Glass CNC machining has revolutionized the way precision components are manufactured, enabling designers and engineers to realize complex geometries and tight tolerances that were previously impractical or impossible. From microfluidic devices to large architectural panels, CNC-machined glass delivers exceptional accuracy, repeatability, and surface finish. This guide delves deeply into the methods, materials, benefits, and considerations of glass CNC machining, empowering you to make informed decisions for your next project.

Can Glass Be CNC Machined?

Yes—advances in machine tool rigidity, spindle design, tooling, and process control now make it feasible to CNC-machine glass reliably. However, glass’s inherent brittleness and hardness require specialized techniques and tooling to minimize chipping, cracking, and tool wear. With proper fixturing, coolant delivery, and parameter optimization, CNC machining can produce intricate cuts, holes, and surface textures in glass panels and components.

How Does CNC Glass Machining Work?

Glass CNC machining follows the standard CAD → CAM → CNC workflow, but with critical adaptations for material behavior.

CAD to CAM Workflow

Design & Tolerancing

Create 3D models in CAD, specifying geometric dimensions and tolerances (GD&T).

Identify critical surfaces (e.g., optical faces) requiring sub-micron flatness or roughness.

Toolpath Generation

In CAM software, select appropriate toolpaths (contouring, pocketing, drilling).

Define step-over, step-down, feed rates, and spindle speeds optimized for glass removal.

Machine Setup

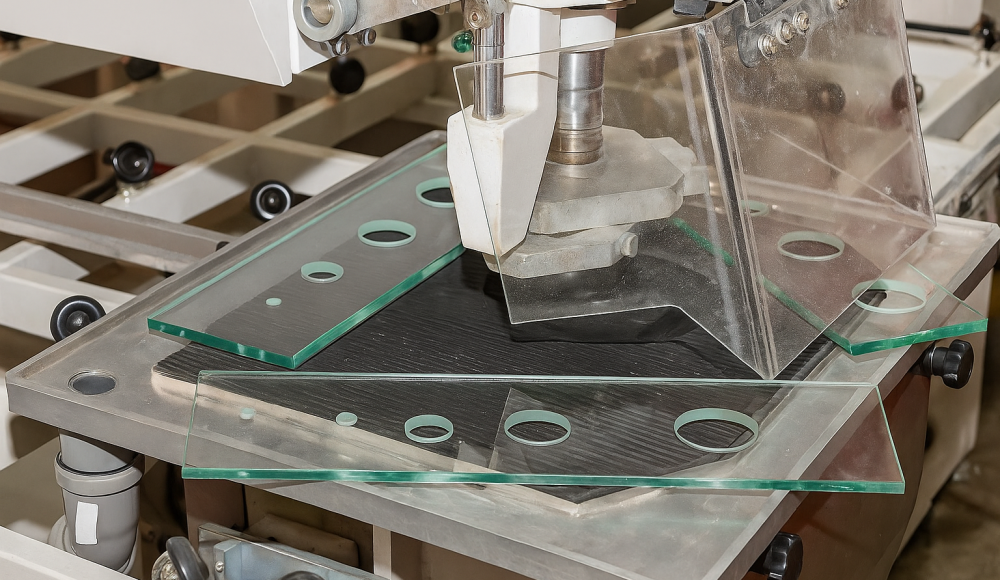

Fixturing

Use vacuum chucks, adhesive pads, or soft jaws to support glass without inducing stress.

Ensure even support to prevent vibration and cracking.

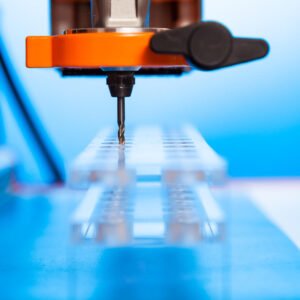

Tooling & Spindle

Employ diamond-coated end mills, drills, and grinding/burr tools.

High-speed spindles (≥ 30,000 RPM) reduce cutting forces and improve surface finish.

Coolant & Dust Control

Flood coolant or micro-lubrication minimizes heat buildup and flushes debris.

Integrated extraction systems capture glass dust to prevent surface scratching.

Machining Operations

Roughing Passes

Begin with conservative depths of cut (e.g., 0.1–0.2 mm) at moderate feed rates to gently remove bulk material.

Finishing Passes

Switch to fine step-downs (≤ 0.05 mm) and reduced feed to achieve target surface roughness (< Ra 0.2 µm).

In-Process Monitoring

Use vibration sensors and acoustic feedback to detect tool wear or part cracking in real time.

Post-Machining Steps

Polishing

Secondary polishing with fine diamond pads or slurry can further improve optical clarity.

Tempering/Strengthening

Thermal or chemical strengthening enhances toughness, critical for load-bearing or safety components.

