CNC machining, or Computer Numerical Control machining, has become a cornerstone of modern manufacturing. From automotive and aerospace to medical devices, industries rely on CNC machining for accuracy, speed, and consistency. Yet, many potential learners wonder: Is CNC machining hard to learn? This article addresses this common question, dispels misconceptions, and provides a clear path for anyone interested in mastering CNC machining.

What is CNC Machining?

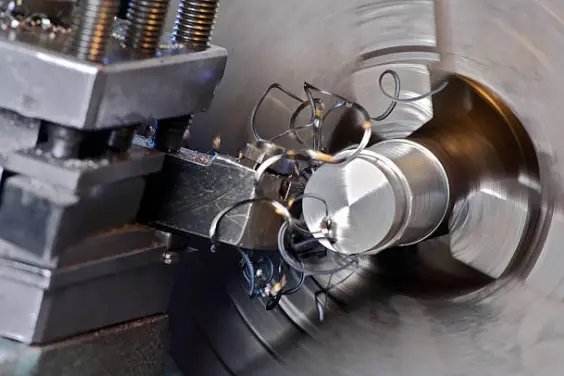

CNC machining is a manufacturing process where computer-controlled machines precisely shape materials like metal, plastic, or wood. Unlike manual machining, CNC machining relies on automation and software like G-code instructions to operate machines such as:

Mills

Lathes

Routers

Grinders

This technology enables the consistent production of complex, high-precision parts, significantly reducing human errors and production time.

Is CNC Machining Hard to Learn?

When people first look into CNC machining, they often wonder: “Is it really tough to learn?” Well, the truth is, CNC machining can seem a bit complicated at first, especially if you’re new to manufacturing or technical fields. There’s a lot to figure out, like how to run different machines, understanding special codes (like G-code), and learning to pick the right tools.

But here’s the good news: while there’s definitely a learning curve, it’s absolutely doable. Just like driving a car or learning to play a new instrument, CNC machining becomes easier the more you practice. You don’t have to know everything overnight—starting small, practicing regularly, and gradually taking on more advanced tasks will help you feel confident and skilled over time.

Common Misconceptions About Learning CNC Machining

Several misconceptions can discourage beginners from exploring CNC machining:

All CNC machinists do the same work:

There are multiple skill levels, ranging from basic operators managing simple setups to highly specialized machinists programming complex components.

CNC programming (G-code) is extremely difficult:

While challenging at first, learning G-code is similar to learning any language—practice and repetition simplify the process.

Not everyone can succeed in CNC machining:

CNC machining requires attention to detail and problem-solving, but these skills can be developed by anyone dedicated and motivated.

You can master CNC quickly:

Although basic operation skills can be gained in months, true expertise typically takes years of hands-on experience and continuous learning.

Essential Skills for Mastering CNC Machining

To succeed in CNC machining, you’ll need a blend of technical knowledge and personal traits:

Personal Traits:

Curiosity and independence: Willingness to explore new methods and self-teach.

Attention to detail: Careful planning and precise execution of tasks.

Problem-solving mindset: Quick decision-making and troubleshooting abilities.

Technical Skills:

Machine Operation: Understanding how CNC machines work.

Tooling Knowledge: Selecting appropriate tools and their specific applications.

Materials Knowledge: Knowing the properties and machinability of different materials.

Programming Skills: Writing and debugging G-code, and using CAM software.

Maintenance Skills: Routine inspections, troubleshooting, and repairs.

Precision Measurement: Accurate measurement to ensure part quality and tolerances.

Programming Knowledge: G-code and CAM Software

G-code and CAM (Computer-Aided Manufacturing) software are foundational tools in CNC machining:

G-code directs CNC machines by specifying movements and operations.

CAM software converts CAD models into G-code automatically.

Popular CAM programs include:

Mastercam: Versatile, widely used software for milling, turning, and EDM.

Fusion 360: User-friendly, cloud-based platform for design and manufacturing.

SolidWorks CAM: Integrated into the SolidWorks CAD system, streamlining design-to-production workflows.

Manual vs CAM Programming:

Manual programming: Provides flexibility and control; beneficial for custom tasks.

CAM programming: Streamlines programming, reduces errors, and enhances efficiency.

Mathematical and Analytical Skills in CNC Machining

Basic math and analytical skills are vital for CNC machining tasks, including calculating feed rates, speeds, tool paths, and dimensions. However, modern CAM software significantly simplifies these calculations, allowing machinists to focus on practical execution.

