When you look inside a computer, gaming console, or even an LED light bulb, one of the least noticeable—but most important—parts you’ll find is the heat sink. At first glance, it may just look like a piece of metal with thin fins or plates, but this small device plays a critical role in keeping electronic systems alive and well. Without effective heat sinks, modern electronics would quickly overheat, malfunction, or even fail permanently.

In today’s world, technology is everywhere—from smartphones and laptops to electric vehicles and spacecraft. Every one of these systems generates heat when operating, especially as they process more power in smaller and more compact designs. That’s where heat sinks come in. Their job is simple but vital: move unwanted heat away from delicate components and release it into the surrounding environment. By doing so, they protect electronics from overheating, improve performance, and extend their lifespan.

This article will take a deep dive into everything you need to know about heat sinks. We’ll start with the definition of a heat sink, then move on to how it works, examine its key components, explore the materials used, and discuss the different types and applications. Along the way, you’ll also learn the benefits, limitations, and performance factors that make one heat sink better than another.

So, whether you’re an engineer designing cooling systems, a gamer curious about what keeps your CPU cool, or just someone interested in how technology stays reliable, this guide will give you a comprehensive understanding of heat sinks and why they are the unsung heroes of the electronic age.

What Is a Heat Sink?

A heat sink is essentially a thermal management device. Its purpose is to transfer heat away from a heat-generating source—like a CPU, GPU, LED chip, or power transistor—and release that heat into the surrounding air or liquid. By doing this, the heat sink prevents the source from reaching dangerously high temperatures that could cause performance drops or permanent damage.

Technically speaking, a heat sink is a type of heat exchanger, much like the radiator in your car or the cooling coils in your refrigerator. The main difference is that a heat sink is usually much smaller and designed for electronics or compact systems. Instead of circulating refrigerants like a fridge, it mostly relies on conduction, convection, and radiation to move heat away.

Here’s a simple way to imagine it: think of a heat sink as a sponge, but instead of soaking up water, it soaks up heat. The sponge (heat sink) absorbs the heat from the hot source and then slowly “squeezes” it out into the surrounding air. The fins and extended surfaces of a heat sink act like ridges on a sponge—they increase the contact area, allowing it to absorb and release more heat.

Heat sinks come in many shapes and sizes. Some are tiny, designed for individual chips on a motherboard. Others are massive, like those found in industrial power electronics or electric vehicle battery systems. What unites them all is their goal of keeping components cool and efficient.

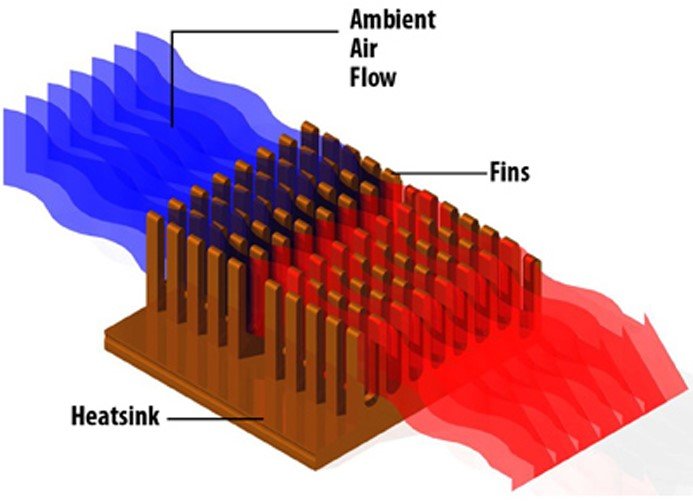

How Does a Heat Sink Work?

The working principle of a heat sink revolves around three major methods of heat transfer:

Conduction – Heat moves from the heat source (like a CPU) directly into the base of the heat sink. This happens because materials like copper and aluminum conduct heat very well. The faster this transfer, the better the cooling.

Convection – Once the heat reaches the fins of the heat sink, it needs to be carried away. This happens through the surrounding air (or liquid, in some cases). Natural convection occurs when warm air rises and cooler air takes its place, while forced convection happens when a fan or pump moves fluid across the fins, carrying heat away much faster.

