Screw threads are basic principles of engineering used for secure joining in some situations. They are used in every field imaginable including area space, and automobile industries for joining purposes. Knowledge of the screw threads, materials used and processes of manufacture is very important for the engineer to get the maximum desired results. This is a thread design guide with this every detail from thread types to the material to be used is explained giving the reader a sound understanding of screw thread design.

What is Machine Screw Thread?

A machine screw thread is an external or internal cavity or ridge of a spiral form surrounding the circumference of a cylindrical shaft which is intended to screw in a threaded hole or nut. Both of these threads enable the user to pass mechanical forces through them and also ensure the secure and repeated engagement of the overall fasteners between various system members.

Standardization of screw threads, as well as all the mechanical elements, is important to organize the complicated procedures of mechanical design and production, machine screw threads are likewise canonical to the process.

Different Machine Screw Thread Types

These types may include:

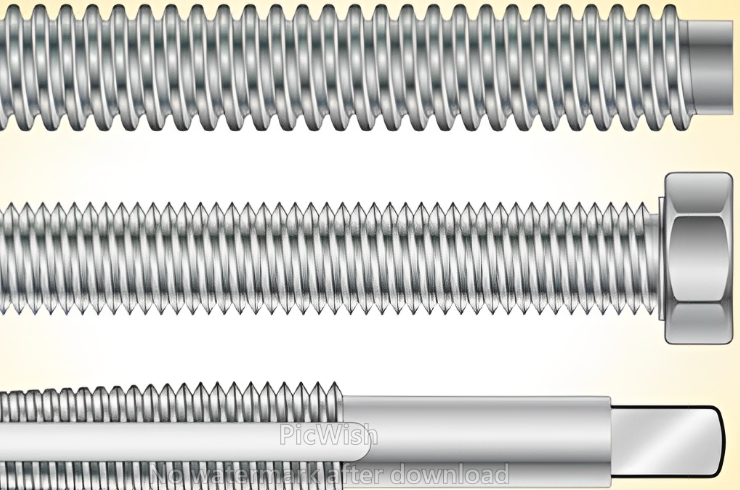

1. Unified Thread Standard (UTS)

One of the most employed threads in the United States and Canada, it comprises both large and small pitch threads. The system is quantified by the threads per inch (TPI) and is commonly utilized in industry and home environments.

2. Metric Thread (ISO)

Interchangeable globally with the standard and commonly implemented model, it describes the diameter and pitch in millimeters. International Organization for Standardization has carried out standardization of ISO metric thread which is in use in Europe and most other countries of the world.

3. Acme Thread

Most commonly used for power transmission applications, mostly found to have a trapezoidal cross-sectional shape which provides more strength. Acme threads are considered to sustain high axial loads, it exhibits smooth motion and can be used in mechanical jacks and lead screws.

4. Buttress Thread

It is particularly intended for circumstances where an application has a considerable force in only one direction and is mostly used in large machines. The cross-sectional shape of the buttress thread is such that on one face it forms a steep angle against the bar for withstanding one kind of load.

5. Square Thread

It is used particularly where high efficiency in transmitting the power is desired which is common in jacks and presses. Simplest square threads have square-shaped thread profiles and have the least friction and wear compared to other thread profiles they are best suited for axial load applications.

How is the Thread Produced on Machine Screws?

The most common methods for making machine screw threads include:

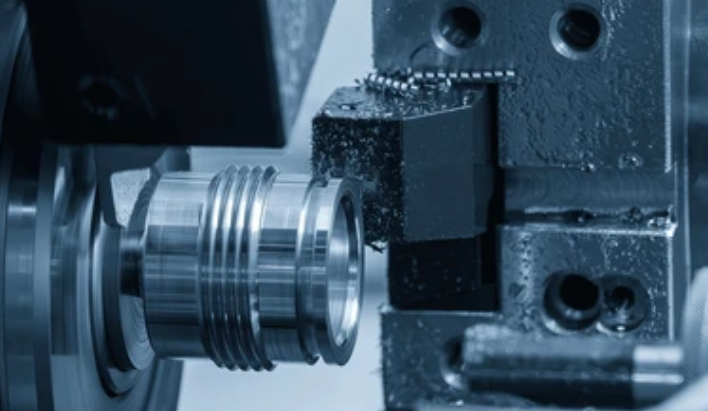

1. Thread Cutting

This is an old-fashioned technique where a cutting tool cuts threads on the workpiece to create the threads. It forms threads slowly and steadily to the required dimensions. The advantage of this process is that it is efficient for the creation of threads in a limited or in individual thread production but if one is looking to produce threads in large quantities then this may not be as efficient or even economical.

