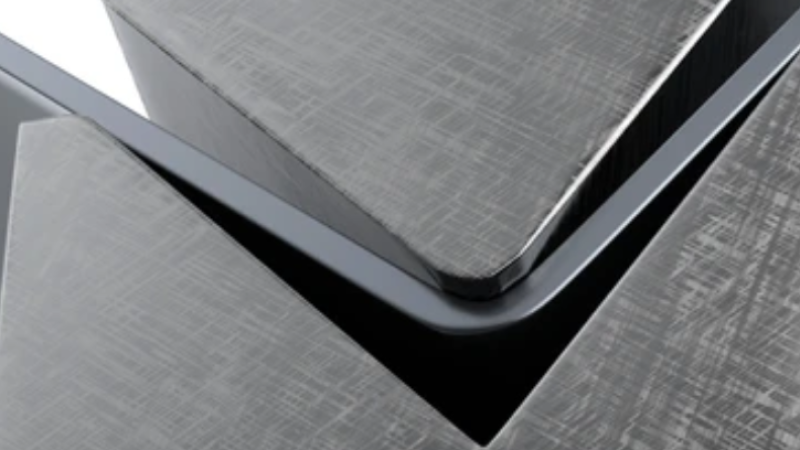

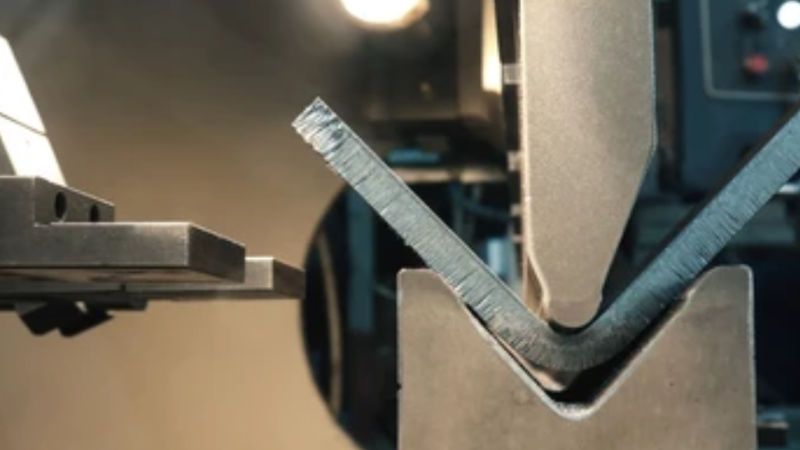

Precision and Accuracy

Our process achieves precise bending tolerances of ±0.3mm and produces consistent results for complex components. Our high-end computer controls on bending machines eliminate production mistakes and variations.

Send Your Inquiry Today