Radiation – A small portion of heat is emitted as infrared radiation from the surface of the heat sink. While radiation is usually a minor player in air-cooled systems, it becomes significant in space applications where there’s no air for convection.

Think of it like this: imagine you place a hot cup of coffee on a metal table. The heat from the coffee moves into the table (conduction). As the table warms up, the air around it also gets warm and rises (convection). If you leave the coffee sitting, you’ll also feel some heat radiating into the room (radiation). The heat sink follows the same logic, only much more efficiently and with carefully engineered designs to maximize surface area and airflow.

There are two main ways a heat sink can operate:

Passive Cooling – Relies only on natural airflow around the fins. This is silent but less efficient. You’ll see it in low-power devices like LED bulbs.

Active Cooling – Uses fans or pumps to push fluid across the fins, dramatically increasing cooling capacity. This is the standard for CPUs and GPUs.

The efficiency of a heat sink depends on multiple factors: the thermal conductivity of the material, the fin design, the airflow conditions, and the temperature difference between the component and the environment. A well-designed heat sink balances all these factors to keep devices cool without wasting space, energy, or money.

Components of a Heat Sink

While heat sinks may look like simple blocks of metal, they actually consist of several carefully designed parts working together to maximize heat transfer. Let’s break them down:

Base

The base is the foundation of a heat sink. It sits directly on top of the heat source and absorbs heat via conduction. Materials like copper or aluminum are preferred because they conduct heat efficiently. To improve thermal contact, a thermal paste or pad is usually applied between the base and the chip, filling tiny air gaps that would otherwise trap heat.

Fins

If the base is the foundation, the fins are the workhorses. Their job is to increase surface area, giving heat more opportunities to escape into the surrounding air. The design of the fins—whether straight, pin-shaped, or wave-patterned—has a huge impact on performance. Dense fins provide more area but may restrict airflow, while wider spacing allows better airflow but reduces surface area. Engineers must balance both.

Heat Pipes

Many high-performance heat sinks include heat pipes—sealed tubes filled with a working fluid. When the base absorbs heat, the fluid inside the pipe vaporizes and travels to a cooler section of the pipe, where it condenses and releases heat into the fins. This cycle repeats continuously, enabling extremely efficient heat transfer. Heat pipes are common in laptops and gaming PCs where space is limited but heat loads are high.

Thermal Interface Material (TIM)

Air is a poor conductor of heat, which is why tiny gaps between the component and heat sink must be eliminated. That’s where thermal interface materials come in. These include thermal pastes, pads, or phase-change materials that fill microscopic voids, ensuring maximum heat transfer from the chip to the heat sink base.

Mounting Hardware

Finally, the heat sink needs to stay firmly in place. Depending on size and application, this can be done with screws, clips, adhesives, or spring-loaded push pins. Larger systems, such as server CPUs, require strong mounting systems to maintain even pressure and prevent warping.

Together, these components make the heat sink more than just a piece of metal—it’s a carefully engineered cooling solution that ensures sensitive electronics stay within safe temperature ranges.