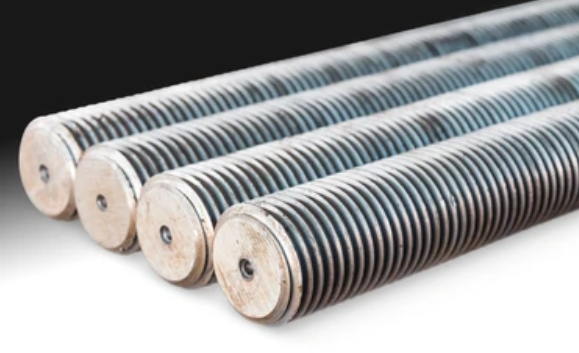

2. Thread Rolling

Thread rolling is a cold-forming process in which various kinds of dies rotate and compress a workpiece to impose thread form on its surface without cutting it. This method creates stronger threads and is most often used for mass production because it maintains the material’s grain structure. However, thread rolling is more efficient and economical for the production of some threads especially through mass production.

3. Thread Grinding

Precision threads, particularly when slender or highly accurate threads, are needed, Fuller’s threads are produced by thread grinding. In this process, a grinding wheel is employed to thread to a great level of accuracy so that it may fit onto another part. This is frequently applied for turning out precision threads such as those required in tools, machines, and instruments.

5. Thread Forming

This is another cold-forming process in which material is reshaped into a thread form by using specially shaped dies. Thread forming is applied to materials that are relatively soft allowing free flow of shaped threads and uniformly correct geometrical shape.

6. Casting or Molding of Thread

Still, for larger and more complex applications, some machine screw threads are made by direct casting or molding. This technique is the process of casting molten material in a mold containing a predetermined thread profile. While they are not used in precision screws, this method proves useful for parts with many threads used in low-cost products.

A Complete Design Guide of Machine Screw Threads

The key aspects of designing machine screw threads are as follows:

1. Thread Size Selection

The first parameter for the design of machine screw thread is having a proper size, that is diameter (major and minor), pitch (space between thread crest), and length of thread.

Standard thread sizes used are metric based on the (ISO) standard or Unified Thread Standard (UTS) and the right size to use depends on the application, the required strength, and compatibility with other parts.

2. Thread Class

Thread Class means the clearance or the fit between the screw and the nut. This is important to guarantee that the threads will properly engage with one another under load.

- Class 1:Loose fit, used for quick fixing of construction blocks.

- Class 2: General purpose fit, this is the most widely used fit.

- Class 3:Characteristic of the high level of accuracy of fit for specialized applications.

3. Thread Pitch

The pitch is the distance between one thread and the other; it determines the tightness and hence the strength of the joint besides ease of assembly.

- Coarse Threads: Have a larger pitch and are useful in places, where the fast and easy mounting or dismantling of the cables is required.

- Fine Threads: They are available in a relatively small one, which gives greater strength and protection from vibration, but they may prove to be more challenging to fix.

4. Thread Tolerance

Permitted deviation can also be described as the range within which the dimensions of the threads can be adjusted. High-accuracy parts design demands closer tolerances so that holes do not allow excess looseness or the corresponding limit of interference to occur.

5. Material Selection

The material of the screw greatly determines the design of the thread. It must provide adequate strength, and durability and resist the wear and corrosion required for the application of the material. As an example, Stainless steel is frequently employed to improve corrosion qualities, while, on the other hand, alloy steels can be used to benefit high strength.