How Can You Start Learning CNC Machining?

You can choose among several educational pathways based on your career goals and preferred learning style:

Educational Paths:

Vocational Training Programs: Hands-on practical courses.

Online Courses: Flexible schedules through platforms like Coursera, Udemy, LinkedIn Learning.

University Programs: Comprehensive programs in engineering or manufacturing technology.

Apprenticeships: Earn while gaining practical experience.

Self-Learning Resources: Tutorials, YouTube channels, textbooks, online forums.

DIY Learning vs Formal Education:

DIY Learning:

Pros: Cost-effective, flexible, specialized topics.

Cons: Requires strong self-discipline, limited practical experience.

Formal Education:

Pros: Structured learning, hands-on training, professional networking.

Cons: More expensive, fixed schedules.

Recommended Online Resources:

Coursera: University-level CNC courses.

Udemy: Affordable, practical video tutorials.

YouTube Channels: Free, comprehensive tutorials.

Manufacturer Websites: Specific guidance for operating equipment.

Choosing the Right CNC Machining Training Program

When choosing a CNC training program, consider:

Accreditation: Verify industry recognition.

Equipment Quality: Access to modern CNC machines.

Hands-on Training: Practical machine operation opportunities.

Top Recommended Programs:

NTMA Training Centers: Hands-on skills for immediate workforce entry.

Goodwin University CNC Program: Comprehensive certificate-level training.

Universal Technical Institute (UTI): Broad curriculum including advanced CNC concepts.

Real Challenges in Learning CNC Machining

Common challenges include:

Mastering foundational skills (blueprints, tools, programming basics).

Overcoming initial self-doubt and gaining confidence.

Gradual exposure to advanced machining tasks.

Developing resilience and effective problem-solving strategies.

Overcoming the CNC Programming Learning Curve

Strategies for success include:

Master basics first: Understand blueprints, tooling, and simple G-code commands.

Incremental learning: Build knowledge progressively from basic to advanced skills.

Simulation software: Use software like Mastercam to visualize and test programs safely.

Hands-on experience: Work directly on CNC machines under professional supervision.

Mistakes as lessons: Adopt a constructive approach to learning from errors.

How Long Does It Take to Become a CNC Operator?

Typically, basic proficiency as a CNC operator takes one to two years, depending on prior experience and program complexity. Advanced skills, such as programming complex machinery, may take longer.

Role and Responsibilities of a CNC Machinist

CNC machinists handle:

Machine setup and programming.

Ensuring part accuracy and quality.

Routine maintenance and troubleshooting.

Collaboration with engineers and production teams.

Career Opportunities for CNC Machinists

CNC machinists have a variety of career paths:

CNC Operator: Manages basic machining operations.

CNC Programmer: Develops G-code for production efficiency.

Quality Control Specialist: Ensures parts meet required standards.

Production Manager: Oversees CNC operations and teams.

Industries frequently hiring include automotive, aerospace, medical manufacturing, rapid prototyping, and custom fabrication.

How to Enhance Your CNC Machining Skills

Continuously improving your CNC skills is critical for career advancement:

Advanced Training and Certification:

Pursue specialized certifications (e.g., NIMS Certification).

Participate in apprenticeship programs.

Learning from Industry Experts:

Attend industry conferences and workshops.

Join mentorship programs or professional associations like NTMA.

Staying Updated with Innovations:

Regular training in new CAM software.

Subscribing to industry journals (Modern Machine Shop).

Networking through professional groups and industry events.

Conclusion

Learning CNC machining may initially feel daunting, but with structured training, hands-on experience, and dedication, it becomes accessible and highly rewarding. CNC machining offers numerous career opportunities and is an essential skill in modern manufacturing. By systematically developing your skills and embracing continuous learning, you’ll position yourself for long-term success in this exciting industry.

FAQs

Is CNC machining stressful?

It can be demanding due to high precision requirements but is manageable with training and experience.

Is CNC programming easy to learn?

Initially challenging, it becomes easier through consistent practice and structured learning.

Is operating a CNC machine difficult?

Initially complex, but proficiency is quickly gained through training and hands-on practice.

Read More:

Understanding the CNC Programming Languages Using G and M Codes

CNC Turning and Milling – A Quick Guide to Understanding Their Differences

Understanding SFM (Surface Feet per Minute): Key Insights and Applications in Machining

Everything You Need to Know about Machining Drawings for CNC Machining

10 Top Benefits of CNC Machining