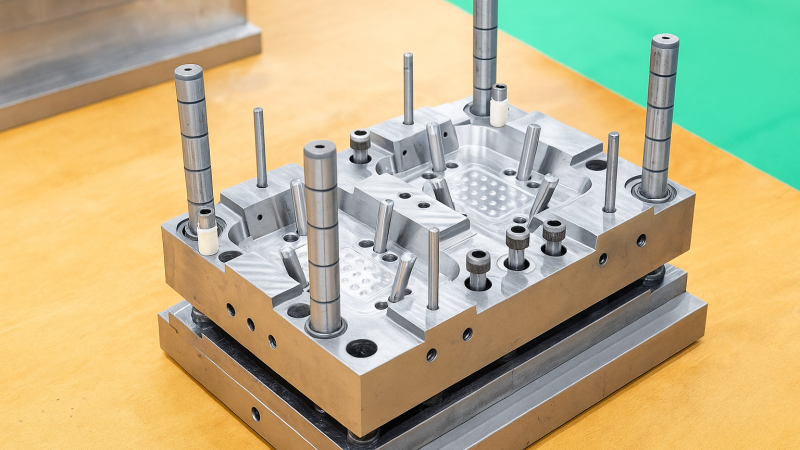

What is Silicone Molding?

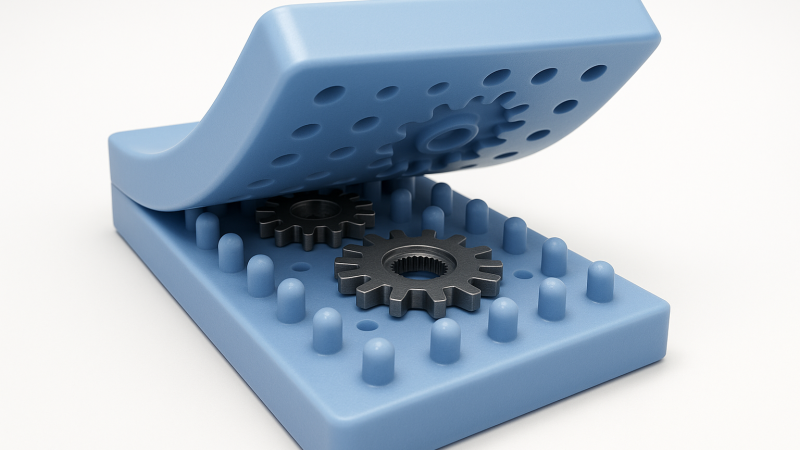

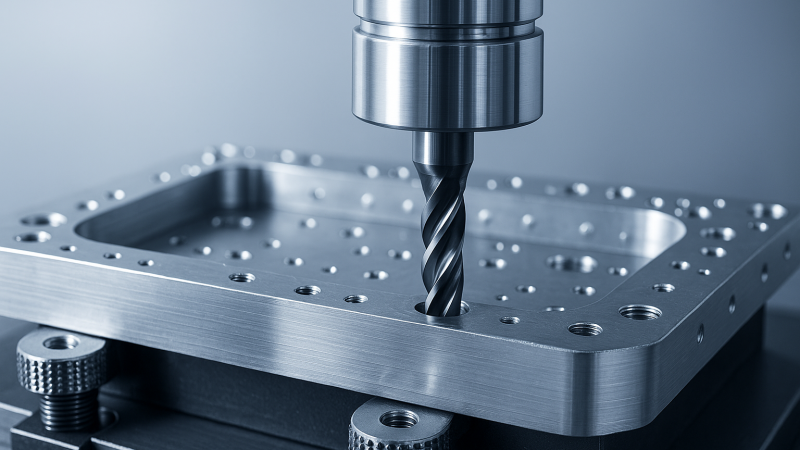

The silicone molding process enables the production of tough yet flexible and temperature-resistant silicone elastomer components. The manufacturing sequence starts by injecting or compressing silicone liquid or solid material into a mold cavity until curing completes to create the endorsed final form.

Silicone molding remains a prominent manufacturing technique because it offers distinct properties which include:

- Silicone exhibits remarkable heat resistance by maintaining its flexibility when exposed to extreme temperatures.

- Durability –High wear resistance for long-lasting performance.

- Biocompatibility – Ideal for medical and food-grade applications.

- Resistance –This material demonstrates resistance against chemical agents to provide UV protection and oil immunity.

- Flexibility & Softness –This material provides flexibility and softness that makes it ideal for soft applications.

Our high-precision method allows each silicone-molded product to fulfill precise dimensional standards while maintaining exact material quality benchmarks.