In the automotive industry, manufacturers constantly seek lighter, stronger, and more environmentally friendly materials. Aluminum has emerged as a superior alternative to steel due to its exceptional combination of lightweight characteristics, durability, corrosion resistance, and cost-effectiveness. Today, aluminum car parts are found extensively across automotive manufacturing—from engines and chassis components to wheels and radiators.

This comprehensive guide dives deep into the world of aluminum automotive parts, covering essential properties, manufacturing methods, advantages, common alloys, and current trends. Let’s explore why aluminum remains a standout choice for automotive engineers worldwide.

Essential Properties Making Aluminum Ideal for Automotive Manufacturing

High Strength and Flexibility

Aluminum alloys offer exceptional strength combined with flexibility. Unlike traditional steel, aluminum retains toughness even at extremely low temperatures, making it an ideal material for producing automotive components that can withstand impact without cracking or deforming.

Excellent Malleability

Aluminum can be easily shaped into complex geometries using processes such as casting, extrusion, and stamping. Its malleability allows manufacturers to create intricate designs, reducing the need for multiple assembly processes and enhancing design flexibility in components like vehicle frames and body panels.

Superior Conductivity

Known for its excellent thermal and electrical conductivity, aluminum is perfect for heat-sensitive automotive applications. Aluminum radiators and heat exchangers, for example, dissipate heat more efficiently, keeping engine components cooler and enhancing overall vehicle performance.

Resistance to Vibration

Aluminum’s vibration-dampening capabilities reduce noise and vibrations within the vehicle. These properties are especially beneficial in suspension systems, engine bays, and body structures, enhancing passenger comfort and component lifespan.

Low-Density and Lightweight

Aluminum has a density approximately one-third that of steel. This low-density characteristic significantly reduces vehicle weight, leading to better fuel efficiency, improved vehicle handling, acceleration, braking performance, and overall environmental benefits.

Corrosion Resistance and Recyclability

Aluminum naturally forms an oxide layer upon exposure to air, providing excellent corrosion resistance. Additionally, aluminum is infinitely recyclable without losing quality, significantly reducing environmental impact and manufacturing costs.

Cost-Effectiveness

Although aluminum initially has higher raw material costs, its ease of machining, recyclability, reduced fuel usage, and improved longevity contribute to long-term cost savings. Technological advancements also continue to decrease production costs, making aluminum increasingly accessible for mass automotive manufacturing.

Common Aluminum Car Parts Manufacturing Processes

Automotive manufacturers employ various advanced processes to produce aluminum parts, each with distinct advantages depending on specific requirements.

