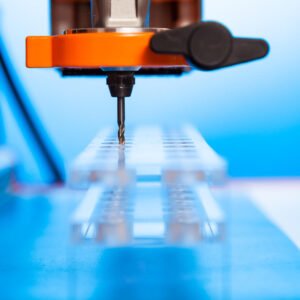

Quality testing and inspection play a crucial role in CNC machining, directly impacting product reliability, functionality, and customer satisfaction. Understanding the tools, techniques, and inspection stages involved ensures consistently high-quality output. This article offers a detailed guide to CNC machining quality testing and inspection practices.

In precision manufacturing, especially CNC machining, maintaining exceptional quality is non-negotiable. Every part must meet strict specifications, ensuring reliability and performance. Comprehensive testing and inspection form the backbone of quality management, helping manufacturers produce flawless components consistently.

What is Quality Testing and Inspection in CNC Machining?

Quality testing and inspection involve examining machined components to verify their compliance with specified criteria—such as dimensions, tolerances, material properties, and surface quality. The objective is to detect and eliminate defects before the product reaches the end user, ensuring optimum functionality and reliability.

Quality Control vs. Quality Inspection vs. Quality Assurance

Quality Control (QC): Making Sure Everything Goes Right

Quality Control means the activities you do during production to keep quality consistent. It’s about checking the process, finding issues early, and fixing them quickly—so you don’t have defects later. Think of QC like following a recipe carefully every time you cook, making sure each dish tastes just as good as the last.

Quality Inspection: Checking the Finished Product

Quality Inspection involves carefully examining finished parts or materials to make sure they match the required specifications. This step focuses on measuring dimensions, checking surfaces, and visually looking for any flaws or defects. Imagine inspecting fruit at a market—you pick each piece up and make sure it’s ripe, unbruised, and good enough to buy.

Quality Assurance (QA): Planning to Prevent Problems

Quality Assurance is about planning and improving processes so that problems don’t happen in the first place. It includes creating guidelines, setting standards, and training employees. QA helps everyone know exactly how to do their jobs properly, ensuring the final products meet quality standards consistently. It’s like practicing good hygiene to stay healthy instead of just treating illnesses after they happen.

Key Quality Control Parameters in CNC Machining

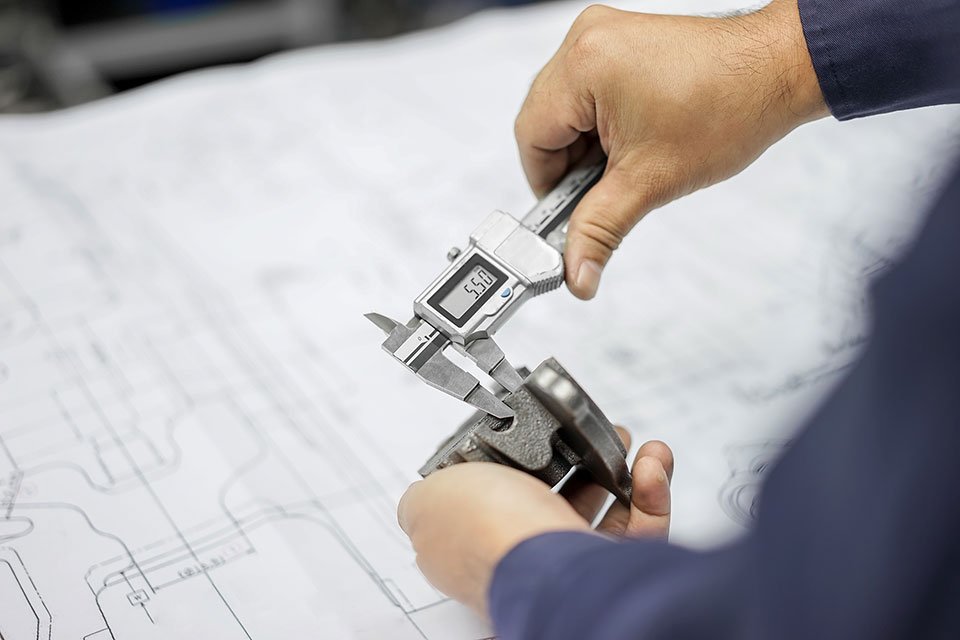

Engineering inspection check dimension automotive parts reference drawing by vernier caliper in industrial factory

Dimensional Accuracy and Tolerance

Dimensional precision is crucial for part performance and fit. High-quality machining demands exact adherence to specified tolerances.

Surface Finish and Roughness

A quality surface finish influences the part’s aesthetic appeal and functional performance, reducing friction and wear.

Material Hardness and Strength

Proper material hardness and strength ensure components withstand their intended operational stresses.

Geometric Tolerancing (GD&T)

Ensures accurate shape, position, and orientation of machined features, critical for assembly and performance.

Machining Process Control

Real-time adjustments and statistical methods maintain consistent machining parameters (speed, feed, and tooling).

Tool Wear and Life

Monitoring tool condition prevents degradation in dimensional accuracy and surface finish.

Assembly and Fit

Precise part dimensions ensure seamless assembly without further modifications.

Environmental Factors

Controlled temperature and humidity are essential to maintaining dimensional stability.

