In the world of manufacturing, the difference between a successful product launch and a costly failure often begins at the very first step: The Request for Quote (RFQ).

For plastic injection molding, a quote is not merely a price tag; it is a feasibility study and a roadmap for production. Many project managers and engineers make the mistake of asking for a “ballpark price” with insufficient data. This leads to inaccurate estimates, future price hikes, and production delays.

To secure a quote that is both accurate and competitive, you must provide the manufacturer with the full context of your project. Below are the five essential areas you must define before hitting “send” on your RFQ.

1. The Drawing: The Technical Foundation

The phrase “a picture is worth a thousand words” is an understatement in manufacturing; a good drawing is worth thousands of dollars in saved tooling costs. The manufacturer cannot guess the geometry of your part.

To get a precise quote, you should provide two types of files:

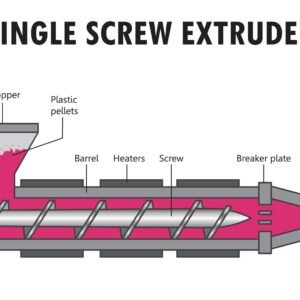

3D CAD Files (STEP or IGES format): These are critical for the mold designer to calculate the volume of plastic required, analyze the “draft angles” (slopes that allow the part to eject from the mold), and determine the complexity of the tool.

2D Drawings (PDF): While 3D files show the shape, 2D drawings show the rules. This is where you specify tolerances.

Why Detail Matters:

If you do not specify tolerances, a manufacturer might assume standard commercial tolerances. However, if your part needs to snap-fit into another component, you might need “tight tolerances” (e.g., +/- 0.05mm). Tighter tolerances require higher-precision CNC machining and higher-grade mold steel, which increases the quote. Always highlight critical-to-quality (CTQ) dimensions upfront.

2. Secondary Operations: The Full Scope

Injection molding is rarely the end of the road for a product. Many buyers treat the molder solely as a supplier of raw plastic parts, only to realize later that they need to hire a third party for assembly.

You must define the “state of delivery.” Ask yourself:

Post-Processing: Does the part need pad printing (logos), painting, or chrome plating?

Assembly: Do two plastic halves need to be ultrasonically welded together? Do metal threaded inserts need to be heat-staked into the plastic?

Packaging: Do you need bulk packaging (parts thrown in a box) or layer packing (to prevent scratches)? Do you need retail-ready packaging with barcodes?

The Impact on Quoting:

If a molder knows you need assembly, they might design the mold to produce multiple mating parts in one cycle (“family mold”), which can drastically reduce your overall assembly costs.

3. Estimated Annual Quantities (EAU): Planning for Scale

“How much does a mold cost?” is a question that cannot be answered without knowing “How many parts do you need?”

Your Estimated Annual Usage (EAU) dictates the Cavitation of the mold:

Low Volume (1,000 – 5,000 parts): The manufacturer may suggest a “Single Cavity” mold made from softer steel or aluminum. This tool is cheap to make but produces parts slowly (higher part price).

High Volume (100,000+ parts): The manufacturer will quote a “Multi-Cavity” mold (e.g., 4, 8, or 16 cavities) made from hardened tool steel. This tool is expensive upfront but produces parts very fast, significantly lowering the unit price.

Strategic Tip: If you are unsure of your volume, ask for a “tiered quote.” Request pricing breaks for 10,000, 50,000, and 100,000 units. This helps you visualize the Return on Investment (ROI) for investing in a higher-quality mold.

4. Material Selection: Balancing Performance and Cost

There are thousands of thermoplastic resins available, ranging from cheap commodity plastics to expensive engineering-grade resins. A quote cannot be generated without knowing the material, as prices vary from $1.50/kg to $50.00/kg.

If you haven’t selected a specific grade, define the properties you need:

Environment: Will the part be used outdoors? (Requires UV stabilizers).

Durability: Does it need to survive a drop test? (Requires high impact strength, like Polycarbonate or ABS).

Flexibility: Does it need to bend? (Requires Polypropylene or TPE).

Compliance: Does it need to be FDA food-safe or medical-grade?

Expertise Check: A good manufacturer will ask, “Can we use regrind?” (Recycled runner material). Allowing a percentage of regrind can lower your unit costs without sacrificing quality for non-critical parts.

5. Application: Context is King

Finally, explain what the product is and where it will be used. This context allows the manufacturer to align their industry expertise with your needs.

Different industries have different “unspoken rules”:

Houseware (e.g., Lunch Boxes): Aesthetics are paramount. The mold must be polished to a high gloss, and the plastic must be food-safe and stain-resistant.

Automotive: Consistency and safety are paramount. The molder will need to provide rigorous quality documentation (PPAP).

Electronics: Dimensional stability is paramount. The molder must account for “shrinkage” rates of technical plastics.

By partnering with a manufacturer specialized in your sector—for example, a company expert in houseware molds for food containers—you leverage their prior experience. They can proactively warn you about potential issues, such as “This lid design might leak if we don’t adjust the rim thickness.”

Conclusion

A plastic injection molding quote is a complex calculation involving cycle times, machine tonnage, resin costs, and tooling hours. By providing a comprehensive package—detailed CAD drawings, a list of secondary operations, realistic volume estimates, clear material requirements, and application context—you move from a “guesstimate” to a firm, actionable partnership proposal.

Preparation is the key to precision. The more information you share upfront, the smoother your journey from concept to mass production will be.

FAQs

Q1: How long does the entire process take, from Quote to First Sample (T1)?

A: While timelines vary based on complexity, here is a typical schedule:

Quoting: Expect a comprehensive quote within 24 to 48 hours after submitting your 3D CAD files and 2D drawings.

Tooling (Mold Building): Once the order is placed and the design is approved, manufacturing the mold typically takes 4 to 8 weeks. Simple, single-cavity molds are faster, while complex, multi-cavity hardened steel molds take longer.

Sampling (T1): Once the mold is finished, the manufacturer will shoot the first samples (T1) and ship them to you for approval.

Tip: Always ask for a “Gantt Chart” or project timeline along with your quote so you can plan your product launch accordingly.

Q2: Who owns the mold after I pay the tooling fees?

A: In standard “custom molding” contracts, you (the client) own the mold once you have paid the tooling invoice in full. You have the right to move that mold to a different factory if you are unhappy with the service.

Warning: Be cautious of quotes that offer “amortized tooling” (where the mold cost is hidden inside a slightly higher part price) or “extremely low” tooling costs. In these arrangements, the manufacturer often retains ownership of the mold to ensure you keep buying parts from them. Always clarify “Tooling Ownership” in writing before signing the quote.

Q3: What is a “DFM Report” and should I expect one with my quote?

A: DFM stands for Design for Manufacturing. It is a technical analysis where the molder reviews your 3D design to identify impossible geometries, risk of warping, or sink marks.

During the Quote: Most molders will provide a “basic feasibility check” with the quote to warn you of major red flags.

After the Order: A full, detailed DFM report (showing gate locations, parting lines, and ejector pin marks) is usually provided after you place the order but before steel is cut.

Why it matters: Never skip the DFM review. Fixing a design on a computer is free; fixing a steel mold is expensive.