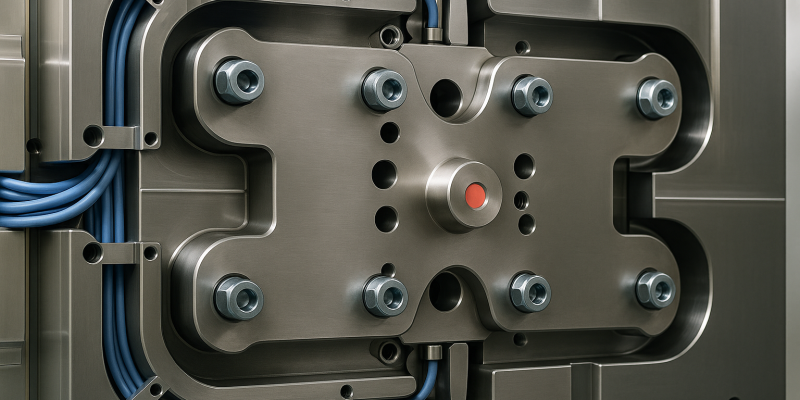

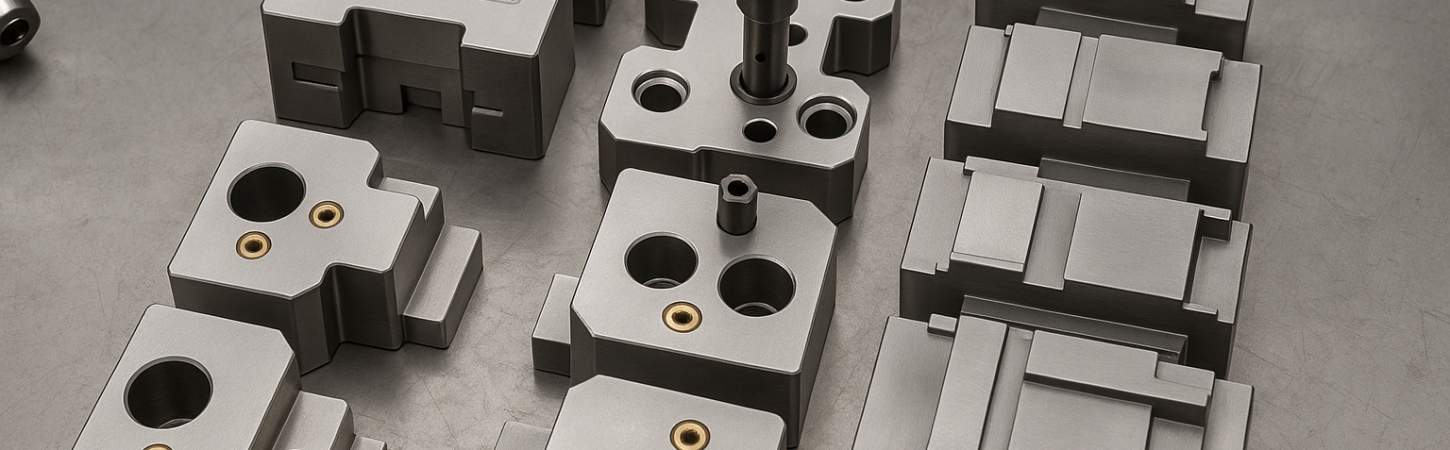

Our Insert Molding Services Key Features

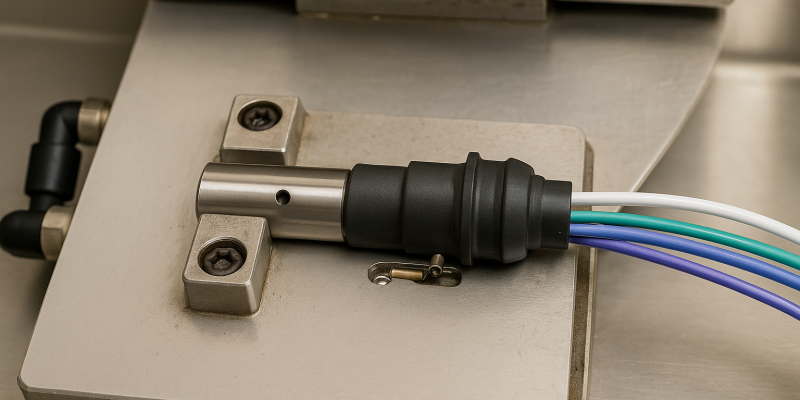

Through our insert molding services, which integrate inserts directly into the molding process, we provide precision, durability, and cost efficiency. Secondary assembly is eliminated, production time is reduced, and performance is increased in high-precision and complex parts.