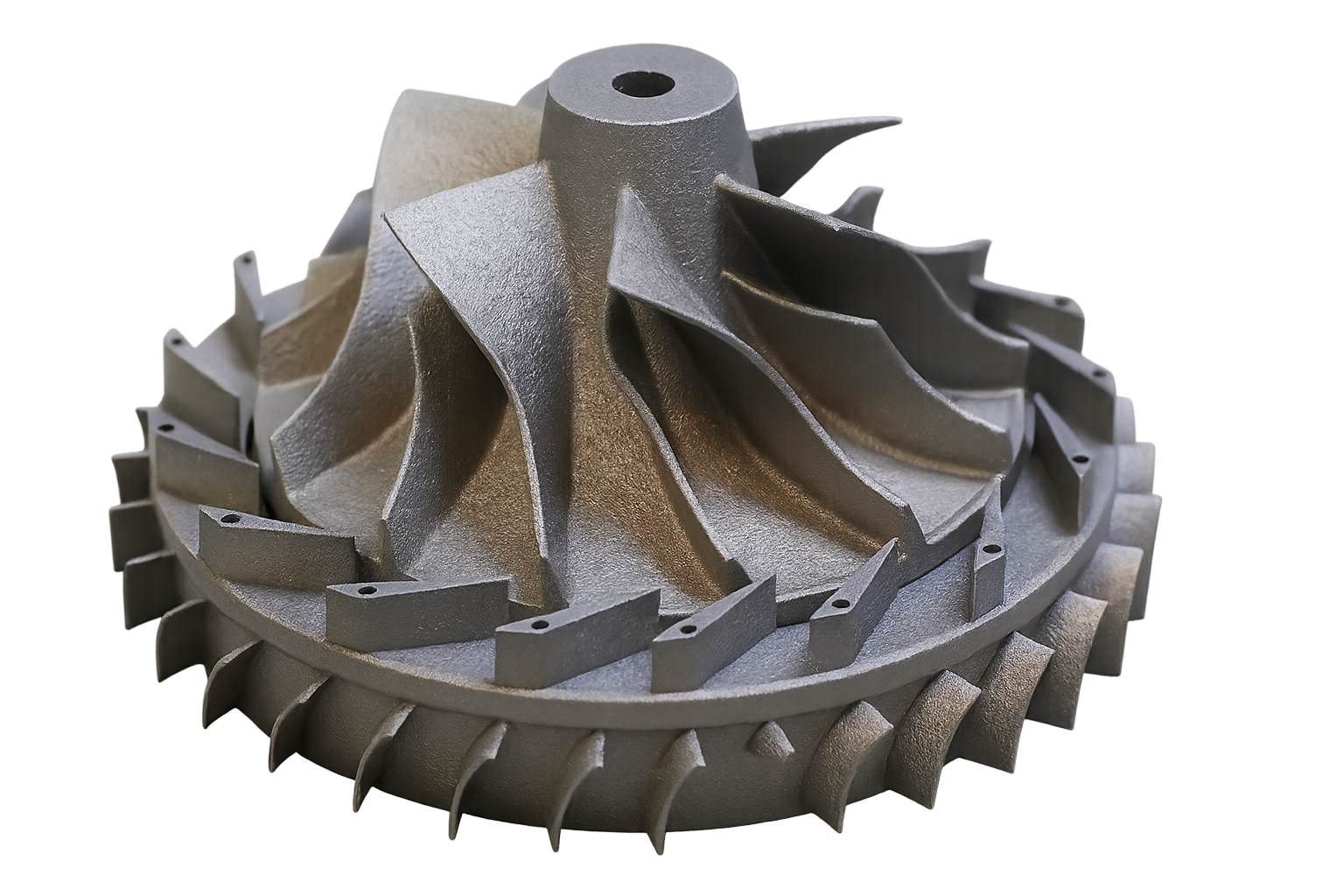

3D Printing Aluminum Car Parts

Additive manufacturing, or 3D printing, involves building parts layer by layer from powdered aluminum, melted and fused using precise laser or electron beam technologies. It’s ideal for rapid prototyping, complex geometries, and custom, small-batch manufacturing.

