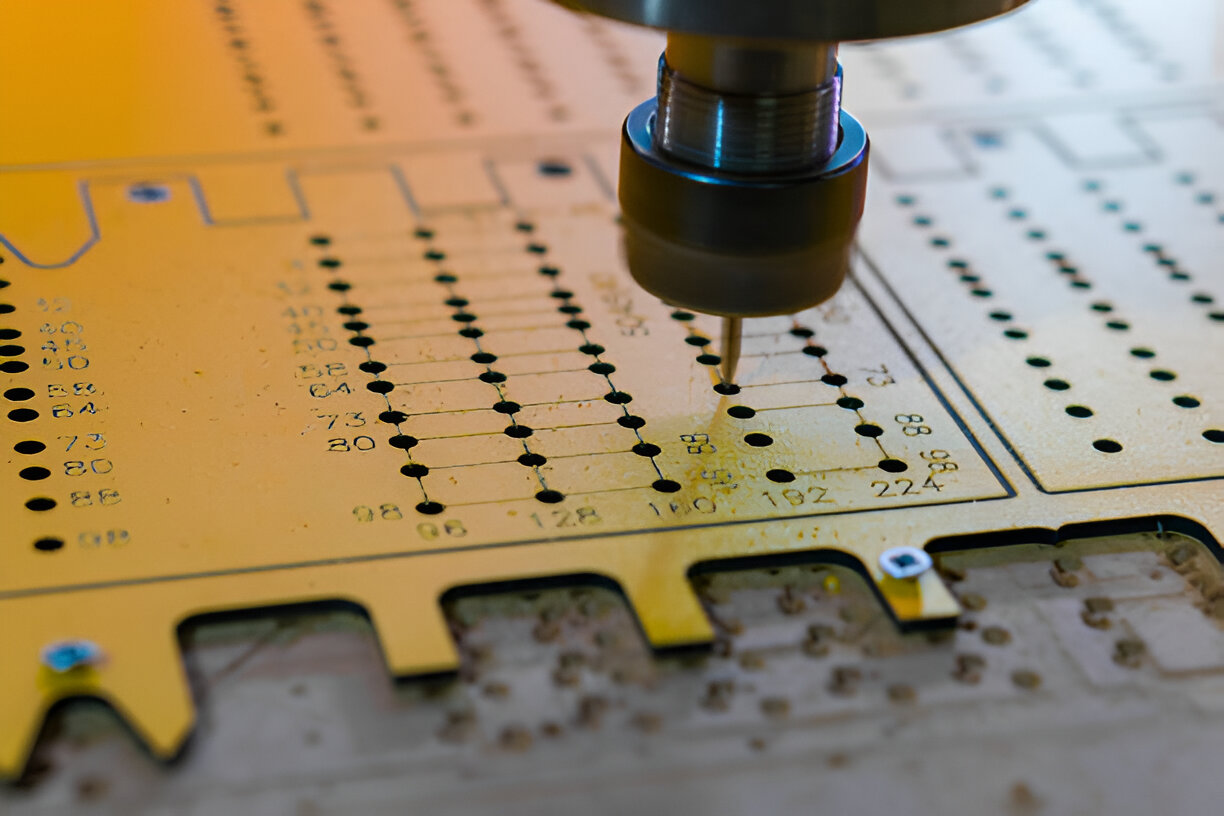

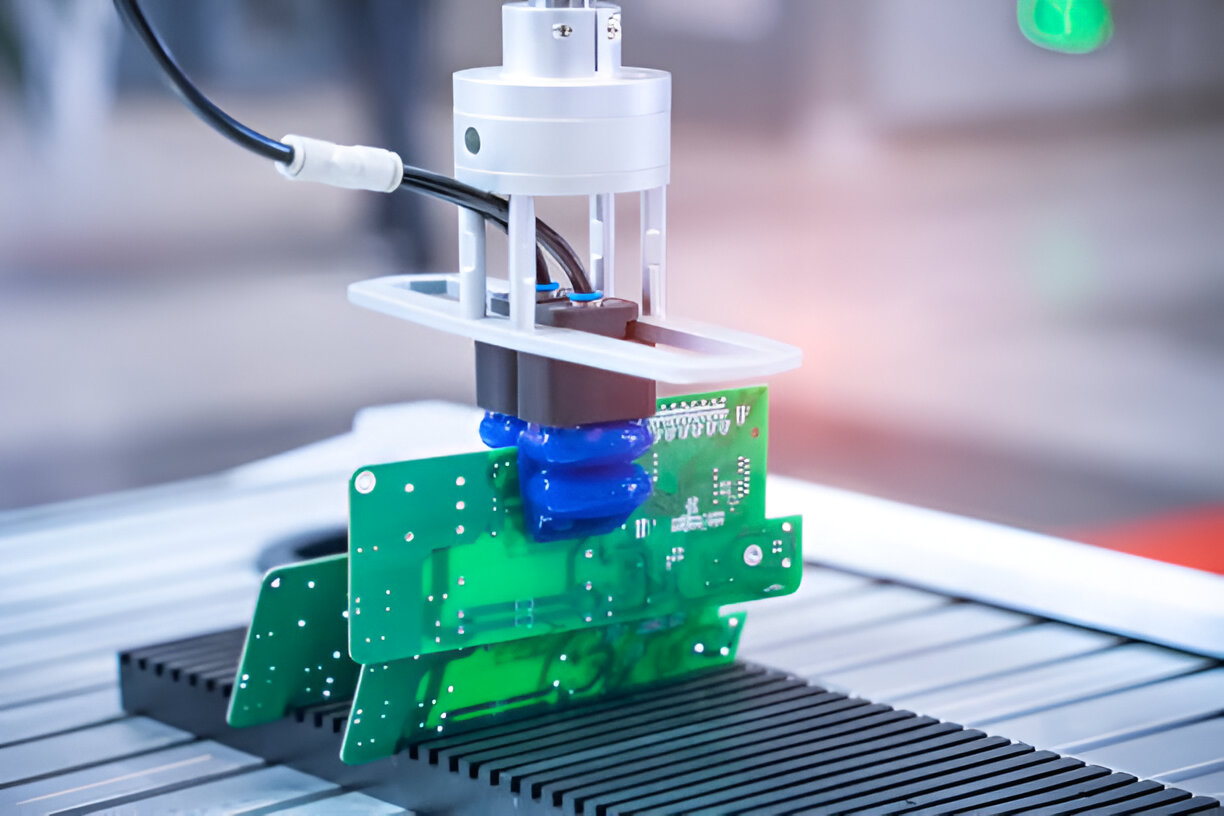

We work with FR4, PVC, and GFK with copper. Each material is handled with the right speed and tools. This allows us to prevent cracks, edge damage, or surface defects.

Every board goes through a clean milling, drilling, and final check. This ensures quality across each stage of the process. With Topsbest Precision, your boards are made to perform from the start.