Milling machines are among the oldest and most important tools used in industrial machining for over 300 years. These flexible machines, usually called multi-tasking machines (MTMs), are capable of performing both milling and turning operations. Having a cutter with them, they cut material from a workpiece and create intricate components, beyond the scope of conventional 3D printers. Milling machines are applied in automotive industries, electronics, and high-precision scientific laboratories among others making it a competitive tool for manufacturers. This article aimed to explain the working principle of the milling machines, the available types, and crucial parameters to focus on.

What are Milling Machines?

A milling machine involves a circular tool with several cutting edges arranged symmetrically on the shank. The workpiece is normally clamped or secured by a vise or other clamping means mounted on a table that is capable of movement. This table can be shifted in three mutually perpendicular directions to place the workpiece against the cutter. Arbor-type cutters are disk, and barrel shapes, fixed on arbors with holes at the middle of the cutters and rotate on the machine spindle having cutting teeth on the periphery. An end mill is a pencil-shaped cutter having a tapered shank and cutting teeth on the face while the lateral surface uses spiral blades for cutting.

How Does a Milling Machine Work?

In milling the workpiece is fed against the rotating cutter either manually or using a machine tool. Even though milling machines are typically used to create flat surfaces. For example, to mill a gear, a specific cutter with the right tooth profile is employed. Every recess on the gear is made one at a time. Such flexibility makes them ideal for the production of different parts and surfaces in many sectors.

Basic Features of a Milling Machine

Some of the main parts of a milling machine include the following:

Base

The base is the strong foundation on which the milling machine is stood. It supports the whole mechanical load of the machine and also serves as a buffer to vibrations created during operations.

Column

The column is the vertical member that encapsulates and sustains the reciprocating part of the machine. It sustains the driving mechanisms that give the framework for the spindle and headstock.

Knee

The knee is supported on the base and supports the work table. It can be raised or lowered which facilitates the up and down movement of the workpiece.

Saddle

The saddle connects the worktable to the knee in a manner of a saddle-like structure. It glides the table in one direction only and this enables the movement to be made in a direction that is perpendicular to the column.

Spindle

The spindle rotates the workpiece and is usually mounted on a cutting tool. It guides the tool during milling operation and it can be positioned in various directions in advanced machines for intricate cutting.

Arbor

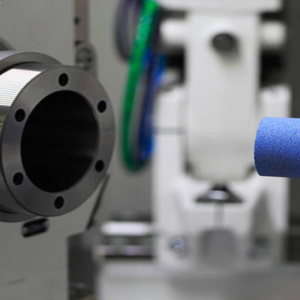

An arbor is a tool holder, mounted on the spindle of the machine tool, it is usually made of steel material. It supports specialized cutting tools such as a side cutter to enhance the milled width of a workpiece when milled across its width.

Worktable

The worktable bears the workpiece and secures it by clamps or fixtures right from the beginning of the work till the end. As for motion, it allows linear, and in some cases rotational or linear reciprocal.

Headstock

The headstock is a machine part on which the spindle is placed. It has the function of causing the spindle to move. It has motors to move the spindle forward and backward so that it rotates and also to get the desired precision during the cutting process.

Overarm

The overarm supports the spindle and the arbor. Sitting on top of the column, it offers support and counterbalance cases of high-load milling processes particularly when large or side-mounted tools are used.

Types of Milling Machines

Milling machines are categorized in different ways. Here are the primary types based on spindle orientation:

Vertical Milling Machines

As the name implies, the spindle moves along the vertical axis. The tool enables the workpiece to enter from the top for drilling and cutting operations. These machines are available in two designs: Other types of machine tools include bed mills and turret mills. Vertical machines normally incorporate long, slender cutting tools for accurate work.

Horizontal Milling Machines

In horizontal milling machines, the spindle is mounted horizontally. In these machines, the cutter tool is placed beside the workpiece and not above it as in the case of the conventional machines.

Universal Milling Machines

A universal milling machine features both vertical milling and horizontal milling performance. This tool can be accessed from multiple directions due to the rotating table on which the workpiece is placed.

Common Milling Machine Operations

There are several working principles of a milling machine to perform several operations. Here are some of the most common operations used across industries:

Up-Milling Operation

Also identified as called up and down milling. In operation, the cutter rotates in a direction opposite to the feed direction of the workpiece. The cutter shaves the material into small particles, and chips with the thickness gradually increasing from the minimum at the start to a maximum at the end. The major drawback is that the cutting force acting on the workpiece tends to lift the workpiece from its fixture and hence has a bad surface finish.

Down-Milling Operation

Down milling, or climb milling, is where the cutter rotates in the same direction as the feed. The chip thickness is at its maximum at the beginning of the cut and at its minimum towards the cutter end. This method produces less heat due to reduced friction and is suitable for use in thin slotting, long-reach cutting, and sharpening operations.

Plain Milling Operation

Slab milling or plain milling is a typical operation where the workpiece is clamped on a milling machine and the machine is used to produce a flat, horizontal surface.. This surface is at right angles to the cutter’s axis of rotation and is often used in finishing operations.

Face Milling Operation

Face milling is the easiest milling operation performed, A face milling cutter is used in cutting flat surfaces and it rotates in a direction perpendicular to the work surface. The depth of the cut is regulated with the aid of the crossfeed screw of the table to give accurate cuts.