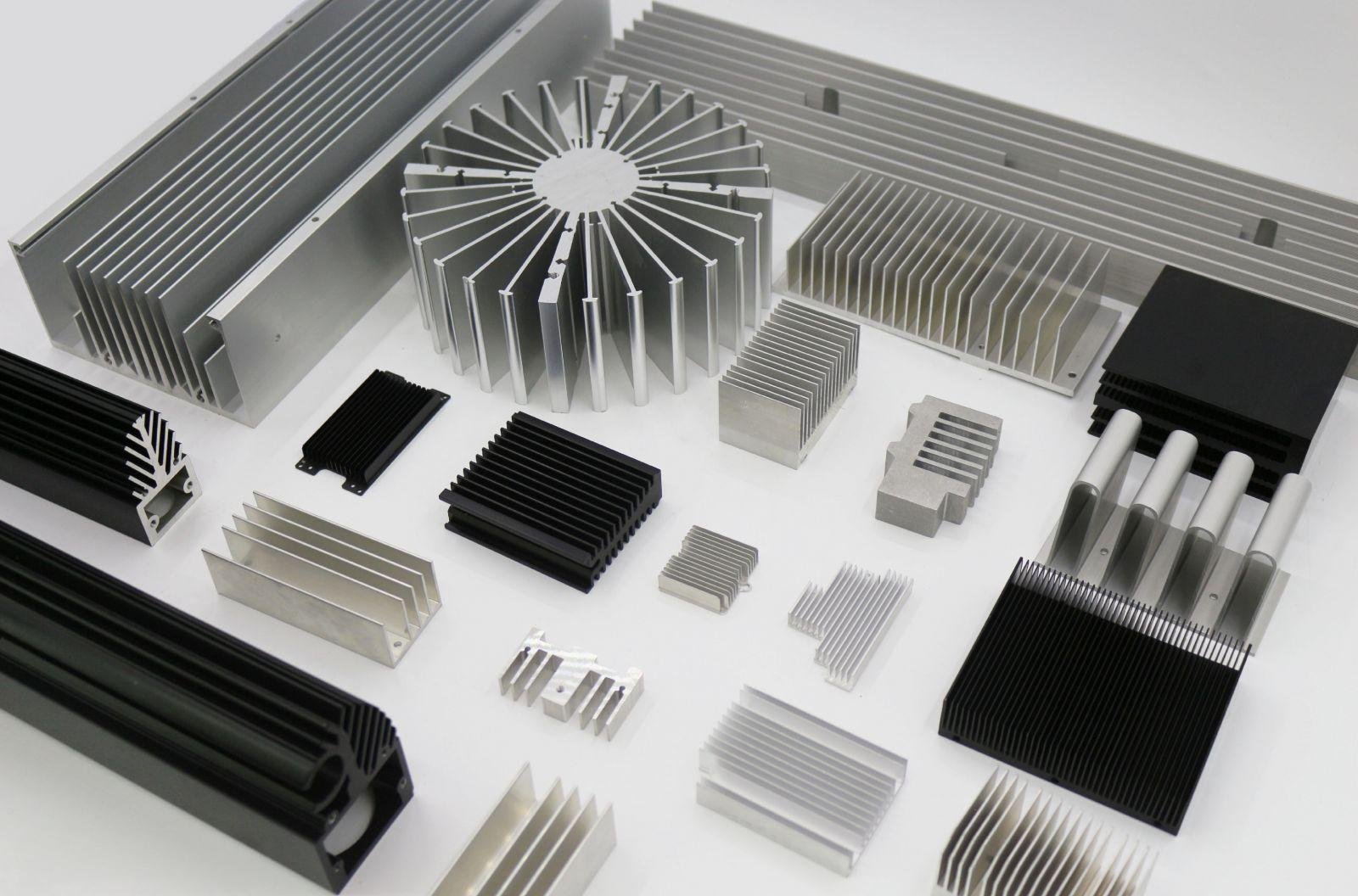

Materials Used in Heat Sink Design

Not all metals (or materials) are created equal when it comes to thermal management. The choice of material has a huge impact on both performance and cost. Here are the most common materials used in heat sink manufacturing:

Aluminum

Aluminum is the most widely used heat sink material. It’s lightweight, relatively inexpensive, and offers good thermal conductivity. Aluminum heat sinks are found in everything from LED bulbs to computer power supplies. The most common alloys are 6061 (for strength) and 1050 (for high conductivity).

Copper

Copper is the gold standard for thermal conductivity—nearly twice as effective as aluminum at conducting heat. This makes it ideal for CPUs and GPUs where every degree matters. However, copper is heavier, more expensive, and harder to machine, which limits its use in cost-sensitive or weight-sensitive designs.

Aluminum Alloys

Pure aluminum is soft and can be difficult to manufacture. By adding other elements, alloys strike a balance between conductivity and durability. Alloys allow engineers to optimize for both strength and machinability without sacrificing too much thermal efficiency.

Graphite & Advanced Materials

Engineered graphite materials, such as pyrolytic graphite sheets, have extremely high in-plane thermal conductivity, sometimes surpassing copper while being much lighter. These are increasingly popular in smartphones, tablets, and aerospace applications where weight is critical.

