Type III, or hard anodizing, is an electrochemical process that forms a thicker and more scratch-resistant aluminum oxide layer on aluminum and titanium alloys. Anodizing improves corrosion resistance, hardness, and wear resistance compared to normal surface finishing methods. In operation, several steps are involved, including cleaning, acid desmutting, anodizing, coloring, and sealing, to ensure the metal is not scratched and is strong. Furthermore, anodized coatings can also be dyed in various colors, which makes the process efficient in terms of protection as well as aesthetic look.

Hard Anodizing Colors – Basic Information

Hard Anodizing

The final-use anodized product is impacted by factors like metal type, process settings, and the dyes used. Several colors are used often for anodizing. These may include; black, blue, red, green, and gold. Besides, the hard anodizing process improves metal parts/product surfaces. Because it builds harder skin on the material surface, thus improving overall strength. The dye penetrates through the oxide layer and creates a new thicker and stronger surface layer in comparison with the first oxide layer. This extra layer not only makes the parts aesthetically rich but also improves their reliability and functioning.

How Color Hard Anodizing Benefits You In Your Project?

There are several reasons, that come into play; Some common ones include;

- Aesthetic Enhancement: If your parts need visibility, then colored anodizing should be preferred.

- Increased Durability: Hard anodizing creates a skin on the aluminum surface, and in doing so another layer of protection is created. This feature is especially vital in extreme weather conditions where parts get intact with corrosive elements.

- Enhanced Hardness: In addition, anodizing increases the metal surface hardness, and offers durability. This in turn increases the lifespan of your parts/components.

- Electrical Insulation: Hard anodizing also gives electrical insulation useful in electrical applications where conductivity has to be regulated.

- Lower Friction: Anodizing is, moreover, significant where you need to reduce the friction on the metal surface. It helps you reduce the material that is likely to wear out due to friction.

Color Anodizing: Process and Methods

Steps for Color Anodizing:

In this case, we will take aluminum as an example.

- Surface Preparation: First of all, clean your aluminum with a diluted lye solution. Mix 3 tablespoons of lye with half a gallon of distilled water. This step removes all the previous anodized layers from the aluminum substrate of the workpiece.

- Electrochemical Anodizing: Fix the anodizing bath with the mixture of sulfuric acid and water in a ratio of 1:1. Connect the aluminum and the battery to start the process of electrochemistry. This phase normally takes about 45 minutes in a well-ventilated compound or room depending on the weather.

- Dyeing: In the anodizing process, immerse the metal in a hot dye bath for approximately 15 minutes after anodizing. Some available options include gold, bronze, blue, green red, copper, black, silver, gray, and bronze.

- Sealing: Finally, it is required to apply a chemical sealer that will help to preserve the color of the aluminum as well as prolong its usage.

Color Anodizing Methods:

Typically, there are three types of anodizing:

- Type 1 Anodization: In type 1, chromic acid is used as the electrolyte in the process of the experiment. It creates a layer of oxide that is nonconductive and is commonly referred to as the anodic layer. This is particularly beneficial in the reinforcement of the adhesion of paint and preserving the substrate, respectively.

- Type 2 Anodization: Consists of sulfuric acid (H2SO4). The type 2 anodizing makes the anodic layer more thicker and porous and as such it can be able to hold more dye. This finish is sealed to lock the color work done on the furniture or any other product that has been treated with such kind of finish.

- Type 3 Anodization (Hard Coat Anodization): Also uses sulfuric acid but forms the thickest anodic layer of the three acids. The strength of this method is that it is more permanent, especially for areas that receive a lot of traffic.

Consequences of Color Hardcoat Anodizing on Part Dimensions

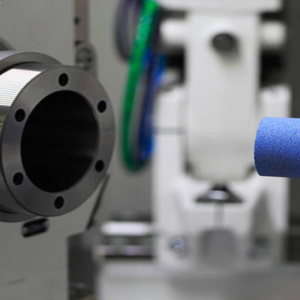

Hard Coat Anodized Aluminum Parts

Hardcoat anodizing entails the conversion of part of the base aluminum to aluminum oxide (Al₂O₃). Type III anodizing is subdivided into two, the first half of the thickness of the coating fuses with the aluminum surface while the second half remains as an outer layer. For example, if a coating thickness of 0.002’’ is applied, you can expect a dimensional change of 0.001’’ on each surface.

In case, you are ordering new parts, it’s crucial to describe the desired coatings in your order. To this end, make sure that the all-specified requirements are met. In the case of thin sections that need high dimensions or tolerances, Topsbest-precision works very closely with you to ensure your part’s anodizing thickness is taken to the exact specifications, required in the end product.

