End milling is a necessary type of machining operation. It is the achievement of many different shapes essential in industries. It employs cutting tools known as end mills that are intended to eliminate material by executing motion in various planes about the workpiece. Besides this, it is expensive but very helpful in creating complex structures and fine surfaces. So, in this article, we will discuss the definition of end milling, the characteristics of end milling, and some comparisons with other kinds of milling. They will assist a manufacturer in making proper decisions about using end milling.

What is End Milling?

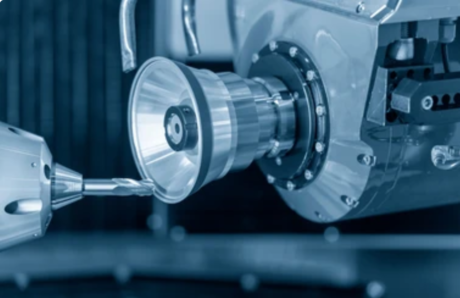

End milling is one of the most common techniques of machining. Here the cutting tools mounted on a spindle are used to remove the material from the workpiece by their rotary motion. The type of cutting tool used is called an end mill, which has cutting edges on its end and sidewise. They allow the workpiece to be cut axially and radially. This operation has many applications for forming elements such as slots, contours, profiles, and holes in different materials. These may include metals, plastics, etc. End milling is important due to a large number of advantages over other methods. These can be a high level of accuracy, flexibility in the creation of steep edges, and improved chronological output. Besides this, it can help create geometrical complexities in one cycle.

How does the End Milling Process Works?

End milling is also another term used for end cutting. It involves a tool or end mill that rotates at a given speed. Then they are fed into the workpiece and are used to shave off the parts that are wanted in the final product. The cutting tool has a sharp point and sides enabling it to cut in all directions. So, this makes it very versatile and allows it to make complex shapes. Here’s how the process works in detail:

1. Axial Cutting

In this operation, the end mill is generally in a vertical direction to the workpiece. This has many applications in a process that helps make indentations such as holes or pockets on the material. The cutting action is mainly at the end part of the end mill. So, it cuts as it moves downwards with a firm plunge.

2. Radial Cutting

Here, the end mill translates along the XY plane of the workpiece in a macro way. This movement helps generate features such as slots, profiles, or contours. The side cutting edges situated on the flanks of the end mill cut through the workpiece as the tool translates along the plane of the workpiece.

3. Helical Cutting

This is a more comprehensive movement and here the end mill can be moved at the axial or vertical as well as radial or the horizontal direction. This makes it possible to form shapes like spiral grooves, threads, or different types of features. These movement directions are in combination with one another. So, it enables the creation of geometries that are otherwise very hard when using other cutting tools.

Properties of the End Milling Machines

End milling machines use a variety of operations, i.e. face milling, profile milling, and plunge milling machines. Key features include:

- High-Speed Spindles: It is used as a tool that can rotate at a high speed in RPMs for quick-cutting solutions.

- Versatile Tooling Options: Hold an assortment of end mills, both flat, ball-nose, and corner-radius forms.

- Precision Control: Sophisticated computer numerically controlled systems serve the purpose of optimizing the operation of cutters and their trajectories.

- Rigidity and Stability: Machines are constructed to reduce vibration. So, they can guarantee no deviations in accuracy on the job.

- Coolant Systems: Heat is controlled by integrated systems and tools durability is maintained.

How does Material Type Impact the Choice of End Mill Tools?

The type of material used greatly influences the decision on which end mill to use. Aluminum is softer, so the cutting edge is often sharp and high-speed. It has a layer to prevent the build-up of material on the tool. Ferrous as well as some of the nonferrous metals such as steel and titanium, require tooltips as end mills of heavier metals like carbide or cobalt and sometimes with special treatment coatings. So, they can reduce the effects of heat and abrasion. Further, the end mill shape, number of flutes, and the helix angle must correlate to the material type. Then they will allow for proper chip evacuation and reduce tool wear.

Design Tips Needed for an Efficient End Milling Operation

So, let’s discuss some of the important design tips to make End Milling operations more effective.

- Optimize Tool Path Planning: Take specific consideration of the motions of the tool during cutting. So, it can help reduce the time that the tool is idle.

- Select the Right Tool Geometry: Select end mills depending on their flute count and number and helix angle. It must be irrespective of the material type and operation the tilting angle of the tip must be appropriate.

- Control Cutting Parameters: It will help manage and vary the spindle speed, feed rate, and depth of cut. Besides this, it can optimize the material removal rate and increase the tool’s durability.

- Use Proper Workholding: Clamp the workpiece to reduce the vibration. So, it can be easier to get a more accurate finish.