Diamond

Believe it or not, diamond is the ultimate heat sink material. It has five times the thermal conductivity of copper. Unfortunately, it’s also extremely expensive, which means its use is limited to niche areas such as semiconductors, lasers, and high-performance military systems.

In practice, most consumer devices use aluminum or copper because they strike the best balance between cost and performance. But in industries where efficiency, weight, or extreme performance is non-negotiable, advanced materials are becoming the future of heat sink technology.

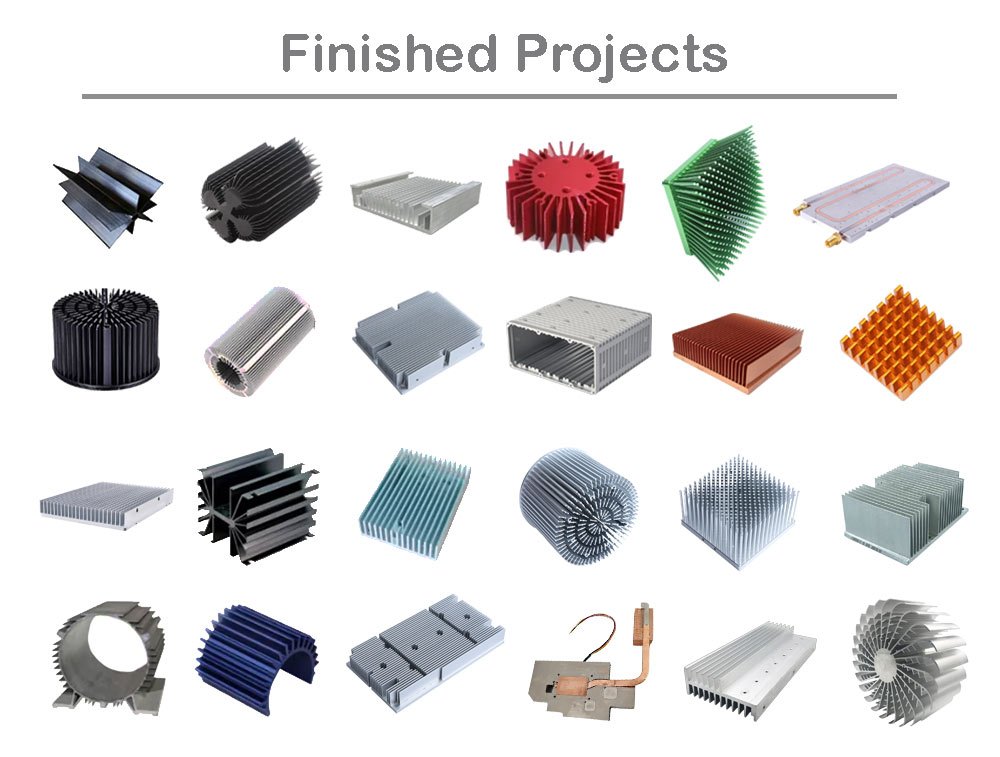

Types of Heat Sinks

Heat sinks may look similar at first glance, but their cooling methods set them apart. Engineers usually categorize them into three main types: passive, active, and hybrid. Each type has its strengths, weaknesses, and ideal use cases.

Passive Heat Sinks

A passive heat sink is the simplest design—just a base with fins. It doesn’t rely on fans or pumps but instead uses natural convection to move air around the fins. As the device heats up, the surrounding air rises naturally, pulling cooler air in to replace it. This cycle repeats, gradually transferring heat away.

The main advantage of passive cooling is its silence—no moving parts mean no noise and no mechanical wear. Passive systems are also cheaper and require less maintenance. You’ll often find them in LED lighting, set-top boxes, or low-power electronics where heat generation is minimal.

However, passive heat sinks have limited cooling capacity. They rely heavily on surrounding airflow, so if the air around them is hot or stagnant, performance drops significantly. For high-performance systems like CPUs or GPUs, passive cooling just isn’t enough.

