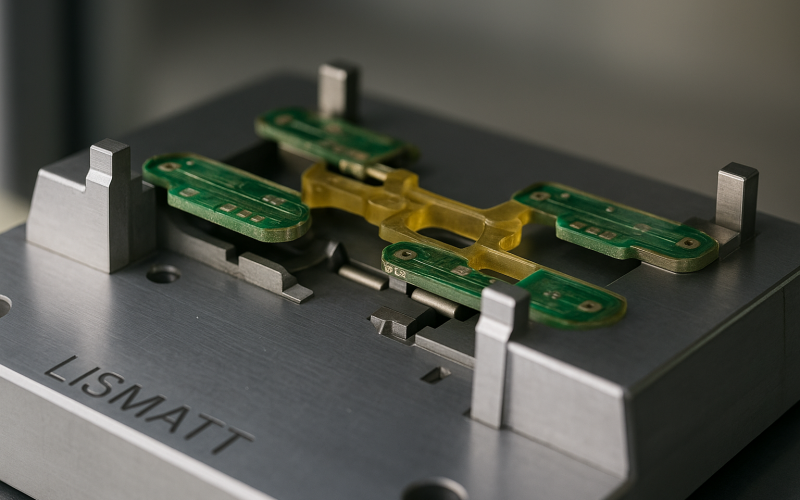

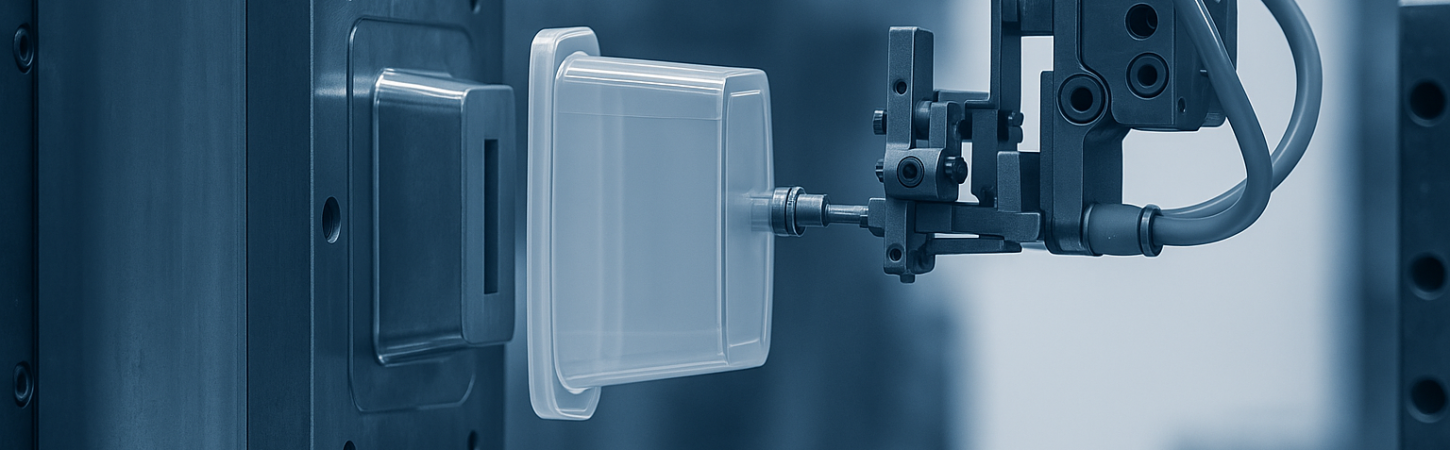

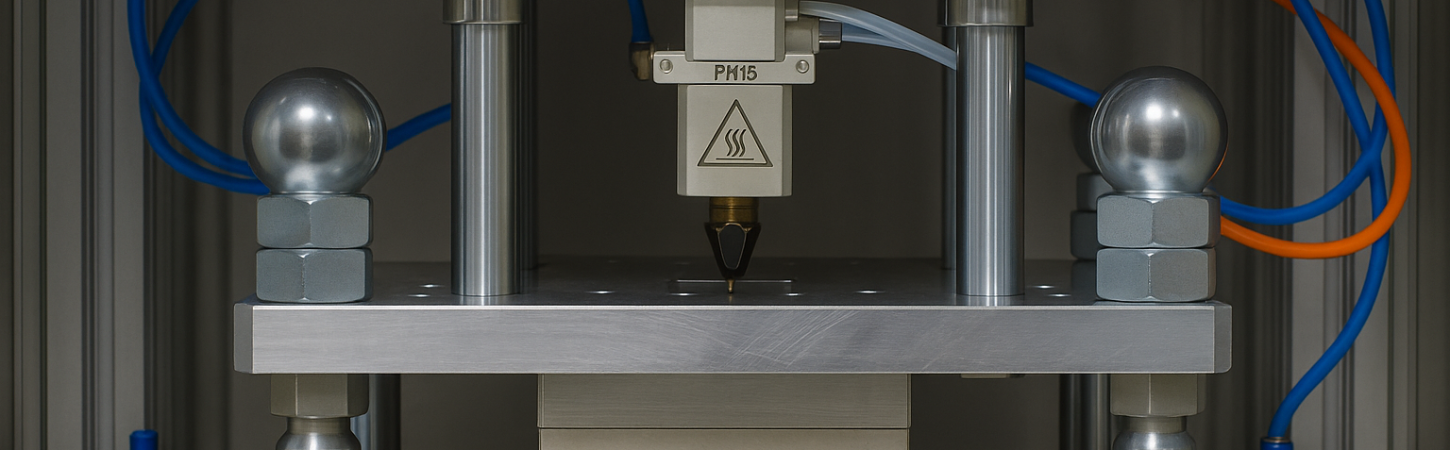

Our Overmolding Capabilities

At Tops Precision, we offer top-quality precision engineering as well as top technology at the highest levels in providing high-quality overmolding solutions. Onsite they have insert molding, multi-material overmolding, and precision injection molding with seamless material integration for medical, automotive, industrial, and consumer applications. We provide custom solutions with a focus on durability, efficiency, and turnaround for low and high volumes.