Compliance with Standards and Regulations

Meeting quality benchmarks such as ISO 9001 (general manufacturing) and AS9100 (aerospace-specific) ensures consistent quality assurance.

Essential Quality Control Techniques and Tools

Dimensional Measurement Tools

Calipers and Micrometers: Accurate measurements for length, diameter, and thickness.

Coordinate Measuring Machine (CMM): Complex dimensional inspection for intricate geometries.

Gauge Blocks and Thread Gauges: Standardization and thread accuracy verification.

Surface Roughness Testers

Profilometers: Detailed surface roughness measurement.

Optical Comparators: Visual inspection of detailed surface characteristics.

Hardness Testing Equipment

Rockwell Hardness Testers: Common method for metals.

Brinell Hardness Testers: Suitable for softer metals and alloys.

Non-Destructive Testing (NDT)

Ultrasonic Testing: Detects internal flaws with sound waves.

X-ray Inspection: Identifies internal defects and material inconsistencies.

Magnetic Particle Inspection: Surface and sub-surface defect detection in ferrous materials.

Statistical Process Control (SPC) Software

Real-time monitoring and statistical analysis ensure consistency and reliability.

Tool Condition Monitoring

Devices and automated systems track tool wear, preventing unexpected failures.

Environmental Monitoring Equipment

Temperature and humidity sensors maintain machining conditions for precision stability.

Geometric Dimensioning and Tolerancing (GD&T) Tools

Gauges and fixtures verify form, orientation, and positional accuracy.

Visual Inspection Tools

Magnifying devices, microscopes, and borescopes facilitate detailed visual analysis.

Material Analysis Equipment

Spectrometers: Verify elemental composition.

Microstructure Analysis: Assesses grain structures and material integrity.

Assembly and Fit Testing Tools

Go/No-Go Gauges: Quick dimensional checks.

Functional Testing Rigs: Validate performance under realistic operating conditions.

Documentation and Traceability Systems

Software tracks inspection data, ensuring transparency and compliance.

Stages of Machining Quality Testing and Inspection

Raw Material Inspection

Verifying material properties before production to ensure compliance.

First Article Inspection (FAI)

Detailed inspection of the first component produced to confirm initial quality adherence.

In-Process Inspection

Regular checks during machining to identify defects immediately and prevent costly rework.

Dimensional Inspection

Careful verification of part dimensions using calibrated measuring instruments.

Surface Finish Inspection

Analyzing surface quality to ensure compliance with functional and aesthetic requirements.

Visual Inspection

Identifying visible imperfections, scratches, and defects that can affect part usability.

Non-Destructive Testing (NDT)

Inspecting for internal flaws without harming parts, essential for high-risk applications.

Hardness Testing

Ensuring material hardness meets specified mechanical property requirements.

Functional Testing

Confirming that parts perform as intended in realistic operating scenarios.

Assembly and Fit-Up Inspection

Validating correct assembly and proper fit of components.

Final Inspection

A comprehensive review of finished parts to ensure complete adherence to quality specifications.

Statistical Process Control (SPC)

Ongoing monitoring of production processes using statistical methods.

Documentation and Record Keeping

Comprehensive record management ensures accountability and facilitates quality improvements.

Post-Machining Treatments

Inspecting results of secondary processes like heat treatment or plating.

Packaging and Shipping Inspection

Ensuring finished parts remain damage-free during transportation and delivery.

Importance of Personnel Training

Skilled personnel are critical to machining quality. Regular training ensures operators understand and effectively apply the latest quality control methods and standards. Training covers:

Proper use of measurement tools.

Interpretation of specifications and tolerances.

Implementation of quality assurance practices.

Quality Inspection and Assurance at Tops Precision

At Tops Precision, quality assurance is integral to our operations. We deploy state-of-the-art inspection equipment including:

X-ray Material Tester: Rapid material identification ensures accuracy in prototype and production.

On-Machine Inspection Systems: Real-time adjustment to machining parameters.

Optical Projectors: Precision geometric measurements.

Coordinate Measuring Machines (CMMs): Advanced geometric and dimensional verification.

Our process integrates thorough inspections from material reception through final product validation, guaranteeing excellence at every step.

Conclusion

Achieving and maintaining high-quality CNC machined parts requires diligent application of robust inspection techniques, skilled personnel, and advanced equipment. By understanding these practices and continually improving upon them, manufacturers can reliably produce precision components, fostering customer trust and industry reputation.

FAQs

Q1: Why is dimensional accuracy critical in CNC machining?

Dimensional accuracy ensures parts fit and function correctly, avoiding assembly problems and functional failures.

Q2: How does surface finish affect component performance?

Surface finish impacts aesthetics, friction, wear resistance, and fatigue life.

Q3: What is non-destructive testing (NDT)?

NDT methods detect internal or external defects without damaging the component, essential in safety-critical industries.

Q4: Why is compliance with ISO and aerospace standards important?

Meeting these standards ensures parts meet universally recognized quality and safety criteria.

Q5: How frequently should inspection occur during machining?

Regular inspections should occur at critical stages including initial material check, first article inspection, in-process monitoring, and final validation.

Read More:

Why Choose Custom CNC Machining Service

Surface Finishes for CNC Machining