CNC (Computer Numerical Control) machines help manufacturing processes to provide precise, accurate, and efficient results. The common CNC manufacturing machines include the CNC Milling Machines and the CNC Routers. Both machines rely on computer control to cut shapes or engrave some material. But, they are most appropriate for different purposes mainly because of their design. So, this article will deal with a detailed comparison between CNC Milling Machines and CNC Routers.

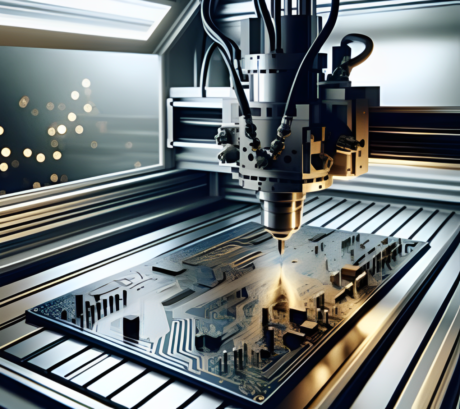

What is a CNC Milling Machine?

CNC milling is a versatile machine that can be used to cut various materials. These materials are mainly metals in varying geometric shapes and sizes through a rotating cutter tool. Besides this, it is the best option for power and precision. For example, it helps machine metal parts, i.e. smooth and complex planes. Some of the common types of Milling machines are bench-mounted milling machines and large industrial Milling machines. Arrayed and generally, less flexible than CNC routers. They work at higher accuracies compared to CNC routers. So, it makes them suitable for highly choreographed demanding tasks with a high surface quality finish.

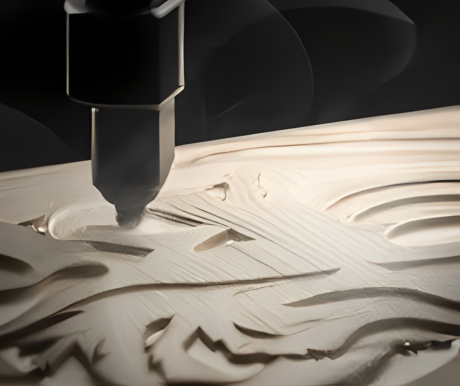

What Does CNC Router Mean?

CNC Router – a tool that cuts the softer materials such as wood, PVC, and foam. It employs a round shaft that oscillates both vertically and horizontally. So, it can chop, shape, or inscribe on the material in use. Compared to milling machines, CNC routers are generally more versatile and have a higher spindle speed. Particularly when used with lighter stock materials and therefore widely used in woodworking industries as well as the production of signages, furniture among others. However, they can also do some minor metal cutting works such as using sheet metal while they are not recommended for heavy metal jobs.

How Does a CNC Milling Machine Work?

CNC Milling Machines employ rotary cutters to cut the material into the desired shape and size through instructions from a computer code known as G-code. Most machines work in various axes with the number usually ranging between 3 and 5 axes to enable the tooling of components of high accuracy and geometry. The workpiece on the other hand remains static or just translates along the X, Y, and Z instruments while the milling cutter is in rotation at high speed.

How Does a CNC Router Work?

Like the CNC Milling machines, the CNC Routers use a computer numerical control cutting tool. Though they differ they are ideal for high-speed cutting over a larger working area. It involves using a cutting tool that slides on the material surface by the router through different axes. So, it can help achieve the required form or design. CNC Routers are known to have a higher RPM than CNC Milling Machines which makes it ideal for use with softer materials. Moreover, their operation is not as precise as other machines but is more flexible and faster. So, they are suitable for architectural and other delicate designs on non-metallic products.

Materials for CNC Milling Machines

CNC Routers are versatile for cutting the following materials:

- Single boards of temperate woods, beech, and maple or mixed woods finished birch, elm, and walnut.

