Metal Prototypes are the best option for fabricating a physical model of a product out of metal materials. Its main use is to test, evaluate, and refine a design before moving into production. Metal prototypes are a great way to learn about the product’s function, fit, and performance. They enable designers to recognize defects early on, ensuring time savings while lowering the cost of production.

Why Create a Metal Prototype?

It is also necessary to metal prototype to confirm that your design works as intended. The metal prototype allows for these mechanical and durability aspects to be tested in the real world. It lets you see how your product would behave when subjected to stress, temperature fluctuations, or other environmental factors. By testing early, we avoid having to make costly changes later, when production begins.

Feeds and Speeds Calculator for Metal Prototyping

Feeds and Speeds Calculator is a crucial tool for CNC machining metal prototypes. It defines the best practices to get accurate, quality results during a cut. The cylinder part will calculate the ideal feed rate and cutting speed, by adding data for example with what material it will cut, what needs tools, and the depth of cut.

How Does the Calculator Work?

The calculator takes into account several elements, including the material’s hardness, tool geometry, and machine capability. Based on the input parameters, it determines the appropriate cutting speed and feed rate for various machining processes. This info is used to minimize tool wear, avoid damages, and optimize a smooth surface finish.

What is a Metal Prototype Used For?

How Do Metal Prototypes Work in the Product Development Process? These models test the functionality, durability, and appearance of designs. Creating a prototype in metal allows you to make pre-emptive design changes before committing to full-scale manufacturing.

Testing Design Performance

The metal prototypes help validate whether the design is structurally sound and also meets certain performance criteria. Whether it’s a mechanical component or a consumer product, prototype testing demonstrates that your product concept will work under real-world conditions.

Verifying Manufacturing Feasibility

Metal prototypes are also extensively used to verify the manufacturability of a design. For example, a prototype helps you assess if your product is producible with the selected manufacturing methods, like CNC machining or casting.

Everything You Need to Know to Build Your DIY Metal Prototype

It can be a cost-effective and satisfying way to create your DIY metal prototype. But it needs the correct tools, skills, and raw materials. You can break it down into a few of the most important steps to get started.

Step 1: Design Your Prototype

The prototyping part: CAD (Computer-Aided Design) Applications such as SolidWorks or AutoCAD permit the development of intricate three-dimensional structures of your design. Make sure your design is practical and feasible, and fine-tune your designs to meet the prototyping method you’re going to be using.

Step 2: Choose Your Materials

Choosing the appropriate one is paramount for the successful progress of your metal prototype. Common metals include aluminum, for its lightweight and machinability; steel, for its strength; and brass, for its corrosion resistance. Depending on what your prototype is for and how long it needs to last, you’ll choose different options.

Step 3: Fabrication Process

You can machine a CNC machining metal prototype or turn it on a lathe machine depending on your tools and experience. Or, if you have complex designs, you deem fit to go for 3D metal printing. So take necessary safety measures, metal fabrication can be dangerous.

Step 4: Assemble and Test

After components are fabricated, assembly will be required. You’ll have to weld, bolt, or screw the pieces together, depending on the design. It is important to test your prototype after assembly. Test its functionality, durability, and fit before moving on to the next phase of production.

What Is The Cost of a Metal Prototype?

Metal prototypes are the priciest to make, as are metal prototypes with the highest complexity, but a metal prototype will cost several hundred euros or more depending on input methods. It can be expensive, especially if you need specialized manufacturing techniques or exotic materials.

Factors Affecting Cost

Fabrication method: The cost prices for CNC machining, 3D printing, and casting are all different. Intricate designs are more expensive when it comes to CNC machining, though 3D printing may prove less expensive for complex shapes.

Material Selection: High-performance materials, such as titanium are pricier in comparison to standard metals like aluminum or steel.

Design Complexity: Simple parts are cheaper to prototype, while complex designs with additional functionalities will require additional work, thereby incurring more cost.

Quantity: When you’re producing several prototypes, the cost per piece tends to be lower. However, one prototype can cost more due to the setup costs.

Help Buying a Metal Prototype

If you are looking to outsource your network prototyping, you need to select your service provider judiciously. When looking for a prototype manufacturing company, you wish to guarantee that the specialist you decide has the experience, gear, and offices to deliver quality prototypes as per your particular.

Things to Consider When Choosing a Prototyping Services

Experience and Expertise: The provider should be an expert in your particular kind of metal prototype. Seek experience in your industry, like automotive, aerospace, or consumer electronics.

Material Options: The provider needs to provide a range of metal options so that you can choose the best adjustable stand for the design and your needs.

Company Background: Have they been in business long enough?

Cost: Starting at $50 per design complexity; request a quote There’s nothing wrong with shopping around for companies and quotes.