- Apply Coolant Strategically: Of temperature, the heat must be controlled by the use of coolant or air blast. It will ultimately reduce the amount of chip accumulation and improve the longevity of the tool.

End Milling vs. Traditional Milling

The following table will help you understand the major difference between End Milling and Traditional Milling.

| Aspect | End Milling | Traditional Milling |

| Tooling | It uses end mills with cutting edges on both tips and sides. | Uses milling cutters with teeth on the periphery. |

| Operations | Can perform various operations in multiple directions. | Typically limited to peripheral or face milling. |

| Flexibility | High, suitable for complex geometries. | Less flexible, better for simpler shapes. |

| Accuracy | High precision and tight tolerances. | Moderate precision. |

| Speed | Faster, especially with CNC machines. | Slower in comparison. |

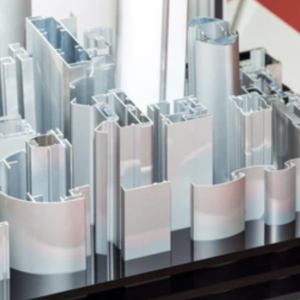

Different Materials Suitable for End Milling

Here we have enlisted a few materials that are more suitable for the End Milling process.

| Material Type | Hardness (Rockwell) | Cutting Speed (m/min) | Tool Material |

| Aluminum Alloys | 30-50 HRB | 150-400 | HSS or Carbide |

| Steel | 45-65 HRC | 50-120 | Carbide or Cobalt |

| Stainless Steel | 40-55 HRC | 30-90 | Carbide |

| Titanium Alloys | 30-45 HRC | 20-60 | Carbide or CBN |

| Plastics (Acrylic, ABS) | 10-20 HRB | 300-600 | HSS |

Applications of End Milling

The following are the applications of End Milling:

- Automotive Industry: Manufacturing engine parts, gutters, and molds.

- Aerospace Industry: Manufacturing of items that require intricate designs such as the blades of the turbines and the frameworks of planes.

- Medical Devices: In fusion, bleeding with slice production and machining of implants.

- Electronics: In fact, manufacturing the enclosures and the connectors is important.

- Tool and Die Making: Creating molds dies and other specialized tools.

When to Choose an End Milling?

End mills are preferred when finishing, adaptation, and the capability of producing aggressive shapes are needed. It is possible to use them for slotting, profiling, and contouring. Besides this, it is particularly used in designs where tolerance levels are complex and stringent. End mills are used especially when the programming involves piercing work, beneath which are holes, slots, or in branched operation. They all have varying thicknesses of plastics, metals, etc.

Advantages of End Milling

So, the following are the advantages of End Milling:

1- High precision and Surface Tolerances.

2- Transportation in various directions, and flexible movement in two directions.

3- The capacity to work as a machine on intricate forms.

4- Should apply with a variety of material types.

5- High-quality surface finishes.

Disadvantages of End Milling

So, the limitations of end milling are:

1-It demands tooling and equipment specific to the material type.

2-Fine finishing is likely to be time-consuming. Besides this, the cutting tool is also likely to wear quickly, particularly if the material is very hard.

3-Purchasing some of the most highly developed machines may be more costly initially.

4-The high level of programming required when using CNC for different operations.

Conclusion

In conclusion, end milling is one of the most widely used processes in the industry. It is mainly because of its geometrical flexibility, enhanced accuracy, and better surface finish. Knowing its characteristics, prices, and use can assist the manufacturers to invest in it to improve the quality of their products. The decision towards the proper choice of tools, materials, and machining parameters makes the end milling process one of the most efficient and inexpensive methods.

Frequently Asked Questions

Q1. What is the difference between face milling and end milling?

In end milling, the cutter revolves on its axis and at the same time moves linearly to remove the material. On the other hand, in face milling, the cutter moves in only one operation along the Y-axis after which the material is dredged. Moreover, in end milling, cutting edges are on the end and sides of the tool. In face milling, the tool only has cutting edges on the face.

face milling vs end milling in detail.

Q2. What factors should I consider for the right end mill for the material?

It can be based on the hardness of the material or the cutting speed. Besides this, must consider the tool geometry for cutting.

Q3. Which materials are more suitable for end milling operations?

End milling is best done on aluminum, steel, titanium, and some plastics.

Q4. Can end mills be used for drilling?

It is possible to use certain end mills as a drill. However, this is not its primary function.

Q5. What factors influence tool life in end milling?

Several factors can have an impact on the tool’s life. These may include the hardness of the material, cutting speed, feed rate, tool material used, and application of coolant.