Final Inspection

Coordinate-measuring machines (CMMs), interferometers, and surface profilometers verify geometric and surface specifications.

Techniques Used in Glass CNC Machining

Glass’s unique properties demand a diverse toolkit of machining techniques:

Milling & Contouring

Removes material to form edges, recesses, and 3D shapes with diamond end mills.

Drilling & Boring

Creates precise holes from sub-0.5 mm to several millimeters using diamond-coated drills and reamers.

Engraving & Pocketing

Diamond cutters carve decorative patterns, serial numbers, or shallow pockets for gaskets.

Grooving & Slotting

Forms narrow channels for seals or assembly features; critical in fluid-handling applications.

Grinding & Lapping

Surface refinement techniques that bring flatness and roughness into optical tolerances.

Water-jet Cutting (Hybrid Systems)

Abrasive water-jet head on a CNC platform achieves 2D profiles without thermal stress.

Thermal/Chemical Strengthening

Post-machining treatments—ion exchange baths or tempering ovens—increase surface compression and durability.

Glass Types Suitable for CNC Machining

| Glass Type | Key Properties | Common Uses |

| Borosilicate | Low thermal expansion, high chemical resistance | Labware, precision optics |

| Soda-Lime | Economical, machinable, moderate strength | Architectural panels, decorative components |

| Fused Silica | Ultra-low expansion, high clarity | Semiconductor wafers, high-power optics |

| Aluminosilicate | High strength, good thermal stability | Smartphone screens, durable display covers |

| Lead Glass | High refractive index, dense | Precision lenses, prisms |

| Quartz | Exceptional purity, UV transparency, high heat resistance | UV lamps, semiconductor process windows |

Advantages of Glass CNC Machining

High Precision & Repeatability

Achieve ±10 µm tolerances consistently across batches.