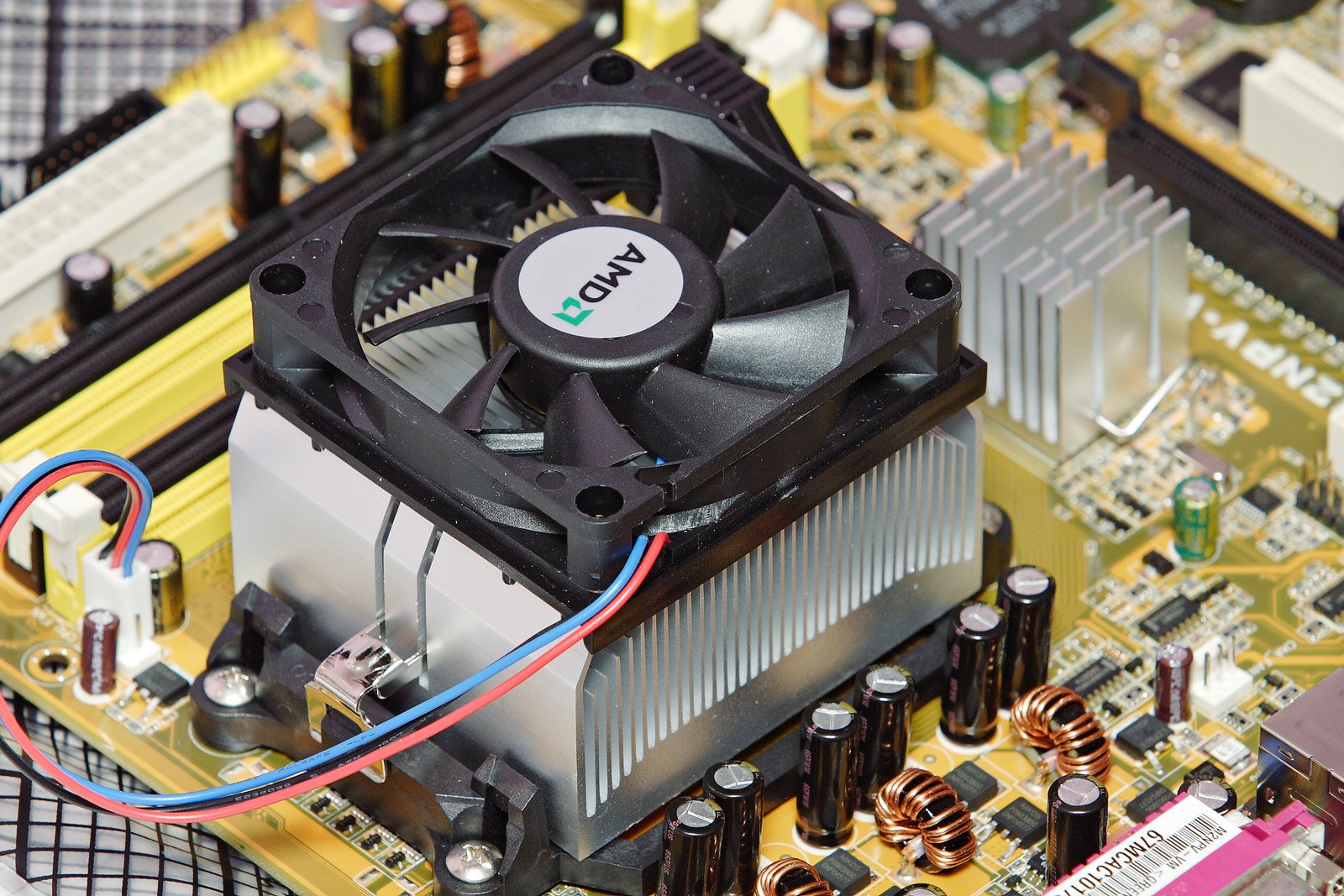

Active Heat Sinks

Active heat sinks take things a step further by adding a fan or liquid pump to force air or liquid across the fins. This forced convection dramatically improves heat transfer efficiency. For example, a small fan on a CPU heat sink can double or triple its cooling performance compared to natural convection.

The downside? Active systems require power, add noise, and can wear out over time. A broken fan means a dead computer in many cases. Still, their efficiency makes them the go-to solution for high-power electronics.

