Anodizing is an oxide layer formation on the metal surface to help prevent rusting. Besides this, it helps enhance the ability to withstand wear and improves the surface capability to adhere to paint or adhesive. Anodizing is done in almost every industry, i.e. aerospace, automotive, electronic, and architecture.

This article discusses the various types of anodizing, some exceptional features, and how to determine the most suitable type of anodizing. Anodizing is a generic and useful surface finishing technique for improving the features of aluminum and other related metals.

Different Types of Anodizing

So, the following are the different types of anodizing we can use:

1. Type I: Chromic Acid Anodizing

Chromic acid anodizing forms a thin anodically produced oxide film on the body of the aluminum which has high corrosion resistance. It is more commonly employed in aerospace industries because of low changes in size and excellent resistance to corrosion. The process is good for air and thin-walled parts but does not have as high wear resistance as other types.

2. Type II: Sulfuric Acid Anodizing

Sulfuric acid anodizing results in the formation of a thicker oxide layer than that of Type I, and provides good levels of corrosion and fairly good wear protection. It is widely applicable for general industrial, automotive, and consumer product use. It can also be colored to allow for the different colors that one may want for either use or the look of the product.

3. Type III: Hard Anodizing

Hard anodizing, on the other hand, takes place at even higher current densities and uses sulfuric acid to make the anodized layer thicker making it harder to offer maximum wear and corrosion resistance. It is well suited for use in manufacturing industries like machine parts and apparatus, and army production, where there is a need for high rubbing as well as high wear and tear resistance.

4. Type IV: Dye Anodizing

The Type II anodizing for this method is closely related to dye anodizing, which provides a bright and rich color to the surface. The process works by utilizing the porous oxide layer to take up the dyes while adding the superficial appearance of the metallic surface in addition to its function of corrosion protection. It is widely applied as a decorative coating in the domains of consumer goods, electronics, and construction.

5. Type V: Phosphoric Acid Anodizing

Phosphoric acid anodizing produces a different kind of oxide layer in aluminum profile; a rougher layer that is optimum for paints and coatings. As the name suggests this method is recommended where improved adhesion of further applied coatings or lubricants is desirable. They are normally used in the aerospace industry for parts that require corrosion protection and additional surface coatings.

6. Titanium Anodizing

Titanium anodizing is similar to that of aluminum anodizing with the difference being that a range of colors is possible depending on the voltage put into it. It forms a stable oxide layer with good anticorrosive properties; this metal is often applied in aerospace, medical, along other ornamental uses; due to its bright colored shades.

7. Magnesium Anodizing

Anodizing of magnesium is normally done with an alkaline solution to form an integral layer of magnesium oxides on the surface of magnesium alloys. It anodizes to offer protection to magnesium parts utilized in aerospace, military, and automotive purposes although the process is slightly rare and tough because of the reactive character of magnesium.

8. Hard Co Anodizing for Aircraft (MIL-8625)

This particular anodizing process satisfies the military specifications and is employed for producing high-thickness anodic films on Aluminum alloys mainly for the aerospace and defense industry. Superalloy provides better wearability and resistance to corrosion, thus serving clients with demanding military parts that are in harsh usage environments.

Step-By-Step Complete the Process of Anodizing

Anodizing coating changes the metal surface by forming a hard, anti-corrosive oxide layer. Here’s a breakdown of each stage in detail:

1. Surface Preparation

The anodizing process begins by treating the surface of the metal or most preferably the aluminum in a very special way that involves cleaning and etching. This step washes or cleans the surface to remove any undesirable items from the anodizing process to have a uniform coat formed on the aluminum surface. This is why a clean surface gives a better oxide layer and therefore a superior finish.

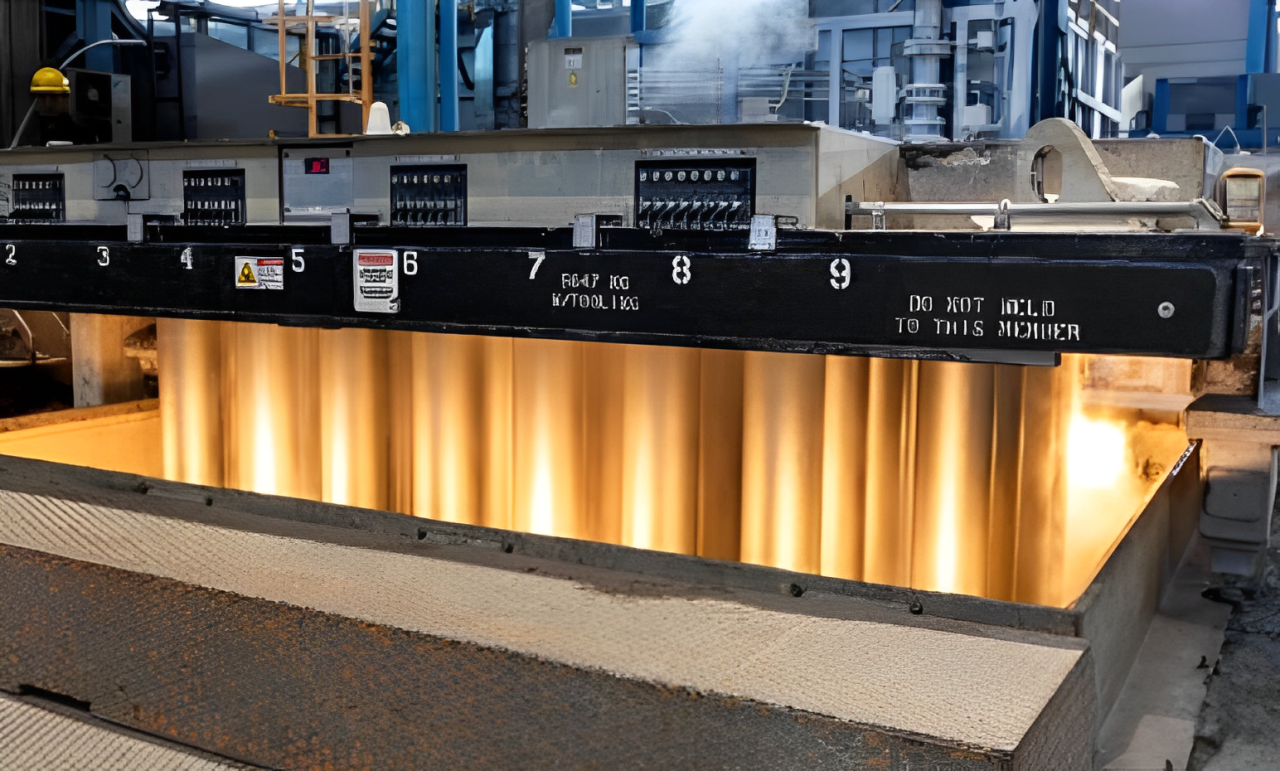

2. Anodizing Bath

After cleaning, the metal is placed in an acid electrolyte system that can be sulfuric or chromic acid. A direct current is passed through the solution, and the metal surface is electronically corroded following a desired mechanism. This reaction forms a stable, iron oxide layer that is basically a part of the metal surface and thus improves on strength and extends the service life of metals.

3. Coloring (Optional)

When a coloring effect is required after anodizing, dyes or pigments can be incorporated into the anodized layer. This oxide layer is full of pores that enable these pigments to bind tightly, and thus create many long-lasting, bright colors on its surfaces.

4. Sealing

The last process that most dentures undergo is sealing. The pores of an anodized layer are closed which means any color applied can stay there since it is safer from wear and corrosion can hardly penetrate the metal. This can be sealed with hot water or chemically so as to provide a better and longer end seal.

Coating Thickness vs. Corner Radius in Anodizing

In anodizing, coating thickness and corner radius are linked, and these two factors help define the efficiency and appearance of the final product. For hardness, thickness provides improved protection against corrosion and general wear, which is ideal. However, in large measures, it welcomes large build-ups at the edges, making them rounded or uneven because of the sharp angles involved. A larger corner radius is preferable regarding coating uniformity because sharp corners cannot have a thinner or non-uniform oxide layer.

To maximize protection and durability and achieve the right standard of quality, particularly in functional or aesthetic applications, the coating’s thickness has to be proportional to the corner radius. The last corner radius should be selected to allow the proper coating thickness while keeping the entire corner uniformly protected, hard-wearing, and aesthetically appealing.

What key factors we should consider to choosing the right anodizing type

Here are some facts we should keep in mind while selecting the right type of anodizing:

- Application Requirements: Different types of anodizing exist depending on the required corrosion resistance, wear resistance, or decorative purpose.

- Coating Thickness: Their types bring out the following: The anodizing thickness of the coatings varies depending on the type, which determines the coating’s durability and protection.

- Environmental Exposure: Think about the conditions such as chemical ranges that can affect the part such as highly acidic, highly alkaline, or extremely hot or cold.

- Material Compatibility: Make sure the anodizing process is appropriate for the given metal mostly aluminum, titanium, and magnesium.

- Aesthetic Preferences: Anodizing types can allow coloring and may be required for products that may need a cosmetic look.

Advantages of Anodizing

Here are some benefits of anodizing that will help you choose the correct type of anodizing:

- Enhanced Corrosion Resistance: Prevents metals from getting rash or rusty.

- Improved Durability: Tends to give a longer-lasting and harder-wearing performance surface.

- Aesthetic Appeal: It’s available in a variety of color choices.

- Environmentally Friendly: Anodizing does not produce hazardous VOCs, as it is widely considered a more environmentally friendly method of surface treatment among aluminum.

- Electrical Insulation: Good for working with insulation material if necessary or when no material conductivity is needed.

Limitations of Anodizing

Here are some challenges posed by the anodizing process:

- Brittleness in Thick Layers: It was also ascertained that thick layers may become bi-stale, i.e., the heterogeneous structures will be brittle under stress.

- Limited Color Options in Hard Anodizing: Hard anodized surfaces have the benefit of having several color possibilities, though there are fewer of them.

- Process-Specific Restrictions: However, certain types of metals and shapes are difficult to anodize.

- Environmental Sensitivity: Some types are more vulnerable to being exposed to either acid or an alkali.

- High Initial Cost: Aluminum anodizing is relatively costly compared to other projects that may require converting aluminum into other products.

Applications of Anodizing

The following are the applications of different types of anodizing in different industrial applications:

- Aerospace Components: Aerospace components for plane structures that are lightweight and have corrosion resistance.

- Automotive Parts: Long-wearing outputs for part wear and trims.

- Consumer Electronics: Anti-scratch, stylish housing, and covers.

- Architecture: Coatings that protect structures from rust and other types of decay, along with ornamental devices.

- Medical Equipment: Both for ease of cleaning and increased product longevity.

Conclusion

Anodizing is a versatile and valuable finishing process for enhancing the properties of aluminum and other metals. Selecting the right type of anodizing makes it possible to obtain the best hardness, the highest level of protection against corrosion, and a desirable outlook for a particular application. Type I, Type II, and Type III are available options in this case and as much as each has its benefits it is crucial to consider the requirements of your project. Anodizing not only enhances the life span of metal parts but also introduces opportunities for aesthetic coatings in numerous sectors.

FAQs

What metals can be anodized?

At present, aluminum is widely used as a base material for anodizing but titanium and magnesium can also be anodized.

How long does anodizing last?

Anodizing can last for three to five years depending on the type and use, and exposure to harsh conditions.

Can the surface of anodized aluminum be painted?

Yes, the anodized surface has good paint and glued adherend characteristics since it is porous.

Is anodizing an environmentally friendly process?

Anodizing is not environmentally degradable and there are no dangerous by-products left behind.

Can anodized coatings be repaired?

Anodized surfaces can be stripped of the anodizing and redeposited if the part becomes damaged. However, the dimensions of the part are impacted.

How does anodizing and powder coating differ?

Anodizing is a process of coating metal and forms part of it while powder is an outer coating and influences wear and durability.

Can’t Type III anodizing work for aesthetic-related processes?

Type III is largely used for this type of application and is only used for aesthetic purposes a few times because the color variety is limited.

1 thought on “Everything You Need to Know About Types of Anodizing”