What Makes TOPS Precision the Best Anodized CNC Machining Company?

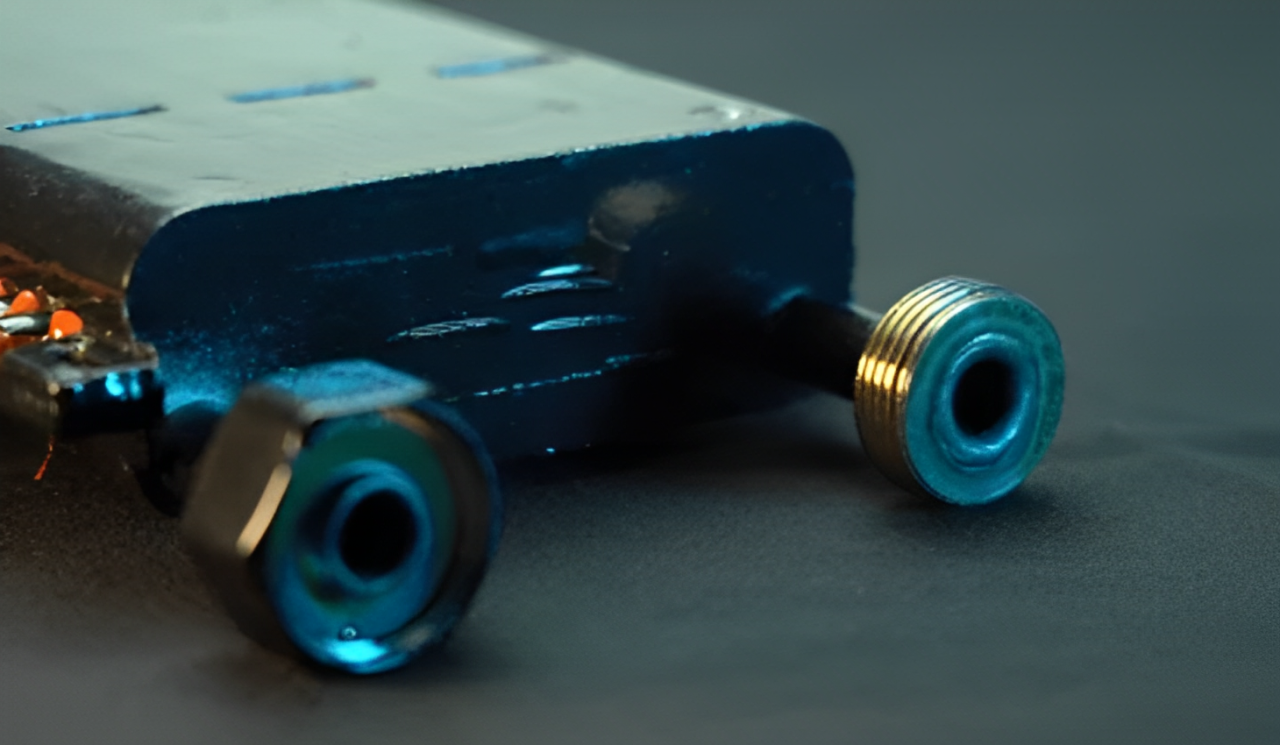

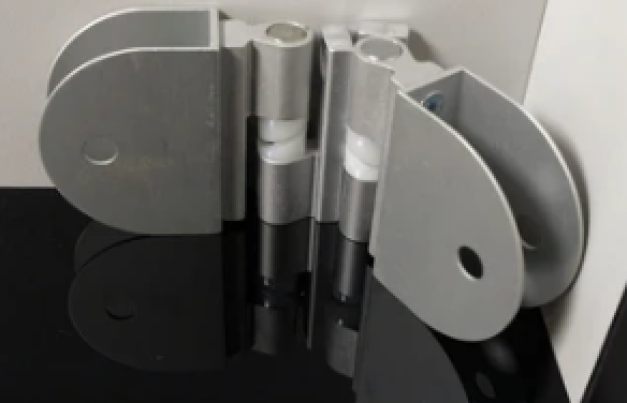

- Expertise and Precision: TOPS Precision has been in the use of CNC machining services for many years to ensure that we offer the best quality parts with the right measures set by the customer.

- Quality Control: We have standards passed down from the time of machining right through to the anodizing of the parts so that they meet industry standards and preferably customer expectations.

- Customization and Flexibility: Anodizing can also be done in various colors and with a variety of surface treatments done to suit the project of the client.

- On-Time Delivery: Our well-organized operational structures and highly committed workforce guarantee your timely delivery of quality parts so that your delivery timelines won’t be affected.

- Sustainable Practices: Our environmentally friendly style developed to reduce wastage in manufacturing plays an important role. By choosing us, you acquire the only solution that has an extremely high performance while generating a significantly lower amount of waste.