- Plastics (acrylic, PVC, ABS)

- Foam (for prototyping)

- Composites (fiberglass, carbon fiber)

- Aluminum (Thin sheets- light usage)

Materials for CNC Routing

CNC Milling Machines are more robust and capable of handling the following materials:

- Steel

- Aluminum often has a thicker and more complex cross-sectional shape is used.

- Brass

- Titanium

- Plastics (for precision machining)

The Difference Between a CNC Milling Machine and a CNC Router

So, let’s make a comparison between CNC milling machines and CNC Routers.

1. Material Capability

CNC Milling Machines are designed to cut harder materials, i.e. metal (steel, Iron, aluminum, titanium). So, that is why they are suitable for rigorous industries such as the aerospace and automobile industries. CNC Routers are mainly employed for cutting lighter materials, i.e. wood, plastics, and foams, and the machines are not constructed to cut through thick or hard metal.

2. Precision

The CNC Milling Machines are rigid because of their designs. So, it helps produce components with high precision. Especially, when the tolerances are tight and complicated designs are required, the CNC milling machines are more suitable. On the other hand, CNC routers are accurate in cutting other softer materials but less accurate in most cases. While they are fast they are not as fine-tuned as can be.

3. Cutting Speed

CNC Milling Machines work at a slower speed, when in contact with hard materials. So, they can avoid sharpeners since cutting is involved. The CNC routers are specifically designed to work with speed. So, this makes it easier to cut and effectively perform the machining processes on softer materials of production processes.

4. Axis Movement

CNC Milling Machines work using several axes at most five axes. They are utilized in the production of complex and multi-layered products. Besides this, the CNC routers can only move in 3 axes and are used on larger, simpler surfaces. Moreover, their construction does not prioritize the complex contortions of a tool.

5. Cost

CNC Milling Machines however are slightly more costly than ordinary Milling Machines. It is mainly because of the better precision, power, and capacity to deal with raw, hard materials. They begin from $10000 to a value over $100000. On the other hand, CNC routers are slightly cheaper with prices ranging from $5,000 with their applications being more inclined towards softer materials and less complex operations.

So, the following table will give deep insights into the comparison between CNC milling machines and CNC routers.

| Aspect | CNC Milling Machine | CNC Router |

| Material Capability | Metals (e.g., steel, aluminum, brass, titanium) | Softer materials (e.g., wood, plastic, foam, thin aluminum) |

| Precision | High precision (± 0.01 mm) | Moderate precision (± 0.1 mm) |

| Cutting Speed | Slower (RPM: 1,000 – 10,000) | Faster (RPM: 10,000 – 24,000) |

| Axis Movement | 3 to 5 axes (for complex geometries) | Typically 3 axes (X, Y, Z) |

| Cost | $10,000 – $100,000+ | $5,000 – $50,000 |

| Strength | High (built for tough, industrial-grade work) | Moderate (focused on softer materials and higher speed) |

| Speed Efficiency | Low-speed, precision-focused | High-speed, production-focused |

| Applications | Aerospace, automotive, industrial parts | Woodworking, sign-making, furniture, foam cutting |

| Typical Tolerance | ± 0.01 mm | ± 0.1 mm |

| Spindle Power | Higher (5-30 HP) | Lower (2-5 HP) |

| Weight | 1,000 – 5,000 kg (heavier and sturdier) | 200 – 1,000 kg (lighter) |

| Workpiece Size | Smaller workpieces (but more complex) | Larger workpieces (with simpler geometry) |

| Operating Environment | Requires industrial setup and space | Can be used in smaller workshops |

When to Select a CNC Milling Machine?

So, the following are different aspects where you should choose CNC milling machines:

- Whenever there’s a need to be accurate and provide great detail.

- When working on steel, aluminum as well as titanium for example.

- Specifically in the production of precision industrial components.

- Whenever one is required for a tougher and thick material then an industrial machine can be used.

- When certain more demanding tasks are to be performed then robust attachment is called into play.