Hybrid Heat Sinks

Hybrid systems combine the best of both worlds. They operate passively under light loads but switch on fans or pumps when temperatures rise too high. This improves efficiency while keeping noise levels down. Hybrid cooling is becoming popular in laptops, gaming consoles, and electric vehicles, where performance and silence must coexist.

Applications of Heat Sinks

Heat sinks are everywhere—working quietly behind the scenes to keep our modern world running. Let’s look at some of the most common applications:

Computer Processors (CPUs & GPUs)

Arguably the most well-known use of heat sinks is inside computers. Both CPUs and GPUs generate massive amounts of heat, especially during heavy workloads like gaming or rendering. Without effective cooling, they would throttle performance or shut down entirely. Most processors rely on active copper heat sinks with fans, while high-end setups use liquid-cooled systems with large radiators.

LED Lighting Systems

Unlike incandescent bulbs, LEDs don’t radiate much heat outward. Instead, they generate heat at the junction inside the semiconductor. If not managed, this heat shortens the LED’s lifespan and reduces brightness. Heat sinks—usually small aluminum ones—are critical for keeping LEDs cool and efficient.

Power Electronics & Converters

Devices like voltage regulators, MOSFETs, and AC–DC converters waste energy in the form of heat. Aluminum heat sinks with or without fans are used to keep these components within safe operating ranges, especially in industrial settings.

Automotive Systems & Electric Vehicles

In cars, heat sinks aren’t just for the control electronics. Electric motors, onboard chargers, and battery packs also rely heavily on thermal management. Active heat sinks with liquid cooling are becoming standard in EVs to handle the extreme power demands.

Aerospace & Spacecraft Cooling

In space, convection doesn’t work because there’s no atmosphere. Here, heat sinks must rely on radiation. Engineers use high-emissivity coatings and heat pipes to radiate thermal energy into space. This ensures satellites and spacecraft electronics remain stable.

Consumer Electronics

Everyday gadgets—from game consoles to smartphones—use miniature heat sinks. They may not look as dramatic as CPU coolers, but they’re vital for preventing overheating and ensuring long battery life.

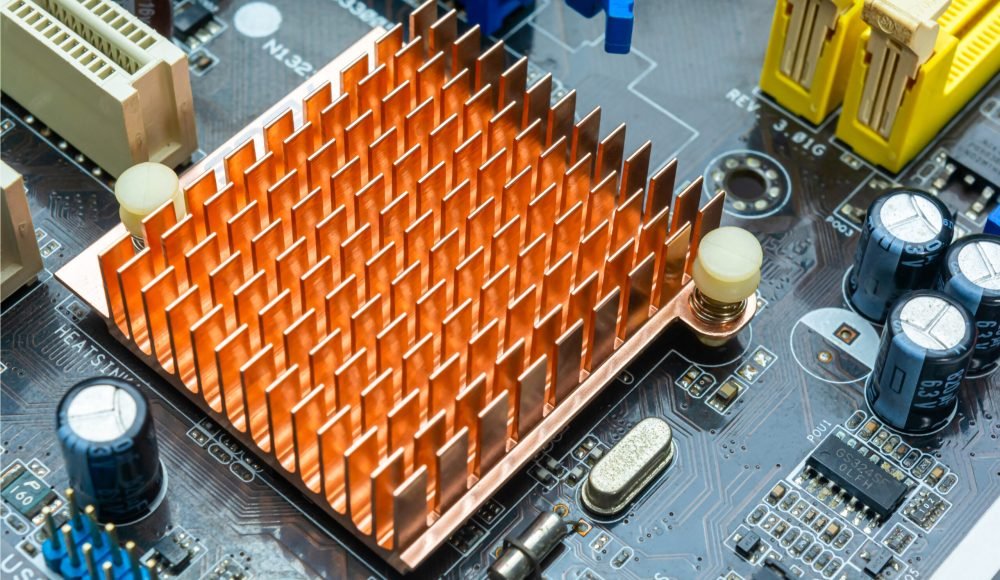

Heat Sinks in Computers

Computers deserve a closer look since they’re one of the most heat-sensitive devices we use daily. Virtually every major component inside a computer uses some form of heat sink.

