The ferromagnetic and non-ferromagnetic materials are central in engineering. Magnetism is a base for various uses but it is often inconvenient in certain circumstances. Most frequent magnetic metals include; iron, nickel, and cobalt, and some steel grades also exhibit magnetism properties.

Understanding the fundamentals of magnets, their types, and how metals behave in magnetic fields is imperative. So, let’s get into it.

Understanding Magnetism

Magnetism could be defined as an ability that pull or push certain types of material. This force is intervened by magnetic fields that pervade different types of media. Some types of material are naturally magnetic while others can be made magnetic or nonmagnetic depending on the situation.

What Makes Metals to Exhibit Magnetism?

Magnetism at the atomic level is caused by electrons. Each electron has a spin and a way to form a small magnetic dipole. If the spin of an electron is unified in a particular direction, then no net magnetic field is observed. But since there are many of these electrons unpaired their small magnetic moment becomes large and a large magnetic field is created around the metal.

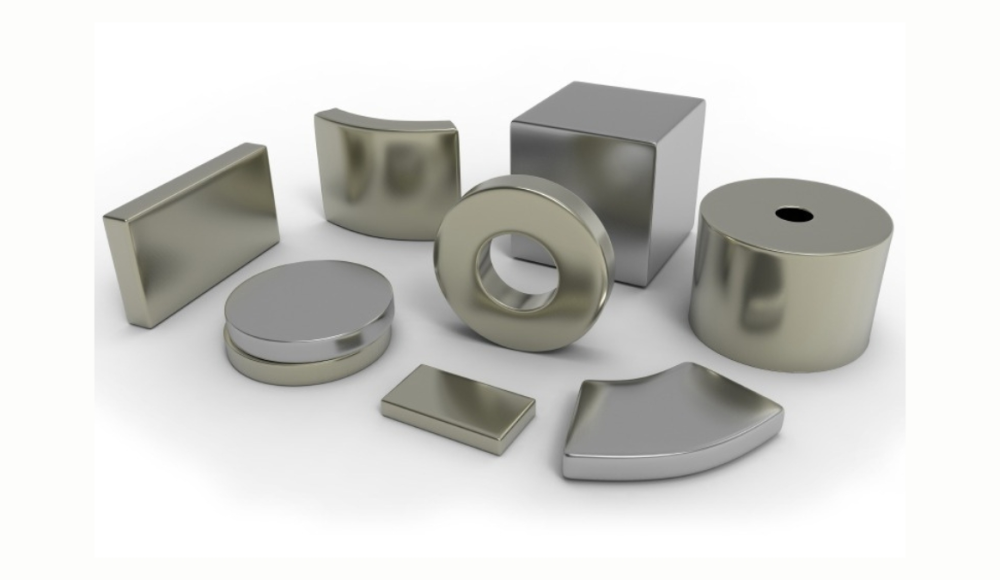

Types of Magnets

Different types of magnets can be grouped according to the permanency of the magnets’ magnetic field. The primary classifications include:

Permanent Magnets

Permanent magnets generate a magnetic field due to their inherent properties. Unlike temporary magnets, they retain their magnetism for a long period. Typically, permanent magnets are difficult to demagnetize and create a stable magnetic field. To understand permanent magnets, one must consider their structure. Magnetic properties occur when the ponderomotive forces in the distinct region of the material prefer a particular status. These domains are small magnetic fields found inside the material’s crystal structure.

Several techniques are used to couple these domains, but heating is the most efficient of all. The degree of alignment differs across the materials resulting in permanent positioning of the domains.

Temporary Magnets

Temporary magnets have the characteristic of being magnetic only in certain conditions. They all disappear once these conditions change. Forces that cause changes in size are often applied to soft materials like annealed iron and steel. These materials create magnetic fields when exposed to a strong magnetic field and exhibit low coercivity.

One good example of temporary magnetism is the paper clip strategy. When a paper clip is stroked on a permanent magnet it acquires some magnetization. However, once the permanent magnet is removed. The clips return to their state in which they are not magnetic.

Electromagnets

Electromagnets generate a magnetic field when electricity flows through them. They are often used in devices like motors, generators, relays, and headphones. The benefit of an electromagnet is the possibility to switch on/off the magnetic force. This feature allows several uses, including the cranes used in lifting scrap metal. Control of metal is possible with the help of an electromagnet by passing an electric current through it, and the metal can be lifted and dropped by switching off the power.

Another fascinating use of this technique is in Maglev trains. Due to power supplied to the electromagnets, these trains do not touch the tracks and this in turn provides low rail resistance for high speeds.