What is the Difference Between the Metal Prototype and the Production Part?

One important difference to note is between prototypes and production parts. A prototype is made to test and perfect a design, while a production part is intended for mass production.

Prototypes Vs. Production Parts

Prototypes: These elements are created to test a design’s functionality and performance. Their finish may be a bit imperfect and generally are made with less refined processes.

Production Parts: A lot of production parts letters must be produced in high volume. Production parts are further developed to be more efficient, robust, and durable.

That is often used to make adjustments to the design, before going into full-scale manufacturing.

Help Selecting and Using an Affordable Metal Prototyping Method

Selecting the right prototyping approach comes down to what you require, and your budget. So below, you will find some of the processes for making metal prototypes and their pros and cons.

CNC Machining

Using CNC machining is a great approach to making exact metal parts with strict tolerances. Best for prototypes needing high accuracy and durability. However, it is costly for complex designs, particularly for small batches.

Powder metallurgy

Powder metallurgy (PM) is a near-net-shape manufacturing process that is recognized as a green technology. PM equipment compacts metal powders into the desired shapes under high pressure and then sintering to fuse the particles together to form precision metal parts. It provides a cost-effective way to mass-produce workpieces with high material utilization and tight tolerances.

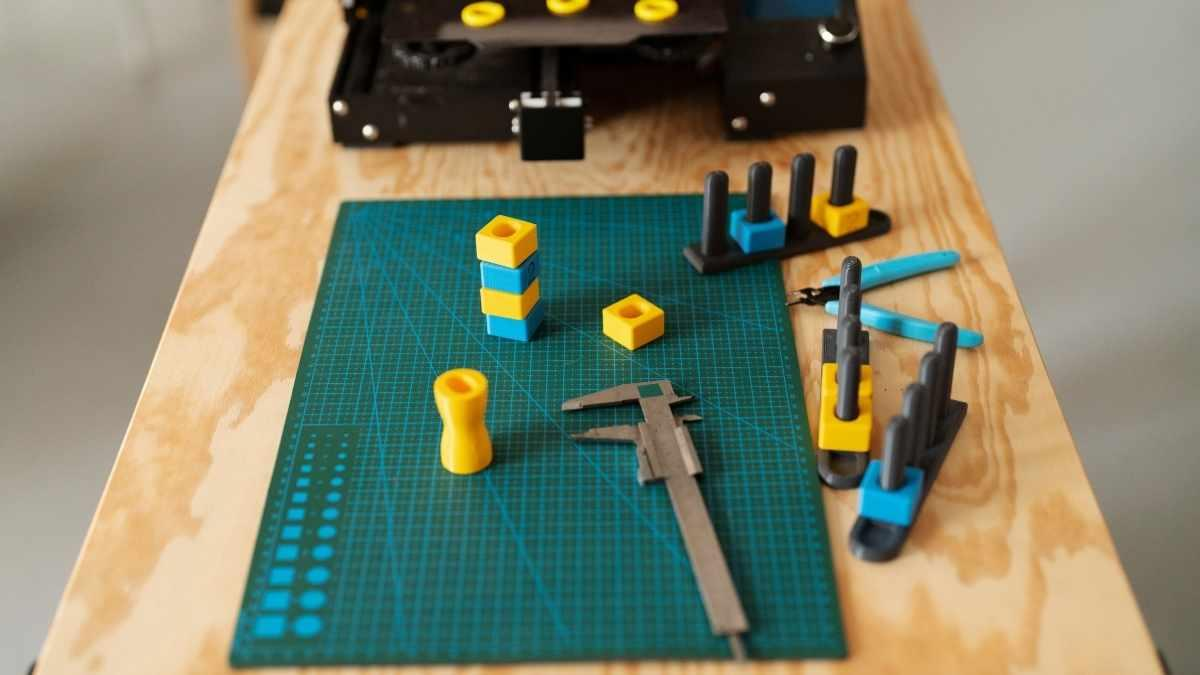

3D Metal Printing

Quick prototyping and ability to print complex shapes and geometries. It’s an inexpensive approach to low-volume production or single-item prototypes. However, the required material characteristics and mechanical specifications may be different than possible via traditional machining.

Casting

Casting is used to make prototypes that must mimic the look and material properties of the final product. It is commonly used for large parts, but the setup cost can be prohibitive for small runs.

Sheet Metal Prototyping

Sheet metal prototyping provides an inexpensive alternative for simple flat parts or enclosures. It is fast and inexpensive but not appropriate for complicated 3D designs.

Techniques And Training In Metal Prototyping

Metal parts prototyping needs special skill and knowledge. Theoretical knowledge, combined with practical methods helps in the delivery of enhanced prototypes.