CPU (Central Processing Unit): The brain of the computer produces enormous amounts of heat. It almost always uses an active heat sink with a fan, and in gaming rigs, liquid cooling is common.

GPU (Graphics Processing Unit): Modern graphics cards have some of the most advanced heat sinks in consumer electronics. Multi-fan coolers, vapor chambers, and even hybrid cooling systems are standard.

RAM (Random Access Memory): High-performance RAM modules often feature small passive heat sinks to stabilize performance during overclocking.

PSU (Power Supply Unit): Power supplies convert high-voltage AC into DC, generating heat in the process. Internal aluminum heat sinks help maintain safe operation.

Motherboard Components: Voltage regulators and chipsets often come with small passive heat sinks, especially in high-end boards designed for gaming and overclocking.

Desktop computers can accommodate large, tower-style heat sinks with multiple fans, but laptops face tighter space restrictions. That’s why laptops often use heat pipes that spread heat from the CPU and GPU to thin radiators along the edges, cooled by small fans.

Without these cooling solutions, modern PCs would simply be impossible. Heat sinks are the backbone of reliable performance in both consumer and professional computing.

Selecting the Right Heat Sink

Choosing the right heat sink isn’t as simple as picking the biggest one available. Instead, engineers consider several key factors to ensure proper cooling efficiency:

Power Output of the Device – The higher the wattage or thermal design power (TDP), the more heat needs to be managed. CPUs, for example, have a rated TDP that guides cooler selection.

Operating Environment – A device in an air-conditioned office has very different cooling needs compared to one in a hot factory or inside a car engine bay.

Space Constraints – Sometimes, the challenge isn’t just cooling but fitting the heat sink in a tight space. Laptops and smartphones require thin, low-profile cooling solutions.

Airflow Conditions – If airflow is limited, passive designs may struggle. Active or hybrid systems may be necessary.

Thermal Resistance – Engineers calculate the thermal resistance (measured in °C/W) to determine how efficiently a heat sink can maintain safe operating temperatures. Lower resistance means better performance.

Cost vs. Performance Trade-offs – Copper offers better cooling but at higher weight and price. Aluminum is cheaper and lighter but slightly less efficient.

For general users, selecting a heat sink usually comes down to compatibility. For example, PC builders choose coolers based on CPU socket type, case clearance, and noise preferences. But at the engineering level, heat sink selection is a balance of performance, size, cost, and environment.

Benefits of Heat Sinks

The widespread use of heat sinks isn’t just about preventing overheating—they bring multiple benefits that directly improve how devices work and how long they last.

Improved Reliability: Overheating can cause sudden failures or unpredictable behavior. By keeping temperatures stable, heat sinks ensure devices perform consistently.

Extended Lifespan: Electronic components degrade faster when exposed to high heat. Effective cooling slows this wear and tear, meaning devices last longer.

Enhanced Performance: Many processors throttle performance when they get too hot. A good heat sink allows CPUs and GPUs to maintain maximum clock speeds for longer.

Noise Reduction: If a passive or hybrid cooling solution is effective, it reduces the need for high-speed fans. Quieter operation is especially important in consumer electronics.

Cost Savings: Better thermal management means fewer breakdowns, lower maintenance costs, and longer replacement cycles. In industries like automotive or aerospace, this translates into huge savings.

In short, a heat sink is not just an accessory—it’s a critical investment in the performance, durability, and efficiency of electronic systems.

Limitations of Heat Sinks

While heat sinks are powerful tools for thermal management, they aren’t perfect. Like any engineering solution, they come with trade-offs and constraints that must be considered during design.

One of the biggest limitations is their cooling capacity. A heat sink can only move heat at a certain rate, depending on its size, material, and airflow conditions. In high-performance applications, such as overclocked CPUs or industrial converters, even the largest heat sinks may struggle to keep up without additional cooling systems like liquid cooling.

Space constraints are another major issue. Large heat sinks can’t always fit into slim devices like laptops, smartphones, or compact embedded systems. Engineers often need to make creative trade-offs, using thinner heat spreaders, vapor chambers, or advanced materials instead of bulky finned designs.