Which Metals Are Magnetic?

Depending on the internal structure of the metals they either attract or repel magnets. They can be classified as:

Ferromagnetic Materials

Ferromagnetic materials pull on magnets very heavily while on the other hand, pull on magnets lightly for paramagnetic materials. Diamagnetic materials are those materials that repel magnets weakly.

List of Magnetic Metals

Some magnetic metals are familiar and some are permanently magnetic while others, for instance, stainless steel are magnetic depending on their composition.

Iron

Iron is a widely known ferromagnetic metal, and at the same time, it is stronger than all the other ferromagnetic metals. More importantly, as a fundamental constituent of the earth, it is responsible for the magnetic field of the earthly sphere.

Some content regarding how iron attracts magnetic fields is due to the presence of atomic electron spin and specific crystal lattice structure. These structures when changed produce different magnetic characteristics. Iron in its body-centered cubic (bcc) alpha-Fe form is ferromagnetic; the face-centered cubic (fcc) gamma-Fe structure is non-magnetic.

Nickel

Another ferromagnetic metal is Nickel and it also has a relation with the earth’s core. Previously, it has served in the circulation of money in the form of coins.

Today, the use of nickel includes batteries, coatings, kitchen utensils, and numerous electronic equipment. That is why nickel is valuable in the creation of ferronickel for stainless steel and Alnico magnets, the magnets that are stronger than rare earth magnets but not as strong as iron-based ones.

Cobalt

Cobalt is one of the most important ferromagnetic metals that have found numerous uses in the last one hundred years. Cobalt is used in both the soft as well as the hard magnets and the saturation magnetization and Curie temperature are high, ranging between 950 – 990 °C. This property makes cobalt useful in high-temperature uses like use in motors and sensors.

Steel

The iron component makes steel ferromagnetic. All the types of steel can work with magnetic fields and a few can be made into permanent magnets. For instance, EN C15D steel has a composition of 98.81/99.26 % iron and therefore is ferromagnetic.

Stainless Steel

Stainless steel has a varying level of magnetic properties. Depending on the content, it is an alloy that contains at least 10.5% of chromium, its magnetism depends on this content. Martensitic and ferritic stainless steels are magnetic because of their iron content, while austenitic stainless steels have low ferromagnetic properties that qualify them for use in MRI situations.

Rare Earth Metals

Some of the cross-sections of the rare earth metals are ferromagnetic in nature and the metals include gadolinium, samarium, and neodymium. These metals can be alloyed with iron, nickel, or cobalt in order to produce magnets that are well suited to a particular application. For example, samarium cobalt magnets are well applied in high-performance motors and turbomachinery.

Non-Magnetic Metals

While many metals are magnetic, some are not. Here are a few examples:

Aluminum

Aluminum also falls under the group of paramagnetic metals as is lithium and magnesium metals. Although it can corrode, it is useful in many corrosive conditions; this makes it popular in many industries.

Gold

Gold belongs to the diamagnetic group of metals. Generally, it experiences minimal repulsion when near a magnet. In its pure state, it is a non-magnetic metal.

Silver

Silver is also non-magnetic. It can be used to detect forged silver products. If a coin or piece of jewelry sticks to a magnet, it is probably not real silver.

Copper

Is Copper Magnetic? Copper by its nature is not magnetic however it does have some magnetic qualities and characteristics. Labeled diamagnetic, copper is the type of material that cannot be aligned with a magnetic field. In the case of generating electricity at power plants, this characteristic is of immense value.

When placed near a magnet Copper creates a magnetic field that forces the surface electrons to flow and spin around the magnet. This makes circular movement create resistance. The electrons cause a magnetic field briefly, and that decreases the speed of the magnetic fall.

Conclusion

In general, all metals are affected by a strong magnetic field. This reaction occurs because when metals are put in a changing magnetic field, they develop what is called eddy currents. Metal detectors follow this principle to identify non-ferromagnetic metals such as gold, silver, copper, and tin. However, for practical use, this interaction is not enough, therefore it has limited applications.

Use Tops Precision for Metal Machining To Get Parts at a Reasonable Price.

Tops Precision is a specialty metals supplier that has earned ISO 9001 certification. Since our company’s inception, has helped many clients in identifying special metals that are difficult to locate.

Some of the magnetic metal materials we supply include cold rolled steel, high carbon spring steel as well as different types of tempered stainless steel. We can supply 10 pounds for specific applications 2,000 pounds for production needs, and everything in between.

Get your metal materials today by completing a Tops Precision Quick Quote. Our staff with expertise in the area is ready to answer any question and usually reply within 2 hours or the same day.