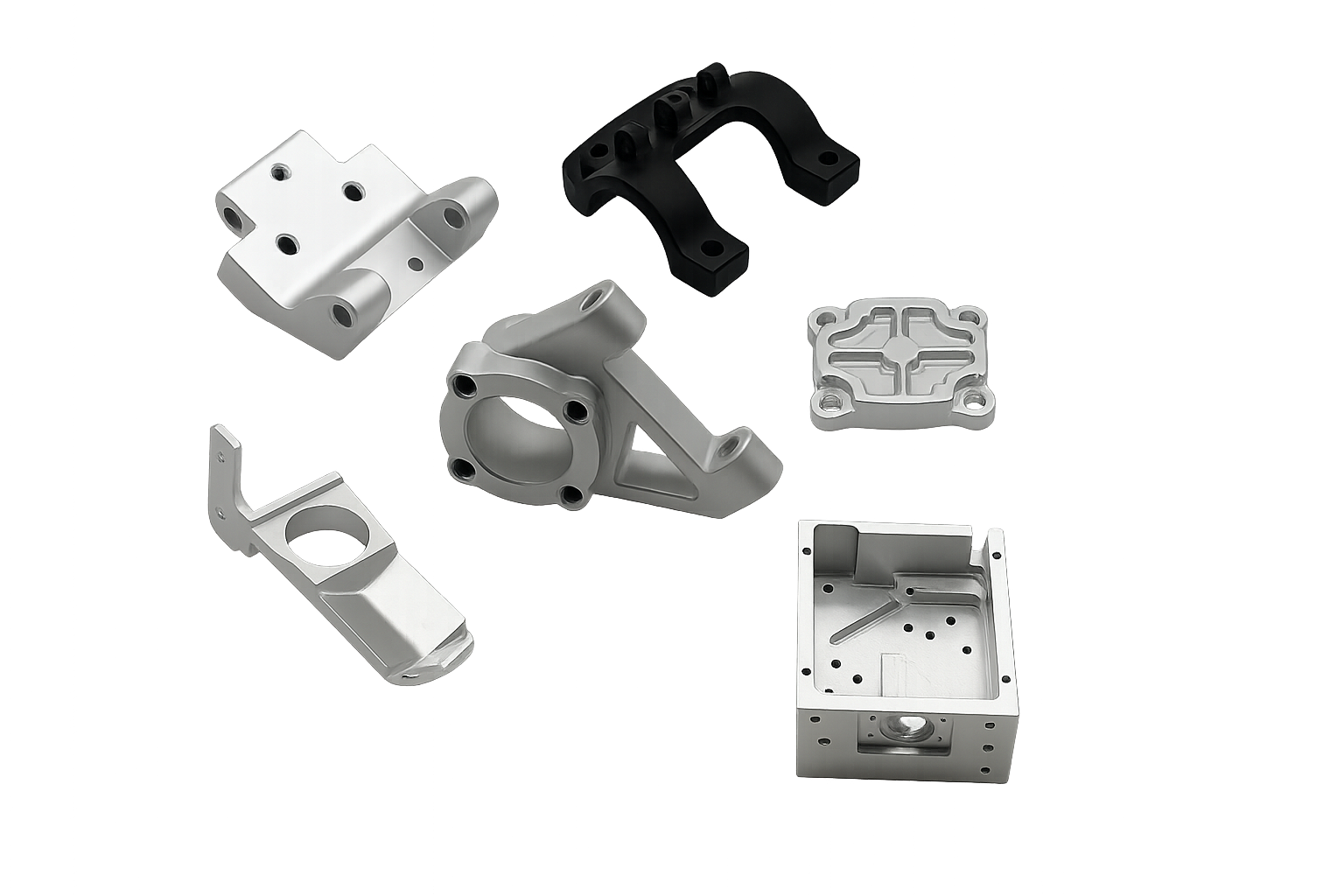

CNC Machining Aluminum Car Parts

CNC (Computer Numerical Control) machining utilizes automated machine tools guided by digital programming to precisely cut and shape aluminum into intricate automotive components. CNC machining provides exceptional accuracy, repeatability, and high-quality surface finishes, ideal for critical automotive components such as cylinder heads, suspension arms, and wheels.