Maintenance requirements also affect performance. In dusty environments—like inside desktop computers—heat sinks often clog with dust, reducing airflow and drastically lowering cooling efficiency. Regular cleaning is essential to keep them functioning properly.

Another drawback is noise. Active heat sinks rely on fans, which inevitably generate noise. While modern fans are quieter than older ones, users sensitive to noise (such as gamers or office workers) may find constant fan hum distracting. Hybrid solutions can help but don’t eliminate the problem entirely.

Finally, there’s the issue of cost. High-performance materials like copper or diamond-based composites are expensive. Even aluminum heat sinks, when designed with complex shapes or integrated heat pipes, can significantly increase manufacturing costs. This is especially problematic in consumer electronics, where margins are tight, and customers expect affordable devices.

In summary, while heat sinks are indispensable, they are not a one-size-fits-all solution. Their limitations drive innovation in cooling technologies, pushing engineers to explore new methods such as liquid cooling, phase-change materials, and even microfluidic cooling systems.

Factors Affecting Heat Sink Performance

Not all heat sinks perform equally—even those made from the same material. Several design and environmental factors influence how well a heat sink can keep components cool.

Thermal Conductivity of Materials – A heat sink’s effectiveness starts with the material itself. Copper conducts heat much better than aluminum, but at a higher cost and weight. Engineers often balance conductivity with affordability.

Fin Design and Density – The fins are the heart of the cooling process. More fins mean greater surface area, which increases heat transfer. However, if fins are too densely packed, they can block airflow, reducing efficiency. Optimal design depends on the available airflow.

Airflow Conditions – Air movement is crucial. In passive cooling, heat sinks rely on natural convection, which is slow. Adding fans or pumps boosts airflow and drastically increases performance. However, the design must also account for turbulence and pressure drops.

Thermal Interface Resistance – The connection between the heat source and the heat sink matters just as much as the heat sink itself. Microscopic gaps trap air, which insulates against heat. Applying thermal paste or pads reduces this resistance, ensuring smooth conduction.

Ambient Temperature – A heat sink doesn’t operate in isolation. If the surrounding air is already hot, it becomes harder to transfer heat because the temperature difference (ΔT) is smaller. This is why electronics struggle in hot environments.

Surface Treatments – Some heat sinks are anodized, painted, or coated to improve emissivity, making them better at radiating heat. Others are polished to improve conduction efficiency at the base.

Together, these factors show that a heat sink is not just a block of metal but a carefully engineered system. Optimizing performance requires balancing material choice, geometry, airflow, and interface quality.

Conclusion

Heat sinks might not grab headlines, but they are the quiet protectors of technology. By channeling and dissipating unwanted heat, they safeguard sensitive components, allowing devices to function smoothly and reliably. The next time your computer runs cool during a heavy workload or your car’s electronics work flawlessly on a hot summer day, remember: there’s a heat sink silently doing its job.

As technology continues to advance, the demand for smarter, lighter, and more efficient heat sinks will only grow. Engineers and innovators will keep refining designs to strike the perfect balance between performance, cost, and size. And while you may not see them, these tiny marvels will remain at the heart of every powerful, efficient device we use.

FAQs

Q1: Can heat sinks be 3D printed?

Yes, heat sinks can be 3D printed using materials like aluminum or copper alloys. However, machining and extrusion are still more common for high-performance designs due to better precision.

Q2: Do heat sinks work in smartphones?

Yes, many smartphones use thin graphite heat spreaders or vapor chambers as mini heat sinks to keep processors cool during heavy use.

Q3: Why are heat sinks usually black?

Black surfaces radiate heat more effectively due to higher emissivity. Anodizing aluminum black is a common way to improve performance slightly.

Q4: How do liquid-cooled systems relate to heat sinks?

Even liquid cooling systems use heat sinks—often called radiators. The liquid moves heat from the device to the radiator, which then acts as a large heat sink with fans.

Q5: Can I use a heat sink without thermal paste?

Technically yes, but it’s not recommended. Without thermal paste, tiny air gaps reduce conductivity, leading to much higher temperatures.