CAD Software and Design Skills

A well-conceived design makes prototyping easier. Use industry-standard CAD software to make accurate and detailed 3D designs of your prototypes. Understanding how to design for the methods of production you intend to employ.

Machining and Fabrication Techniques

Understand different machining techniques (e.g. CNC milling and turning) If you play with casting or 3D printing, understanding those processes will also help to make your prototypes more resilient and functional.

Industrial Metal Prototyping: When You’re Ready for Commercial-level Performance

Industrial-level prototyping, for example, uses high-precision, high-volume production processes, which makes them ideal for prototyping complex products to test and fine-tune them before mass manufacturing. Industrial prototyping is usually quicker and much more accurate than small-scale prototyping.

Industrial Metal Prototyping: Why Bother?

This is why industrial prototyping is ideal for businesses with the need for scalability allowing for faster turnaround times and higher accuracy. This means that the prototypes will be manufactured just like the final product, with the same tools and processes, which teaches a lot about the production.

Products and Accessories Related to Metal Prototyping

A few tools and accessories can make your metal prototyping process better:

CNC Milling Tools: Using high-quality milling tools can improve the precision of your machining.

Metal 3D printers: These printers can create complex geometries quickly for prototyping purposes.

Molds for Casting: To make intricate metal pieces.

Sheet Metal Cutters: For fast and accurate cuts in flat metal parts.

They improve the prototype’s speed and quality.

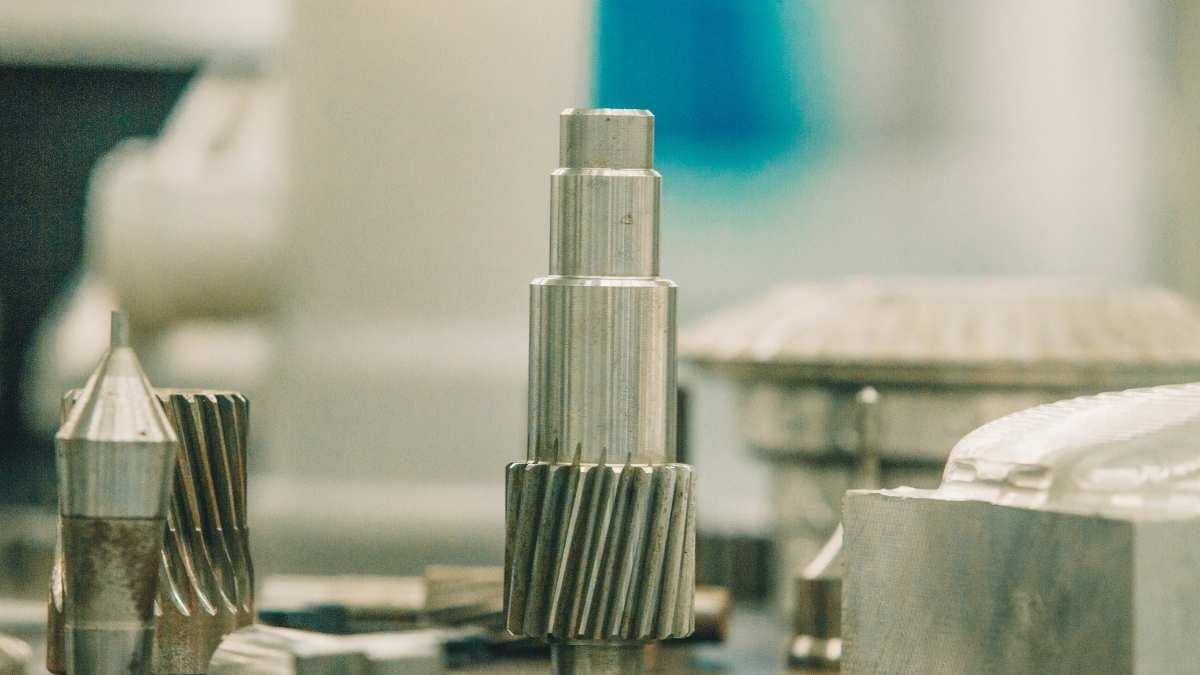

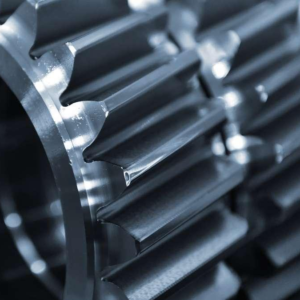

What Will You Build: Metal Prototype Projects

When it comes to metal prototyping, there are no limits. Prototyping is critical regardless of what you are designing, whether custom tools, machine parts, or consumer products. Start with something relatively simple, like brackets, or housings, or gears. As you get more experienced, you can start with more functional and complex parts. Contact us for more information.