1. Precision and Consistency

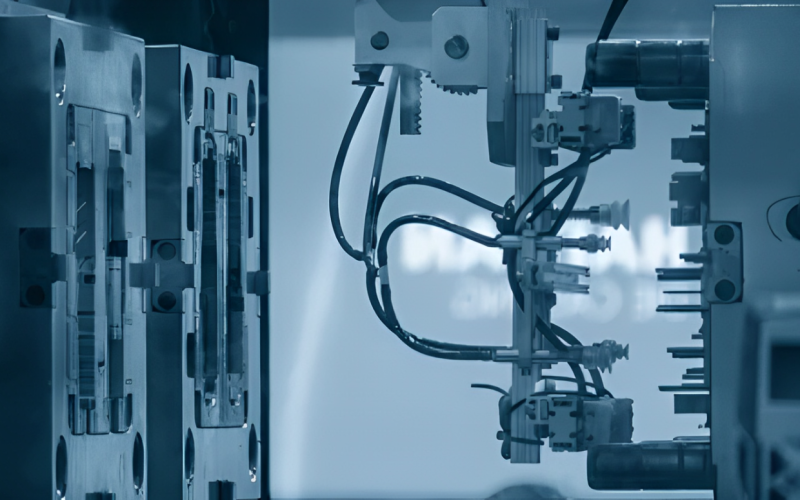

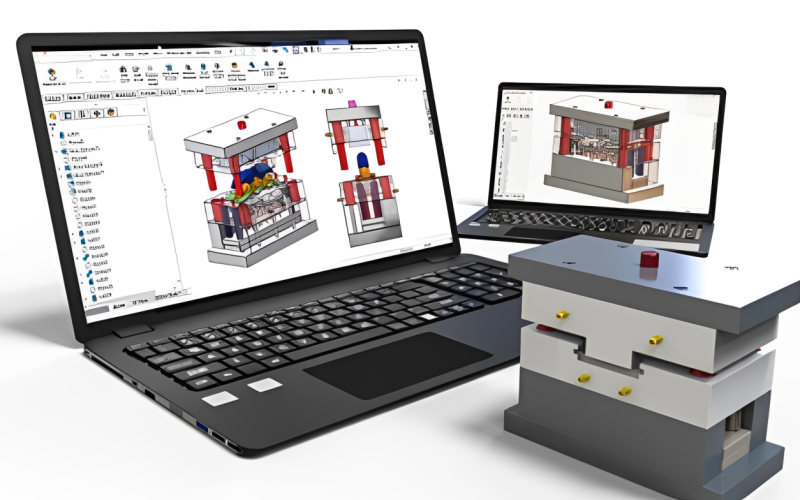

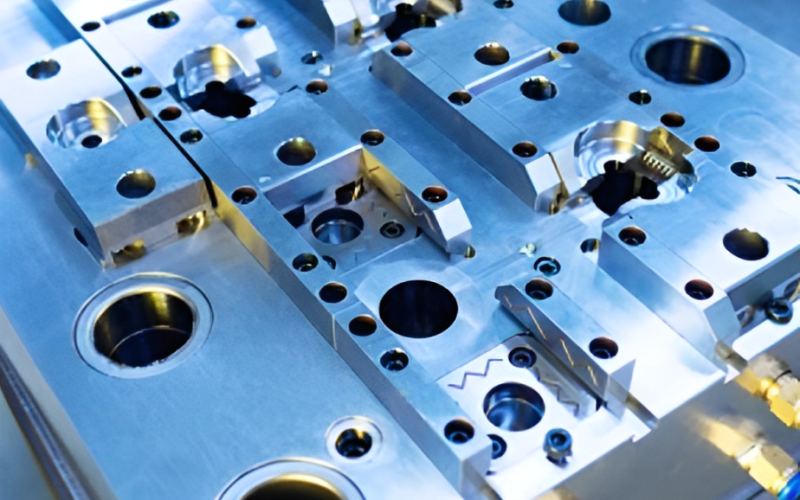

- The process reaches high precision levels to achieve ±0.01mm parts tolerances.

- The process runs its CNC-controlled molding machines under advanced automated control systems, ensuring maximum quality performance and exceptional operational consistency.

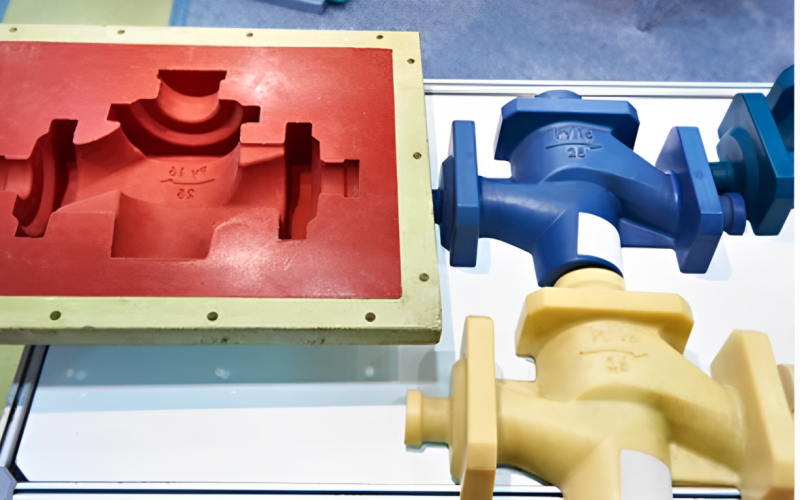

2. Versatile Material Options

- TOPS operates with all thermoset and thermoplastic materials including ABS and polycarbonate, nylon, polypropylene, and PEEK.

- The process creates parts that feature intricate shapes and tight dimensional features.

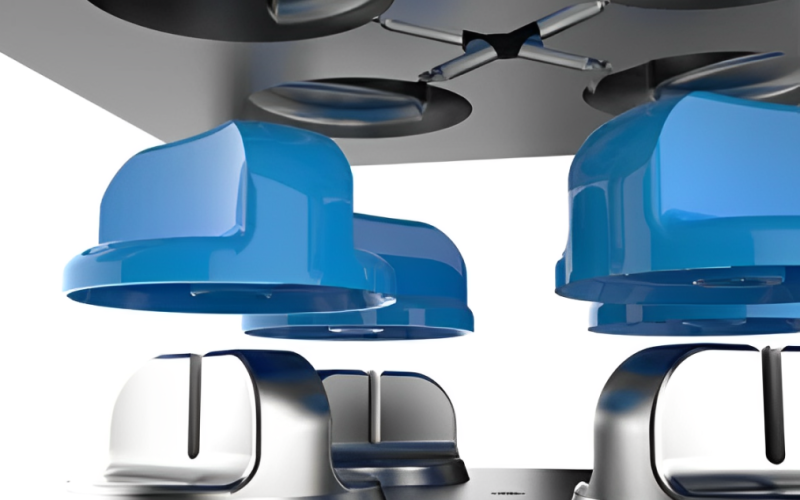

3. Fast Turnaround & High Efficiency

- The setup process takes less time while the production cycles operate at maximum efficiency to lower overall lead times.

- The two approaches match one another as they suit applications between product development prototypes and mass-scale productions.