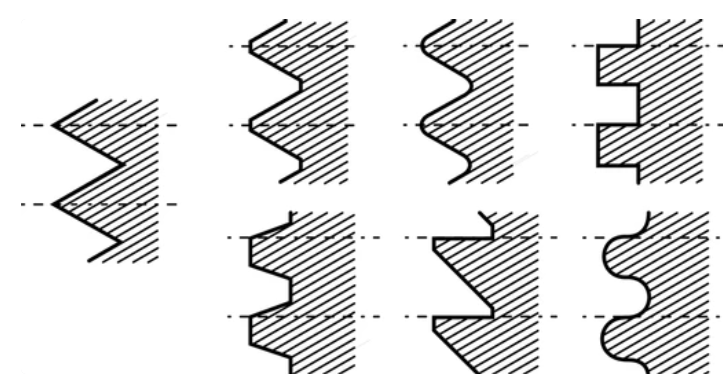

6. Thread Form and Geometry

Each of the threads has its specific profile that can be chosen, including triangular, square, and buttress ones. The geometry of the thread must match the intended function:

- Triangular threads are most of use in the machine screws and bolts and screws and bolts and machine screws.

- Square threads are applied where greater efficiency for the power transmission is needed.

- The buttress thread is best suited where you have a unidirectional force applied to the component.

7. Thread Lubrication

Reducing friction at the threaded areas will improve the ease of assembling more of the fasteners and their durability. Anti-seize of mechanical threads involves grease or oil used to reduce thread galling and wear.

So, the following is the summary of the design consideration for the machine screw threads:

| Aspect | Description |

| Thread Size | Diameter, pitch, and length. Common sizes: M, UNC, UNF. |

| Thread Class | Tolerance: Class 1 (loose), Class 2 (general), Class 3 (precise). |

| Thread Pitch | Coarse (easy assembly), fine (stronger, precise). |

| Thread Tolerance | Variations: 6H/6G for precision, wider for general use. |

| Material Selection | Steel (carbon, stainless), aluminum, and brass based on strength needs. |

| Thread Form | Shapes: Triangular (common), square (efficient), trapezoidal (Acme). |

| Strength | Larger threads = stronger, but risk stripping. |

| Lubrication | Grease/oil reduces friction and wear. |

| Manufacturing Process | Cutting, rolling (faster, stronger), or grinding. |

| Fit | Match threads to application: fine for strength, coarse for general use. |

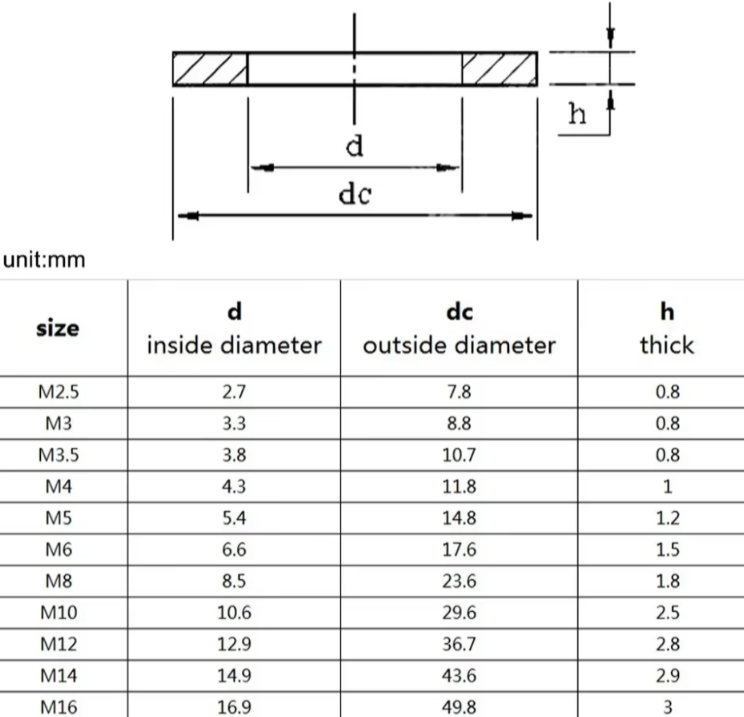

What is the Meaning of M2.5, M3, M3.5M4, M5?

These designations denote metric thread sizes, where the “M” stands for “Metric” and the number that comes after refers to the nominal diameter of the screw in millimeters. For example:

- 5: A screw with a diameter of 2.5 millimeters.

- M3: A screw with a 3 mm diameter.

- 5: 7.35mm; A screw has threads as its working part and their typical diameter sizes are 3.5 mm.

- M4: A screw with a 4 mm diameter.

- M5: A screw with a 5 mm diameter.