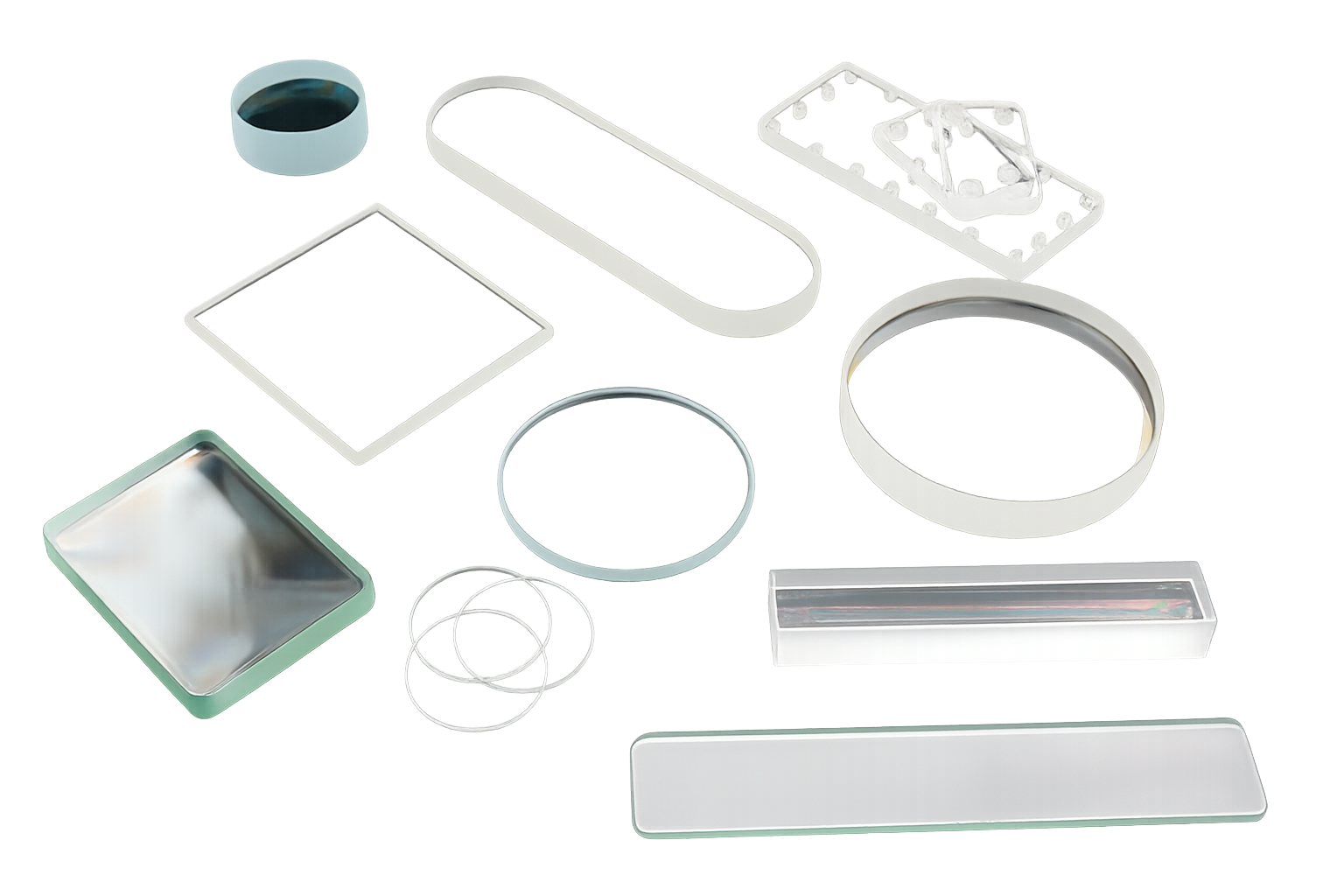

Complex Custom Geometries

Produce undercuts, microchannels, and freeform surfaces in a single setup.

Superior Surface Finish

Ra down to 0.05 µm without extensive manual polishing.

Material Efficiency

Minimized kerf loss and scrap through optimized toolpaths and nesting.

Automation & Safety

CNC control reduces operator exposure to glass shards; automated loading options increase throughput.

Limitations of Glass CNC Machining

Brittleness Risk

Thin cross-sections (< 2 mm) and tight corners can crack under stress.

Equipment & Tooling Cost

High-precision spindles and diamond tools demand significant capital investment.

Operator Expertise

Requires specialized training in glass behavior, tooling selection, and process tuning.

Applications of Glass CNC Machining

Optics & Photonics

Lenses, prisms, waveguides, and beam-shaping elements.

Semiconductor Equipment

Wafer substrates, mask aligner windows, and protective covers.

Medical & Biotechnology

Microfluidic chips, catheter lumens, diagnostic slide chambers.

Aerospace & Defense

Pressure windows, sensor housings, and high-temperature viewports.

Consumer Electronics

Touchscreen covers, camera lens covers, and decorative glass parts.

Architectural & Decorative

Etched glass panels, lighting fixtures, and artistic installations.

Cost Considerations

Capital Expenditure

CNC machine with high-speed spindle: $150,000–$500,000+.

Diamond-coated tooling: $100–$500 per cutter.

Operating Costs

Skilled operator wages, coolant, tool wear, and maintenance.

Volume Economics

Higher volumes offset setup costs; small runs carry premium per part.

Design Complexity

Intricate features increase cycle time; balance between design ambitions and budget.

Comparison with Other Glass Fabrication Methods

| Aspect | CNC Machining | Laser Cutting | Manual Techniques |

| Precision | ±10 µm | ±50–100 µm | ±100–300 µm |

| 3D Capability | Full 3D contours and undercuts | Primarily 2D profiles | Limited shapes |

| Thermal Stress | Minimal (with coolant) | Potential micro-cracks | Low but inconsistent |

| Setup Time | Moderate (CAM programming) | Low | Very low |

| Surface Finish | Ra 0.05–0.2 µm | Ra 1–3 µm | Ra > 3 µm |

Selecting a Glass CNC Machining Provider

Equipment & Certifications

Look for ISO 9001:2015, AS9100 for aerospace, or ISO/IEC 17025 for metrology.

Technical Expertise

Review case studies in optics, medical, or semiconductor industries.

Quality Control

In-process probing, CMM inspection, interferometry, and surface profilometry.

Lead Time & Capacity

Confirm throughput capabilities and backup plans for urgent runs.

Post-Processing Services

Polishing, tempering, coating, and assembly integrations.

Case Study: Tops Precision’s Glass CNC Machining Process

Incoming Inspection

Verify glass type, thickness, and pre-certify flatness with laser interferometry.

Toolpath Optimization

Use in-house CAM templates tuned for minimal tool engagement and vibration control.

Multi-Stage Machining

Rough cut at 20,000 RPM; finish pass at 40,000 RPM with 1 µm step-down.

Surface Enhancement

Optional diamond slurry polishing or ion-exchange strengthening.

Final QA & Packaging

CMM and optical inspection; custom crating with vibration-damping foam.

Conclusion

Glass CNC machining bridges the gap between design ambition and manufacturability, unlocking feats of precision and complexity that drive innovation across industries. By understanding the nuances of tool selection, process parameters, and material behavior, you can harness CNC machining to produce glass components that meet the strictest standards of performance and aesthetics. When evaluating partners, prioritize technical expertise, quality systems, and a proven track record in glass fabrication—such as demonstrated by Tops Precision—to ensure your project’s success from prototype to production.

Read More: