Aluminum stamping is a fundamental process in the modern metal fabrication industry. Known for its strength, lightweight nature, and excellent formability, aluminum is a preferred material across aerospace, automotive, consumer electronics, and medical industries. Whether you’re developing high-precision electronic housings or large-scale structural brackets, stamping aluminum offers unmatched efficiency and versatility.

In this comprehensive guide, we’ll cover everything you need to know—from choosing the right aluminum alloy to mastering advanced stamping techniques and solving common manufacturing issues.

Choosing the Right Aluminum Alloy for Stamping

Aluminum alloys are classified by series (1xxx to 8xxx), each defined by their primary alloying element and specific performance characteristics.

| Alloy Series | Main Alloying Element | Key Properties |

| 1xxx | 99%+ pure aluminum | Excellent ductility, corrosion resistance |

| 2xxx | Copper | High strength, limited corrosion resistance |

| 3xxx | Manganese | Good workability, moderate strength |

| 4xxx | Silicon | Wear resistance, improved weldability |

| 5xxx | Magnesium | High strength, corrosion resistance |

| 6xxx | Magnesium + Silicon | Heat-treatable, excellent strength and weldability |

| 7xxx | Zinc | Highest strength, used in aerospace |

| 8xxx | Miscellaneous | Specialty uses (e.g., lithium, iron) |

In addition, aluminum comes in various tempers:

F: As fabricated

O: Annealed

H: Strain-hardened

W: Solution heat-treated

T: Thermally treated

Popular Grades for Aluminum Stamping

| Grade | Advantages |

| 1100 | High ductility, excellent for complex shapes and deep drawing |

| 3003 | Improved strength, good corrosion resistance, ideal for cookware & panels |

| 5052 | High fatigue strength, excellent corrosion resistance, good for marine parts |

| 6061 | Heat-treatable, great strength, good machinability, used for structural parts |

| 7075 | Aerospace-grade strength, reduced formability, high-performance parts |

Benefits of Aluminum Stamped Parts

Stamped aluminum parts are not only lightweight but also offer exceptional performance across multiple axes:

High Strength-to-Weight Ratio: Critical for aerospace, automotive, and robotics.

Excellent Corrosion Resistance: Naturally forms a protective oxide layer.

Superior Thermal and Electrical Conductivity: Ideal for heat sinks and connectors.

Non-toxicity and Reflectivity: Suitable for consumer products and lighting.

Recyclability: Aluminum is 100% recyclable without degradation in quality.

Great Aesthetic and Finishing Properties: Compatible with anodizing, painting, powder coating.

Despite these advantages, some drawbacks include:

Higher cost compared to steel.

Lower weldability for certain alloys.

Limited heat treatment options for some grades.

Key Aluminum Stamping Techniques

Blanking – Cutting Out the Shape You Need

Blanking is like using a cookie cutter on dough. You take a sheet of aluminum and punch out the shape you want. The part that’s punched out becomes your final piece. It’s a quick way to get basic flat shapes.

Piercing – Making Holes or Openings

Need a hole in your aluminum piece? Piercing is the way to go. This method uses sharp tools (called punches and dies) to create holes, slots, or notches. It’s commonly used when the design needs wiring holes, vents, or fastener spaces.

Coining – Pressing in Details

Coining is about pressing the aluminum really hard between two tools to create small shapes, grooves, or textures. Think of it like stamping a design onto a coin—hence the name. It helps add strength or design features to a part.

Deep Drawing – Pulling It into a Cup Shape

Ever seen an aluminum can? That’s deep drawing. This technique pulls aluminum into a deep, hollow shape. It’s great for parts like battery housings, cooking pots, or any round, deep containers.

Embossing – Raising or Sinking Patterns

Embossing is like adding a logo or textured design to the aluminum surface. A shaped die presses into the metal to raise or sink the pattern. This adds a stylish touch or useful texture for grip or identification.

Flanging – Making a Bent Edge

Flanging bends the edge of the metal up or down, kind of like folding paper. It’s useful for making connection points, strengthening edges, or creating flares around holes. Flanges are often seen in brackets or panel frames.

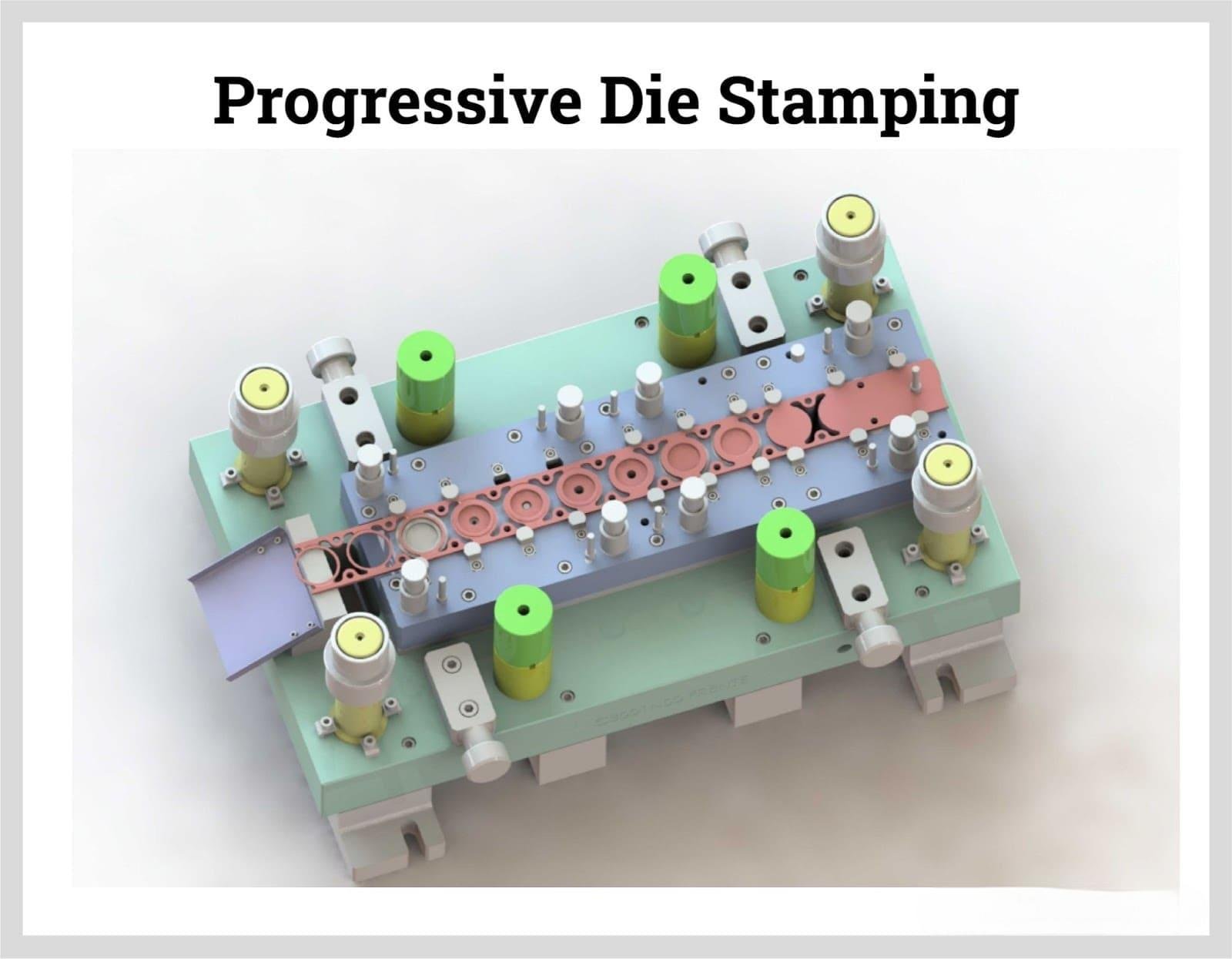

Progressive Die Stamping – One Step at a Time

This method feeds the aluminum sheet through a line of stations, each doing one small job—cutting, bending, or shaping. By the end, you get a complete part. It’s perfect for high-volume production with the same design.

Transfer Die Stamping – Moving Pieces Between Steps

Here, the aluminum part is cut out early and then moved from station to station. It’s usually done by a machine arm or conveyor. It’s ideal for making big parts that need several forming steps.

Four-slide Stamping – Forming from All Sides

This one’s a bit different—it uses four tools at once that slide in from different directions. It’s like getting squished from all sides at the same time! Great for making small, complex parts quickly and efficiently.

Fine Blanking – Super Clean, Sharp Edges

Fine blanking gives you smooth, accurate edges without roughness or burrs. It uses more pressure and special tooling, making it ideal for parts where the edge needs to be clean—like gears or washers.

Want me to reformat this for a website article with headings and bullets? I can also suggest visuals to go with each technique!

Industries That Rely on Aluminum Stamping

Aerospace: Wing ribs, brackets, housings.

Automotive: Battery enclosures, panels, sensor mounts.

Electronics: Heat sinks, EMI shielding enclosures.

Appliances: Housings, structural supports.

Medical: Diagnostic device parts, instrument panels.

Construction: Window frames, decorative trims, facade elements.

Lighting: Reflectors, heat-dissipating structures.

Real-World Applications of Aluminum Stamped Parts

| Alloy | Applications |

| 1100 | Reflectors, anodized panels, nameplates |

| 2024 | Aerospace parts, machined aircraft fittings |

| 3003 | Roofing, utensils, storage containers |

| 5052 | Marine parts, appliance covers, fuel tanks |

| 6061 | Bicycle frames, automotive chassis components |

| 6063 | Architectural extrusions, railings |

| 7075 | Aerospace fasteners, high-performance suspension arms |

Common stamped parts include:

Connectors

Heat sinks

Brackets

Shielding covers

Gaskets

Clamps

Spacers

Trays

Challenges in Aluminum Stamping and How to Solve Them

Aluminum Oxide Build-Up

Hinders welding and electrical contact.

Solution: Clean prior to welding; use special fluxes or anodizing.

Tooling Wear

Aluminum can cause abrasive wear on dies due to its softness and stickiness.

Solutions:

Use harder tool steels (e.g., D2, M2).

Apply PVD coatings or nitriding.

Use proper lubricants.

Perforation Problems

Some alloys (e.g., 3xxx, 4xxx) shrink or deform when punched.

Solutions:

Increase die clearance.

Use flat punch faces without shear angles.

Galling

Occurs when aluminum sticks to punch or die, leading to uneven surfaces.

Solutions:

Use anti-galling coatings.

Reduce surface roughness.

Use high-performance lubricants.

Other Issues

Springback: Use overbending or heat treatments.

Wrinkling: Control blank holder force.

Cracks/Splits: Use annealed tempers or adjust bend radius.

Die Tooling and Press Options for Aluminum Stamping

Single Station Dies

Compound Dies: Multiple cutting actions in one stroke.

Combination Dies: Performs cutting and forming in one step.

Multi-Station Dies

Best for progressive and transfer stamping operations.

Types of Stamping Presses

Mechanical Presses: High speed, used for shallow operations.

Hydraulic Presses: Better for deep drawing and thick materials.

Servo Presses: Programmable and highly accurate.

Conclusion

Aluminum stamping is a dynamic, cost-effective, and scalable fabrication method that meets the demands of modern industries. With the right alloy selection, tooling, and stamping process, you can achieve high precision, structural integrity, and surface finish in your aluminum components.

At TOPS, we bring decades of expertise in stamped aluminum parts—providing end-to-end support from in-house tooling and prototyping to large-volume production. Contact us today for a tailored solution that fits your exact requirements.

FAQs

Q1: Is aluminum good for stamping?

Yes. Its ductility, strength, and corrosion resistance make it ideal for a wide range of stamping applications.

Q2: Can you anodize stamped aluminum?

Absolutely. Anodizing improves surface hardness and corrosion resistance, especially in marine or architectural uses.

Q3: What aluminum grade is best for forming?

3003 and 5052 are preferred for forming due to their high ductility and corrosion resistance.

Q4: Are there lubricants made for aluminum stamping?

Yes. Use fully synthetic, oil-free lubricants for clean and effective operations.

Q5: Can you use standard dies for aluminum?

Yes, though for longer tool life and better part quality, coated or hardened dies are preferred.