Gang Milling Operation

The gang milling process uses several cutters of different diameters to mill several surfaces at one go. All the cutters’ speed is regulated by the largest cutter. This operation is time-saving and is mostly applied where there are several similar tasks to be performed.

Straddle Milling Operation

In straddle milling machine mills two parallel faces on the workpiece, For instance; to mount two side milling cutters on the same arbor. Collars are used to maintain proper spacing to ensure cutting is accurate and consistent. The process is optimal for creating hexagonal or square shapes only.

Angular Milling Operation

Angular milling is used to produce surfaces on a workpiece that are not perpendicular to the spindle axis. The operation is determined by the geometry and the kind of the angular cutter. V-blocks are an example of this method at the micro-level of organizing work.

Form Milling Operation

Form milling is used to create forms with complex shapes such as concave, convex, or other forms of irregularity in the form cutters. The kind of cutter used depends on the required shape and the operation has a lower cutting rate than the plain milling operation in several cases.

Side Milling Operation

Side milling employs a cutting tool to make flat vertical faces on the sides of the workpiece. The depth of the cut is controlled by changing the vertical feed with the help of the table screw.

Keyway Milling Operation

Keyway milling is used to produce keyways, grooves, or slots of various sizes and shapes. This operation can be done with an end mill, plain milling cutter, side milling cutter or metal slitting saw. So, accurate tools should be used to achieve the right sizes.

Types of Materials Milled By Milling Machines

Milling machines are versatile, and they can cut about all material types. The commonly processed, metals include steel, aluminum, brass, and stainless steel since they are easily machined and strong. Other materials such as ABS, nylon, and HDPE are also ideal candidates for the milling machine. It is possible to mill ceramics such as porcelain and alumina using specific tools but they have to be handled carefully. Moreover, several other materials can be used including composites like FRP and carbon composites, woods like softwoods, hardwoods, and engineered woods.

Types of Cutting Tools Applied in Milling

Milling machines use a range of cutting tools, specialized for different uses in the machines. Some tools such as end mills are designed to operate cutting material from the sides of a workpiece and not from the end. The face mills are preferred for smooth finishes as they possess flat surfaces with several cutting edges. Shell mills with different cutters and arbors are modularity in design. Slab mills, cylindrical with straight/angular tooth form are recommended for large metal removal rates. T-slot cutters generate T-shaped slots, slot drills can both, drill and slot. Ball nose cutters make spherical shapes while fly cutters are involved in planning. Internal thread mills produce internal threads while external thread mills produce threads on the outer surface of the workpiece, chamfer mills produce inclined planes.

Milling Machines Uses

Milling machines are used in different industries and are considered necessary tools. In the automotive and aerospace industries, they are applied to the sections of the exact components and parts. The manufacturing of metals and electronics requires an intricate and long-lasting finish, which milling offers. Milling in woodworking is used in making furniture and structures while in construction projects milled parts are used. Mold and die-making industries use the milling process for precision tools. Furthermore, milling is useful in the manufacturing of medical and dental implants and instruments as well as artificial limbs research and development activities. Moreover, milling is often used in the creation of prototypes.

Advantages & Disadvantages of Milling Machines

There are many advantages of using Milling machines such as high versatility and precision. They yield accurate results, which are suitable for large-scale production and can easily be incorporated with CNC systems for operation. But they have their disadvantages too. The initial cost of the milling machines is relatively expensive, and this may not be affordable to most companies especially those that are small. They also demand a large floor space and tooling knowledge, which results in a longer set-up time. Milling is usually done on all the faces of the workpiece except the last part which is called the base or the bottom.

How Much Does Milling Machines Cost?

The prices of new advanced milling machines depend on the manufacturer and model, and they can cost as low as $10000 or as high as $200000. The factors can be the type of mill, number of axes, size of the machine, and the brand. Some of the high-end models that are equipped with additional functions and have higher accuracy are rather costly. Another factor that impacts the price of the control system is the complexity where the higher complexity leads to increased price.

Endnotes

To conclude the discussion, milling machines enhance the quality of parts being produced in large quantities, thus making them suitable for manufacturing requirements. They are not limited to large-scale production but are equally useful in the creation of models and the testing process. Therefore, getting a milling machine is a very wise decision that will ensure that you get a proper solution for your production line.

FAQ’s

Q1: What is the level of accuracy of milling machines?

Milling machines have a high degree of accuracy and precision which is within ±0.001 inches, but it depends on the setup and material. Thus, milling machines are highly preferred for engineering tasks.

Q2: Can milling machines handle both small and large production?

Indeed, milling machines are in a way versatile. They can be used in small-scale production of intricate parts, and in large-scale production as well.

Q3: Milling machine Vs. Drill Press, what are the differences?

A drill press only drills vertically and in a straight line. A milling machine is capable of producing intricate shapes, it can cut materials both in a straight line and across the grain.

Q4: What is the difference between a milling machine and a drill press?

A machining center has a built-in tool changer that allows one to perform several operations on the workpiece without the need to change tools physically while a milling machine requires the tools to be changed manually for different operations.

4 thoughts on “What is a Milling Machine?”