The number refers to the outer diameter of the screw or bolt while the pitch, or the distance between threads is usually given independently. These sizes are employed widely in applications especially where standardization with other equipment is desired.

Pros of Machine Screw Thread

Its pros are given as follows:

- Ensure that the interface has a safe connection with these parts.

- They should be somewhat convenient to assemble and disassemble within a short period.

- It is ideal to provide flexibility in tension and pressure adjustments.

- Generally adopted wherein compatibility is encouraged.

- Axially and radially loaded conditions can be addressed depending on the design.

Limitations of Machine Screw Thread

- This means that with successive use the threads of that particular component become worn out.

- Susceptible to stripper under high torque.

- Fit – demand very accurate manufacturing to achieve the right fit.

- Not very suitable for high-speed applications.

- It can be prone to wearing and tear and is probably affected by the environmental factors like corrosion.

Application of Machine Screw Thread

- Automotive engine assembly.

- Sustaining apparatus and mechanization.

- Portable appliances and machinery and other electric and electronic devices.

- Additional uses like bodying (construction).

- Household items which include; furniture, refrigerators, television sets, etc.

Conclusion

Machines screw threads are basic elements in engineering providing reliable fastening, adjustment, and interchangeability used in different branches of industry. Knowledge of various types of machine screw threads, and the advantages or disadvantages of each type improve the chances of selecting the right machine screw threads for the job thus increasing its efficiency, durability, and reliability.

FAQs

What does it mean when we say coarse threads or fine threads?

Coarse threaded screws and bolts are easier to fit and more robust while fine threaded members provide better accuracy and strength.

What is used for forming threads on machines screws?

Standard types include stainless types and carbon types, aluminum, and brass.

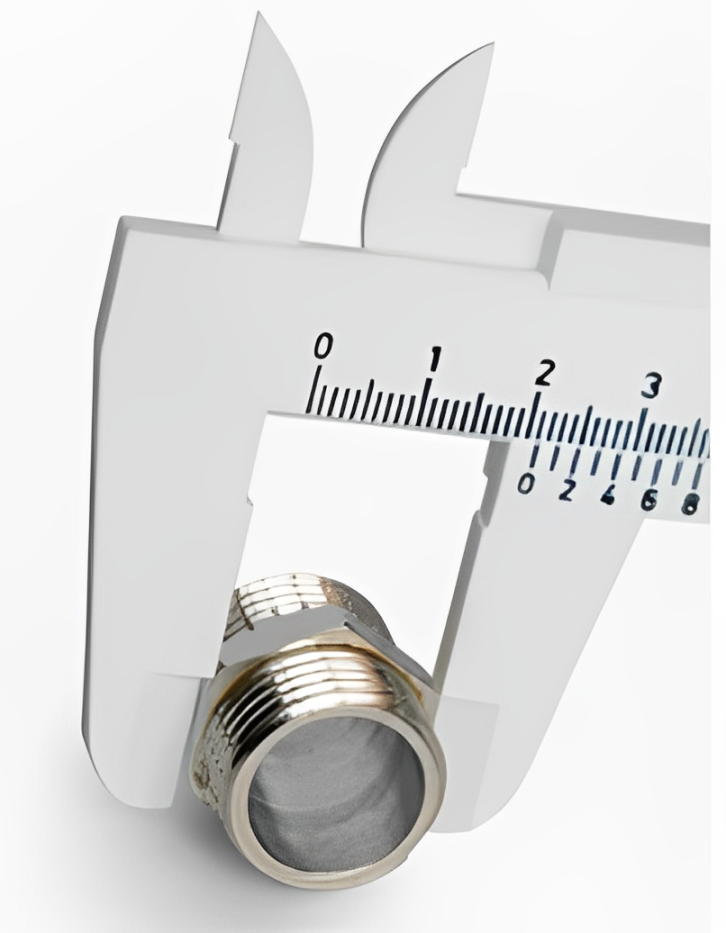

Wear that thread-size chart like a badge of honor how do I calculate the correct one?

Thread size can be measured using a thread calculator or by comparing it to a standard chart where the right size can be determined depending on the actual pipe use.

What can I do to avoid strapping of machine screw threads?

Revisit and apply proper torque and lubricants and; choose the exact type of material and thread combinations.