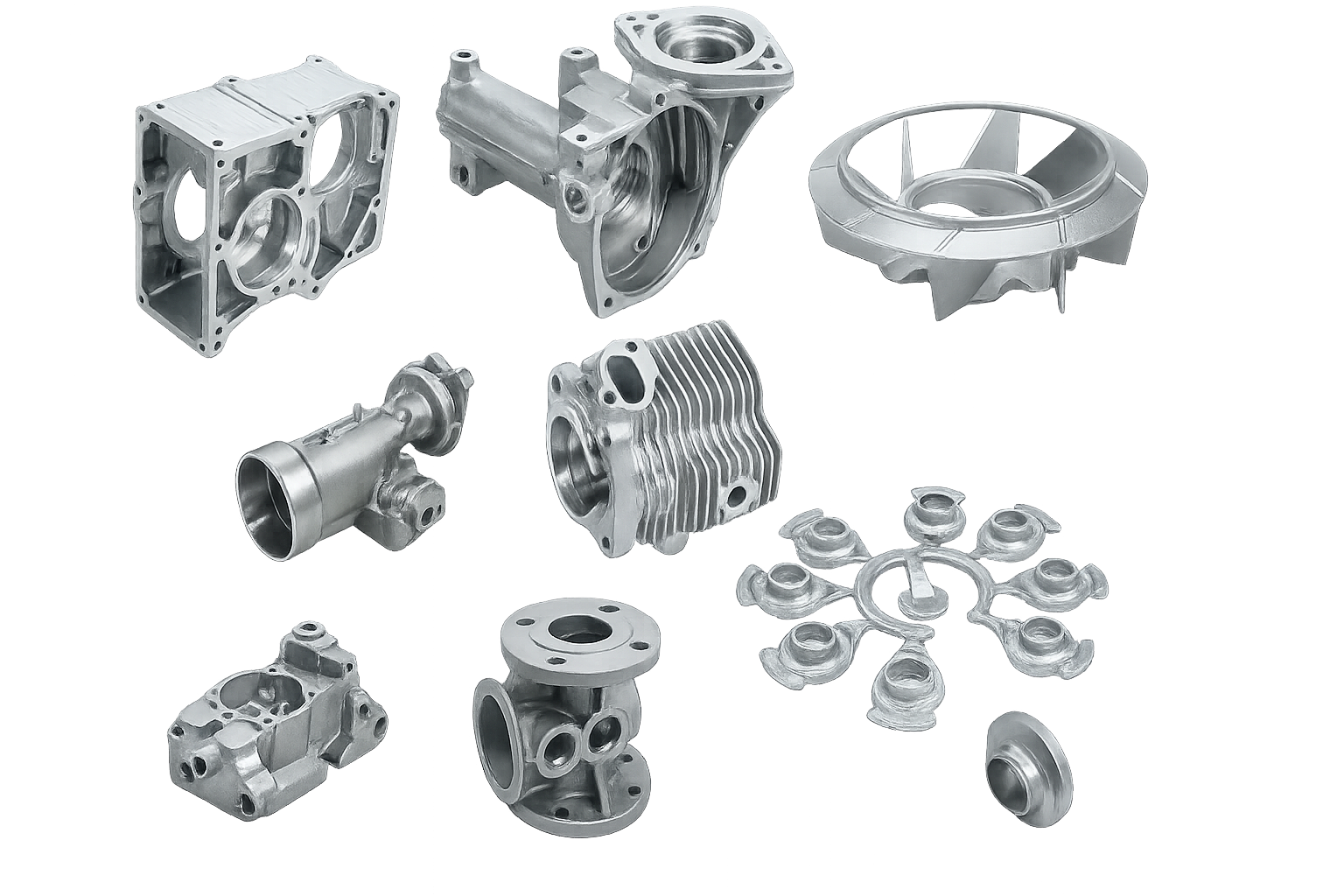

Die Casting Aluminum Car Parts

Die casting involves injecting molten aluminum into high-pressure molds, creating highly detailed parts quickly and efficiently. Die casting is ideal for mass production of engine blocks, transmission housings, brackets, and structural elements due to its precision, high productivity, and cost-effectiveness.

Advantages of Aluminum Car Parts

Exceptional Longevity

Aluminum’s inherent corrosion resistance extends component life, reducing rust-related repairs and replacements, especially beneficial for vehicles in harsh climates or off-road conditions.

Enhanced Vehicle Safety

Aluminum parts provide superior energy absorption during collisions, enhancing safety for occupants. Aluminum absorbs twice as much collision energy compared to steel of similar strength, reducing injury risks during accidents.

Improved Vehicle Performance

Lighter aluminum parts improve vehicle dynamics significantly, resulting in better acceleration, braking, handling, and fuel economy. These performance enhancements are increasingly critical in modern automotive design.

Increased Fuel Efficiency

Due to aluminum’s low density, vehicles incorporating aluminum components weigh substantially less, directly translating into improved fuel efficiency. Manufacturers frequently utilize aluminum for components like body frames and wheels specifically to enhance mileage.

Reduced Environmental Impact

Reduced vehicle weight also leads to decreased emissions, making aluminum an essential choice for manufacturers aiming to meet stringent global environmental regulations and sustainability goals.

Flawless Functionality

Advances in aluminum machining and forming technologies have greatly improved part precision, reducing assembly complexity, ensuring durability, and enabling tighter tolerances and improved functionality in aluminum automotive components.

Common Aluminum Alloys Used in Vehicle Parts

Automotive manufacturers select specific aluminum alloys based on required strength, corrosion resistance, and workability:

1100 Series: Excellent corrosion resistance, ideal for decorative trim.

2024 Series: High strength-to-weight ratio, used in structural and aerospace-inspired auto components.

3003, 3004, 3105 Series: Formable, corrosion-resistant alloys for heat exchangers and automotive tubing.

4032: Used in pistons due to high heat resistance.

6016, 6022, 6061, 6181 Series: Popular for vehicle panels, frames, chassis, and suspension components due to exceptional strength, weldability, and corrosion resistance.

5005, 5251, 5052, 5182, 5083: Robust and corrosion-resistant, suitable for fuel tanks and structural panels.

7003, 7046: Very high strength, used in safety-critical structural parts like crash rails.

Typical Aluminum Car Parts Applications

Body Panels

Automotive body panels made from aluminum provide excellent structural rigidity, corrosion resistance, and substantial weight savings compared to steel, enhancing aesthetics, safety, and fuel economy.

Radiators and Heat Exchangers

Aluminum radiators offer superior heat dissipation, durability, and reduced weight. Compared to copper and brass, aluminum is both lighter and more environmentally sustainable.

Wheels

Aluminum wheels are corrosion-resistant, lighter, and offer better performance, fuel efficiency, and reduced unsprung weight—directly translating to superior vehicle handling and ride comfort.

Chassis and Structural Components

Aluminum chassis structures and enclosures enhance rigidity, crashworthiness, and overall vehicle performance. They support critical components while significantly reducing vehicle mass.