Standard Hard Anodizing Colors

In hard anodizing, you will be able to get several standard colors. Each color has its benefits and its adorable appearance varies depending on the alloy type, and the anodizing procedure. Here are some of the available options:

- Clear Anodizing: As the name suggests, the finish is colorless and non-tinted like all the other finishes of the product. Clear anodizing is employed to prevent the metal from corroding as well as to retain its intended color.

- Black Anodizing: is one where the hair is dyed black, and then it is left with a matte black finish. It’s mostly chosen for its attractive appearance.

- Gold Anodizing: The gold anodizing finish is done with yellow dye. It gives the metal parts an aesthetic outlook and improves their integrity.

- Red Anodizing: Red anodizing, is typically, selected to make a part bright red, a color that makes the part conspicuous and easily noticeable.

- Blue Anodizing: When using blue dye, means, you are choosing a medium to dark blue color finish. Normally, applied for its beauty.

- Green Anodizing: Green anodizing is applied because of its rarity.

However, if you would prefer a certain color, other colors like purple, pink, and bronze are also possible.

Standard Specifications for Color Hard Coat Anodizing

Several standard guidelines are followed in hard anodizing to guarantee quality and performance. These specifications include:

- MIL-A-8625, Type III: A military standard. Usually, involves hard anodizing processes, which gives the requirements for the anodic coating.

- AMS 2469: For aerospace material specification.

- ASTM B580, Type A: The ASTM standard, gives information on hard anodizing coatings and their characteristics.

- ISO 10074: These are international standards, and also provide information on hard anodizing quality.

- MIL-A-63576 (PTFE Sealed): The military specification grade. Contains provisions for sealing in PTFE in hard anodized coatings.

- AMS 2482 (PTFE Sealed): The Aerospace material specification relates to PTFE sealing on hard anodized surfaces.

Applications of Color Hard Anodizing

Hard anodizing is applied in different manufacturing fields because of the good protection, and enhancement of the appearance of the products. Key consumers of anodizing include:

- Medical: Specifically for surgical instruments and medical equipment, needed to be long-lasting and resistant.

- Food Manufacturing: Applied where cleanliness and immunity to rusting is an important consideration.

- Military: Used in parts that require a higher degree of wear and tear resistance.

- Automotive: For the engine parts and other parts that are needed to have high strength and low friction.

- Housing: Used in the construction of buildings as trim as well as for decorative and protective purposes.

- Electrical: It is also used in parts that must provide insulation and corrosion resistance.

- Machinery: Used to increase the durability of the mechanical parts.

- Petrochemical: For parts that are subjected to chemically reactive agents and other unfavorable conditions.

- Aviation: Applied in aerospace parts for enhanced operating efficiency and durability.

- Robotics: For those components, are expected to undergo a lot of stress and strain.

Some of the components that are usually treated with hard anodizing are pistons, cylinder heads, levers, heat plates, cam discs, bearings, nozzles, valves, gears, and blast shields.

Guidelines to Achieve Consistent Color Anodizing

The following guidelines should be practiced to achieve consistent color throughout anodized parts:

- Batch Processing: To maintain consistency of color in components, They must be treated together as a batch. The reason being, when grouped the chances of some of the parts having different colors from others are greatly reduced.

- Approved Samples: The use of approved samples should always be used in checking color accuracy. It’s incorrect when using digital images. Because the mages can alter depending on the lighting and the screen setting. As we have noted, physical samples are more useful in terms of color comparison.

- Centralized Anodizing: All parts should be anodized by the same company, using the same type of material. This makes it easier to have control over the various parameters that can be applied and processed in the anodizing process hence getting a consistent color.

How to Remove Color from an Anodized Part if It Doesn’t Match

If you discover that the color of your anodized part is not what you wanted. Then, do not need to worry about it. You have several choices for its removal. However, the typical method you will use will vary depending on your part’s condition; whether it is sealed or unsealed as well as the type of dye.

For sealed anodized parts, chromic or phosphoric stripping solutions, are normally used. This method will help to remove the dye while preserving your part in the process. If you do not mind the fact that some of the surface of the aluminum will be damaged, you can use an alkaline etch to remove the dye.

For unsealed anodized parts, it’s possible to use a 10-15% nitric acid solution. The specified concentration is useful when applying many dyes, though it may not be effective at all times.

Conclusion

To conclude, anodizing is an electrolytic process typically adopted for surface improvements and enhancement in surface finish. It added durability and improved the parts’ lifespan. This article showed how to anodize and color metal parts and what has to be considered when it comes to matching colors. You can obtain excellent outcomes cheaply if you know what you are doing. However, the process of anodizing may sound complicated and requires expert professionals to handle. So, If you are looking for a partner to help you with your anodizing project contact Tops precision for high standard-anodizing services.

2 thoughts on “Hard Anodizing Colors: What You Need To Know”