When to Select a CNC Router?

Here are some occasions where CNC Routers are one of the best options to go with:

- For instance, in projects where the assembly line has to maintain production rate.

- Deals with softer materials.

- For large flat workpieces like signs for advertising and furniture such as tables, chairs among others.

- When the design is elaborate and complex and the need for flexibility in production is also vital.

- The Kyandee 3-phase lathe is designed for light and small metalworking jobs or foam or plastic cutting and prototype making.

What’s the Cost Difference Between a CNC Milling Machine and a CNC Router?

Most CNC Milling Machines are costly because of their accuracy, longer life, and ability to work under harder materials. They can span anywhere between $10,000 and $150,000 or more and more depending on the make, size, and options. The CNC Routers on the other hand are comparatively cheaper, cost ranging from $5000 for the basic model and $30000 for the sophisticated model. This is expected due to the differences in the type of material that the two types of machines are intended to work on as well as the respective accuracy rates that they are programmed to deliver.

Which is Better: a CNC Milling Machine or a CNC Router:

The decision between a CNC Milling Machine and a CNC Router largely depends on your specific needs:

- CNC Milling Machines: They are perfect for accuracy, quality work, and when working with materials such as metals and are used for heavy work.

- CNC routers:They’re more appropriate for high and flexible design cutting and good for materials, i.e. wood or plastic.

Advantages Of CNC Milling Machines And Some Disadvantages

The following are some advantages and disadvantages of CNC milling machines:

Pros:

- High precision and accuracy.

- Cutting can be done on harder forms of metals as well.

- Especially applicable when there is frequent and precise manipulation work.

- High rigidity and durability.

- The technology is capable of accommodating geometries of high intricacy.

Cons:

- Higher cost.

- Slower than CNC Routers.

- Requires more maintenance.

- Larger footprint.

- Slopes are steeper for operators of equipment with rumble strips than for operators of equipment without rumble strips.

Advantages and Disadvantages of CNC Routers

Here are some merits and demerits of CNC Routers:

Pros:

- Faster cutting speeds.

- It is cheap compared to other machines such as milling machines.

- Perfect for softer materials and fashionable ones such as wood, and plastics among others.

- Versatile and user friendly especially when working on art-related projects.

- Smaller footprint.

Cons:

- Unlike milling machines, they are not very accurate.

- Not good for large-scale metal processing.

- Lower rigidity and strength.

- Limited material variety.

Applications of CNC Milling Machines

These are some areas of CNC milling machine applications:

- Creating accurate and fine pieces of metals.

- Tool and die-making.

- Aerospace and automotive assemblies.

- Medical device components.

- Complex, high-tolerance machining.

Applications of CNC Routers

Here are some uses of CNC Routers:

- Furniture making.

- Signage and 3D carving.

- Artistic and decorative work.

- Foam and plastics part creation and manufacturing of the first examples.

- Lightweight aluminum work.

Conclusion

To go for a CNC Milling Machine or a CNC Router depends on the type and kind of material to work with, and the level of accuracy required. Besides this, it is also important to have the amount of money you are willing to spend. CNC Milling Machines offer greater precision and durability than their counterparts due to their use in Metal and Industrial applications. On the other hand, CNC routers are comparatively faster and are more versatile for soft material operations like woodworking and signs. It is recommended to assess your requirements for manufacturing, which will help to conclude which of the two machines is more suitable for the company’s activity.

Frequently Asked Questions

Q1. Can a CNC Router cut metal?

Yes, it can. But CNC routers are suitable for softer metals than much harder metals, i.e. steel.

Q2. What materials can a CNC Milling Machine handle?

Steel, aluminum, titanium, and plastic can also be worked on using CNC Milling Machines.

Q3. What is the price of a CNC Milling Machine?

If we are talking about a CNC Milling Machine, then it will range from $10,000 to over $100,000. However, the size and functions of the equipment vary.