Trends in Aluminum Car Manufacturing

Electric Vehicle Integration

With the rise of electric vehicles (EVs), aluminum usage has increased dramatically. Battery casings, lightweight frames, and suspension systems extend EV range and enhance efficiency and safety.

Advanced Manufacturing Technologies

Advancements in high-precision CNC machining, additive manufacturing (3D printing), and advanced die-casting enable manufacturers to produce increasingly complex aluminum components efficiently, fueling growth in luxury and high-performance vehicles.

Increased Adoption in Critical Safety Components

Future automotive design trends show expanding aluminum use in critical components such as crumple zones, structural frames, and battery housing, due to aluminum’s superior crash energy absorption and environmental benefits.

Conclusion: Tops–Precision, Your Expert in Aluminum Automotive Components

Aluminum’s unique blend of lightweight strength, durability, and corrosion resistance has revolutionized the automotive industry. For manufacturers aiming to meet stringent performance, efficiency, and sustainability demands, partnering with a trusted aluminum component manufacturer is critical.

Tops Precision offers precision CNC machining, advanced die casting, and high-quality additive manufacturing to produce premium aluminum car parts. Certified with ISO 9001, ISO 14001, and ISO 45001, our experienced team ensures top-notch quality and service for your automotive manufacturing needs.

Ready to optimize your automotive component performance? Contact our engineering experts at AT-Machining today and discover how we can enhance your vehicle manufacturing solutions.

FAQs

1. How does aluminum compare to high-strength steel in terms of crash safety?

Aluminum enhances crash safety because it has superior energy absorption capacity compared to traditional high-strength steel. When designed into specific structural components like crumple zones or crash rails, aluminum can absorb twice as much kinetic energy as a steel part of similar strength and mass through controlled deformation. This controlled collapse redirects impact forces away from the passenger cabin, enhancing occupant safety.

2. Why is aluminum particularly important for the manufacturing of Electric Vehicles (EVs)?

Aluminum is vital for EVs because reducing overall vehicle weight is directly linked to extending battery range and increasing efficiency. Aluminum is used extensively for battery casings (providing lightweight protection and thermal management) and structural frames. A lighter chassis means the battery power lasts longer, directly addressing a primary consumer concern regarding EV performance.

3. What is “Unsprung Weight,” and why does using aluminum wheels improve a vehicle’s handling?

Unsprung weight refers to the mass of the vehicle that is not supported by the suspension (e.g., wheels, tires, brakes, axles). Reducing unsprung weight is highly desirable because it allows the suspension system (springs and dampers) to react faster and more effectively to road imperfections. Lighter aluminum wheels reduce this mass, leading to improved acceleration, better braking performance, and superior vehicle handling and ride comfort.

4. What are the key distinctions between CNC Machining and Die Casting aluminum car parts?

| Feature | CNC Machining | Die Casting |

| Process | Subtractive (material removal) | Additive (molten metal injection) |

| Volume | Low to Medium (prototypes, small batches) | High to Mass Production |

| Precision/Tolerance | Highest accuracy; best for critical features | High accuracy; good for complex shapes |

| Cost | High initial cost per part; low setup cost | Low cost per part in mass volume; high tooling cost |

| Best For | Engine heads, suspension arms, complex one-offs | Engine blocks, housings, transmission cases |

5. Which aluminum alloy series are commonly used for external body panels, and why?

The 6000 Series alloys (like 6016, 6022, and 6181) are the most popular for body panels (hoods, fenders, doors). These alloys offer an excellent balance of properties:

-

Formability: They can be stamped and shaped into complex aesthetic designs.

-

Strength: They provide adequate dent resistance.

-

Weldability: They are easily joined to the aluminum structural frame.

-

Corrosion Resistance: Their natural oxide layer protects the exterior.

6. How does aluminum contribute to better thermal management in an engine?

Aluminum has superior thermal conductivity compared to steel. This property makes it highly effective for components that need to dissipate heat rapidly. In radiators and engine blocks/cylinder heads, aluminum efficiently draws excess heat away from combustion chambers and engine fluids, ensuring the engine operates within its optimal temperature range, thereby enhancing performance and longevity.

7. What is the biggest long-term cost advantage of using aluminum in vehicles?

The biggest long-term cost advantage is the reduced environmental impact and fuel consumption resulting from the lower vehicle weight. For every kilogram of weight saved, less fuel is consumed over the vehicle’s lifespan, translating to significant operational savings for the end-user and helping manufacturers meet increasingly strict global emissions regulations. This lower lifetime operating cost outweighs the initial higher raw material cost.